Thingiverse

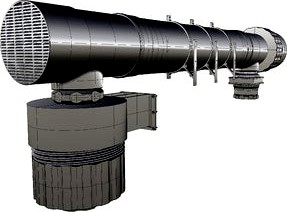

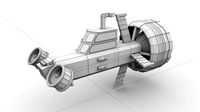

AIR HEAT RECOVERY - TUBULAR - PIPE IN PIPE - WITH ARDUINO CONTROL

by Thingiverse

Last crawled date: 4 years, 3 months ago

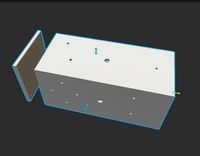

HEAT RECOVERY TUBULAR - PIPE IN PIPE

WITH ARDUINO CONTROL

It use 160mm PVC drain pipe (thickness 3.2) and an extensible aluminium tube 100mm to build the heat exchange unit.

https://www.hornbach.ro/shop/Teava-canal-Valplast-160mm-3m/7408966/produs.htmlhttps://www.hornbach.ro/shop/Mufa-canal-Valplast-PVC-160mm/7408994/produs.htmlhttps://mathaus.ro/p/tub-aluminiu-100-3/000000000011111795?gclid=Cj0KCQiAjfvwBRCkARIsAIqSWlNtamy4JMNm9ZCjEraIEla8kAG0K67GS4kjpztjsquX6P7AaXs5DCYaAiPjEALw_wcB

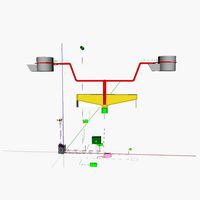

2X120mm Fan - for inlet and outlet. Use same type of fans and connect them in parallel, in order to have same airflow for inlet and outlet. An Arduino unit can control the speed of the motors, in order to reduce it, until the heat exchanger reach the maximum efficiency.https://www.youtube.com/watch?v=IG5vw6P9iY4

If you look for something fancy... can add some moisture and temperature sensors!

In order to preserve the inside surfaces clean, use HEPA filter also on the evac line.

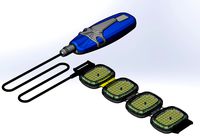

Use Spacer to center the aluminium pipe, secure it with aluminium tape to the aluminium tube - every 300mm.

Aluminium pipe will be secured at the end terminations with a pipe clamp and aluminium tape. (If you do not have a pipe clamp, see the 3d printable model provided - it use a M4 - 18mm bolt/nut/washer.)

All parts are check for naked edges or errors - therefore ... all are going to be printable! If the design is good or if the parts are going to fit... that's another story!

Design to print without support ... mostly... except for the parts what need support :) By Costa

WITH ARDUINO CONTROL

It use 160mm PVC drain pipe (thickness 3.2) and an extensible aluminium tube 100mm to build the heat exchange unit.

https://www.hornbach.ro/shop/Teava-canal-Valplast-160mm-3m/7408966/produs.htmlhttps://www.hornbach.ro/shop/Mufa-canal-Valplast-PVC-160mm/7408994/produs.htmlhttps://mathaus.ro/p/tub-aluminiu-100-3/000000000011111795?gclid=Cj0KCQiAjfvwBRCkARIsAIqSWlNtamy4JMNm9ZCjEraIEla8kAG0K67GS4kjpztjsquX6P7AaXs5DCYaAiPjEALw_wcB

2X120mm Fan - for inlet and outlet. Use same type of fans and connect them in parallel, in order to have same airflow for inlet and outlet. An Arduino unit can control the speed of the motors, in order to reduce it, until the heat exchanger reach the maximum efficiency.https://www.youtube.com/watch?v=IG5vw6P9iY4

If you look for something fancy... can add some moisture and temperature sensors!

In order to preserve the inside surfaces clean, use HEPA filter also on the evac line.

Use Spacer to center the aluminium pipe, secure it with aluminium tape to the aluminium tube - every 300mm.

Aluminium pipe will be secured at the end terminations with a pipe clamp and aluminium tape. (If you do not have a pipe clamp, see the 3d printable model provided - it use a M4 - 18mm bolt/nut/washer.)

All parts are check for naked edges or errors - therefore ... all are going to be printable! If the design is good or if the parts are going to fit... that's another story!

Design to print without support ... mostly... except for the parts what need support :) By Costa

Similar models

thingiverse

free

HEAT RECOVERY TUBULAR - PIPE IN PIPE 2

...fit... that's another story!

design to print without support ... mostly... except for the parts what need support :) by costa

grabcad

free

Tubular heat exchanger / Echangeur tubulaire

...angeur tubulaire

tube inlet : burner smoke 600°c

shell inlet : air 20°c

shell outlet : air 250°c (combustion air for fuel burner)

grabcad

free

Condenser Heat Exchanger

...grabcad

heat exchanger with copper tubes and aluminium side supports with a water inlet and outlet

do like model and follow me

thingiverse

free

Air Exchange Heat Recovery by OTandAT

....5 aluminum inter tube for the counter flow heat exchanger.

how this was made video: https://www.youtube.com/watch?v=lfzsid0ieca

grabcad

free

tubes for heat exchanger

...tubes for heat exchanger

grabcad

pipes are used in shell and tube type heat exchangers

grabcad

free

CO2 Heat Exchanger

...nlet/outlet on the front. hope you guys like this and comes to great help to your own project . share this with everyone

thanks.

grabcad

free

Heat Exchanger

...heat exchanger

grabcad

shell-tube tubular heat exchanger.

grabcad

free

plate-type heat exchanger DN150/DN100_PN16

...plate-type heat exchanger dn150/dn100_pn16

grabcad

inlet/outlet of steam - dn150_pn16

inlet/outlet of water - dn100_pn16

grabcad

free

Cross Pipe Joint

...nd three outlets, or there inlets and one outlet. the diameter of the outlet and inlet can be the same and can also be different.

grabcad

free

Heat exchanger type AEM

...heat exchanger type aem

grabcad

heat exchanger type aem, high pressure, 4" nozzles for inlet and outlet.

Recovery

turbosquid

$19

Recovery Roller

... model recovery roller for download as max, obj, fbx, and max on turbosquid: 3d models for games, architecture, videos. (1363235)

turbosquid

$100

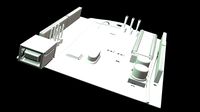

ENERGY RECOVERY UNIT (ERU)

... free 3d model energy recovery unit (eru) for download as max on turbosquid: 3d models for games, architecture, videos. (1259438)

turbosquid

$28

Road Commander Wreck Recovery Truck

...mander wreck recovery truck for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1473949)

3d_export

$25

t-34t recovery vehicle version 2

...ion 2

3dexport

t-34t - tractor, recovery vehicle created on the basis of the soviet t-34-85 tank *modifier - subdivision surface

3d_export

$25

t-34t recovery vehicle version 1

...ion 1

3dexport

t-34t - tractor, recovery vehicle created on the basis of the soviet t-34-85 tank *modifier - subdivision surface

3d_export

$70

RAC Vehicle Recovery Trailer 3D Model

...a tow flatbed flat bed garage repair mechanic vehicles pickup

rac vehicle recovery trailer 3d model 3dillustration 23584 3dexport

turbosquid

$129

Daf XF 106 Recovery Truck Model

...6 recovery truck model for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1333595)

turbosquid

$30

IR Bracelet Light Therapy Pain Recovery System

...acelet light therapy pain recovery system for download as ige on turbosquid: 3d models for games, architecture, videos. (1493109)

turbosquid

$30

COVID Sanitization UV Bracelet Light Recovery System

...acelet light therapy pain recovery system for download as ige on turbosquid: 3d models for games, architecture, videos. (1493107)

3d_export

$85

3D Scania S730T Omars Recovery Truck Model

...ded<br>format available: obj file<br>on request,after purchase,i can offer other file formats the customer is in need

Tubular

turbosquid

$5

Tubular Key

...royalty free 3d model tubular key for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1489994)

turbosquid

$10

Tubular Bells

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Tubular Horizontal Pendant

... horizontal pendant

designconnected

henge tubular horizontal pendant computer generated 3d model. designed by castagna, massimo.

turbosquid

$25

Brno Tubular Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Clothes tubular Gondola

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Climbing tubular device

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Tubular Steel Shelf

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Tubular Steel Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Tubular Wood Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

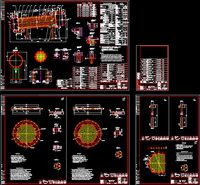

33m3 tubular heat exchanger diagram

...33m3 tubular heat exchanger diagram

3dexport

33m3 tubular heat exchanger diagram

Arduino

turbosquid

$7

Arduino

...turbosquid

royalty free 3d model arduino for download as max on turbosquid: 3d models for games, architecture, videos. (1197165)

turbosquid

$3

Arduino

...turbosquid

royalty free 3d model arduino for download as c4d on turbosquid: 3d models for games, architecture, videos. (1305484)

3d_export

$5

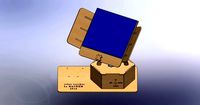

arduino satellite

...rt

this model is the exact arduino based satellite model with some basic sensors and camera modules and also includes batteries.

turbosquid

$1

Arduino UNO

...alty free 3d model arduino uno for download as , stl, and wrl on turbosquid: 3d models for games, architecture, videos. (1515932)

3d_export

$5

esp8266 box arduino

...esp8266 box arduino

3dexport

box for esp8266 module with wire hole. inside dimensions: 49x26 mm. height 15 mm.

3d_export

$60

Arduino Uno Rev3 Microcontroller 3D Model

...mega328p circuit board spark cable wire 5v 74v 9v 111v

arduino uno rev3 microcontroller 3d model danielgarnier4403 97237 3dexport

3d_export

free

arduino rover kit

...no!!! materials: no!!! rigged: no animated: no uv mapped: no it is not an exact copy of the original! not subject to 3d printing!

3d_ocean

$7

The housing for the 3d Printer

...the housing for the 3d printer 3docean arduino device housing stl the housing consists of two portions:...

3d_export

$5

arm 4 axis

...uno -4 servo motor 180° -3 joystick (x,y) for arduino -mdf wood -some wires -cnc laser cut...

3d_export

$5

solar tracker

...machine for the frame . list of material : -arduino uno -2 step motor with driver -4 ldr sensor...

Heat

3d_export

$5

heat

...heat

3dexport

heat tool

3ddd

$1

electric heating

...electric heating

3ddd

обогреватель

electric heating

3d_export

$6

The heating module

...any questions also you can email to me. designed with solidworks 2017, render with keyshot **************************************

turbosquid

$2

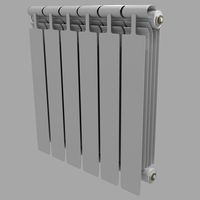

Heating Radiator

...

royalty free 3d model heating radiator for download as blend on turbosquid: 3d models for games, architecture, videos. (1561908)

3d_export

$35

heating instalation with heat pump and solar system

...el , please contact me. before buying a model, you can try to download one of my free models and testing. thank you for watching.

turbosquid

$29

Heating Mantle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Heating Radiator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

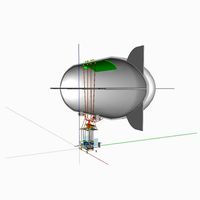

AT_airship_control_stand_(heated)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

AT_airship_(heated)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Heating radiator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Pipe

3d_ocean

$3

Pipe

...pipe

3docean

pipe

a high quality pipe with high resolution texture

archibase_planet

free

Pipe

...pipe

archibase planet

pipe conduit piping tubing

pipe unit polymix n210411 - 3d model (*.3ds) for interior 3d visualization.

3d_ocean

$2

Pipes

...pipes

3docean

pipes

a high quality pipes which are ready to use in interiros and contains shader.

3d_export

$10

pipes

...dexport

pipes set – 3d models of a oil pipes for your games/media productions. these are low polygonal models, easy to assemble.

archibase_planet

free

Tobacco pipe

...bacco pipe

archibase planet

tobacco pipe pipe tobacco-pipe

tobacco pipe n020312 - 3d model (*.3ds) for interior 3d visualization.

turbosquid

$7

Smoking Pipe - E-pipe

...g pipe - e-pipe for download as 3ds, lwo, obj, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1188985)

archibase_planet

free

Tobacco-pipe

...tobacco-pipe

archibase planet

tobacco-pipe pipe

tobacco-pipe n030312 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$10

Pipe

...pe

turbosquid

royalty free 3d model pipe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1143449)

turbosquid

$7

pipe

...pe

turbosquid

royalty free 3d model pipe for download as prj on turbosquid: 3d models for games, architecture, videos. (1374588)

turbosquid

$2

Pipe

...

turbosquid

royalty free 3d model pipe for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1214323)

Control

3d_ocean

$4

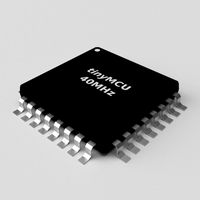

Controller TQFP32

...qfp32

3docean

chip controller cpu electronic gpu mcu micro controller silicon smd tqfp wafer

a micro controller in tqfp32 package

3d_ocean

$4

Controller TQFP44

...44

3docean

chip controller cpu electronic gpu mcu micro controller package smd tqfp tqfp44

a micro controller in a tqfp44 package

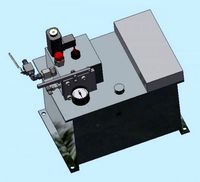

3d_export

$15

control unit

...control unit

3dexport

control unit

3ddd

$1

Yacht control

...yacht control

3ddd

yacht control

3d_export

$5

controle pgdm

...controle pgdm

3dexport

carcaca controle pgdm

turbosquid

free

controler

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Control

...

http://www.schmitz-leuchten.de/html-ru/einzelleuchten-lampentyp-details.php?lamptype_no=700&group;=917&id;=731

3d_ocean

$4

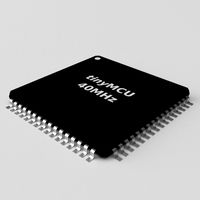

Controller TQFP100

...100

3docean

chip computer cpu electronic gpu mcu micro controller pin platine silicon wafer

a micro controller in tqfp100 package

3d_ocean

$4

Controller TQFP64

...qfp64

3docean

chip computer cpu gpu mcu micro controller package silicon tqfp tqfp64 wafer

a micro controller in a tqfp64 package

3d_ocean

$7

Remote controller

... control switcher tv remote

remote controller for tv, sound systems etc easy to edit textures photo real rendered with mental ray

Air

3ddd

$1

Calligaris air

...calligaris air

3ddd

air , calligaris

cтул calligaris air

3ddd

$1

Air freshener

...air freshener

3ddd

air freshener , освежитель

air freshener

design_connected

$16

Air

...air

designconnected

flexform air lounge chairs computer generated 3d model. designed by antonio citterio.

turbosquid

$250

Heat pump air air

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

air

...air

3dexport

3ddd

$1

Кухня AIR

...кухня air

3ddd

air , мария

кухня air фабрики "мария"

3ddd

$1

Лампа AIR

...лампа air

3ddd

boconcept , air

настольная лампа air, boconcept. в50½xø32см

3d_export

$40

air deflector

...air deflector

3dexport

air deflector

3d_export

$15

air purifier

...air purifier

3dexport

air purifier

3d_export

$5

macbook air

...macbook air

3dexport

macbook air