Thingiverse

Acrow prop Vive lighthouse mounting system by PhobosIndustries

by Thingiverse

Last crawled date: 3 years ago

This is a non destructive acrow prop based mounting system for the HTC Vice lighthouses. I wanted a method to quickly set up and take down the lighthouses without having to install fixings in different environments. My design is a remix of the great idea by cmooney91 (https://www.thingiverse.com/thing:1793515). I liked the wedge based quick change system, and wanted to incorporate it into my prop design.

The basic idea is that pressure is applied between the floor and ceiling to hold the fixture in place. The props use a telescopic design, where the excess of the upper stage is kept inside the lower stage. This allows for a use with various ceiling heights. The pipe is just standard PVC electrical conduit, 25mm and 20mm, each cut to a length of 1800mm.

The floor foot (25mm) has a 10mm thick rubber pad screwed to the bottom. The rubber is drilled and tapped to accept M3 machine screws from the top, so that only the rubber makes contact with the floor. Similarly the ceiling foot (20mm) has 10mm thick self adhesive polyethylene foam attached to it to prevent markings. This was picked up at the local hardware store. Each foot has horizontal holes to fit the conduit in place, and these are need to be tapped for M5. The conduit is inserted into each foot and fixed in place with M5 x 10mm machine screws. Anything will work pretty well here, even if you want to screw into the conduit to fix it. Additionally there are holes in the feet for cable ties in case that suits your setup better.

I have made some handles to accept M6 hex head bolts (30mm) so that installing and changing can be done without tools. Each prop uses 4 of these cranks. The design has a thin layer to support the hex slot, and this needs to be drilled out before the bolt can slide through. It was put there to eliminate the need for supports during printing. The inserts are made to fit snugly over the bolt, but I needed to clean up the edges of the hex holes so that they would fit easily.

Next the screwed adjuster needs to be assembled. The large nut has both left and right hand threads to match the 20mm and 25mm parts, so keep the arrow facing up towards the 20mm half. Thread these all the way to the centre. The 20mm side needs to be tapped to accept the M6 bolts with handles, and the 25mm side to accept M5 x 10mm screws. Slide the 25mm conduit into place and tighten. Before inserting the 20mm conduit we need to slide on the lighthouse mount.

The lighthouse mount is held in place with more of the M6 hand cranks, so those holes need to be tapped to M6 as well. Slide the bracket onto the 20mm conduit and then place the whole length into the screwed adjuster. The 20mm conduit fits nicely inside the 25mm.

Now the whole strut can be roughly installed where you need it, tightening the hand cranks to get the 20mm side locked in position. Finally the extra pressure can be applied by turning the centre nut. The holes in the nut are ready for more M6 screws if you need to fix it in place, but haven't needed to do this. I did notice that the more pressure you apply, the bendier the conduits became. It doesn't seem to need much tension to hold it tightly in place though.

The lighthouse puck needs to be fixed to the back of the Vive lighthouse bracket, and for this I have included two versions. The hex model can accept an M5 nyloc nut, the round model fits an M5 socket cap machine screw. I have made the puck a bit deeper compared to the original so the nut or socket cap screw could fit without fouling. This also makes it incompatible with the original design by cmooney91. I used a pair of M5 x 10mm socket cap machine screws.

Finally slide the lighthouse puck and lighthouse into the slot and you're good to go.

I printed this on a Prusa i3 MK2S in white eSun PETG, 0.2mm layer height, 3 walls, 5% infill and no support.

The parts I used per prop:

M3 x 10mm button head machine screw (x4)

M5 x 10mm button head machine screw (x6)

M5 x 10mm socket cap machine screw (x2)

M5 nyloc nut (x2)

M5 washer (x2)

M6 x 30mm hex head bolt (x4)

20mm electrical PVC conduit (1x 4m length)

25mm electrical PVC conduit (1x 4m length)

10mm x 75mm x 75mm polyethylene strip (self adhesive)

10mm x 75mm x 75mm rubber sheet

I have included the source file from Fusion 360 in case anybody wants to change dimensions to suit the materials available to them. If you do make changes I would encourage you to share your design to help others as well.

The basic idea is that pressure is applied between the floor and ceiling to hold the fixture in place. The props use a telescopic design, where the excess of the upper stage is kept inside the lower stage. This allows for a use with various ceiling heights. The pipe is just standard PVC electrical conduit, 25mm and 20mm, each cut to a length of 1800mm.

The floor foot (25mm) has a 10mm thick rubber pad screwed to the bottom. The rubber is drilled and tapped to accept M3 machine screws from the top, so that only the rubber makes contact with the floor. Similarly the ceiling foot (20mm) has 10mm thick self adhesive polyethylene foam attached to it to prevent markings. This was picked up at the local hardware store. Each foot has horizontal holes to fit the conduit in place, and these are need to be tapped for M5. The conduit is inserted into each foot and fixed in place with M5 x 10mm machine screws. Anything will work pretty well here, even if you want to screw into the conduit to fix it. Additionally there are holes in the feet for cable ties in case that suits your setup better.

I have made some handles to accept M6 hex head bolts (30mm) so that installing and changing can be done without tools. Each prop uses 4 of these cranks. The design has a thin layer to support the hex slot, and this needs to be drilled out before the bolt can slide through. It was put there to eliminate the need for supports during printing. The inserts are made to fit snugly over the bolt, but I needed to clean up the edges of the hex holes so that they would fit easily.

Next the screwed adjuster needs to be assembled. The large nut has both left and right hand threads to match the 20mm and 25mm parts, so keep the arrow facing up towards the 20mm half. Thread these all the way to the centre. The 20mm side needs to be tapped to accept the M6 bolts with handles, and the 25mm side to accept M5 x 10mm screws. Slide the 25mm conduit into place and tighten. Before inserting the 20mm conduit we need to slide on the lighthouse mount.

The lighthouse mount is held in place with more of the M6 hand cranks, so those holes need to be tapped to M6 as well. Slide the bracket onto the 20mm conduit and then place the whole length into the screwed adjuster. The 20mm conduit fits nicely inside the 25mm.

Now the whole strut can be roughly installed where you need it, tightening the hand cranks to get the 20mm side locked in position. Finally the extra pressure can be applied by turning the centre nut. The holes in the nut are ready for more M6 screws if you need to fix it in place, but haven't needed to do this. I did notice that the more pressure you apply, the bendier the conduits became. It doesn't seem to need much tension to hold it tightly in place though.

The lighthouse puck needs to be fixed to the back of the Vive lighthouse bracket, and for this I have included two versions. The hex model can accept an M5 nyloc nut, the round model fits an M5 socket cap machine screw. I have made the puck a bit deeper compared to the original so the nut or socket cap screw could fit without fouling. This also makes it incompatible with the original design by cmooney91. I used a pair of M5 x 10mm socket cap machine screws.

Finally slide the lighthouse puck and lighthouse into the slot and you're good to go.

I printed this on a Prusa i3 MK2S in white eSun PETG, 0.2mm layer height, 3 walls, 5% infill and no support.

The parts I used per prop:

M3 x 10mm button head machine screw (x4)

M5 x 10mm button head machine screw (x6)

M5 x 10mm socket cap machine screw (x2)

M5 nyloc nut (x2)

M5 washer (x2)

M6 x 30mm hex head bolt (x4)

20mm electrical PVC conduit (1x 4m length)

25mm electrical PVC conduit (1x 4m length)

10mm x 75mm x 75mm polyethylene strip (self adhesive)

10mm x 75mm x 75mm rubber sheet

I have included the source file from Fusion 360 in case anybody wants to change dimensions to suit the materials available to them. If you do make changes I would encourage you to share your design to help others as well.

Similar models

thingiverse

free

Conduit Pipe Camera Tripod (Extendable)

...time.

please feel free to record yourself doing these steps to help improve this guide.

you can contact me on 1997corry@gmail.com

cg_trader

$3

Screws with nuts

...h nuts m5, m6, m8, m10 screw nuts tool bolt nut thread wrench screwdriver hole fixing twine industrial machine industrial machine

thingiverse

free

Open OX CNC Dual Belt Clamp for Y-axis by OBC

... 15mm low profile hex bolts

2 - m5 x 25mm hex bolts

2- m5 lock nuts

note: you must tap the extrusion to fit this to your machine.

thingiverse

free

GoPro 25mm Conduit Pole Mount by paulwilliamss

...o suit gopro hand screw. can be glued but preferably bolted to the conduit. m5 nut required or gopro nut. quite strong. enjoy! :)

thingiverse

free

Sony FS5 Grip Relocator by AltoScroll

...s on printer accuracy)

a lanc extension cable. smallrig makes one that works great.

gently tap the bolts in place with a hammer.

thingiverse

free

Griffschraube handle screw for M6 Mutter nut

...ndle screw for m6 mutter nut

thingiverse

hand screw for m6 (10x10mm) nut/bolt

what you need is a m6 nut or m6 a hex bolt 10x10mm

grabcad

free

M5 Hex Bolts 0.8mm Thread 20-40mm

...m5 hex bolts 0.8mm thread 20-40mm

grabcad

m5 x 20mm

m5 x 25mm

m5 x 30mm

m5 x 35mm

m5 x 40mm

thingiverse

free

M6 bolt knob by thingivinz

...m6 bolt knob by thingivinz

thingiverse

knob for m6 bolt or nuts.

scaled the original from b_emme3d up to fit 10mm hex.

thingiverse

free

Tap-O-Mat - M3/M4/M5/M6 Thread Cutter/Tap to Drill-Bit Adapter by mariust

... or petg.

screws i used:

2x m5x16 with a hex-head

2x m5 wing nuts

optional but recommended to fix the clamps:

2x m3x8 countersunk

thingiverse

free

Gearbox Hanger for 20mm Extrusions

...o the gearbox before assembling to the extrusion. if done in the opposite order, it will be impossible to place the top m6 screw.

Acrow

grabcad

free

BT30 spindle inside contour.

...contour. grabcad bt30 spindle inside contour using data from acrow manufacturer of petal clamps. there are a few dimensions...

3dwarehouse

free

Andamio Acrow

...andamio acrow

3dwarehouse

vista andamio fachada con acrow

3dwarehouse

free

Simple Acrow Prop

...el of an acrow prop without collar and pin details. feel free to edit and add details! #acrow #building #construction #prop #site

3dwarehouse

free

Panel Acrow

...panel acrow

3dwarehouse

encofrado #panel #saul

3dwarehouse

free

puntal acrow 700XS

...puntal acrow 700xs

3dwarehouse

tornapunta o puntal

3dwarehouse

free

diagonal vertical de acrow 700XS

...diagonal vertical de acrow 700xs

3dwarehouse

diagonal vertical éstándar

3dwarehouse

free

Unidad de piso epoxica

...unidad de piso epoxica 3dwarehouse piso de acrow panel...

3dwarehouse

free

Formwork for Retaining Walls

...formwork for retaining walls 3dwarehouse formwork for retaining walls. #acrow #concrete_retaining_walls #formwork #majid36livecouk...

3dwarehouse

free

Construction of Retaining Wall

...construction of retaining wall 3dwarehouse construction of retaining wall. #acrow #concrete_walls #formwork #majidmaclcouk #reinforcement #retaining_walls...

Vive

turbosquid

$40

HTC vive headset

...model htc vive headset for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1174451)

turbosquid

$19

HTC Vive Lighthouse

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Natuzzi Re-Vive

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$69

HTC Vive VR headset

... 3d model htc vive for download as ma, max, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1242503)

turbosquid

$23

E3D -HTC Vive Tracker

...model e3d -htc vive tracker for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1190728)

turbosquid

$14

HTC Vive Joystick Rose

...htc vive joystick rose for download as max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1520802)

turbosquid

$14

HTC Vive Joystick Blue

...htc vive joystick blue for download as max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1520789)

turbosquid

$24

Loreal Elseve Shampoo Color Vive 400ml

...el loreal elseve shampoo color vive 400ml for download as max on turbosquid: 3d models for games, architecture, videos. (1400713)

3d_export

$15

VR HTC VIVE COSMOS GEAR REPAIR

... vive cosmos gear repair mechanical element for restoring the helmet mount stl format: rar archive print nylon or abs layer 0,1mm

3ddd

$1

плитка Vives - Special Pieces Titan

...литки.

ссылка на производителя:http://www.vivesceramica.com/en/products/floor-tiles/porcelain-clay/serie.html?sid=521

Lighthouse

3d_export

free

lighthouse

...lighthouse

3dexport

lighthouse

3d_export

$5

Lighthouse

...lighthouse

3dexport

image of an island with a lighthouse.

3d_export

$5

lighthouse

...lighthouse

3dexport

low poly lighthouse tower.

3d_export

free

lighthouse

...lighthouse

3dexport

building lighthouse for your project<br>4k texture

design_connected

$11

Lighthouse

...lighthouse

designconnected

established & sons lighthouse computer generated 3d model. designed by bouroullec, erwan.

3d_export

free

lighthouse on the islands

...lighthouse on the islands

3dexport

lighthouse on the islands

turbosquid

$34

Lighthouse

...bosquid

royalty free 3d model lighthouse for download as max on turbosquid: 3d models for games, architecture, videos. (1188357)

turbosquid

free

Lighthouse

...bosquid

royalty free 3d model lighthouse for download as upk on turbosquid: 3d models for games, architecture, videos. (1194918)

turbosquid

$5

Lighthouse

...oyalty free 3d model lighthouse for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1604302)

turbosquid

$5

lighthouse

...

royalty free 3d model lighthouse for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1683838)

Prop

3ddd

$1

Props

...props

3ddd

props

3d_ocean

$10

Props

...ject you need this props design this 6 taype for props to get your design perfect and nice file include : 1 max 2 obj 3 3ds 4 zip

turbosquid

$15

Props

...s

turbosquid

royalty free 3d model props for download as max on turbosquid: 3d models for games, architecture, videos. (1249032)

turbosquid

$1

PROPS

...d model props for download as unitypackage, obj, fbx, and tga on turbosquid: 3d models for games, architecture, videos. (1627660)

turbosquid

$5

props

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

PROP

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

kids props

...kids props

3ddd

декоративный набор

kids props

3d_ocean

$8

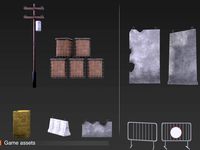

Street props

...l barrier prop roads street street prop

street props game models barrel barrier roads aircos jerrycan models fbx obj and max file

turbosquid

$39

Apocalyptic Props

...uid

royalty free 3d model apocalyptic props for download as on turbosquid: 3d models for games, architecture, videos. (1380028)

turbosquid

$1

Bunker props

...rbosquid

royalty free 3d model bunker props for download as on turbosquid: 3d models for games, architecture, videos. (1196014)

System

archibase_planet

free

System

...m

archibase planet

fire alarm system fire alarm box

security light system - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spider system

...stem spider glass system

spider system to fix glass stefano galli n050912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Euforia System

...euforia system

3ddd

euforia

euforia system

3d_export

$50

Roof system Truss system 3D Model

...oof system truss system 3d model

3dexport

roof system truss truss stage

roof system truss system 3d model aleksbel 38970 3dexport

3ddd

$1

DVD System

...dvd system

3ddd

dvd , schneider

dvd system

design_connected

free

Seating system

...seating system

designconnected

free 3d model of seating system

3d_export

$5

solar system

...solar system

3dexport

solar system in c4d, with 8k nasa textures

3ddd

$1

Quanta System

...quanta system

3ddd

медицина

quanta system.

лазерное оборудование для медицинских центров

3d_export

$15

solar system

...nd the other the sun, the earth and the moon, the latter has an animation with camera movement included, the files are in spanish

3d_export

$14

missile system

...missile system

3dexport

Mounting

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)