Thingiverse

65 mm Router Dust Shoe by biocatmeat

by Thingiverse

Last crawled date: 4 years, 9 months ago

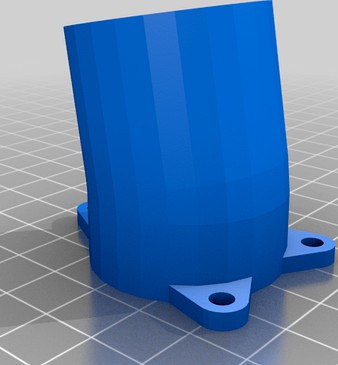

Needed a narrow dust shoe for my custom CNC router. Simple, multi-part design is easily assembled with a few bolts. I generally use SAE bolts since they are cheap and easier to get than metric here, so I used #6 bolts for everything, but M4 should work as well.

I use a Performax compact router which appears to be an almost identical clone of the Makita RT0701C, but this dust shoe should work on any router that has a 65mm body. These routers are air cooled and direct the air flow toward the bit which ends up blowing dust/chips everywhere making it difficult to suck them up with a shop vac. This design isolates the air flow from the router out holes in the top part, away from the cutting bit to keep from blowing the dust around.

The dust shoe is multi-part to make it easy to print as well as easy to assemble. Because there wasn't room for nuts in the top part, I made the holes slightly undersized for a #6 screw and made the section where the screws go a little thicker for strength, then tapped the plastic so I could screw directly into the plastic to connected the middle section to the top. I did use a little Loctite on the screws so they don't work their way out from the vibration of the router.

After doing several test cuts in a few different types of wood, it appears there is no need for a bristle skirt around the outside of the shoe. Since there is little to no air from the router blowing dust around, all the dust is very effectively sucked up by the shop vac even when the shoe is up to an inch or more above the work piece. I have not tried using the shoe while milling aluminum, but since I don't typically do very thick aluminum pieces, it should be easy to keep the shoe much closer to the pieces to suck up aluminum chips.

The holes on the bottom are countersunk to allow the use of flat head screws to allow the shoe to be positioned as close to the work pieces as possible without the screws getting in the way. The screws go in through the foot pass through the bottom and is used locking nuts on the middle piece. 1.25 inch long #6 screws would be perfect, though I could only fine one and the the other two on my piece are current 1.5 inch long, but it works just fine.

The Shop Vac I'm using is a small 1.5 gallon, 2.0 HP model with a 1 1/4" hose which fits snug inside the adapter on the shoe.

I designed this item to be easy to print and does not require supports and since it really just needs to hold a flexible hose, doesn't need to be all that strong. I printed this with 10% infill out of PLA and it seems plenty strong and hasn't had any issues so far.

I did include the Sketchup files I created these parts with in case you want to make alterations.

I use a Performax compact router which appears to be an almost identical clone of the Makita RT0701C, but this dust shoe should work on any router that has a 65mm body. These routers are air cooled and direct the air flow toward the bit which ends up blowing dust/chips everywhere making it difficult to suck them up with a shop vac. This design isolates the air flow from the router out holes in the top part, away from the cutting bit to keep from blowing the dust around.

The dust shoe is multi-part to make it easy to print as well as easy to assemble. Because there wasn't room for nuts in the top part, I made the holes slightly undersized for a #6 screw and made the section where the screws go a little thicker for strength, then tapped the plastic so I could screw directly into the plastic to connected the middle section to the top. I did use a little Loctite on the screws so they don't work their way out from the vibration of the router.

After doing several test cuts in a few different types of wood, it appears there is no need for a bristle skirt around the outside of the shoe. Since there is little to no air from the router blowing dust around, all the dust is very effectively sucked up by the shop vac even when the shoe is up to an inch or more above the work piece. I have not tried using the shoe while milling aluminum, but since I don't typically do very thick aluminum pieces, it should be easy to keep the shoe much closer to the pieces to suck up aluminum chips.

The holes on the bottom are countersunk to allow the use of flat head screws to allow the shoe to be positioned as close to the work pieces as possible without the screws getting in the way. The screws go in through the foot pass through the bottom and is used locking nuts on the middle piece. 1.25 inch long #6 screws would be perfect, though I could only fine one and the the other two on my piece are current 1.5 inch long, but it works just fine.

The Shop Vac I'm using is a small 1.5 gallon, 2.0 HP model with a 1 1/4" hose which fits snug inside the adapter on the shoe.

I designed this item to be easy to print and does not require supports and since it really just needs to hold a flexible hose, doesn't need to be all that strong. I printed this with 10% infill out of PLA and it seems plenty strong and hasn't had any issues so far.

I did include the Sketchup files I created these parts with in case you want to make alterations.