Thingiverse

Aluminum angle iron for Y-axis support by Taz_3d

by Thingiverse

Last crawled date: 3 years ago

Update 2-5-17

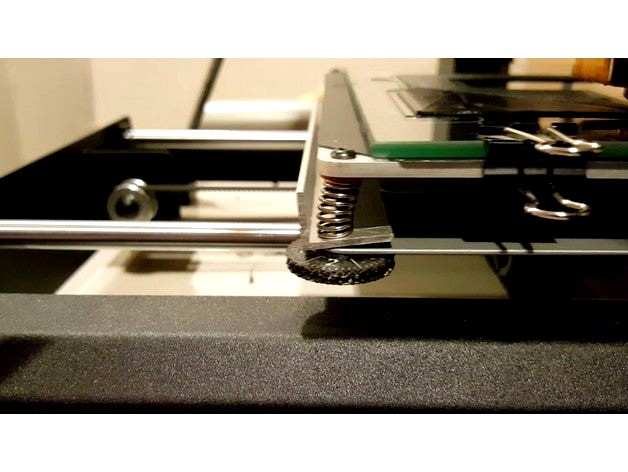

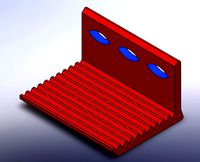

noticed I was still having bed leveling issues, I replaced the y-carriage with a new one made out of Aluminum and 3mm thick ( https://www.amazon.com/gp/product/B01MUAMRN7/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1 ) instead of the 1mm thick steel plate that comes on the machine - What a Difference that made. Picture shows the difference of the thickness of the 2 plates vs the heating bed

According to my dial gage ( http://www.thingiverse.com/thing:2040422 ) the bed is now level within .010 mm (10 microns)

I noticed on my Wanhao Duplicator i3 V2.1 that my plate was not staying flat when trying to get the bed to level with the nozzle at all points.

Upon looking closer, it appeared that the bed the Y-axis bearings are mounted to, was flexing and this was causing 2 opposite corners to either be way too loose or too tight when screwing down the springs, due to the flexing.

Went to the hardware store and got a piece of 1/2 x 3/4 inch Aluminum angle iron (only size there that would fit - would have preferred 1/4 x 1/2 inch)

Drilled out 2 holes on each end on the 3/4 flat side, and mounted the angle iron between the Y-axis carriage plate and the springs, and releveled the bed.

What a difference it made.

All 4 corners came into acceptable tolerances and were not ratcheted down all the way. - Good thing too because at the back of the heated bed the wires are getting pinched a bit - not a good thing!! Adjustments will have to be made there.

there is enough material left over to run the angle iron down the sides as well, but there might not be a need for it now.

noticed I was still having bed leveling issues, I replaced the y-carriage with a new one made out of Aluminum and 3mm thick ( https://www.amazon.com/gp/product/B01MUAMRN7/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1 ) instead of the 1mm thick steel plate that comes on the machine - What a Difference that made. Picture shows the difference of the thickness of the 2 plates vs the heating bed

According to my dial gage ( http://www.thingiverse.com/thing:2040422 ) the bed is now level within .010 mm (10 microns)

I noticed on my Wanhao Duplicator i3 V2.1 that my plate was not staying flat when trying to get the bed to level with the nozzle at all points.

Upon looking closer, it appeared that the bed the Y-axis bearings are mounted to, was flexing and this was causing 2 opposite corners to either be way too loose or too tight when screwing down the springs, due to the flexing.

Went to the hardware store and got a piece of 1/2 x 3/4 inch Aluminum angle iron (only size there that would fit - would have preferred 1/4 x 1/2 inch)

Drilled out 2 holes on each end on the 3/4 flat side, and mounted the angle iron between the Y-axis carriage plate and the springs, and releveled the bed.

What a difference it made.

All 4 corners came into acceptable tolerances and were not ratcheted down all the way. - Good thing too because at the back of the heated bed the wires are getting pinched a bit - not a good thing!! Adjustments will have to be made there.

there is enough material left over to run the angle iron down the sides as well, but there might not be a need for it now.

Similar models

thingiverse

free

Y Carriage Plate for TEVO Tarantula 3D Printer by gulfcoast_robotics

...ce surface for leveling heated bed.

here we have it for sale:https://gulfcoast-robotics.com/pyp6

dxf file is available by request

thingiverse

free

Anet A8 corner clip by Rainerlan_2

...older which is unlikely to collide with any parts attached to the printer head as eg. bed level sensor, cooler ducts or the like.

thingiverse

free

Another remix of Handle and Camera Mount for Creality Ender 3 Y Carriage Plate by claidheamohmor

...mera mount, the other parts are in the original thing:https://www.thingiverse.com/thing:3606128

(sorry for my awful english...:p)

thingiverse

free

Heatbed Glassplate Holder 5.5mm 220x220mm by Keigun

...ently interfere with the clips.

this object is not print ready.

clips are made for 220x220mm print beds and a thickness of 5.5mm.

thingiverse

free

Lower Plate (wood) for Y axis by Yolurb

...ed on y-axis carriage.

heat bed or upper plate can be connected to this part.

work in progress : measured values to be verified !

thingiverse

free

Heated Bed Stabilizers for Monoprice Maker Select v2.1 (Wanhao i3) by xyzaxis

...fan shroud

bracket for thorped's fan duct

adjustable bltouch front mount for wanhao i3

mount for biqu heated bed mosfet board

thingiverse

free

Maker Select/Duplicator i3 Spring Guide by JaMaNder

...i'll upload some variations.

to anybody thinking about making the change to 3-point bed leveling i definitely recommend it.

grabcad

free

200mm x 300mm Heated Bed Carriage

...iexpress.com/item/funssor-200x300mm-heated-bed-support-3mm-aluminum-alloy-extended-y-carriage-plate-for-prusa-i3/32916372375.html

thingiverse

free

Angle Iron Foot by Orion36

...of them. some of them were a little bit of a loose fit, but could easily be glued on or resized on either both or a single axis.

thingiverse

free

Bed Leveling Corner by Thomllama

.../nuts for sizing...

bedversion3 - for use with 3mm thick aluminum bed carriages

bedlevelcornerm4size - is m4 sized screw and nut

Taz

3d_ocean

$19

TAZ RIGGED

...ax version only texture is used only for wb logo, taz dont need texture no special render engine needed, just unzip and render...

3d_export

$5

Taz character 3D Model

...taz character 3d model

3dexport

taz toon character cartoon

taz character 3d model supercigale 22095 3dexport

cg_studio

$10

Taz 3D3d model

...taz 3d3d model

cgstudio

.3ds .max - taz 3d 3d model, royalty free license available, instant download after purchase.

cg_studio

$15

Taz Rigged3d model

...ged3d model

cgstudio

.3ds .fbx .max .obj - taz rigged 3d model, royalty free license available, instant download after purchase.

3d_export

$10

Taz Toy Calendar 3D Model

... 3d model

3dexport

taz toy calendar day month year looney tunes cartoon kid child

taz toy calendar 3d model nkfrds 49687 3dexport

3d_export

$10

Taz Tasmanian Devil RIGGED 3D Model

...y tunes anime bunny rigged material fantasy creature diable dessin

taz tasmanian devil rigged 3d model supercigale 28390 3dexport

3d_export

$19

Thylacine 3D Model

...animalia chordata mammalia marsupial dog extinct animals tiger tassie taz thylacine 3d model poly3dmodels 90790...

3d_export

$12

Bowl Decorated 3D Model

...bowl decorated 3d model 3dexport bowl tazn elements ceramics kitchen plastic cup container decorative cake biscuits...

3ddd

$1

Crate & Barrel Serveware

...crate & barrel поднос -http://www.crateandbarrel.com/feast-platter/s186961 набор ножей для сыра -http://www.crateandbarrel.com/tazcheese-knife-3-piece-set/s681377 бокал...

thingiverse

free

TAZ by Taz8373

...taz by taz8373

thingiverse

my 1st print

Aluminum

3d_export

$5

aluminum crutch

...aluminum crutch

3dexport

aluminum crutch

3d_export

free

aluminum cane

...aluminum cane

3dexport

aluminum cane

3d_export

$5

the aluminum canister

...

3dexport

the aluminum canister is designed for storing and transporting liquids( water), fuels and lubricants (gasoline, oils).

turbosquid

$2

Aluminum Wheel

...uid

royalty free 3d model aluminum wheel for download as fbx on turbosquid: 3d models for games, architecture, videos. (1371918)

turbosquid

$2

aluminum pulley

...

royalty free 3d model aluminum pulley for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1671716)

turbosquid

$40

Aluminum Can

... free 3d model aluminum can for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1301606)

turbosquid

$15

Curved aluminum

...ee 3d model curved aluminum for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1260293)

turbosquid

$12

Aluminum pot

... free 3d model aluminum pot for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1653492)

3d_export

$5

Aluminum Bottle

... for shampoo, conditioner or any liquids (500ml 17floz) separated all parts, able to customize any color, material and finishing.

turbosquid

$19

Aluminum windows

...model aluminum windows for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1646740)

Iron

archibase_planet

free

Iron

...ase planet

iron flatiron flat iron smoothing-iron

iron scarlett sc1133s n260112 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Iron

...et

iron flatiron flat iron smoothing-iron

iron black & decker n131213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

free

Iron

...mbo-unlimitedideas.com/produtos_post/iron-console/

в архиве сцена 2011 и 2014, fbx и obj, текстуры

рендер: vray 2.4

3d_ocean

$15

Steam iron

...ign made by me. you can use it for your projects and games as you want. iron, steam iron, philips,siemens, clothes,ironing, tefal

turbosquid

$8

Iron Chandelier - Iron Chandelier

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

iron

...on

turbosquid

royalty free 3d model iron for download as max on turbosquid: 3d models for games, architecture, videos. (1365250)

3d_export

$20

iron press

...iron press

3dexport

iron press

3d_export

$5

old iron

...old iron

3dexport

old iron

3d_export

free

iron man

...iron man

3dexport

iron man

3d_export

$49

Iron Giant

...iron giant

3dexport

iron giant film

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award

Angle

design_connected

$25

Angle

...angle

designconnected

flou angle sleep furniture computer generated 3d model. designed by rodolfo dordoni.

3ddd

$1

FLOU / Angle

...flou / angle

3ddd

flou

кровать flou angle. все карты процедурные.

3ddd

free

Кровать ANGLE flou

...le , flou , постельное белье

кровать angle flou

design_connected

$16

Calin Angle

...calin angle

designconnected

ligne roset calin angle computer generated 3d model. designed by mourgue, pascal.

3d_export

$5

angle grease nipple

...angle grease nipple

3dexport

angle grease nipple

3ddd

$1

Двуспальная кровать Angle

...ngle. двуспальную кровать с подъемным механизмом angle оценят и те, кто любит практичность: кровать имеет объемый ящик для белья.

turbosquid

$10

Angle Wardrobe

...e 3d model angle wardrobe for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1301544)

turbosquid

$9

Angle Stool

...y free 3d model angle stool for download as max, skp, and skp on turbosquid: 3d models for games, architecture, videos. (1694318)

3d_export

free

angle bracket

...t 3d model part. it is the combination of a bra and ket (bra+ket = bracket) which represents the inner product of two functions.

turbosquid

$6

Angles Pouf

...e 3d model angles pouf for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1577097)

Y

turbosquid

$1

Tetera y Galletas y Caf

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Смеситель Y-CON

...смеситель y-con

3ddd

смеситель , y-con

смеситель y-con

3ddd

$1

Y-Chair

...y-chair

3ddd

tom dixon

y-chair designed by tom dixon,

3ds max + obj, corona

3ddd

$1

Y Chair compilation

....net/products/us/y-chair-sled-base

y chair swivel basehttp://www.tomdixon.net/products/us/y-chair-swivel-base

turbosquid

$190

Y-8

...y-8

turbosquid

royalty free 3d model y-8 for download as max on turbosquid: 3d models for games, architecture, videos. (1658891)

turbosquid

$7

Bench Y

...turbosquid

royalty free 3d model bench y for download as obj on turbosquid: 3d models for games, architecture, videos. (1488746)

turbosquid

$15

bonePile Y

...oyalty free 3d model bonepile y for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1546374)

turbosquid

$7

Y for Yarn

...d

royalty free 3d model y for yarn model for download as max on turbosquid: 3d models for games, architecture, videos. (1699732)

turbosquid

$2

FONT Y

...quid

royalty free 3d model font y for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1549457)

3ddd

$1

WOOD-y

...wood-y

3ddd

wooden guy

Support

turbosquid

$5

Support

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Support 3D Model

...support 3d model

3dexport

support cantilever console

support 3d model tasal 73900 3dexport

3d_export

$5

phone support

...phone support

3dexport

phone

turbosquid

$12

Support bars

...squid

royalty free 3d model support bars for download as max on turbosquid: 3d models for games, architecture, videos. (1411542)

turbosquid

$8

support weights

...id

royalty free 3d model support weights for download as max on turbosquid: 3d models for games, architecture, videos. (1411538)

turbosquid

$2

headphone support

...royalty free 3d model headphone support for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1357583)

turbosquid

$2

Support for flowers

...royalty free 3d model support for flowers for download as max on turbosquid: 3d models for games, architecture, videos. (1463543)

turbosquid

$14

Flower Support

...alty free 3d model flower support for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1497066)

turbosquid

$5

serum support

...yalty free 3d model serum support for download as c4d and obj on turbosquid: 3d models for games, architecture, videos. (1551267)

3d_export

$10

spyro joystick support

...spyro joystick support

3dexport

joystick support of spyro dragon