Thingiverse

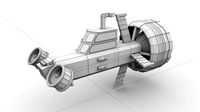

A cylinder for magazine for Air Arms S200 or CZ 200 air rifle

by Thingiverse

Last crawled date: 4 years, 2 months ago

A cylinder for magazine for Air Arms S200 air rifle, which also fits CZ 200.

The plastic version of cylinder is much better because with the stock aluminium cylinder you will wear out the plastic body of magazine much faster.

The cylinder consists of two parts which can be fixed by screw and nut, so you don't need to glue both parts. You'll need the M2.5 x 10mm flat head screw and M2.5 nut.

I used the O-ring 13 x 3mm which is different from the original one (12 x 3.5mm). They have the same outer diameter (19mm) but smaller ring height (difference is 0.5) make the ring be more softer and it reduces the pressure amount you need to apply to move the push rod. The bullets stay in their position just as well as before. I tested on different sizes and shapes, all went well.

Also mine cylinder is a little bit bigger in diameter than the original one I have because it sits better in the magazine. I'm talking about 30.25mm diameter instead of 29.66mm. Don't worry, it works fine even in cold weather, I tested it at -20 Celsius.

I tried to print with 0.4 nozzle and 0.2mm layer and the quality was the same, I mean I haven't noticed the difference in how the pellets went from the cylinder into the barrel.

Instead I would recommend to decrease the printing speed to get better quality. I printed at 15mm/second.

Some note about the screw:

Ideally we need the 9mm length but there is no such screw on a market. We have 8mm or 10mm. 10 works fine, don't worry, it fits, but if you want perfect look you might want to sandpaper it to 9.5mm which is quite enough.

If your printer prints with bigger size or smaller, there is a chance you can resize the model in slicer in X/Y plane by 0.5-1% without touching the Z axis.

If you need to make better holes for pellets then use the 5.2mm drill.

More photos and video: https://photos.app.goo.gl/YT6UbgmzyWhWtEg18

Link to the design: https://a360.co/2pm8wAf

Update: I've added a version which has 3 locking pins instead of 2.

Update (4 Dec 2019): I've added "v3" version after I changed the o-ring on the push rod (it has 3 x 1mm size) and found out that I can't longer go through the pellet channels with the new o-ring. I happened because my old ro-ing was slightly smaller due to it's age (almost 7 years), and the new one appeared bigger. I tried to make the channels diameter bigger (+0.2mm), but it appeared that the surface of the channels must be very smooth (the FFF printer can't get on this level). I decided to take a 5.3mm drill bit and drill the channels to this diameter. The surface became smoother and roughly equals to original channel diameter. To be precise with original you need to find 5.26mm drill bit. Also I had to use the original O-ring (12 x 3.5mm) because with more space my 13 x 3mm ring can't hold the pellet steady anymore. Also it's a good idea to lubricate the channels with some grease. Also, you can make the channel ever bigger in diameter (5.4mm) to avoid grease and polishing the channel surface, but it adds more space and pellet might go out from the channel.

Also this version was re-designed to make the channels "solid".

The plastic version of cylinder is much better because with the stock aluminium cylinder you will wear out the plastic body of magazine much faster.

The cylinder consists of two parts which can be fixed by screw and nut, so you don't need to glue both parts. You'll need the M2.5 x 10mm flat head screw and M2.5 nut.

I used the O-ring 13 x 3mm which is different from the original one (12 x 3.5mm). They have the same outer diameter (19mm) but smaller ring height (difference is 0.5) make the ring be more softer and it reduces the pressure amount you need to apply to move the push rod. The bullets stay in their position just as well as before. I tested on different sizes and shapes, all went well.

Also mine cylinder is a little bit bigger in diameter than the original one I have because it sits better in the magazine. I'm talking about 30.25mm diameter instead of 29.66mm. Don't worry, it works fine even in cold weather, I tested it at -20 Celsius.

I tried to print with 0.4 nozzle and 0.2mm layer and the quality was the same, I mean I haven't noticed the difference in how the pellets went from the cylinder into the barrel.

Instead I would recommend to decrease the printing speed to get better quality. I printed at 15mm/second.

Some note about the screw:

Ideally we need the 9mm length but there is no such screw on a market. We have 8mm or 10mm. 10 works fine, don't worry, it fits, but if you want perfect look you might want to sandpaper it to 9.5mm which is quite enough.

If your printer prints with bigger size or smaller, there is a chance you can resize the model in slicer in X/Y plane by 0.5-1% without touching the Z axis.

If you need to make better holes for pellets then use the 5.2mm drill.

More photos and video: https://photos.app.goo.gl/YT6UbgmzyWhWtEg18

Link to the design: https://a360.co/2pm8wAf

Update: I've added a version which has 3 locking pins instead of 2.

Update (4 Dec 2019): I've added "v3" version after I changed the o-ring on the push rod (it has 3 x 1mm size) and found out that I can't longer go through the pellet channels with the new o-ring. I happened because my old ro-ing was slightly smaller due to it's age (almost 7 years), and the new one appeared bigger. I tried to make the channels diameter bigger (+0.2mm), but it appeared that the surface of the channels must be very smooth (the FFF printer can't get on this level). I decided to take a 5.3mm drill bit and drill the channels to this diameter. The surface became smoother and roughly equals to original channel diameter. To be precise with original you need to find 5.26mm drill bit. Also I had to use the original O-ring (12 x 3.5mm) because with more space my 13 x 3mm ring can't hold the pellet steady anymore. Also it's a good idea to lubricate the channels with some grease. Also, you can make the channel ever bigger in diameter (5.4mm) to avoid grease and polishing the channel surface, but it adds more space and pellet might go out from the channel.

Also this version was re-designed to make the channels "solid".

Similar models

thingiverse

free

Air Arms S200 .177 Magazine V2 by Hadgee

...ss with the new magazine working and cycling after minimal clean up.

it is safe to print and will work, it also cleans up easier.

thingiverse

free

Generic Cylinder Generator by amthe

...e

you can make cylinders here. it's honest work.

this was made because i needed a cylinder for the open air purifier project

thingiverse

free

Air Arms S200 .177 Magazine by Hadgee

... here. to be honest check out my v2 external 'o' ring magazine it is better design for cleaning supports and works great.

thingiverse

free

Drill chuck key holder by winand

...e screw to let the key click in its place. work beautifully!

i also made a universal version you could mount virtually anywhere

thingiverse

free

Spare part of Pot lid holder by Milhause

...ead down.

resolution 0,2

infill 20%

diameter hole is 9mm,

if you need a larger diameter, use a drill if you need wiader drill it.

grabcad

free

Transfer port for Weihrauch HW45 air gun

...ith a 3.5mm hole, an one with original 3mm if someone doesn't want to drill in the air cylinder, that hole is 3mm and angled.

thingiverse

free

Pellet Gun Suppressor by Teubert1162

...r barrel. may need to run a drill bit through it to make sure there's enough clearance for the pellet. customize as you wish.

thingiverse

free

Customizable cylinder by painteddigital

... also use openscad to customize the file.

about openscad

free modeler that runs a script to generate stlshttp://www.openscad.org/

grabcad

free

Pellet_Press_kit

...pellet_press_kit

grabcad

a simple pellet press kit for making 25mm diameter cylinder pellets.

cg_trader

$25

MAGAZINE 12 | 3D

...i, magazine 12 round for airgun marauder chamber, dimension of pellet in diameter 5,5 mm. now you can make it diy by 3d printing.

S200

turbosquid

$20

ACER NEOTOUCH S200

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Synesso S200 Espresso Machine

...del synesso s200 espresso machine for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1456543)

humster3d

$75

3D model of Toyota Crown Royal Saloon (S200) 2010

...of toyota crown royal saloon (s200) 2010 in various file formats. all our 3d models were created maximally close to the original.

3d_ocean

$89

Toyota Crown Royal Saloon (S200) 2010

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

3d_export

$99

Toyota Crown Royal Saloon S200 2010 3D Model

... wheel base 2002 2012 2013 2014 minivan van mpv us american

toyota crown royal saloon s200 2010 3d model humster3d 63717 3dexport

3ddd

free

Люстра MAYTONI SPIKE

...maytoni spike 3ddd maytoni хрустальная потолочная люстра maytoni spike (s200pt60-n). материал основания: металл материал плафона: хрусталь размеры (высота), мм:...

3dfindit

free

S55720-S200

...s55720-s200

3dfind.it

catalog: siemens building technologies eu

thingiverse

free

JVC HA-S200 Speaker ring by nakwada

...jvc ha-s200 speaker ring by nakwada

thingiverse

a replacement part for the jvc ha-s200 heaphones

thingiverse

free

Air Arms S200 .22 Magazine by Hadgee

...air arms s200 .22 magazine by hadgee

thingiverse

same as air arms .177 magazine v2 but in .22.

thingiverse

free

NAD S200 Hi-Fi Amplifier Main Power Button Replacement by Non-ICE

...0 hi-fi amplifier main power button replacement by non-ice

thingiverse

replacement powerbutton for the nad s200 hi-fi amplifier.

Cz

turbosquid

$148

CZ-11

...1

turbosquid

royalty free 3d model cz-11 for download as max on turbosquid: 3d models for games, architecture, videos. (1662373)

turbosquid

$30

Cz 75

...squid

royalty free 3d model cz 75 for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1193409)

turbosquid

$4

CZ-550

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

CZ 75B

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

CZ Pistol

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

CZ 75

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

cz upgrade

...cz upgrade

3dexport

https://www.buymeacoffee.com/mestrezen3d https://linktr.ee/mestrezen3

3d_export

$5

CZ 100 3D Model

...cz 100 3d model

3dexport

cz 100 3d model term!x 993 3dexport

3d_export

$59

CZ 75 3D Model

...rt

75 automatic bullet cz czech czub gun pistol semi semi-automatic weapon semi-automatic

cz 75 3d model humster3d 90621 3dexport

cg_studio

$20

CZ 40B3d model

... gun pistol handgun game ready gameready

.max - cz 40b 3d model, royalty free license available, instant download after purchase.

Magazine

archibase_planet

free

Magazines

...ibase planet

magazine journal periodical magazines

magazines dual n200111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Magazines

...magazines

archibase planet

magazine periodical journal

magazines - 3d model for interior 3d visualization.

3d_ocean

$5

3d magazine

...3d magazine

3docean

3d magazine book journal magazine newspaper

3d magazine model.

turbosquid

$2

magazines

...rbosquid

royalty free 3d model magazines for download as c4d on turbosquid: 3d models for games, architecture, videos. (1264164)

3d_export

$5

Magazine stand

...magazine stand

3dexport

magazine stand

3d_export

$5

magazine stand

...magazine stand

3dexport

magazine stand

3ddd

$1

Stool Magazine

...stool magazine

3ddd

stool magazine дизайнерское кресло

turbosquid

$10

magazine

...3d model magazine for download as max, max, max, fbx, and max on turbosquid: 3d models for games, architecture, videos. (1691943)

turbosquid

$2

Magazine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Magazines 3D Model

...magazine periodical journal

magazines n160212 - 3d model (*.3ds) for interior 3d visualization.

Rifle

3d_ocean

$9

rifle

...rifle

3docean

gun low poly rifle soldier weapon

rifle model max 2013 and obj 1024×1024 texture lowpoly

turbosquid

$30

Rifle

...le

turbosquid

royalty free 3d model rifle for download as ma on turbosquid: 3d models for games, architecture, videos. (1161496)

turbosquid

$1

rifle

...turbosquid

royalty free 3d model rifle for download as blend on turbosquid: 3d models for games, architecture, videos. (1344661)

3d_export

$5

longfire rifle

...longfire rifle

3dexport

longfire rifle

3d_export

free

butt of the rifle

...butt of the rifle

3dexport

butt of the rifle

3d_export

free

repeater rifle

...repeater rifle

3dexport

repeater rifle

3d_export

$15

Rifle v2

...rifle v2

3dexport

assault rifle, designed for the protection and storming of objects. the rifle has a paralytic function.

turbosquid

$20

Rifle

...quid

royalty free 3d model rifle for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1301083)

3d_export

$5

rifle sks

...rifle sks

3dexport

rifle sks simonov

turbosquid

$49

Rifle

...

royalty free 3d model rifle for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1582428)

Cylinder

turbosquid

$1

Piston - Cylinder Cylinder Engine

...nder cylinder engine for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1235278)

3ddd

$1

sofa cylinder

...sofa cylinder

3ddd

круглый

sofa cylinder

turbosquid

$1

Cylinder Head - Single Cylinder Engine

...ngle cylinder engine for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1222618)

turbosquid

$16

Cylinder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Cylinder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$120

Four cylinder

...four cylinder

3dexport

four cylinder render 3d modelling

3d_export

$5

piston cylinder

...piston cylinder

3dexport

piston cylinder arrangement sketched in solidworks

3ddd

$1

Cylinder Lamp A

...cylinder lamp a

3ddd

cylinder form lamp for loft interior

archive3d

free

Cylinder 3D Model

... model

archive3d

cylinder drum

cylinder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Cylinder 3D Model

...odel

archive3d

drum cylinder

cylinder 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

200

design_connected

$27

Lifewood 200

...lifewood 200

designconnected

flexform lifewood 200 computer generated 3d model.

design_connected

$27

Nonnamaria 200

...nonnamaria 200

designconnected

flexform nonnamaria 200 computer generated 3d model.

design_connected

free

XZ3 200

...xz3 200

designconnected

free 3d model of xz3 200 by magis designed by van onck, andries & hiroko.

3d_export

$17

Boeing 717-200

...boeing 717-200

3dexport

boeing 717-200

3ddd

free

Possoni /200 / 25

...possoni /200 / 25

3ddd

possoni

possoni/200/25

turbosquid

$10

Set-200

...yalty free 3d model set-200 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1296305)

3ddd

$1

LG TS-200

...lg ts-200

3ddd

dvd , lg , пульт

lg ts-200

turbosquid

$5

Chair 200

...d model chair 200 for download as max, max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1647835)

turbosquid

$5

Chair 200

...d model chair 200 for download as max, max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1648696)

turbosquid

$3

200 Euro

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Arms

archibase_planet

free

Arm

...ase planet

arm hand right hand skeleton

arm human skeleton right arm n030515 - 3d model (*.gsm+*.3ds+*.max) for 3d visualization.

3ddd

$1

arm chair

...arm chair

3ddd

arm chair , пуф

arm chair

turbosquid

$5

arm

...arm

turbosquid

royalty free 3d model arm for download as obj on turbosquid: 3d models for games, architecture, videos. (1306158)

turbosquid

free

Arm

...arm

turbosquid

free 3d model arm for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1346955)

turbosquid

$29

Arm

...osquid

royalty free 3d model arm for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1382436)

3d_export

$5

coat of arms

...coat of arms

3dexport

coat of arms

3ddd

$1

ARM SOFA

...arm sofa

3ddd

arm sofa

3ddd

$1

Arm chair

...arm chair

3ddd

arm chair

3ddd

$1

Arm chair

...arm chair

3ddd

угловое

arm chair

3ddd

$1

ARM CHAIR

...arm chair

3ddd

arm chair clothes

Air

3ddd

$1

Calligaris air

...calligaris air

3ddd

air , calligaris

cтул calligaris air

3ddd

$1

Air freshener

...air freshener

3ddd

air freshener , освежитель

air freshener

design_connected

$16

Air

...air

designconnected

flexform air lounge chairs computer generated 3d model. designed by antonio citterio.

turbosquid

$250

Heat pump air air

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

air

...air

3dexport

3ddd

$1

Кухня AIR

...кухня air

3ddd

air , мария

кухня air фабрики "мария"

3ddd

$1

Лампа AIR

...лампа air

3ddd

boconcept , air

настольная лампа air, boconcept. в50½xø32см

3d_export

$40

air deflector

...air deflector

3dexport

air deflector

3d_export

$15

air purifier

...air purifier

3dexport

air purifier

3d_export

$5

macbook air

...macbook air

3dexport

macbook air