Thingiverse

Adapters to attach Prosthetic Hand to Black Ram Mount and updated Pins by AlwaysTinkering

by Thingiverse

Last crawled date: 2 years, 11 months ago

This is a merge of two great projects and is a continuation of projects they were built off of.

This parts library only contains additional parts or modifications to existing parts when needed. You will need to download the parts and instructions from the original libraries to complete this mod.

The PINS can be used in the existing Black Ram models in places you don’t want to use the plastic screws.

I added an STL for a flat sided screw for the Black Ram so that they can be printed on their side.

The Prosthetic hand source https://www.prusaprinters.org/prints/12224-prosthetic-hand

By SoniaVerdu. It will on the Black Ram Hand (Robotic/Prosthetic Hybrid) - Mark V by Black_Ram_Industries

at https://www.thingiverse.com/thing:1717809

And credit to the flex hand that I have not printed but was referenced by the creator of this version of the prosthetic hand - "Flexy-hand" http://www.thingiverse.com/thing:380665 I used part of a connector brought forward from there model.

I have a family member that had finger surgery on the left hand. It could take a year or more to return to full functionality. I printed the Black Ram Claw to bring some humor to their situation. Then I started to wonder if it could provide basic practicality… could it hold a jar while they opened a lid? I found challenges:

• Being above and in front of the hand is awkward for movement.

• The holding pressure on most claws is in-adequate (for all ends)

• Slippery plastic is a challenge

So I started looking at prosthetic prints. There is some insane work that has been done in this area. They are largely designed for people that are missing an appendage. So I decided to try to adapt one to the Black Ram Assembly. It is a lot of pieces to get it to work well together. Getting the assembly to generate enough power to overcome the pull resistance took some time. After several pull designes, I eventually reduced the pull pressure enough to where to where my wrist did not hurt using it.

The Prosthetic does not solve all the problems. I printed the end fingers in flex with the recommended high fill. So its kind of like pla, with a more tactile touch. The visual motion is great. The hand sits pretty far out. I did this to reduce it hitting a healing finger. I was also trying to place the pull cord entry into the hand level with the Black RAM pull. Unknowingly I removed the designed in leverage of the low pivot point in the original Prosthetic design. Do to the nature of the Black RAM design, the hand is mounted fixed and the ram moves. I did consider angling the hand down more.

Parts I am providing for the BLACK RAM ASSEMBLY:

• I cut the side off a screw so I can print a plate of them lying flat. If I print them without supports I lose a little thread detail as I transition of the bottom. Since they were PLA I printed them with support off the plate giving great threads all around. Works great you can let them all print at once. I used a .15 layer height.

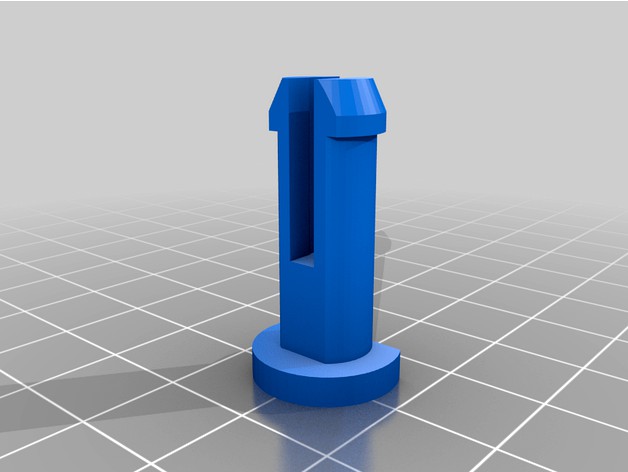

• I designed Pins to replace the screws in places they don’t need screw tension and tend to fall out from the rotation. The pins have nuts to just latch in place. The 10mm short slots are probably best but a little harder to insert.

• The Prosthetic Mount adapters for the RIGHT and LEFT hands (right hand not tested yet).

• A tensioning box to hold the prosthetic cords using tensioning_piece from the prosthetic hand design. It is the same piece, I had to trim the knobs so they did not hit each other… so the trimmed version is included.

• Tension Box cover if I can get it to stay… I spaced it with tape to prevent rattle… this cover is optional.. once our hand cords are adjusted the tension will hold them in place. Lift them so the top octagon clears the block and turn them to tighten. Nice design Sonia.

• The lever to pull the hand. The lever requires two 688 bearings (16mm diam, 5mm wide, 8mm hole) or print the plastic SHIM I will provide to reduce the hole).

• 8mm Pins for the new lever to go through the bearings.

• Stub-Tendon to go in the lever

• Fixed Tendon for the gauntlet port. This is required to raise the pull position… my first version was a tall fixed tendon. I recommend the half height for improved leverage.

• The gauntlet to lever tendon requiring 8mm pin on the lever side (top tendon).

Improvements that I think could be made:

Black Ram Assembly

The joint between the gauntlet and the wrist assembly could use a conversion to a ball bearing. That joint counters the pressure applied to the apparatus at the end. While testing the prosthetic in its first version the pressure to close the hand was about 7 to 10 pounds (3.1 to 4.5kb) of pull. I was bending the pins I had put in addition to the squeak. It also made my wrist hurt.

The hooks are great but in the double claw you have too little leverage to keep the claw closed. This is true for all the hooks. There lots of ways to increase leverage at the end of the gripper such as a mod on this https://www.youtube.com/watch?v=YX1MsP7aRvo or one of the many other examples online that could be converted.

Prosthetic Observations

I know nothing about Prosthetics. These are my observations.

1) Compounding the grip pressure at the tips to be able to hold things securely. Maybe sleeving the channels through the hand with something like Teflon would reduce friction. While I did not use the original wrist, my hack could use some way to compound the pressure I apply to a significantly increased factor at the tips of the fingers.

2) Independent suspension? Slip differential? The 5 fingers travel as a unit. The first two to hit can prevent the others from making contact. It was harder to pickup items with the fingers than the simple tri-claw. How do we make each finger travel independently so the travel of the others is not interrupted… and not compromise the overall grip?

3) A floating palm? The fixed palm gives a surface to close against. If the closing pressure of the fingers is increased and stabilized, could the palm apply additional counter pressure and close the grip on the object without releasing it from the fingers? We are mimicking the hand, but we are not limited to what a hand can do if a feature adds benefit.

4) The thumb. School always taught us this is what differentiates humans from other species. This mimics the two external joints, but the inside joint going to your wrist is what provides the real wrapping action in our thumbs and the closing pressure on the object to push it into the palm and the fingers. I would see a requirement that the fixed assembly holding the current thumb design would need to move as well to close the grip. This prosthetic model overall is missing a section in all the other fingers and therefore may be wrap challenged in some situations.

Other files I am providing…

My openscad hacks to make the parts.

Several openscad files to cut the large parts for printing… I then glued them back as suggested in this youtube video. Made printing so much easier. https://www.youtube.com/watch?v=stry5kibhyY&t=86s

Prosthetic assembly notes:

10mm and 20mm long 2mm machine screws are too long and will need trimming in many holes. I think I will prefer the piece of metal and seal it with filament. I don’t know how that will work in the flex.. I tried melting some flex with an iron and it burnt at the same temp I do PLA with. No science in that test though. I was afraid a PLA plug would pop out of the flex. The metal pieces save you money in bolts… and no MICROSCOPIC nuts to come off… glued or not.

I started with nylon fishing wire. Stranded is so much easier to work with. I didn’t even tie it… I just would the extra around the octagon fitting.

This was actually my first flex print. I have 5 incomplete fingers to prove it. It took me that long to figure out the config I downloaded that was tuned by someone for flex on my Prusa MK3S still had retraction on… at reduced settings, but the speed of the retraction was way too high. The finger would get almost to the top and fail.. I assume there was more retraction required there.

If I print a hand body again I will print it with a bit more fill. I can see it warping slightly under the strain of all 5 fingers pulling at once. I likely did it at 20% for this one.

Thanks to all the creators of these items. In addition to working correctly right off the printer, they provided a great documentation.

This parts library only contains additional parts or modifications to existing parts when needed. You will need to download the parts and instructions from the original libraries to complete this mod.

The PINS can be used in the existing Black Ram models in places you don’t want to use the plastic screws.

I added an STL for a flat sided screw for the Black Ram so that they can be printed on their side.

The Prosthetic hand source https://www.prusaprinters.org/prints/12224-prosthetic-hand

By SoniaVerdu. It will on the Black Ram Hand (Robotic/Prosthetic Hybrid) - Mark V by Black_Ram_Industries

at https://www.thingiverse.com/thing:1717809

And credit to the flex hand that I have not printed but was referenced by the creator of this version of the prosthetic hand - "Flexy-hand" http://www.thingiverse.com/thing:380665 I used part of a connector brought forward from there model.

I have a family member that had finger surgery on the left hand. It could take a year or more to return to full functionality. I printed the Black Ram Claw to bring some humor to their situation. Then I started to wonder if it could provide basic practicality… could it hold a jar while they opened a lid? I found challenges:

• Being above and in front of the hand is awkward for movement.

• The holding pressure on most claws is in-adequate (for all ends)

• Slippery plastic is a challenge

So I started looking at prosthetic prints. There is some insane work that has been done in this area. They are largely designed for people that are missing an appendage. So I decided to try to adapt one to the Black Ram Assembly. It is a lot of pieces to get it to work well together. Getting the assembly to generate enough power to overcome the pull resistance took some time. After several pull designes, I eventually reduced the pull pressure enough to where to where my wrist did not hurt using it.

The Prosthetic does not solve all the problems. I printed the end fingers in flex with the recommended high fill. So its kind of like pla, with a more tactile touch. The visual motion is great. The hand sits pretty far out. I did this to reduce it hitting a healing finger. I was also trying to place the pull cord entry into the hand level with the Black RAM pull. Unknowingly I removed the designed in leverage of the low pivot point in the original Prosthetic design. Do to the nature of the Black RAM design, the hand is mounted fixed and the ram moves. I did consider angling the hand down more.

Parts I am providing for the BLACK RAM ASSEMBLY:

• I cut the side off a screw so I can print a plate of them lying flat. If I print them without supports I lose a little thread detail as I transition of the bottom. Since they were PLA I printed them with support off the plate giving great threads all around. Works great you can let them all print at once. I used a .15 layer height.

• I designed Pins to replace the screws in places they don’t need screw tension and tend to fall out from the rotation. The pins have nuts to just latch in place. The 10mm short slots are probably best but a little harder to insert.

• The Prosthetic Mount adapters for the RIGHT and LEFT hands (right hand not tested yet).

• A tensioning box to hold the prosthetic cords using tensioning_piece from the prosthetic hand design. It is the same piece, I had to trim the knobs so they did not hit each other… so the trimmed version is included.

• Tension Box cover if I can get it to stay… I spaced it with tape to prevent rattle… this cover is optional.. once our hand cords are adjusted the tension will hold them in place. Lift them so the top octagon clears the block and turn them to tighten. Nice design Sonia.

• The lever to pull the hand. The lever requires two 688 bearings (16mm diam, 5mm wide, 8mm hole) or print the plastic SHIM I will provide to reduce the hole).

• 8mm Pins for the new lever to go through the bearings.

• Stub-Tendon to go in the lever

• Fixed Tendon for the gauntlet port. This is required to raise the pull position… my first version was a tall fixed tendon. I recommend the half height for improved leverage.

• The gauntlet to lever tendon requiring 8mm pin on the lever side (top tendon).

Improvements that I think could be made:

Black Ram Assembly

The joint between the gauntlet and the wrist assembly could use a conversion to a ball bearing. That joint counters the pressure applied to the apparatus at the end. While testing the prosthetic in its first version the pressure to close the hand was about 7 to 10 pounds (3.1 to 4.5kb) of pull. I was bending the pins I had put in addition to the squeak. It also made my wrist hurt.

The hooks are great but in the double claw you have too little leverage to keep the claw closed. This is true for all the hooks. There lots of ways to increase leverage at the end of the gripper such as a mod on this https://www.youtube.com/watch?v=YX1MsP7aRvo or one of the many other examples online that could be converted.

Prosthetic Observations

I know nothing about Prosthetics. These are my observations.

1) Compounding the grip pressure at the tips to be able to hold things securely. Maybe sleeving the channels through the hand with something like Teflon would reduce friction. While I did not use the original wrist, my hack could use some way to compound the pressure I apply to a significantly increased factor at the tips of the fingers.

2) Independent suspension? Slip differential? The 5 fingers travel as a unit. The first two to hit can prevent the others from making contact. It was harder to pickup items with the fingers than the simple tri-claw. How do we make each finger travel independently so the travel of the others is not interrupted… and not compromise the overall grip?

3) A floating palm? The fixed palm gives a surface to close against. If the closing pressure of the fingers is increased and stabilized, could the palm apply additional counter pressure and close the grip on the object without releasing it from the fingers? We are mimicking the hand, but we are not limited to what a hand can do if a feature adds benefit.

4) The thumb. School always taught us this is what differentiates humans from other species. This mimics the two external joints, but the inside joint going to your wrist is what provides the real wrapping action in our thumbs and the closing pressure on the object to push it into the palm and the fingers. I would see a requirement that the fixed assembly holding the current thumb design would need to move as well to close the grip. This prosthetic model overall is missing a section in all the other fingers and therefore may be wrap challenged in some situations.

Other files I am providing…

My openscad hacks to make the parts.

Several openscad files to cut the large parts for printing… I then glued them back as suggested in this youtube video. Made printing so much easier. https://www.youtube.com/watch?v=stry5kibhyY&t=86s

Prosthetic assembly notes:

10mm and 20mm long 2mm machine screws are too long and will need trimming in many holes. I think I will prefer the piece of metal and seal it with filament. I don’t know how that will work in the flex.. I tried melting some flex with an iron and it burnt at the same temp I do PLA with. No science in that test though. I was afraid a PLA plug would pop out of the flex. The metal pieces save you money in bolts… and no MICROSCOPIC nuts to come off… glued or not.

I started with nylon fishing wire. Stranded is so much easier to work with. I didn’t even tie it… I just would the extra around the octagon fitting.

This was actually my first flex print. I have 5 incomplete fingers to prove it. It took me that long to figure out the config I downloaded that was tuned by someone for flex on my Prusa MK3S still had retraction on… at reduced settings, but the speed of the retraction was way too high. The finger would get almost to the top and fail.. I assume there was more retraction required there.

If I print a hand body again I will print it with a bit more fill. I can see it warping slightly under the strain of all 5 fingers pulling at once. I likely did it at 20% for this one.

Thanks to all the creators of these items. In addition to working correctly right off the printer, they provided a great documentation.

Similar models

thingiverse

free

Black Ram Hand (Robotic/Prosthetic Hybrid) - Mark V by Black_Ram_Industries

...osing. i recommend first using simple or pincer claws first as the multi-joint fingers take some tuning to get working correctly.

thingiverse

free

Fin Gripper (Robotic/Prosthetic Hybrid) - Mark VI by Black_Ram_Industries

...ecific goal. the black ram hand is designed to help those with missing fingers or conditions such as dupuytren's contracture.

thingiverse

free

Fusion Hand by 1d1

...ters. there are videos for overview, assembly and construction techniques as well as files for one entire, adult-size right hand.

thingiverse

free

e-NABLE Raptor Reloaded finger assembly jig by JohnDiamond

...cular relevance in a hand assembly event where a group of individuals or teams are learning to assemble these prosthetic devices.

thingiverse

free

Black Ram Hand - MVII (BIG Robot) by Black_Ram_Industries

... to change the opening and closing claw size. use velcro strips to attach to your wrist and forearm.

https://youtu.be/1bxfs37s4ps

thingiverse

free

Finger/thumb assembly jig for an e-NABLE Phoenix prosthetic hand by JohnDiamond

...alignment with the proximal phalanges (also referred to as a phalanx) so that a snap pin can be pushed or driven in to join them.

thingiverse

free

#YYC3D Hand for Bruce: Hand-Wrist by neo777

...iverse

for the pins that list 2 fingers need to print 2 times!

please read the included pdf for print and assembly instructions!

thingiverse

free

eNable 3D Printed Prosthetic Hand "Reverse Grip" by Tyler_Wooten

...osthetic hand opens. this allows the user to hold onto objects for longer periods of time without feeling fatigue in their wrist.

thingiverse

free

Luke Skywalker Robot Hand (The Force Awakens) by segall

...ubber bands to attach this to my hand. fyi - you will probably need to do some after print finishing to get this to work for you.

thingiverse

free

Inmoov hand with MyoWare Muscle Sensor by tfan

... sometimes the line will come out from the pulleys.

found different version of pulleys from thingiverse and will be testing them.

Alwaystinkering

thingiverse

free

Tongs with Ribs by AlwaysTinkering

...re grab. the are a little wider to fit in the slots tightly.

get the ring here.https://www.thingiverse.com/thing:3129212/remixes

thingiverse

free

Air POT Planter Knob by AlwaysTinkering

...would likely be better with most printers for the details in the thread. printing screw with the cap down should work just fine.

thingiverse

free

Add Text to your Graduation Bowl Cap by AlwaysTinkering

...bowl here.https://www.thingiverse.com/thing:2954009

no spell check in the editor so double check what you wrote before you print.

thingiverse

free

Solar LED Bulb Base Replacement by AlwaysTinkering

...b sold under aiyego or viewpick names

outdoor / camping item you may want to use petg or some other heat / uv resistant material.

thingiverse

free

AIYEGO or Viewpick LED Bulb Replacement Base by AlwaysTinkering

... hot place or direct sunlight. it is snug but fits. i included the scad file if you want to play with changing the dimensions.

thingiverse

free

Fix US Weight Fillable Umbrella Base by AlwaysTinkering

...aller than the hole has a tendency to lean. the shim will keep it tight and straight so hopefully the wind does not pull it out.

thingiverse

free

Snap Ring to hold Spirograph Pieces together by AlwaysTinkering

... ring is larger than the smallest ring, but being a small part be careful to monitor it is not being put in a mount or chewed on.

thingiverse

free

Customizable locking rings by AlwaysTinkering

... export

slice your stl in your slicer and print

maybe customizer in thingiverse will work for you. it has never launched for me.

thingiverse

free

FiBo Desiccant Cages for the center well. by AlwaysTinkering

...you have your settings, generate a base and the generate a lid changing the variable at the top to select which part will render.

thingiverse

free

Illuminated Hummingbird Remix by AlwaysTinkering

...913680https://www.thingiverse.com/thing:3041589https://www.thingiverse.com/thing:2930668https://www.thingiverse.com/thing:3471293

Prosthetic

turbosquid

$49

Prosthetic Arm

...uid

royalty free 3d model prosthetic arm for download as max on turbosquid: 3d models for games, architecture, videos. (1556291)

turbosquid

$20

Prosthetic for small dogs 3D print model v2

...osthesis for small dogs 3d print model v2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1290474)

3d_export

$10

knee joint prosthesis with guides sample of individual prosthetics

...mm, 20 grams tibial component: ti6al4v material, 76×77×70 mm, 90 grams femoral component: cocrmo material, 70×52×62 mm, 290 grams

3d_export

$5

individual tmj prosthesis real operation

...left tmj. it consists of the following parts:: * prosthetic condylar process (ti6al4v); * joint cavity prosthesis (high molecular...

3d_export

$44

Hip Replacement

...damaged bone and cartilage is removed and replaced with prosthetic components. the damaged femoral head is removed and replaced...

3d_export

$10

itap implant osteointegration operation

...the implant. tested on more than 15 operations. itap prosthetic is an installation of "intraosseous transcutaneous amputation prosthesis". in...

thingiverse

free

Prosthetic arm

...prosthetic arm

thingiverse

prosthetics arm

3d printable

thingiverse

free

Prosthetic Arm

...prosthetic arm

thingiverse

a prosthetic arm purely for asthetic purposes. it was made for a client's wedding.

thingiverse

free

Dog Prosthetic by 3DESIGNER27

...animal allies. cheap alternative for dog prosthetic limb. scale in your slicer to fit the dog you are looking to apply prosthetic

thingiverse

free

XOR Prosthetic Hand by chandlersupple

...xor prosthetic hand by chandlersupple

thingiverse

prosthetic hand - two part

Ram

design_connected

$16

Rams

...rams

designconnected

paola lenti rams computer generated 3d model. designed by carrasco, victor.

design_connected

$11

Ram

...ram

designconnected

ligne roset ram computer generated 3d model. designed by kuehne-thompson, barbara.

3d_ocean

$5

ram

...s, chordates, mammals, bovina, ram, toy figurine, netsuke fully configured scene with camera and lighting material. v ray 2.40.04

3d_export

$10

ram sculpture

...ram sculpture

3dexport

ram sculpture

3d_export

$25

Ram

...ram

3dexport

3d_export

free

RAM module

...ram module

3dexport

a model of computer ram memory.

turbosquid

$20

Ram

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Ram

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$14

Ram

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$8

Ram

... you want. maya 2009 or latest is recommended because it is created in maya2009. you can open obj and fbx in old version of ma...

Pins

3d_export

$5

Pin

...pin

3dexport

very god pin

3d_ocean

$1

Bowling pins

...e inside of cinema 4d. there are 3 files included : pin.c4d : pins array.c4d : pin.obj pins array is the bowling pins set up i...

3d_ocean

$5

Pins

...v-ray studio render setting ready close-ups camera support polys: low: 6.314 high: 1.681.922 (with turbosmooth modifier) *incl...

turbosquid

$4

pin

...osquid

royalty free 3d model pin for download as 3dm and max on turbosquid: 3d models for games, architecture, videos. (1669685)

3d_ocean

$15

Map Pins

...map pins

3docean

factory kremlin map moscow oil oil-derrick pin pins red russia soviet soviet union star

some stylized map pins.

turbosquid

$9

Pins

...lty free 3d model pins for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1506195)

turbosquid

$7

Pin

...alty free 3d model pin for download as dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1609891)

turbosquid

$35

Pins

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Pin

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Pin

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Adapters

3d_export

$10

Adapter 3D Model

...adapter 3d model

3dexport

adapter

adapter 3d model mur 20260 3dexport

archive3d

free

Adapter socket 3D Model

...dapter socket adapter

adapter socket n090211 - 3d model (*.3ds) for interior 3d visualization.

turbosquid

$400

cell adaptation

...

royalty free 3d model cell adaptation for download as blend on turbosquid: 3d models for games, architecture, videos. (1701655)

archive3d

free

Adapter 3D Model

...ups pc equipment

adapter extron n180813 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$5

usb adapter

...royalty free 3d model usb adapter for download as ige and stl on turbosquid: 3d models for games, architecture, videos. (1582234)

turbosquid

$15

Power adapter

...free 3d model power adapter for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1510024)

turbosquid

$8

USB adapter

...e 3d model usb adapter for download as max, fbx, obj, and dwg on turbosquid: 3d models for games, architecture, videos. (1713542)

turbosquid

$30

adapter.3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Nokia Adapter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Universal adapter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Hand

3d_export

$8

hand

...hand

3dexport

fantasy hand

3d_export

$5

hand

...hand

3dexport

male hand

3d_export

$5

hand

...hand

3dexport

realistic male hand

3d_export

$5

hand

...hand

3dexport

hand with nails and structure

archibase_planet

free

Hand

...hand

archibase planet

hand

hand n190111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Hand

...hand

3ddd

hand

модель руки будды

3d_export

$5

hand

...hand

3dexport

it is my wrist of hand and this is on 3d sculpt

3d_export

$5

hand

...hand

3dexport

realistic male hand obj file

3d_export

$7

hand-006 rigged hand

...hand-006 rigged hand

3dexport

rigged right hand 3d model additional textures for pbr rendering included

3d_ocean

$6

Hand

...

this 3d models of the hands, made in 3ds max, has textures(.jpg), materials(.mat), rigged, the models in .max, fbx, obj format.

Updated

turbosquid

$5

orthographic room (updated)

...ee 3d model orthographic room (updated) for download as blend on turbosquid: 3d models for games, architecture, videos. (1375451)

turbosquid

$95

Romantic Bedroom - Updated

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Sofa. Updated release

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Procedurally updating cartoon crystal

...l procedurally updating cartoon crystal for download as blend on turbosquid: 3d models for games, architecture, videos. (1525853)

3d_export

$5

10 Surfboard s UPDATE

...10 surfboard s update

3dexport

3d_export

$10

chair updated rocking

...chair updated rocking

3dexport

armchair renewed plywood 18 mm. for cnc machines. layout in the stp archive.

turbosquid

free

Marble Table Updated

...el marble table for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1201300)

turbosquid

$35

Mauser 1930the model is updated with the kits

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$145

Contemporary Bedroom Collection Vol 1 - Updated

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$16

B&B Mart Armchair MPRN (Updated)

...art armchair mprn (updated) for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1284355)

Attach

turbosquid

$20

M4A1 + Attachements

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Attached House

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Attache case

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

cg_studio

$75

Attached House3d model

...d model

cgstudio

.3ds .fbx .max .obj - attached house 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

M416 AR with attachments

... model m416 ar with attachments for download as blend and fbx on turbosquid: 3d models for games, architecture, videos. (1614294)

turbosquid

$10

M16A2 with M203 Attachment

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

bench attached to greenery

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Modern 1911 with Attachments

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

Mercedes Sprinter sun visor attachment

...mercedes sprinter sun visor attachment

3dexport

mercedes sprinter sun visor attachment

turbosquid

$14

Residential building with attached shop

...l residential building with attached shop for download as max on turbosquid: 3d models for games, architecture, videos. (1482935)

Black

turbosquid

$25

Black Mamba black snake

...ck mamba black snake for download as blend, stl, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1672843)

turbosquid

$3

Black

...turbosquid

royalty free 3d model black for download as blend on turbosquid: 3d models for games, architecture, videos. (1278842)

3d_export

$5

Black Piano

...black piano

3dexport

black piano

3d_export

$5

Black Oven

...black oven

3dexport

black oven

3ddd

$1

Black curtain

...black curtain

3ddd

black curtain

3d_export

$5

Black coffe

...black coffe

3dexport

sweet black coffe

3d_export

$5

Black Sofa

...black sofa

3dexport

black velvet sofa

3d_export

$5

Black Chair

...black chair

3dexport

black velvet chair

3d_export

free

black desk

...black desk

3dexport

black desk for bedroom

3d_export

free

Black Chair

...black chair

3dexport

black velvet chair

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)