Thingiverse

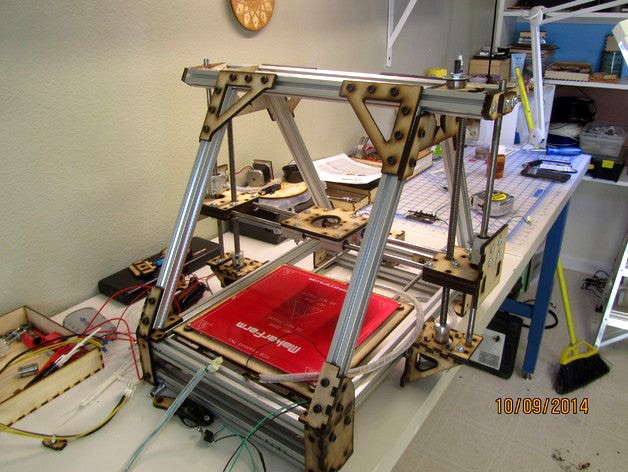

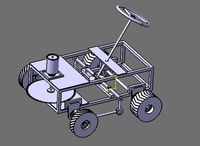

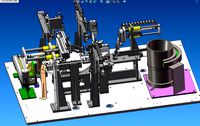

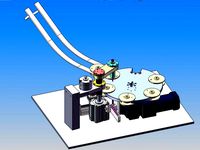

All laser cut Mendelmax wood Assembly Hardware. 5mm birch plywood for model 1.5. Additional design features for easy lasering and added structural strength. by TexasLaser

by Thingiverse

Last crawled date: 3 years ago

10/09/2014 - Taking longer than I thought. I've done a lot of tests and trials and keep coming up with new ideas. Made many changes and additions and uploaded some new photos. Also uploaded the latest source file along with a pdf vesion. I have left to finish the design for the x motor and idler wheel. Also need to make a controller dock and limit stops. Plan to have 100% all lasered wood/acrylic 3D printer in the end, no 3D printed parts.

.

After having the Mendel Prusa model for over a year and tired of tweaking it, I decided to upgrade to the Mendelmax, v1.5. I'm making all of the support hardware from 5mm birch plywood with a laser. I started from this design: http://www.thingiverse.com/thing:166838.

.

After cutting this design and trying it out, I came up with a lot of enhancements. I have made some additions too. Upgrading many of the mechanical parts to higher quality and precision.

.

Making changes specifically for easy laser work. Reworked the x-ends to cut out a hex to hold the nuts for the 2 z-threaded rods.

Adding structural support in several areas.

.

I've done a lot of design, retrofit and rework. This is a work in progress, so keep checking back, hope to be complete is about a week or so.

.

After having the Mendel Prusa model for over a year and tired of tweaking it, I decided to upgrade to the Mendelmax, v1.5. I'm making all of the support hardware from 5mm birch plywood with a laser. I started from this design: http://www.thingiverse.com/thing:166838.

.

After cutting this design and trying it out, I came up with a lot of enhancements. I have made some additions too. Upgrading many of the mechanical parts to higher quality and precision.

.

Making changes specifically for easy laser work. Reworked the x-ends to cut out a hex to hold the nuts for the 2 z-threaded rods.

Adding structural support in several areas.

.

I've done a lot of design, retrofit and rework. This is a work in progress, so keep checking back, hope to be complete is about a week or so.

Similar models

thingiverse

free

Laser Cut sword with a fluer de lis design by homeshopmakerspace

...gned with 5mm 3 layer plywood that i have. it works out to just over 0.19 inches. the plywood i have is 12 inches by 36 inches.

thingiverse

free

Laser cut Cutting Board made of Birch Plywood by JupiterKala

...e made this cutting board using birch plywood of 6 mm thickness. you can also make this product from the material of your choice.

thingiverse

free

NEJE 30watt Air assist nose by Are-Inc

...s now and it works perfect and i dont mind having some printing "lines" on it :)

i used support material when printing.

thingiverse

free

Laser cut box by Esartmaldives

...aser cut wooden box with 3mm plywood and its 150x75x50mm in size...i will come up with upgraded version of this box at later time

thingiverse

free

Mailbox by CFdesign20

...s a possibility for a future design. i have also attached some keyshot renderings as well as some real life photos and a drawing.

thingiverse

free

Laser cut oval bowl

... is designed to get most of a 18x24 plywood board. i used quarter inch baltic birch.

https://www.youtube.com/watch?v=4sv_wk9kvmw

thingiverse

free

Reddit Snu (Laser Cut)

...reddit snu (laser cut)

thingiverse

laser cut out of 1/8" baltic birch plywood

thingiverse

free

Torsion Catapult by rexinator

...ned. it fires small projectiles. it is meant to be laser cut out of 5mm plywood. feel free to modify it and make improvements.

thingiverse

free

Laser Cut Box cutter blade holder acrylic cutter by phana007

...e this for box cutting and scoring acrylic sheets to break apart. i've added the 123d design file for you to make amendments.

thingiverse

free

Wood parts for MendelMax by llegoff

...giverse.com/thing:28536

extruder seehttp://www.thingiverse.com/thing:31267

panelolu seehttp://www.thingiverse.com/thing:35440

Texaslaser

thingiverse

free

Calendar Clock. by TexasLaser

...calendar clock. by texaslaser

thingiverse

i've made plenty of clocks and calendars, now i've combined them into one.

thingiverse

free

Lasered Jewelry Tree with base. by TexasLaser

....thingiverse.com/thing:93291, i modified the file a little and also made a base.

note: the tree is 3mm birch, the base is 5mm.

thingiverse

free

2015 Hex Calendar. Laser Cut, Wood. Configurable. by TexasLaser

...5 calendars now.

i have several versions of laser cut wood calendars on my page. http://www.thingiverse.com/texaslaser/designs

thingiverse

free

6 Pack Beer Holder. Lasered Wood. DOS-XX by TexasLaser

...eer holder. lasered wood. dos-xx by texaslaser

thingiverse

lasered a 6 pack holder. customized it to my favorite beer dos xx.

thingiverse

free

Laser cut Dice Speaker Box by TexasLaser

...s so i came up with this. dice speakers.

the "one" side is the speaker.

can customize to any small 3-3.5 inch speaker.

thingiverse

free

Raspberry Pi Workstation/dock. Laser cut. by TexasLaser

... case.

designed with slots and holes on top back and sides to guide cables.

cut on 5mm wood. very easy to pick up and transport.

thingiverse

free

Lasered quadcopter. 24" wide, 3mm plywood. by TexasLaser

...k with 3mm plywood. all fits together well. there is no glue holding it together in the photos, very tight fit. 24" wide.

thingiverse

free

Universal phone and small tablet stand. Lasered by TexasLaser

...es it a universal stand for any size phone and small tablets as well

this was inspired byhttp://www.thingiverse.com/thing:33077

thingiverse

free

Laser Cut Dice by TexasLaser

... top = 6. be sure to place 2-5 and 3-4 opposite each other, as they are all identical shape and can be placed in any combination.

thingiverse

free

Lasered key hanger, hook, rack, holder. by TexasLaser

...slightly larger than needed so i grinded off the tips as they went through. i'm using velcro to hold it on the refrigerator.

Mendelmax

thingiverse

free

Logo Mendelmax by tytanos

...logo mendelmax by tytanos

thingiverse

logo mendelmax

thingiverse

free

MendelMax Toolbox by STB

...mendelmax toolbox by stb

thingiverse

small toolbox for the mendelmax.

thingiverse

free

PenHolder for MendelMax by makeitBana

...penholder for mendelmax by makeitbana

thingiverse

penholder for mendelmax

add rubberbands

thingiverse

free

Spooler for Mendelmax by Lke

...spooler for mendelmax by lke

thingiverse

universal spooler for mendelmax printer.

thingiverse

free

MendelMax Panel by Jezu88

...mendelmax panel by jezu88

thingiverse

my first project, panel mendelmax fan and light switch

thingiverse

free

MendelMax Cable Clip by nischi

...mendelmax cable clip by nischi

thingiverse

mendelmax cable clip

it is a clip for mendelmax misumi parts to hold cables.

thingiverse

free

Filament guide for MendelMax by Simonious

...filament guide for mendelmax by simonious

thingiverse

filament guide for mendelmax

thingiverse

free

MendelMax Keychain by kludgineer

...mendelmax keychain by kludgineer

thingiverse

just a keychain to print on your mendelmax to show your friends what it can do.

thingiverse

free

MendelMax plug profile by grzesiek82

...mendelmax plug profile by grzesiek82

thingiverse

za?lepka profila mendelmax 10cm

thingiverse

free

Messuhrhalter für Mendelmax by giersberg

...messuhrhalter für mendelmax by giersberg

thingiverse

messuhrhalter für mendelmax mit magneten.

Birch

turbosquid

$25

birch

...h

turbosquid

royalty free 3d model birch for download as max on turbosquid: 3d models for games, architecture, videos. (1321576)

3d_export

$10

birch tree

...birch tree

3dexport

birch tree

turbosquid

$30

Birch

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

birch

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

vizpark

$26

Birch Trees

...trees is a set of 13 photorealistic 3d models of small, mid and large birches with scanned trunks for pbr and various 3d formats.

3d_export

$10

birch tree 2

...birch tree 2

3dexport

birch tree

archive3d

free

Birch 3D Model

...odel

archive3d

birch tree plant

birch n240512 - 3d model (*.3ds) for exterior 3d visualization.

archive3d

free

Birch 3D Model

... 3d model

archive3d

tree birch plant

birch n310512 - 3d model (*.3ds)exterior 3d visualization.

archive3d

free

Birch 3D Model

...odel

archive3d

tree birch plant

birch n290811 - 3d model (*.3ds) for exterior 3d visualization.

archive3d

free

Birch 3D Model

...odel

archive3d

birch tree

birch n111212 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

Plywood

3ddd

free

plywood chair

...plywood chair

3ddd

plywood chair , plywood

plywood chair

turbosquid

$10

Plywood

...yalty free 3d model plywood for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1432356)

3d_ocean

$19

Watch plywood

...watch plywood

3docean

clock horologe plywood timekeeper timepiece timer watch wood

watch plywood + vray

3d_ocean

$2

Old Plywood

...old plywood

3docean

cracked fracture green old paint painted plywood wood

the texture of old painted plywood.

3d_ocean

$7

Plywood Chair

...ood chair

3docean

chair female screw kitchen plywood screw seat stuhl tiled floor tiles wood wooden chir

a chair made of plywood.

3ddd

$1

Стол Eames Plywood

... круглый , кофейный

стол eames plywood

d: 860mm

h: 400mm

turbosquid

$29

Plywood Stool

...free 3d model plywood stool for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1410610)

turbosquid

$29

Plywood Chair

...free 3d model plywood chair for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1410607)

turbosquid

$10

Plywood Armchair

...e 3d model plywood armchair for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1678524)

turbosquid

free

Plywood Bench

...l plywood bench for download as blend, fbx, obj, dae, and png on turbosquid: 3d models for games, architecture, videos. (1587899)

Strength

3d_ocean

$8

Hammer strength game

...hammer strength game

3docean

carnival fuerza game hammer juego martillo quermes strength

carnival hammer strength game.

turbosquid

free

Father's Strength

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

key strength tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Cybex Strength Training Equipment

...d model cybex strength training equipment for download as max on turbosquid: 3d models for games, architecture, videos. (1572260)

turbosquid

$9

Hammer Strength Seated Bicep gym

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

gym Hammer Strength ISO - Lateral Shoulder Press

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

gym Hammer Strength Leg Raise Abs Exercise

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

treadmill strength weight fitness active man exercise cardio gym

...o gym

3dexport

treadmill strength weight fitness active man exercise cardio gym<br>max2013 vray<br>fbx<br>obj

3d_export

$8

Balls Pack

...each of which is distinct and has its own strength and distinctive throwing abilities. this slam dunk basketball pack...

3d_export

$8

thorn blade

...say that the blood of it's owner gives it strength the thorns on the handle of the sword make...

5Mm

3d_export

$25

5mm Explosive Flechette 3D Model

...xplosive flechette 3d model

3dexport

assault rifle grenade launchers

5mm explosive flechette 3d model awnonbhowmik 74565 3dexport

turbosquid

$15

engagement simple ring with diamond (5mm)

...engagement simple ring with diamond (5mm) for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1157278)

turbosquid

$1

Flexible shaft coupling 5mm x 8mm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$7

Tiny bracelet clasp lock 20mm X 5mm

... your bracelet parts to the clasp, also there is the original file in the files so you can change it on your own simply. enjoy it

3d_export

$5

cross with text jesus

...the text jesus is in an contur offset with 5mm ...

3d_export

$5

ring

...ring 3dexport lovely ring, adopt for print, one stown 5mm material : white / yellow gold/ silver. stl,...

3d_export

$11

crescent ring

...ring size is 17mm.<br>ring rail size is 53.4<br>stone size 5mm ...

3d_export

$5

Hex Spacers M3 Male-Female

...male-female 3dexport hex spacers m3 male-female with length from 5mm to 60mm for printed circuit boards. step...

3ddd

$1

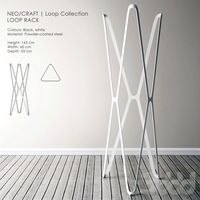

LOOP RACK

...вешалка the clothes rack’s elegant frame is made of 5mmthick steel. it creates simple shapes, that vary depending on...

3d_export

free

solar rechargeable single led flashing light

...ties onto a pole etc, i used a single 5mm red/blue alternating flasher that pushes snugly into the 5mm...

Laser

3d_export

$5

laser

...laser

3dexport

a 3d laser

3d_export

free

cnc 3dp laser nozzle for 2w laser opt lasers

...logy that gave birth to cutting and engraving laser heads this laser nozzle was designed for, read the article in the link below:

3d_export

free

cnc laser mount opt lasers

...eive the engraving and cutting laser heads this cnc machine laser mount was designed for, read the article on the following page:

turbosquid

$20

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

laser sword

...laser sword

3dexport

it is a blue laser sword with a metal frame

3d_ocean

$19

Laser Turret

...be used in any sf type of game, especially in tower defense games. - laser turret: 3025 polygons - props: 270 polygons - textu...

3d_export

free

workbee cnc laser mount for opt lasers

...the specifications of engraving and cutting laser heads this mount was designed for, please take a look at the following website:

3d_export

free

shapeoko cnc laser mount for opt lasers

...ind out the opportunities that adding a cutting and engraving laser head to your cnc can bring, take a look at the website below:

Lasering

3d_export

$5

laser

...laser

3dexport

a 3d laser

3d_export

free

cnc 3dp laser nozzle for 2w laser opt lasers

...logy that gave birth to cutting and engraving laser heads this laser nozzle was designed for, read the article in the link below:

3d_export

free

cnc laser mount opt lasers

...eive the engraving and cutting laser heads this cnc machine laser mount was designed for, read the article on the following page:

turbosquid

$20

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

laser sword

...laser sword

3dexport

it is a blue laser sword with a metal frame

3d_ocean

$19

Laser Turret

...be used in any sf type of game, especially in tower defense games. - laser turret: 3025 polygons - props: 270 polygons - textu...

3d_export

free

workbee cnc laser mount for opt lasers

...the specifications of engraving and cutting laser heads this mount was designed for, please take a look at the following website:

3d_export

free

shapeoko cnc laser mount for opt lasers

...ind out the opportunities that adding a cutting and engraving laser head to your cnc can bring, take a look at the website below:

Hardware

3ddd

$1

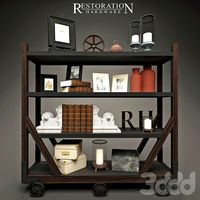

Restoration Hardware

...restoration hardware

3ddd

restoration hardware

restoration hardware

3ddd

$1

RESTORATION HARDWARE

...restoration hardware

3ddd

restoration hardware , телескоп

restoration hardware

3ddd

$1

Restoration Hardware

...restoration hardware

3ddd

restoration hardware

restoration hardware, кресло,

3ddd

$1

Restoration Hardware

...restoration hardware

3ddd

restoration hardware , декоративный набор

restoration hardware

3ddd

$1

Restoration Hardware

...restoration hardware

3ddd

restoration hardware , декоративный набор

restoration hardware

3ddd

$1

Restoration Hardware

... hardware , боров , свинья

restoration hardware

3ddd

$1

Restoration Hardware

...ardware , корона , медведь

restoration hardware

3ddd

$1

Restoration Hardware

...ation hardware

3ddd

restoration hardware , тумба

тумба прикроватная restoration hardware

3ddd

free

Restoration Hardware

... кашпо , куст , свеча

restoration hardware

3ddd

free

Restoration Hardware

...restoration hardware

3ddd

restoration hardware

restoration hardware menlo table lamp

Structural

3ddd

$1

structure

...structure

3ddd

structure

turbosquid

$28

structure

...rbosquid

royalty free 3d model structure for download as max on turbosquid: 3d models for games, architecture, videos. (1338108)

turbosquid

$4

structure

...rbosquid

royalty free 3d model structure for download as max on turbosquid: 3d models for games, architecture, videos. (1338171)

turbosquid

$3

structure

...rbosquid

royalty free 3d model structure for download as fbx on turbosquid: 3d models for games, architecture, videos. (1392940)

turbosquid

free

Structure

...y free 3d model structure for download as 3ds, obj, and blend on turbosquid: 3d models for games, architecture, videos. (1163360)

3d_export

$5

Abandoned structure

...abandoned structure

3dexport

abandoned structure consisting of ground floor and first floor walkable.

3d_export

$5

Small Structure

...all structure

3dexport

small structure static object, formed by a large room and a closet inside, lowpoly model supports the pbr

3ddd

$1

Structure - Kubik

... (в размерах+текстуры+ obj)http://www.lancko.com/structure-collection-kubik-p/lancko-walls-st-ku.htm

archive3d

free

Structure 3D Model

...nstruction structure prefabricated elements

structure - 3d model for interior 3d visualization.

archive3d

free

Structure 3D Model

...chive3d

metal construction structure

structure part-2 - 3d model for interior 3d visualization.

Additional

turbosquid

$5

addition

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Addit Swift

...addit swift

designconnected

danerka addit swift computer generated 3d model. designed by pelikan design.

3d_export

$7

FIREPLACE ADDITIONALS 3D Model

...tionals 3d model

3dexport

fireplace plier coal brush shovel screen fire

fireplace additionals 3d model loscarpello 55166 3dexport

turbosquid

$7

PAHL Table With Additional Module

...pahl table with additional module for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1682973)

3ddd

$1

Illulian carpets (addition 3)

...lulian , ковер

количество текстур: 18

размер min/max: 637 x 4156

производитель: illulian

3ddd

free

Illulian carpets (addition 2)

...lulian , ковер

количество текстур: 17

размер min/max: 660 x 2953

производитель: illulian

turbosquid

$24

Modern table in green,blue with addition of red

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

MIWE Cube additional components 3D model

...nts 3d model for download as max, max, max, fbx, obj, and max on turbosquid: 3d models for games, architecture, videos. (1601300)

turbosquid

$10

MIWE Cube additional components 3D model

...nts 3d model for download as max, max, max, fbx, obj, and max on turbosquid: 3d models for games, architecture, videos. (1601309)

turbosquid

$10

MIWE Cube additional components 3D model

...nts 3d model for download as max, max, max, fbx, obj, and max on turbosquid: 3d models for games, architecture, videos. (1601304)

Cut

design_connected

$11

e15 Cut Cutting Boards

...e15 cut cutting boards

designconnected

e15 cut cutting boards computer generated 3d model.

design_connected

$16

Cut

...cut

designconnected

lapalma cut computer generated 3d model. designed by rota, francesco.

3d_export

$5

cutting machine

...cutting machine

3dexport

crop cutting machine

3d_export

$5

cutting board

...cutting board

3dexport

12 models for cutting boards

3d_export

$20

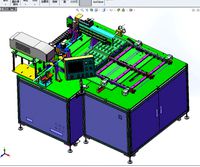

wire laser cutting peeling cutting machine ffc cutting machine

...and receiving machine, with the structure of this drawing, you don't need to draw by yourself, welcome to collect, thank you.

3ddd

$1

Lapalma CUT

... cut

фабрика: lapalma

коллекция: cut

размер:↑ 74 cm, ↔ 55 см.

описание: стул, ткань, кожа, дерево.

сайт: www.lapalma.it

3ddd

$1

стул lapalma cut

...стул lapalma cut

3ddd

lapalma , cut

стул lapalma cut

3ddd

$1

Lapalma CUT

...

коллекция: cut

размер:↑ 74 cm, ↔ 55 см.

описание: стул, порошковое покрытие, черный, белый, ткань, пластик.

сайт: www.lapalma.it

design_connected

$16

Hi Cut

...hi cut

designconnected

kartell hi cut computer generated 3d model. designed by starck, philippe.

3ddd

$1

Vorwerk Cut

...vorwerk cut

3ddd

ковер

vorwerk cut

прямоугольный:

размеры : 2400mm x 3200mm

круглый:

размеры : 2400mm

Assembly

3d_export

$7

Electronic product assembly machine assembly machine

...electronic product assembly machine assembly machine

3dexport

electronic product assembly machine assembly machine

3d_export

$15

generator assembly line

...ced and assembled in the form of module block. it is a demonstration project of generator assembly. welcome to download and learn

3d_export

$10

elevator traction machine assembly line motor assembly process

... traction machine assembly line motor assembly process

3dexport

elevator traction machine assembly line (motor assembly process)

3d_export

$16

pin assembly machine

...pin assembly machine

3dexport

pin assembly machine

3d_export

$7

tower-crane-assembly

...tower-crane-assembly

3dexport

tower-crane-assembly

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658296)

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658293)

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658291)

turbosquid

$75

Platform Assembly

...royalty free 3d model platform assembly for download as blend on turbosquid: 3d models for games, architecture, videos. (1472939)

turbosquid

$15

generator assembly

...y free 3d model generator assembly for download as and sldas on turbosquid: 3d models for games, architecture, videos. (1469469)

Features

turbosquid

$55

feature wall

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Water Feature

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

1989 GLASS-features

...1989 glass-features

3ddd

ванна

ванна с хвостом на деревянной ноге

turbosquid

$39

Animated Granite Water Feature

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Hyundai Feature Car Platform

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

2 way feature fixture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$87

MALE HUMAN HEAD WITH ELONGATED FEATURE

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

Download free Exterior Features 3D Model

...

exterior base factory

exterior features 3d model download free .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl f0x3z 107565 3dexport

turbosquid

$10

Modular 3D Feature Wall Panels. Cubes

...ure wall panels. cubes for download as 3ds, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1194990)

3d_export

$19

Ponds lakes Lotus leaf park water features Lotus

...nds lakes lotus leaf park water features lotus

3dexport

1.ponds lakes lotus leaf park water features lotus 2.files include 3dmax

Added

3ddd

$1

Ad-Hoc

...ad-hoc

3ddd

ad-hoc , viccarbe

ad-hoc

design jean-marie massaud 2007

viccarbe

design_connected

$16

Ad Hoc

...ad hoc

designconnected

viccarbe habitat ad hoc lounge chairs computer generated 3d model. designed by jean-marie massaud.

turbosquid

$160

AD-3D_Pradelles_Door_France

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

AD Desk

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

AD Wardrop

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

orange for ads

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Ad A Board

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Petracers Ad Maiora

...petracers ad maiora

3ddd

petracers ad maiora , плитка

50x100

cg_studio

$50

Ad truck3d model

...omo van billboard board

.3ds .c4d .dxf .obj - ad truck 3d model, royalty free license available, instant download after purchase.

turbosquid

$150

Pilar ad Forniture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Easy

design_connected

$16

Easy

...easy

designconnected

sollos easy computer generated 3d model. designed by almeida, jader.

design_connected

$20

Easy

...easy

designconnected

established & sons easy armchairs computer generated 3d model. designed by ed carpenter.

3d_ocean

$1

Easy Button

... it is accurate in close-ups. you can drop this model right into any setting. the textures are included as well as links to do...

design_connected

$16

Easy Armchair

...easy armchair

designconnected

easy armchair computer generated 3d model. designed by jeanneret, pierre.

3ddd

$1

Pouf EASY

... easy

3ds max 2010.v-ray 2.40.03.file formats fbx,obj. pouf desiree 2014 easy. dimensions 100x100x45 cm.

design_connected

$18

Easy Armchair

...easy armchair

designconnected

fsm easy armchair computer generated 3d model. designed by hartmann, markus.

design_connected

$16

Easy Chair

...easy chair

designconnected

magis easy chair computer generated 3d model. designed by seymour, jerszy.

design_connected

$16

Easy Rider

...easy rider

designconnected

bulo easy rider computer generated 3d model. designed by venlet, danny.

design_connected

$11

Easy Footstool

...easy footstool

designconnected

fsm easy footstool computer generated 3d model. designed by hartmann, markus.

design_connected

$18

Doda - Easy

...doda - easy

designconnected

molteni & c doda - easy computer generated 3d model. designed by laviani, ferruccio.

Wood

3ddd

$1

Wood

...wood

3ddd

wood

3ddd

$1

Wood

...wood

3ddd

wood

3ddd

$1

Wood

...wood

3ddd

wood

3ddd

$1

Wood

...wood

3ddd

wood

3ddd

$1

Wood

...wood

3ddd

доска

wood

3ddd

$1

Wood

...wood

3ddd

доска

wood

3ddd

$1

wood

...wood

3ddd

дрова

wood, log

3d_ocean

$3

Wood Crate

...wood crate

3docean

box crate wood

a model of a wood crate

3ddd

free

Wood crafts

...wood crafts

3ddd

wood , crafts

wood crafts of chinese style

turbosquid

$2

Wood

...od

turbosquid

royalty free 3d model wood for download as obj on turbosquid: 3d models for games, architecture, videos. (1576561)

5

turbosquid

$6

Rock 5-5

...urbosquid

royalty free 3d model rock 5-5 for download as obj on turbosquid: 3d models for games, architecture, videos. (1639063)

3d_export

$5

hinge 5

...hinge 5

3dexport

hinge 5

turbosquid

$10

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

A-5

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Calligraphic Digit 5 Number 5

...hic digit 5 number 5 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389333)

3ddd

$1

5 роз

...5 роз

3ddd

5 роз в стеклянной вазе

design_connected

$11

iPhone 5

...iphone 5

designconnected

apple iphone 5 computer generated 3d model.

3ddd

$1

Lola 5

...lola 5

3ddd

miniforms

lola 5 miniforms 300*65*134

3ddd

$1

Nexus 5

...dd

nexus , phone , телефон

google nexus 5 phone

3d_ocean

$15

iPhone 5

...iphone 5

3docean

3d 4d apple cinema iphone model modeling phone screen texture

iphone 5 3d model and texture realistic iphone 5.

1

turbosquid

$69

armchairs(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

ring 1+1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Chair(1)(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

RING 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

house 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Table 1(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Formula 1(1)

...lty free 3d model formula 1 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1567088)

design_connected

$11

No 1

...no 1

designconnected

sibast no 1 computer generated 3d model. designed by sibast, helge.

turbosquid

$2

desert house(1)(1)

...3d model desert house(1)(1) for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1055095)

All

turbosquid

$20

all

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

all

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$29

All-Two

...all-two

designconnected

bonaldo all-two computer generated 3d model. designed by bicego, sergio.

design_connected

$29

All-One

...all-one

designconnected

bonaldo all-one computer generated 3d model. designed by bicego, sergio.

design_connected

$16

Holly All

...holly all

designconnected

serralunga holly all computer generated 3d model. designed by starck, philippe.

3d_export

$15

all terrain

...all terrain

3dexport

turbosquid

$29

Holly All

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Design

3ddd

$1

LINE DESIGN (Doors Design)

...line design (doors design)

3ddd

дверь

modern doors design - line design concept

turbosquid

$5

designer

...alty free 3d model designer for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1422665)

3ddd

$1

VER DESIGN

...ver design

3ddd

ver design

кресло ver design

3ddd

$1

VER DESIGN

...ver design

3ddd

ver design

диван ver design

3ddd

$1

Bagno design

...bagno design

3ddd

bagno design , унитаз

санитария bagno design

3ddd

free

VER DESIGN

...ver design

3ddd

ver design , стеллаж

полка ver design

3ddd

$1

VER DESIGN

...ver design , лежак , шезлонг

шезлонг ver design

3d_export

free

designer

..., trees and much more. the model has 3 types of parts: - 4 cells - 6 cells - 8 cells the *.max file contains 5 colored materials.

3d_export

$19

level design

...level design

3dexport

you can use this design (level design) in your own game.

3d_export

$7

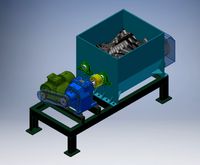

Crusher design

...crusher design

3dexport

crusher design