Thingiverse

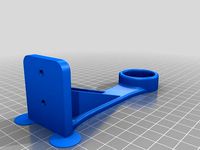

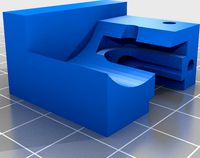

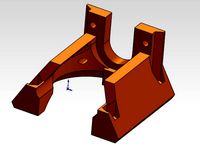

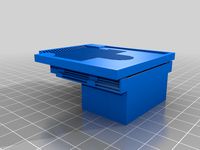

Alpha Piezo Hotend Z-Probe Mini Groovemount/Titan 20mm piezo by DjDemonD

by Thingiverse

Last crawled date: 3 years ago

Update 14-05-2017 This unit is now in release candidate and is available here:http://www.thingiverse.com/thing:2319993

Also available to buy ready made at http://www.precisionpiezo.co.uk/shop

Update 16-7-17 latest thinking in terms of firmware setup can be read here http://forums.reprap.org/read.php?1,767998,page=9

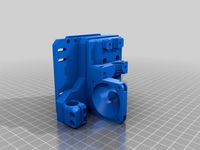

Update 07-03-2017 Made a version for titan (or generic groovemount) where the top piece is two parts (instead of 3). Should be quite tight in the groovemount. Print it 100% infilled with moderate-high nozzle temperature for good layer adhesion. I have kept the 3 part top available in case you need it.

Update 05-03-17 - changed the length of the groove mount piece for titan so it should be snug against the base of the titan when fitted. Don't file/adjust the groove mount flange after printing its better if its a tight fit.

Update 05-03-17 - changed titan mount system (again), now the top plate of the sensor assembly is printed in two parts and then bonded back together at assembly, this enable the sensor surface and the surface for the groove mount adaptor to be smooth and free from support material.

Description

So not going to put a lot of detail here you can get the majority of the info on these devices from

http://reprap.org/wiki/Piezo-electric_sensorshttp://www.thingiverse.com/thing:2069480

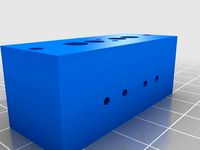

This is a miniature version piezo z-probe module using 20mm piezo. I have not enough time or a suitable machine to fully test it, but I have done some work on basic feasibility and it will trigger when connected to a piezo sensor signal conditioning board which you can make as per the circuit diagram in the wiki page above or by contacting Moriquendi on reprap forum who can sell one to you for a very modest amount, please be patient as he makes them in batches at home.

Assembly: important - drill out the 4x screw holes in the clamp/lower part to 3.2mm approx so that the screws do NOT bind or stick, the lower part needs to be able to "slide" on these screws (it's only 0.1mm). I used countersunk screws which can be screwed into (threaded) the top part to keep them fixed and steady, then m3 nuts or locknuts below the clamp/lower part. Do them up just beyond hand tight and evenly.

This unit could be integrated into a carriage, the titan version print it as orientated and then bond (acetone/superglue) the e3d groove mount piece into the top plate. This is necessary as the recess for the piezo needs to print well and should be upwards. Youll need a little support for the groove mount, this has to have a square collar to work so no easy support free orientation is possible.

If you make and test one please feedback to me via thingiverse any issues.

New drafts/revisions will appear here as/when.

Also available to buy ready made at http://www.precisionpiezo.co.uk/shop

Update 16-7-17 latest thinking in terms of firmware setup can be read here http://forums.reprap.org/read.php?1,767998,page=9

Update 07-03-2017 Made a version for titan (or generic groovemount) where the top piece is two parts (instead of 3). Should be quite tight in the groovemount. Print it 100% infilled with moderate-high nozzle temperature for good layer adhesion. I have kept the 3 part top available in case you need it.

Update 05-03-17 - changed the length of the groove mount piece for titan so it should be snug against the base of the titan when fitted. Don't file/adjust the groove mount flange after printing its better if its a tight fit.

Update 05-03-17 - changed titan mount system (again), now the top plate of the sensor assembly is printed in two parts and then bonded back together at assembly, this enable the sensor surface and the surface for the groove mount adaptor to be smooth and free from support material.

Description

So not going to put a lot of detail here you can get the majority of the info on these devices from

http://reprap.org/wiki/Piezo-electric_sensorshttp://www.thingiverse.com/thing:2069480

This is a miniature version piezo z-probe module using 20mm piezo. I have not enough time or a suitable machine to fully test it, but I have done some work on basic feasibility and it will trigger when connected to a piezo sensor signal conditioning board which you can make as per the circuit diagram in the wiki page above or by contacting Moriquendi on reprap forum who can sell one to you for a very modest amount, please be patient as he makes them in batches at home.

Assembly: important - drill out the 4x screw holes in the clamp/lower part to 3.2mm approx so that the screws do NOT bind or stick, the lower part needs to be able to "slide" on these screws (it's only 0.1mm). I used countersunk screws which can be screwed into (threaded) the top part to keep them fixed and steady, then m3 nuts or locknuts below the clamp/lower part. Do them up just beyond hand tight and evenly.

This unit could be integrated into a carriage, the titan version print it as orientated and then bond (acetone/superglue) the e3d groove mount piece into the top plate. This is necessary as the recess for the piezo needs to print well and should be upwards. Youll need a little support for the groove mount, this has to have a square collar to work so no easy support free orientation is possible.

If you make and test one please feedback to me via thingiverse any issues.

New drafts/revisions will appear here as/when.

Similar models

thingiverse

free

20mm Precisions Piezo underbed mounts by SupraGuy

...small amount of movement that the sensor should require. there are 2 slots for the sensor wires, though you should only need one.

thingiverse

free

Precision-Piezo Probe with 3 Piezo 15mm by Tech-Raton

...if bigger, you'll lose the piezo marks)

you just have to slide the part between the heatsink and the effector (or your mount)

thingiverse

free

Remixed Hevo E3D titan Extruder carriage by alexflin

...he pinda probe with a mount for the optical sensor.

the sensor is mounted with screws for which you'll need to place inserts.

thingiverse

free

Bracket for E3D Titan/Aero with piezo probe by Whosrdaddy

...ro extruder which can be used with 20mm piezo disc for accurate probing. use sensor board from https://www.precisionpiezo.co.uk/.

thingiverse

free

Kossel Mini J-Head Retainer by goopyplastic

...f the allen key probe so it wobbles less.

edit 10/28/13: someone asked so i uploaded a 40mm fan mount i used to cool the jhead.

thingiverse

free

ReDuplicator i3 MK3x - Titan Aero Mount Piezo Remix by silvrswt

...should work if installed in the same fashion as the djdemond's piezo z-probe mount:

https://www.thingiverse.com/thing:2526978

thingiverse

free

BETA - Piezo z-probe for E3D Titan Aero (mounted direct via motor) by DjDemonD

...thingiverse precision piezo presents - titan aero (or other similar extruder system) piezo sensor plate. this is a beta,...

thingiverse

free

18mm sensor mount for E3D Titan Extruder by dereulenspiegel

...which makes assembly a bit more complicated), but everything seems to be fine. i had my first few successful prints this weekend.

thingiverse

free

Reach 3D Precision Piezo Mount by jmg123

...so a funnel that takes a 40mm fan that is used to cool the part being printed.

step file included incase anyone wants to edit it.

thingiverse

free

(Beta) Piezo UnderBed Mounts by Precision Piezo by DjDemonD

...sulation to the mounts to keep heat from the bed away from the piezos.

future release might include some clamps on the top parts.

Djdemond

thingiverse

free

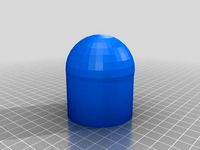

50mm Towball cover Hitch Cap by DjDemonD

...50mm towball cover hitch cap by djdemond

thingiverse

cover for 50mm towball.

thingiverse

free

Duet3D Smarteffector Nimble Mount DjDemonD Remix by DjDemonD

...ess sensitive. you also need to consider the orientation of the large nut to you heatsink when assembling the hotend into the se.

thingiverse

free

Brio Wooden Train Tunnel by DjDemonD

...valley etc.. multiple units can be joined to make a longer tunnel. 80mm diameter so even fairly large trains can make it through.

thingiverse

free

Bowden pushfit locking ring for clone titan and y-splitter by DjDemonD

...for clone titan and y-splitter by djdemond

thingiverse

locking clip for trianglelabs clone titan and y-splitter bowden fittings.

thingiverse

free

3-Way Approach for Brio Thomas Engine Shed by DjDemonD

...ond

thingiverse

i bought one of these engine sheds but didn't have the approach track which is a custom piece so i made one.

thingiverse

free

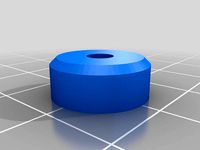

Precision Piezo - 27mm and 20mm Piezo Disc drill guide. by DjDemonD

... djdemond

thingiverse

drilling guide for piezo discs to centre your drill.

see youtube video here: https://youtu.be/ms1fd0v5z68

thingiverse

free

Mechanical Z Endstop for DjDemonD/AndreasL Dual z axis smartrapcore alu by DjDemonD

...babystep z on the first print and used m206 to enter the home offset. (nb. if the nozzle was 1mm too high the m206 z would be 1.)

thingiverse

free

Paper Towel Holder Strengthened Remix by DjDemonD

...t to allow for the strengthening braces. since altering it, it works perfectly in fact i am even using some as spool holders too.

thingiverse

free

Sensor Test Rig by DjDemonD

...aver. i am not going to provide full build instructions, if you cannot figure out how to build it, should you be testing sensors?

thingiverse

free

Technics 1200 Turntable with spinning record by DjDemonD

... fits over a 5mm motor shaft and spins as my printer prints.

just bond it all together after assembly with superglue or acetone.

Groovemount

thingiverse

free

Groovemount lasercut mount plate. by karandex

...groovemount lasercut mount plate. by karandex

thingiverse

groovemount lasercut mount plate.

title says it all.

thingiverse

free

Groovemount for PG35L extruder for Kossel by SystemsGuy

...ble to try out johann's design.

rather than modify his extruder, i simply made a groovemount plate with integrated standoffs.

thingiverse

free

Mk5 Acrylic Bridge Groovemount by Nova1313

...giverse

this is a replacement bridge for a makerbot cupcake to add a mk5 bridge compatible with a makergear groovemount hot end.

thingiverse

free

Fanholder for JHead groovemount by blender

...holder for reprap printer. this one fits between wades extruder and jhead groovemount. it can carry a 7cm x 7cm large cpu cooler.

thingiverse

free

E3D Volcano Groovemount for the RailCore II by kraegar

...approximately the same for layer fan compatibility. adjust your z-probe offset!

print with the same settings as the stock mount.

thingiverse

free

Titan Groovemount Integrated TopPiece by TechGirl_Mods

... couple of cavities under the groovemount. i remixed the groovemount and the top plate of the piezo mount to remove the cavities.

thingiverse

free

Fan mount, combined with ubis adapter for wade groovemount by lenoxjoseph

...two here. groovemount-fan.stl is for regular groovemount hotends (like the e3d v6), groovefan.stl is for ubis hotends (printrbot)

thingiverse

free

Stepper GrooveMount Brutstruder by prototypist

... it is no longer "quick change" though (regarding the hot end) because the groovemount is on the back in this version.

thingiverse

free

Parametric Groovemount by Eloque

...ened using 2 m3 hexbolts, leaving no room to wiggle whatsoever.

the stl provided works perfectly for my e3d v6 3mm direct feed.

thingiverse

free

GrooveMount 90° Bracket for Birdstruder by Ember

...onious' supa-flat x-carriage in mind. if you are not using these two parts, i can't guarantee it will work right for you.

Piezo

turbosquid

$5

Buzzer Piezo

...odel buzzer piezo for download as max, max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1607700)

3d_export

$7

buzzer piezo

...;all materials are logically named<br>the main format is in 3ds max 2013.<br>satisfaction guarranteed<br>thanks

3d_export

$15

Buzzer 3D Model

...audio electronic component signalling piezoelectric disk alarm timer electric piezo industrial part electrical bell doorbell buzzer 3d model download...

thingiverse

free

Hypercube_evolution E3D_Titan_Aero with piezo

...ercube_evolution e3d_titan_aero with piezo

thingiverse

hypercube_evolution a piezo z-axis sensor was attached to e3d_titan_aero.

thingiverse

free

Precision-Piezo Probe with 3 Piezo 15mm by Tech-Raton

...if bigger, you'll lose the piezo marks)

you just have to slide the part between the heatsink and the effector (or your mount)

thingiverse

free

Piezo Chimera mount by RKS7204

...piezo chimera mount by rks7204

thingiverse

mount for e3d chimera hotend and piezo sensor

thingiverse

free

Piezo v1.22 Mount by Suggy

...piezo v1.22 mount by suggy

thingiverse

mount for under bed piezo censor pcb

thingiverse

free

Precision Piezo - 27mm and 20mm Piezo Disc drill guide. by DjDemonD

... djdemond

thingiverse

drilling guide for piezo discs to centre your drill.

see youtube video here: https://youtu.be/ms1fd0v5z68

thingiverse

free

Underbed Piezo Mounts by fcollingwood

...the piezos are smooth. two of the arms a required and two of the mirror arms are required

everything else can be printed at 0.2mm

thingiverse

free

(Beta) Piezo UnderBed Mounts by Precision Piezo by DjDemonD

...sulation to the mounts to keep heat from the bed away from the piezos.

future release might include some clamps on the top parts.

Probe

turbosquid

$25

Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

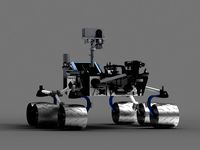

Mars probe space space exploration lunar probe

...be space space exploration lunar probe for download as max on turbosquid: 3d models for games, architecture, videos. (1630876)

turbosquid

$35

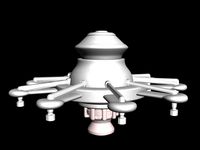

Space Probe

...osquid

royalty free 3d model space probe for download as c4d on turbosquid: 3d models for games, architecture, videos. (1571168)

turbosquid

$15

Space Probe

...osquid

royalty free 3d model space probe for download as obj on turbosquid: 3d models for games, architecture, videos. (1314864)

turbosquid

$25

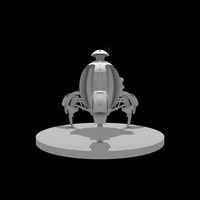

Robot Probe

...y free 3d model robot probe for download as fbx, obj, and dae on turbosquid: 3d models for games, architecture, videos. (1537490)

turbosquid

$1

Dental Probe

...e 3d model dental probe for download as ma, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1312400)

turbosquid

$60

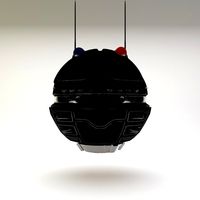

Police Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Dental Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Space probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Cassini Probe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Titan

design_connected

$18

Titan

...titan

designconnected

original btc titan computer generated 3d model.

3d_ocean

$25

RMS Titanic

...rms titanic

3docean

ship steamer titanic

3d model of the rms titanic

turbosquid

$49

Titan

...quid

royalty free 3d model titan for download as obj and ztl on turbosquid: 3d models for games, architecture, videos. (1314276)

turbosquid

$8

Titan

...d

royalty free 3d model titan for download as , fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1545505)

3d_export

$15

eren yeager titan from attack on titan

...eren yeager titan from attack on titan

3dexport

3d model of eren titan

3d_export

$5

titanic new

...titanic new

3dexport

titanic 3d model normal quality for animation

3d_export

$100

Titan 3D Model

...titan 3d model

3dexport

silo launcher rocket titan

titan 3d model acquarius 37854 3dexport

3d_ocean

$25

Titan

...nfs nfshs one ps ps1 psone rod speed sports stakes titan transport vehicle

quality exterior and low polygon interior concept car.

3ddd

$1

Titanic Lamp(table)

...titanic lamp(table)

3ddd

titanic lamp(table)

turbosquid

$10

Titan chair

...osquid

royalty free 3d model titan chair for download as max on turbosquid: 3d models for games, architecture, videos. (1301533)

Hotend

thingiverse

free

hotend by fablab_lueneburg

...hotend by fablab_lueneburg

thingiverse

hotend model

thingiverse

free

Hotend for Graber

...hotend for graber

thingiverse

hotend complement pastes for graber printerhttps://youtu.be/0koxhnsuhdy

thingiverse

free

Hotend adapter by antaviana

...hotend adapter by antaviana

thingiverse

hotend adapter

thingiverse

free

hotend fan by mming1106

...hotend fan by mming1106

thingiverse

hotend fan

thingiverse

free

Hotend schema by ione

...hotend schema by ione

thingiverse

hotend project schema

thingiverse

free

Fabtotum XY Hotend holder for E3D Hotend

...s with integrated supports.

more for the project you can see here: https://kf-designs.com/2019/09/07/fabtotum-printer-conversion/

thingiverse

free

HotEnd Stand by onepointdiy

...tend, when you make your new hotend or repair your j-head or mg-plus hotend.

the hole of 16mm, please adjust using a reamer, etc.

thingiverse

free

fast magnetic hotend changer for Chimera Hotend by Draman

...chimera hotend !

and new basis (the hole from original is to small)

it is a remix form skimmy's fast magnetic hotend changer

thingiverse

free

Hotend Fan Adapter for MicroSwiss All Metal Hotend by jo_schi_man

...

thingiverse

little change for the hotend fan adapter to hold the microswiss all metal hotend (slightly longer and sharp edges).

thingiverse

free

Merlin Hotend by Alejanson

...merlin hotend by alejanson

thingiverse

this is a 1:1 drawing of the classic merlin hotend.

Alpha

turbosquid

$3

Alpha

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$67

alpha romeo

...quid

royalty free 3d model alpha romeo for download as blend on turbosquid: 3d models for games, architecture, videos. (1670661)

3ddd

$1

Jacuzzi Morphosis Alpha

...jacuzzi morphosis alpha

3ddd

jacuzzi , ванна

jacuzzi morphosis alpha

turbosquid

$9

alpha zerage

... free 3d model alpha zerage for download as tga, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1299299)

turbosquid

$5

Alpha Chair

...y free 3d model alpha chair for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1145182)

3d_ocean

$12

Kembo Alpha Table

...docean

alpha c4d cinema4d desk kembo kemboalpha kembodesk kembotable office table vray vrayforc4d

kembo alpha table in cinema 4d.

turbosquid

$39

Phone Alpha

...el generic phone alpha for download as c4d, obj, 3ds, and stl on turbosquid: 3d models for games, architecture, videos. (1631060)

turbosquid

$35

Alpha Sedan

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Chair Alpha

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Alpha Radar

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

20Mm

3d_export

$20

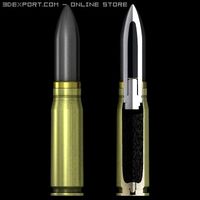

german 20mm flak

...german 20mm flak

3dexport

german 20mm flak

turbosquid

$58

M-75 20mm AA

...squid

royalty free 3d model m-75 20mm aa for download as obj on turbosquid: 3d models for games, architecture, videos. (1174302)

turbosquid

$5

Drill Bit Set 6mm to 20mm

...ill bit set 6mm to 20mm for download as stl, sldpr, and sldas on turbosquid: 3d models for games, architecture, videos. (1257104)

turbosquid

free

Oerlikon 20mm anti-aircraft gun

...mm anti-aircraft gun for download as lwo, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1430549)

turbosquid

free

20mm Flak 38 Flakveirling (Simple)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Ammo Box WWII US Military 20mm MK3

...mmo box wwii us military 20mm mk3 for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1360607)

cg_studio

$35

German 20mm MG151/20 Sprgr cartridge with cutaway3d model

...j - german 20mm mg151/20 sprgr cartridge with cutaway 3d model, royalty free license available, instant download after purchase.

cg_studio

$35

German 20mm MG151/20 Pzgr cartridge with cutaway3d model

...obj - german 20mm mg151/20 pzgr cartridge with cutaway 3d model, royalty free license available, instant download after purchase.

3d_export

$35

German 20mm MG15120 cartridge with cutaway 3D Model

...ammunition munition granate panzer airforce luftwaffe

german 20mm mg15120 cartridge with cutaway 3d model emeral_d 21635 3dexport

3d_export

$35

German 20mm MG 15120 cartridge with cutaway 3D Model

...mmunition munition granate panzer airforce luftwaffe

german 20mm mg 15120 cartridge with cutaway 3d model emeral_d 21633 3dexport

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

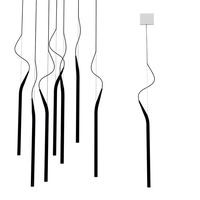

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)

Mini

turbosquid

$10

Mini Mini Luceplan

...

royalty free 3d model mini mini luceplan for download as max on turbosquid: 3d models for games, architecture, videos. (1227359)

3d_ocean

$39

Mini Cooper

...mini cooper

3docean

cabrioler cooper mini

mini cooper cabrioler

3d_export

$30

Mini lathe

...mini lathe

3dexport

mini lathe

3d_export

$5

mini mouse

...mini mouse

3dexport

mini mouse

3d_export

$5

mini house

...mini house

3dexport

mini house

3d_export

free

Mini Mecha

...mini mecha

3dexport

concept of mini mecha

3d_ocean

$20

Mini Gun

...mini gun

3docean

gatling gun gun machine gun mini gun weapon

model of a mini gatling gun.

3ddd

free

Herve mini

... кофейный , herve

http://www.mobiliavenanti.it/ru/products/hervè-mini

3d_export

$5

mini wall

...mini wall

3dexport

mini wall for living room

3d_export

$5

mini bank

...mini bank

3dexport

mini bank 3d model