Thingiverse

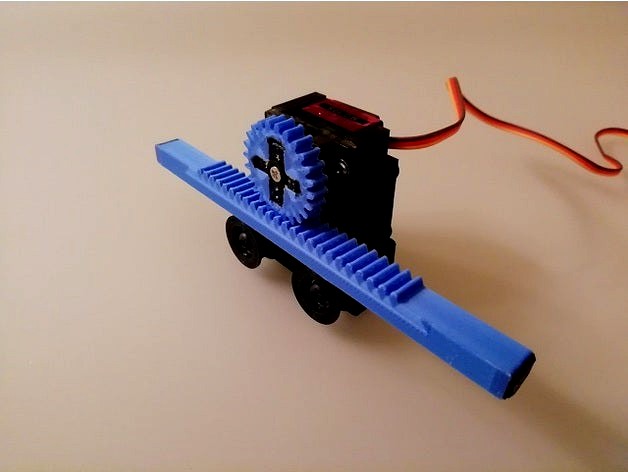

9g Servo Linear Actuator (Ball Bearing) by N7_Cat

by Thingiverse

Last crawled date: 3 years, 3 months ago

Prints as one part, some trimming of the raft will be needed but I've added clearances around the gears to reduce trimming needed there.

The intent of this is to create a relatively low cost / low backlash linear actuator using the common and cheap 9g mini servos. I've included rear and bottom 3 mm x 10 mm screw holes so you can integrate this with your projects. BOM is included in the image, I'll add more details in post once I finish printing. I bought my servos and carbon fiber tube at https://uangel.aliexpress.com/store/603538 but I think most 9G servos are the same basic dimensions so it should fit others.

I've also included a solid version of the rack in case you don't want to bother with the tube reinforced version.

Quick notes (detailed instructions to follow):

Gear modulus is 1, pitch diameter of 24 mm, 180 degrees of servo rotation should result in 37.7 mm of linear travel

The 6mm carbon fiber rod is inserted into the rack then capped off

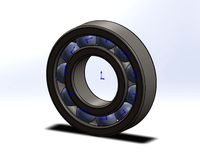

Bearing sleeves are snapped over the bearings

Servo: 9g servo https://www.aliexpress.com/item/33005962141.html

Reinforcement: 6 mm OD 4 mm ID Carbon Fiber Rods https://www.aliexpress.com/item/32310771446.html

Embedded nuts must not be over inserted, they form part of the standoff for the bearing inner race. I can no longer find the M3 X 5.3 X 6 that I used, (old link no longer works - possible substitution M3 X D5 X L6) https://www.aliexpress.com/item/4000232858343.html

The Pinion must be glued to a clipped servo arm (I did this because the servo arms that come with the servos will have better retention against the servo drive gear - trying to friction fit a 3d printed part against a small modulus gear might work but I think this way is better)

Updated 9/7/2020, minor improvement - reduced amount of raft trimming needed by clearing openings for bearings and screws

Updated 9/16/2020, Realized after printing that I forgot to create wiring cutout :P, removed some of the raft trimming needed for bearing sleeves and rack. Added a cylinder for helping with pressing bearing into sleeve. Saved the solid rack as a print package option instead of a separate part. Added a 220mm rack for those using 360 enabled servos that can be cut to size (for this length carbon tube reinforcement is necessary imo)

The intent of this is to create a relatively low cost / low backlash linear actuator using the common and cheap 9g mini servos. I've included rear and bottom 3 mm x 10 mm screw holes so you can integrate this with your projects. BOM is included in the image, I'll add more details in post once I finish printing. I bought my servos and carbon fiber tube at https://uangel.aliexpress.com/store/603538 but I think most 9G servos are the same basic dimensions so it should fit others.

I've also included a solid version of the rack in case you don't want to bother with the tube reinforced version.

Quick notes (detailed instructions to follow):

Gear modulus is 1, pitch diameter of 24 mm, 180 degrees of servo rotation should result in 37.7 mm of linear travel

The 6mm carbon fiber rod is inserted into the rack then capped off

Bearing sleeves are snapped over the bearings

Servo: 9g servo https://www.aliexpress.com/item/33005962141.html

Reinforcement: 6 mm OD 4 mm ID Carbon Fiber Rods https://www.aliexpress.com/item/32310771446.html

Embedded nuts must not be over inserted, they form part of the standoff for the bearing inner race. I can no longer find the M3 X 5.3 X 6 that I used, (old link no longer works - possible substitution M3 X D5 X L6) https://www.aliexpress.com/item/4000232858343.html

The Pinion must be glued to a clipped servo arm (I did this because the servo arms that come with the servos will have better retention against the servo drive gear - trying to friction fit a 3d printed part against a small modulus gear might work but I think this way is better)

Updated 9/7/2020, minor improvement - reduced amount of raft trimming needed by clearing openings for bearings and screws

Updated 9/16/2020, Realized after printing that I forgot to create wiring cutout :P, removed some of the raft trimming needed for bearing sleeves and rack. Added a cylinder for helping with pressing bearing into sleeve. Saved the solid rack as a print package option instead of a separate part. Added a 220mm rack for those using 360 enabled servos that can be cut to size (for this length carbon tube reinforcement is necessary imo)

Similar models

grabcad

free

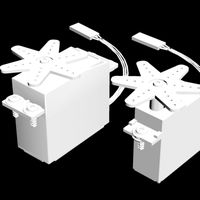

dual linear servo actuator

...linear servo actuator

grabcad

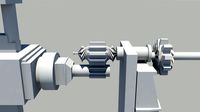

freecad files for linear servo gear and rack driven by 9g. used to animate a life cast hand/wrist

cults

free

Multi-body Carbon Fiber Reinforced Gear

...multi-body carbon fiber reinforced gear

cults

multi-body carbon fiber reinforced gear

multi-body carbon fiber reinforced gear

thingiverse

free

Tunnelplan carbon support by tunnelplan

...free-shiping-4pcs-x-10mm-x-6mm-x-1000mm-high-quality-3k-carbon-fiber-plain-fabric/32348177924.html?spm=a2g0s.9042311.0.0.gapjom )

thingiverse

free

Servo Linear Actuator (9g) + adjustable backlash Version by Geekmakes

...l that should also work for most 9g servos. (borrowed the gear ratio as well in the new design)

servos:http://tinyurl.com/htv7pnn

thingiverse

free

SCS8UU Bushing Block by salfter

.../3d-printer-bushing-1-pcs-8mm-11-mm-30-mm-8-mm-copper-bush-graphite-sleeve/32476367665.html) in place of an lm8uu linear bearing.

thingiverse

free

Elegoo Mars air filter

... x gb819 m2.5x8 mm screws (https://www.aliexpress.com/item/32404902201.html)

4 x thin double side adhesive tapes (50x5 mm aprox.)

thingiverse

free

MG995 Servo linear actuator by sbabber

...mount, which i reccomend highly.

i hope this helps anyone. i made this for a syringe pump, which works great with this addition!

thingiverse

free

Dual Y rod holder for linear bearings by 3RC4N

.../item/optical-axis-300-320-330-350-390-400-500-mm-smooth-rods-8mm-linear-shaft-rail/32816641684.html?spm=a2g0s.9042311.0.0.9gisw2

thingiverse

free

Rack and Pinion Linear Actuator for Micro Servo

...n super glued to the servo horn. i also clipped the servo horn to make it shorter.

full build video: https://youtu.be/kujzazrud4e

thingiverse

free

Multi-body Carbon Fiber Reinforced Gear by MosaicManufacturing

...printed with carbon fiber infused filament to give the gear more strength!

printed with palette (http://mosaicmanufacturing.com).

N7

turbosquid

$10

N7 Pistol

...rbosquid

royalty free 3d model n7 pistol for download as fbx on turbosquid: 3d models for games, architecture, videos. (1472924)

3ddd

$1

Стол N7 от Casamania

...стол n7 от casamania

3ddd

casamania

футуристичный стол n7 от casamania

evermotion

$8

CASAMANIA N7 AM72

...nia design with all textures, shaders and materials. it is ready to use, just put it into your scene.. evermotion 3d models shop.

turbosquid

$70

Spaceship N7-1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$60

Spaceship N7-3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

Spaceship N7-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

Clothes n7

...tures are in png format and they are available in these dimensions:<br>dimensions of the 3d model: 0.402m x 0.324m x 0.912m

3d_sky

free

Table N7 from Casamania

...table n7 from casamania

3dsky

casamania

futuristic table n7 from casamania

3dbaza

$3

Coffe Table N7 (154932)

...coffe table n7 (154932)

3dbaza

coffe table 3d model<br>coffe table n7 wood metall

thingiverse

free

weapon-n7-valiant by Worffpack104TH

...on-n7-valiant by worffpack104th

thingiverse

weapon-n7-valiant is for mass effect 3 it is a good gun to use now u can . print it

9G

thingiverse

free

9G Octopod by kelliott

...9g octopod by kelliott

thingiverse

an octopod robot with 3dof and using 9g/sg90 servos.

thingiverse

free

9g servo arm by puttezip

...9g servo arm by puttezip

thingiverse

arms for 9g servo.

thingiverse

free

Servo 9G holder (redesigned)

...servo 9g holder (redesigned)

thingiverse

servo 9g holder (redesigned)

thingiverse

free

hexapodo servo 9g by montoro

...hexapodo servo 9g by montoro

thingiverse

hexapodo para servomotores 9g

thingiverse

free

Servo 9g by Daired

...servo 9g by daired

thingiverse

model of common 9g servo

might become handy during assembly of your project (robotics etc.).

thingiverse

free

support servo 9g by lluiscolomer

...support servo 9g by lluiscolomer

thingiverse

soporte vertical para micro servo 9g.

thingiverse

free

OpenScad Servo 9g by RafaelEstevam

...penscad source

i needed one 9g servo to model a extruder and can not find one.

now you can find one =)

(and it is public domain!)

thingiverse

free

Aero Servo Mount 9G servo

...aero servo mount 9g servo

thingiverse

aero cover for a 9g servo

thingiverse

free

remix rhino for 9g servo by HelloTher

...remix rhino for 9g servo by hellother

thingiverse

it uses 9g servo instead

thingiverse

free

9g Servo Lego Adapter by MakerFoxYT

...9g servo lego adapter by makerfoxyt

thingiverse

a 9g servo adapter that connects to lego.

Actuator

turbosquid

$5

Linear Actuator

...

royalty free 3d model linear actuator for download as blend on turbosquid: 3d models for games, architecture, videos. (1589061)

turbosquid

$2

pneumatic actuator

...l pneumatic actuator for download as 3ds, obj, blend, and stl on turbosquid: 3d models for games, architecture, videos. (1333375)

3d_export

free

valve pneumatic actuator housing

...valve pneumatic actuator housing

3dexport

turbosquid

$1

Garrett GT2860R Turbocharger - Wastegate Actuator

...- wastegate actuator for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1259740)

3d_export

$10

hps hydraulic disc brake device brake actuator 4 specifications

...ic disc brake device brake actuator 4 specifications

3dexport

hps hydraulic disc brake device, brake actuator (4 specifications)

turbosquid

$16

(Project) Food packing helper machine with holding clamp and press table driven by an actuator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$25

hydraulic cylinder

...(also called a linear hydraulic motor) is a mechanical actuator that is used to give a unidirectional force through...

3d_export

$5

automatic gluing machine

...power system (power source), sensor detection system (sensor), and actuator system (such as...

3d_export

$20

si cantik cargo plane for humanity medicine kit

...and the ground. control system. in addition, as an actuator on the control surface and system release cargo in...

3d_export

$5

3D MOTORCYCLE DISC BRAKE MOTORBIKE model

... the components include the disc, master cylinder, caliper (which contains cylinder and two brake pads) on both sides of the disc

Servo

turbosquid

$30

Servo

...d model servo for download as obj, blend, dae, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1394011)

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.

turbosquid

$1

Servo Moter

...quid

royalty free 3d model servo moter for download as blend on turbosquid: 3d models for games, architecture, videos. (1650816)

turbosquid

free

Motor/Servo

...osquid

royalty free 3d model motor/servo for download as obj on turbosquid: 3d models for games, architecture, videos. (1522522)

turbosquid

$60

Servo Skull

...

royalty free 3d model servo skull for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1318573)

3d_export

$5

Servo 3D Model

...rvo 3d model

3dexport

servo

servo 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl pasqualesiciliano 104590 3dexport

turbosquid

$50

Servo Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Servo Motor

...model servo motor for download as 3ds, max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1324153)

turbosquid

$29

Servo Set

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

machine servo

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Linear

3ddd

$1

Linear Diffusers

...linear diffusers

3ddd

диффузор

set of linear diffusers for ceiling.

design_connected

$27

Linear Sofa

...linear sofa

designconnected

scp linear sofa computer generated 3d model.

design_connected

$18

Atlantis linear

...atlantis linear

designconnected

terzani atlantis linear pendant lights computer generated 3d model. designed by barlas baylar.

3d_export

$5

light linear unit

...light linear unit

3dexport

light linear unit

turbosquid

$5

Linear Actuator

...

royalty free 3d model linear actuator for download as blend on turbosquid: 3d models for games, architecture, videos. (1589061)

turbosquid

$29

Linear panel

...oyalty free 3d model linear panel for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1391254)

turbosquid

$10

Grohe Lineare

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Linear Unit 3D Model

...linear unit 3d model

3dexport

linear unit force torque velocity

linear unit 3d model fau 71218 3dexport

turbosquid

$8

Sircle Linear Pendan

...oyalty free 3d model sircle linear pendan for download as max on turbosquid: 3d models for games, architecture, videos. (1669285)

Cat

3d_export

$26

Cat

...cat

3dexport

cat

3d_export

$6

Cat

...cat

3dexport

cat

3d_export

$6

cat

...cat

3dexport

this is a cat

3d_export

$5

Cat

...cat

3dexport

cat

3d_export

$5

Cat

...cat

3dexport

cat

3d_export

$5

cat

...cat

3dexport

low poly cat ball

archibase_planet

free

Cat

...cat

archibase planet

cats animals

cat n140208 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

cat

...cat

3dexport

a cat that may look like a leopard because of its color.

turbosquid

free

Tidy Cats Cat Litter

...alty free 3d model tidy cats cat litter for download as blend on turbosquid: 3d models for games, architecture, videos. (1206013)

turbosquid

$15

The Battle Cats Cat Base

...odel the battle cats - eraser cat for download as max and ige on turbosquid: 3d models for games, architecture, videos. (1591322)

Bearing

3d_export

$6

Bear

...bear

3dexport

bear

3d_export

$5

bearing

...bearing

3dexport

bearing

3d_export

$12

bear

...bear

3dexport

bear for 3d printing toy

3d_ocean

$9

Bearing

...ne ball ballbea bearing bearings engine hard industrial machine mechanic metal part piece plastic ring screw sphere steel

bearing

archibase_planet

free

Bear

...bear

archibase planet

statuette bear picturesque element

bear - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

bear

...bear

3dexport

bear have a stl.,3dm files

archibase_planet

free

Bear

...bear

archibase planet

bear animals omnivorous animal

bear angry n250907- 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bear

...bear

archibase planet

bear animals omnivorous animal

bear easy n250907 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Teddy bear

...teddy bear

3ddd

teddy bear , медведь

teddy bear :)

3d_ocean

$12

Bear

... formats. created with 3d max 9.0. this file is very useful for learning & rigging. it can be used for any professional work.

Ball

turbosquid

$5

Ball on a Ball

...uid

royalty free 3d model ball on a ball for download as obj on turbosquid: 3d models for games, architecture, videos. (1484719)

archibase_planet

free

Ball

...ball

archibase planet

ball golf ball

ball - 3d model (*.gsm+*.3ds) for 3d visualization.

3d_export

$5

ball

...ball

3dexport

ball

archibase_planet

free

Ball

...ball

archibase planet

ball football soccer ball

ball n100714 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

3d_export

$5

ball

...ball

3dexport

soccer ball

archibase_planet

free

Ball

...ball

archibase planet

ball football

ball n100914 - 3d model (*.gsm+*.3ds+*.max) for 3d visualization.

3d_ocean

$5

Snooker Balls

... set balls snooker snooker balls white ball yellow ball

set snooker balls format include : .c4d .3ds .obj build in cinema 4d r13

3d_export

free

ball

...ball

3dexport

this is 3d model ball's

3d_ocean

$2

Soccer Ball

...soccer ball

3docean

ball red and yellow ball red ball soccer ball

a gorgeous red and yellow seamless soccer ball

3d_ocean

$5

Billard Balls

...low poly billiard balls. numbering from 1 to 15 plus the cue ball. each of the balls excluding the cue ball has a 4k texture map.