Thingiverse

60 cm Cubic Enclosure with Easy Detaching Panels by tianyu_liu

by Thingiverse

Last crawled date: 3 years, 4 months ago

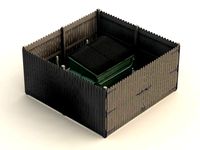

A 60 cm cubic enclosure for 3D printers. It is designed to allow access from all directions (for CoreXY 3D printers). Panels are only "hooked/hanged" onto the frames for easy detaching.

Thermally, the sealing should be good enough (my poorly designed PLA belt tighteners on the hotend carriage were once softened with a 60 °C bed temperature inside the enclosure).

Acoustically, the sealing is not good enough to meet my expectation. Probably because the plastic sheets bend easily and cannot press firmly against the window seals. I also didn't seal the printed corners.

Fusion 360 design file attached.

Non-printed parts

Besides the printed parts, the design also needs:

12×12×1.6 mm metal angle extrusions for frames, cut to 570 mm long, 12 pieces;

3-mm- or 5-mm-thick (acrylic) plastic sheets for panels, cut to 60 cm × 60 cm, 5 pieces (if the enclosure will be placed against wall, then only 4 plastic sheets needed); and

M3 screws that are between 10 to 20 mm long (e.g. 15 mm) to fasten the frames, 24 pieces (and nuts too; maybe washers as well).

I also attached window seals (6-mm thick) for better sealing. Each facet needs about 4 × 60 = 240 cm. So totally about 12 metres for 5 facets. The gap between the angle frames and the panels is about 5 mm. The gap between the printed corners and the panels is about 3 mm.

Printed parts

Parts to be printed:

Corner × 8;

Clamp × 24;

Hook, 4 for each panel, use Hook 3mm and Hook 5mm according to the thickness of plastic sheets.

All parts are designed to be printed with 0.4 mm layer height, without support.

Fastening the angle frames

The clamps were not planned with enough clearance for errors. However, just tighten them, and the angle frames will be held firmly together anyway.

Attaching the hooks

I only used double tapes (several layers) to attach the hooks onto the panels. I might super glue them later, as this is irreversible.

Updates

It appears that 60cm height may leave too little clearance for CoreXY printers. The filament gets softened in the PTFE feeding tube and eventually clogged. Hence, I think this enclosure should be (X mm) taller:

Replace 4 of the 570mm-long angle extrusions with (570 + X)mm.

Replace 4 (or 3, if placed against wall) of the 600×600mm plastic sheet with (600 + X)×600mm ones.

X should be something like 150mm (15cm).

Thermally, the sealing should be good enough (my poorly designed PLA belt tighteners on the hotend carriage were once softened with a 60 °C bed temperature inside the enclosure).

Acoustically, the sealing is not good enough to meet my expectation. Probably because the plastic sheets bend easily and cannot press firmly against the window seals. I also didn't seal the printed corners.

Fusion 360 design file attached.

Non-printed parts

Besides the printed parts, the design also needs:

12×12×1.6 mm metal angle extrusions for frames, cut to 570 mm long, 12 pieces;

3-mm- or 5-mm-thick (acrylic) plastic sheets for panels, cut to 60 cm × 60 cm, 5 pieces (if the enclosure will be placed against wall, then only 4 plastic sheets needed); and

M3 screws that are between 10 to 20 mm long (e.g. 15 mm) to fasten the frames, 24 pieces (and nuts too; maybe washers as well).

I also attached window seals (6-mm thick) for better sealing. Each facet needs about 4 × 60 = 240 cm. So totally about 12 metres for 5 facets. The gap between the angle frames and the panels is about 5 mm. The gap between the printed corners and the panels is about 3 mm.

Printed parts

Parts to be printed:

Corner × 8;

Clamp × 24;

Hook, 4 for each panel, use Hook 3mm and Hook 5mm according to the thickness of plastic sheets.

All parts are designed to be printed with 0.4 mm layer height, without support.

Fastening the angle frames

The clamps were not planned with enough clearance for errors. However, just tighten them, and the angle frames will be held firmly together anyway.

Attaching the hooks

I only used double tapes (several layers) to attach the hooks onto the panels. I might super glue them later, as this is irreversible.

Updates

It appears that 60cm height may leave too little clearance for CoreXY printers. The filament gets softened in the PTFE feeding tube and eventually clogged. Hence, I think this enclosure should be (X mm) taller:

Replace 4 of the 570mm-long angle extrusions with (570 + X)mm.

Replace 4 (or 3, if placed against wall) of the 600×600mm plastic sheet with (600 + X)×600mm ones.

X should be something like 150mm (15cm).

Similar models

thingiverse

free

Simple Enclosure / Casing Corners by RossHaddow

.... wing nuts and bolts were used to assemble the corners to the acrylic sheet (finger tight only to avoid damaging the acrylic.).

thingiverse

free

Clips for corrugated plastic sheets by CJMind

...heets. i used these to hold the walls of my 3d printer enclosure in place between the 2 ikea lack tables for my ceiling and base.

thingiverse

free

ender 5 corexy linear rails by jaruwit

...irmware

marlin with ender 5 config.

only uncomment #define corexy in configuration.h

thank you

grabcad.com for ender 5 cad model.

thingiverse

free

screwless enclosure frame

...e

4x enclosure corner

4x enclosure corner under

16x length ctoc

5 sheets of acrylglass

my second design ever.... still growing.

thingiverse

free

Ender 3 Printer enclosure corners

...ickness,- to print, i advise placing all 4 units flat on the pad and you do not need support but do print a brim around each unit

thingiverse

free

kajakens Solidoodle 3 enclosure by kajakmannen

... degrees c bed temp. with this temp there is no problem with part not sticking to the bed. note: i use this temp with abs plastic

3d_export

free

ender 3 enclosure corners

...er corners and 4 upper corners, using 25mmx25mm angled aluminium pieces that gets covered on inside of the frame with plexiglass

thingiverse

free

Enclosure parts and 45 degree spool holder by askiladin

...any size enclosure. all you need is perspex or similar sheets. drill holes in sheets as needed and use...

3d_sky

free

3D panel corners

...ners. size: 50x50 cm (1 pc.) thickness: 1.5 mm height: 20 mm weight: 275 grams material: begassa options: 4 pcs. (1 sq m of wall)

thingiverse

free

IKEA LACK Ender 3 Enclosure by Olivarius

...ddle to attach it to the lack table, this adds rigidity.

i hope you guys like it, if you do make one please let me know.

thanks.

Tianyu

3d_export

$8

New Chinese style Tianyu area landscape SU model

...new chinese style tianyu area landscape su model

3dexport

new chinese style tianyu area landscape su model

3dwarehouse

free

Skyfame Center Landmark Tower

...3dwarehouse the skyfame center landmark tower, also known as tianyu tower, is a 346 m / 1,135 ft tall...

Liu

turbosquid

$59

Liu

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

liu-chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Meridiani LIU KUOIO

...meridiani liu kuoio

3ddd

meridiani

http://www.meridiani.it/introduction/living/bergeres/liu-kuoio_en_0_1_130.html

turbosquid

$7

Caillou. Sideboard by Liu Jo

...u. sideboard by liu jo for download as max, max, max, and obj on turbosquid: 3d models for games, architecture, videos. (1576330)

3ddd

$1

Natuzzi armchairs LIU - 2228

...natuzzi armchairs liu - 2228

3ddd

natuzzi

dimensions:

800 h x 730 w x 870 d

turbosquid

$32

Architecture Xian Liu Taiwan miscellaneous pieces

... - xian liu taiwan - miscellaneous pieces for download as max on turbosquid: 3d models for games, architecture, videos. (1452847)

3d_export

$10

liu h73 bistrot table

...yes<br>box trick: yes<br>model parts: 12<br>render: v-ray, corona<br>formats: 3ds max 2013, obj, fbx, 3ds

3d_export

$10

liu ct oval coffee table

... yes<br>box trick: yes<br>model parts: 4<br>render: v-ray, corona<br>formats: 3ds max 2013, obj, fbx, 3ds

3d_export

$5

Caillou Console Table by Liu Jo Living Collection

... https://www.archiproducts.com/en/products/liu-jo-living-collection/mdf-console-table-secretary-desk-caillou-console-table_430687

3d_export

$5

Caillou Console Table by Liu Jo Living Collection with Mirror

...e 1.3 geometry: polygon p (quad) unwrapped uvs: yes, non-overlapping https://www.liujoliving.com/en/products/caillou-make-up-set/

Detaching

turbosquid

$5

Detached Garage

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Detached Single Story

...royalty free 3d model detached single storey for download as on turbosquid: 3d models for games, architecture, videos. (1365704)

turbosquid

$15

Detached Single Story

...alty free 3d model detached single storey for download as skp on turbosquid: 3d models for games, architecture, videos. (1365711)

turbosquid

$10

Semi Detach House

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

semi-detached House

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Detached house 2 3D Model

...tached architecture building bricks uburban housesc ity architectural exterior

detached house 2 3d model sanchiesp 93523 3dexport

cg_studio

$59

Semi Detached House3d model

...el

cgstudio

.3ds .fbx .max .obj - semi detached house 3d model, royalty free license available, instant download after purchase.

turbosquid

$19

Detached Garages for two cars

...ee 3d model detached garages for two cars for download as max on turbosquid: 3d models for games, architecture, videos. (1567476)

turbosquid

free

Detached House with 4 rooms

...free 3d model detached house with 4 rooms for download as skp on turbosquid: 3d models for games, architecture, videos. (1331200)

3d_ocean

$80

Semi Detached House

... a drafts of the project (layout of the floor plans in pdf format), 3 renders (perspectives), a mini video (.mp4 format) files...

Cubic

turbosquid

$2

Cubic

...ic

turbosquid

royalty free 3d model cubic for download as ma on turbosquid: 3d models for games, architecture, videos. (1547488)

3d_export

$5

cubic planet

...cubic planet

3dexport

cubic planet

3d_ocean

$6

Cubic rubic

...e orange red toy white yellow

here is a nice cubic rubic made in 3ds max 9, with special system for rotation and moving the cubic

3ddd

$1

Pianca / Cubic

...pianca / cubic

3ddd

pianca

кровать фабрики pianca, модель cubic (169x214)

3ddd

$1

BNOS / Cubic

... cubic

3ddd

om , стул

мягкая мебель серии cubic фирмы bnos. подробнее на www.bnos.com.ua

turbosquid

$50

Cubic Dream

...osquid

royalty free 3d model cubic dream for download as stl on turbosquid: 3d models for games, architecture, videos. (1337475)

3ddd

$1

boconcept Cubic, ковер

...boconcept cubic, ковер

3ddd

ковер , boconcept

boconcept cubic, ковер

turbosquid

free

Cubic Abacus

...

free 3d model cubic abacus for download as 3ds, obj, and skp on turbosquid: 3d models for games, architecture, videos. (1260109)

3ddd

$1

Moll Cubic

...moll cubic

3ddd

moll

moll

3d_export

$30

cubic building

...cubic building

3dexport

cubic building<br>117 objetos<br>34 materiales<br>9 textures

Enclosure

3d_export

free

electrical enclosure

...l enclosure where electrical devices like (relays, contactors, busbars ) are kept in order to protect from hazardous environment.

turbosquid

$100

GPU Enclosure

...yalty free 3d model gpu enclosure for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1381061)

3d_export

$5

Electrical Enclosure

...ed. also has tower lights attaced on the top.<br>file format that are available:<br>.step<br>.obj<br>.stl

archive3d

free

Enclosure 3D Model

...closure 3d model

archive3d

shower enclosure-acquarius- 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-omega- 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-vega - 3d model for interior 3d visualization.

archive3d

free

Enclosure 3D Model

...enclosure 3d model

archive3d

shower enclosure-zenith - 3d model for interior 3d visualization.

turbosquid

$20

shower enclosure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$14

Dumpster Enclosure

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

3d printer enclosure

... model 3d printer enclosure for download as ipt, skp, and fbx on turbosquid: 3d models for games, architecture, videos. (1634310)

60

3ddd

free

Life 60-60

...life 60-60

3ddd

life , часы

автор модели; aeroslon

design_connected

$29

60

...60

designconnected

restoration hardware 60" kensington leather sofa computer generated 3d model.

turbosquid

$1

60

...60

turbosquid

royalty free 3d model 60 for download as stl on turbosquid: 3d models for games, architecture, videos. (1158799)

3ddd

$1

ARKEL 60

...arkel 60

3ddd

arkel , круглый

arkel диаметр 60

design_connected

$13

60-0270

...60-0270

designconnected

christopher guy 60-0270 computer generated 3d model.

3ddd

$1

Pillows 60

...pillows 60

3ddd

подушка

pillows 60. i hope you like it. thank you !

design_connected

$13

Stool 60

...stool 60

designconnected

artek stool 60 computer generated 3d model. designed by aalto, alvar.

design_connected

$11

Mac 60

...mac 60

designconnected

linbrasil mac 60 computer generated 3d model. designed by rodrigues, sergio.

design_connected

$16

60-0246

...60-0246

designconnected

christopher guy 60-0246 armchairs computer generated 3d model. designed by n/a.

3ddd

$1

Pillows 60

...pillows 60

3ddd

подушка

pillows 60

new pillows .i hope you like it .thank you .

Panels

3d_export

$15

panel

...panel

3dexport

panel

archibase_planet

free

Panel

...panel

archibase planet

panel

panel - 3d model for interior 3d visualization.

3d_export

$5

panel

...panel

3dexport

panel with cones

3ddd

$1

Panels

...panels

3ddd

панель

panels

3d_export

$5

panel

...panel 3dexport panels grapes with...

archibase_planet

free

Panel

...panel

archibase planet

panel wainscot dado

play panel n050707 - 3d model for interior 3d visualization.

archibase_planet

free

Panel

...panel

archibase planet

lining panel facing material

panel 2 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Panel

...panel

archibase planet

lining panel facing material

panel 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Panel

...panel

archibase planet

keyboard patchboard finger-board

security panel - 3d model for interior 3d visualization.

turbosquid

$10

Panel

...l

turbosquid

royalty free 3d model panel for download as stl on turbosquid: 3d models for games, architecture, videos. (1387163)

Easy

design_connected

$16

Easy

...easy

designconnected

sollos easy computer generated 3d model. designed by almeida, jader.

design_connected

$20

Easy

...easy

designconnected

established & sons easy armchairs computer generated 3d model. designed by ed carpenter.

3d_ocean

$1

Easy Button

... it is accurate in close-ups. you can drop this model right into any setting. the textures are included as well as links to do...

design_connected

$16

Easy Armchair

...easy armchair

designconnected

easy armchair computer generated 3d model. designed by jeanneret, pierre.

3ddd

$1

Pouf EASY

... easy

3ds max 2010.v-ray 2.40.03.file formats fbx,obj. pouf desiree 2014 easy. dimensions 100x100x45 cm.

design_connected

$18

Easy Armchair

...easy armchair

designconnected

fsm easy armchair computer generated 3d model. designed by hartmann, markus.

design_connected

$16

Easy Chair

...easy chair

designconnected

magis easy chair computer generated 3d model. designed by seymour, jerszy.

design_connected

$16

Easy Rider

...easy rider

designconnected

bulo easy rider computer generated 3d model. designed by venlet, danny.

design_connected

$11

Easy Footstool

...easy footstool

designconnected

fsm easy footstool computer generated 3d model. designed by hartmann, markus.

design_connected

$18

Doda - Easy

...doda - easy

designconnected

molteni & c doda - easy computer generated 3d model. designed by laviani, ferruccio.