GrabCAD

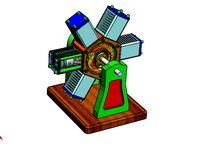

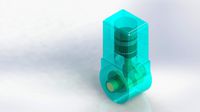

6 Cylinder Radial Engine (Pneumatic)

by GrabCAD

Last crawled date: 1 year, 11 months ago

Complete Assembly to build this 6 Cylinder Radial engine(Pneumatic type).

Ready for 3D printing, Just make a prototype at home or use the blueprints to learn how to model this stuff.

The radial engine is a reciprocating type internal combustion engine configuration in which the cylinders "radiate" outward from a central crankcase like the spokes of a wheel. It resembles a stylized star when viewed from the front, and is called a "star engine" in some languages. The radial configuration was very commonly used for aircraft engines before turbine engines became predominant.

Engine operation[edit]

Since the axes of the cylinders are coplanar, the connecting rods cannot all be directly attached to the crankshaft unless mechanically complex forked connecting rods are used, none of which have been successful. Instead, the pistons are connected to the crankshaft with a master-and-articulating-rod assembly. One piston, the uppermost one in the animation, has a master rod with a direct attachment to the crankshaft. The remaining pistons pin their connecting rods' attachments to rings around the edge of the master rod. Extra "rows" of radial cylinders can be added in order to increase the capacity of the engine without adding to its diameter.

Four-stroke radials have an odd number of cylinders per row, so that a consistent every-other-piston firing order can be maintained, providing smooth operation. For example, on a five-cylinder engine the firing order is 1, 3, 5, 2, 4 and back to cylinder 1. Moreover, this always leaves a one-piston gap between the piston on its combustion stroke and the piston on compression. The active stroke directly helps compress the next cylinder to fire, making the motion more uniform. If an even number of cylinders were used, an equally timed firing cycle would not be feasible.[1] The prototype radial Zoche aero-diesels (below) have an even number of cylinders, either four or eight; but this is not problematic, because they are two-stroke engines, with twice the number of power strokes as a four-stroke engine.[citation needed]

The radial engine normally uses fewer cam lobes than other types. As with most four-strokes, the crankshaft takes two revolutions to complete the four strokes of each piston (intake, compression, combustion, exhaust). The camshaft ring is geared to spin slower and in the opposite direction to the crankshaft. The cam lobes are placed in two rows for the intake and exhaust. For the example, four cam lobes serve all five cylinders, whereas 10 would be required for a typical inline engine with the same number of cylinders and valves.[citation needed]

Most radial engines use overhead poppet valves driven by pushrods and lifters on a cam plate which is concentric with the crankshaft, with a few smaller radials, like the Kinner B-5 and Russian Shvetsov M-11, using individual camshafts within the crankcase for each cylinder. A few engines utilize sleeve valves such as the 14-cylinder Bristol Hercules and the 18-cylinder Bristol Centaurus, which are quieter and smoother running but require much tighter manufacturing tolerances.

Blueprints were refrenced from inventorworks.be

Ready for 3D printing, Just make a prototype at home or use the blueprints to learn how to model this stuff.

The radial engine is a reciprocating type internal combustion engine configuration in which the cylinders "radiate" outward from a central crankcase like the spokes of a wheel. It resembles a stylized star when viewed from the front, and is called a "star engine" in some languages. The radial configuration was very commonly used for aircraft engines before turbine engines became predominant.

Engine operation[edit]

Since the axes of the cylinders are coplanar, the connecting rods cannot all be directly attached to the crankshaft unless mechanically complex forked connecting rods are used, none of which have been successful. Instead, the pistons are connected to the crankshaft with a master-and-articulating-rod assembly. One piston, the uppermost one in the animation, has a master rod with a direct attachment to the crankshaft. The remaining pistons pin their connecting rods' attachments to rings around the edge of the master rod. Extra "rows" of radial cylinders can be added in order to increase the capacity of the engine without adding to its diameter.

Four-stroke radials have an odd number of cylinders per row, so that a consistent every-other-piston firing order can be maintained, providing smooth operation. For example, on a five-cylinder engine the firing order is 1, 3, 5, 2, 4 and back to cylinder 1. Moreover, this always leaves a one-piston gap between the piston on its combustion stroke and the piston on compression. The active stroke directly helps compress the next cylinder to fire, making the motion more uniform. If an even number of cylinders were used, an equally timed firing cycle would not be feasible.[1] The prototype radial Zoche aero-diesels (below) have an even number of cylinders, either four or eight; but this is not problematic, because they are two-stroke engines, with twice the number of power strokes as a four-stroke engine.[citation needed]

The radial engine normally uses fewer cam lobes than other types. As with most four-strokes, the crankshaft takes two revolutions to complete the four strokes of each piston (intake, compression, combustion, exhaust). The camshaft ring is geared to spin slower and in the opposite direction to the crankshaft. The cam lobes are placed in two rows for the intake and exhaust. For the example, four cam lobes serve all five cylinders, whereas 10 would be required for a typical inline engine with the same number of cylinders and valves.[citation needed]

Most radial engines use overhead poppet valves driven by pushrods and lifters on a cam plate which is concentric with the crankshaft, with a few smaller radials, like the Kinner B-5 and Russian Shvetsov M-11, using individual camshafts within the crankcase for each cylinder. A few engines utilize sleeve valves such as the 14-cylinder Bristol Hercules and the 18-cylinder Bristol Centaurus, which are quieter and smoother running but require much tighter manufacturing tolerances.

Blueprints were refrenced from inventorworks.be

Similar models

grabcad

free

Radial engine

...s and the 18-cylinder bristol centaurus, which are quieter and smoother running but require much tighter manufacturing tolerances

grabcad

free

radial engine assembly

...cylinders was used, the firing order would be something similar to 1,3,5,2,4,6, which leaves a three-piston gap between firing...

grabcad

free

Radial Engine

...ectly to the crankshaft - this is the master rod. the other cylinders' rods connect to pivoting points around the master rod.

grabcad

free

Radial engine piston

...by articulated rods. in an 18-cylinder engine, which has two rows of cylinders, there are two master rods and 16 articulated rods

grabcad

free

CamShaft

...lve. the cam lobes force the valves open by pressing on the valve, or on some intermediate mechanism, as they rotate.

automotive

cg_trader

$35

Single cylinder 4-stroke engine

...r motorcycle piston valve motorbike automobile crankshaft camshaft combustion fourstroke 4stroke singlecylinder motorcycle engine

grabcad

free

Radial Engine Model

...ts and motion links. the following parts are animated:

• rotor

• pistons

• camshafts

• camshaft gears

• connecting rods

• valves

grabcad

free

Piston-Cylinder and Crankshaft assembly

...on within the working cylinder into a piston stroke, which the crankshafts converts into useful torque available at the flywheel.

grabcad

free

Two stroke apposed pistons parallel cylinders internal combustion engine

...ns or their multiples connected in coordination to one crankshaft by means of rods and a swing arm for each of the two cylinders.

grabcad

free

Master Connecting Rod

...aft by a master connecting rod. the master connecting rod serves as the connecting link between the piston pin and the crank pin.

Pneumatic

3d_export

$7

pneumatic charging car

...pneumatic charging car

3dexport

pneumatic charging car

turbosquid

$20

pneumatic flap

...model pneumatic flap for download as dxf, ige, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1410890)

turbosquid

$2

pneumatic actuator

...l pneumatic actuator for download as 3ds, obj, blend, and stl on turbosquid: 3d models for games, architecture, videos. (1333375)

turbosquid

$30

Cylinder pneumatic

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

booster pneumatic

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Pneumatic Fitting

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

pneumatic wheel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Pneumatic Unit 3D Model

...pneumatic unit 3d model

3dexport

pneumatic unit pressure velocity

pneumatic unit 3d model fau 71223 3dexport

turbosquid

$3

Pneumatic grinder

...r download as 3ds, dxf, obj, xsi, wrl, fbx, dwg, dae, and skp on turbosquid: 3d models for games, architecture, videos. (1389593)

3d_export

free

pneumatic manifold block

...atic manifold block

3dexport

modified pneumatic manifold block for shooting particles, using festo valves installed on its face.

Radial

3d_ocean

$5

Radial engine

...dial engine

3docean

engine radial

this is a radial engine used by the old airplanes. it is made in autodesk inventor and autocad.

3d_export

$5

radial engine

...ne , clearly shows how a radial engine works and all the parts present in it for a student or an engineer to have a glans on it .

3d_export

$5

shaft radial bearing

...shaft radial bearing

3dexport

shaft radial bearing

turbosquid

$7

Radial engine

...bosquid

royalty free 3d model radial engine for download as on turbosquid: 3d models for games, architecture, videos. (1672376)

turbosquid

$7

Radial Tyre

...osquid

royalty free 3d model radial tyre for download as max on turbosquid: 3d models for games, architecture, videos. (1433150)

turbosquid

$60

Radial engine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

VOITH RADIAL PROPELLER

...alty free 3d model voith radial propeller for download as max on turbosquid: 3d models for games, architecture, videos. (1338129)

3d_export

$20

radial engine assembly

...radial engine assembly

3dexport

turbosquid

$4

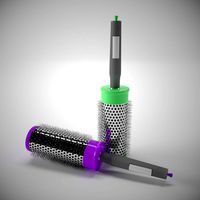

Radial Hair Brush

... 3d model radial hair brush for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1183870)

turbosquid

$39

Wheel ATS Radial

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Cylinder

turbosquid

$1

Piston - Cylinder Cylinder Engine

...nder cylinder engine for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1235278)

3ddd

$1

sofa cylinder

...sofa cylinder

3ddd

круглый

sofa cylinder

turbosquid

$1

Cylinder Head - Single Cylinder Engine

...ngle cylinder engine for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1222618)

turbosquid

$16

Cylinder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Cylinder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$120

Four cylinder

...four cylinder

3dexport

four cylinder render 3d modelling

3d_export

$5

piston cylinder

...piston cylinder

3dexport

piston cylinder arrangement sketched in solidworks

3ddd

$1

Cylinder Lamp A

...cylinder lamp a

3ddd

cylinder form lamp for loft interior

archive3d

free

Cylinder 3D Model

... model

archive3d

cylinder drum

cylinder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archive3d

free

Cylinder 3D Model

...odel

archive3d

drum cylinder

cylinder 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

6

3d_export

$18

tulip 6

...tulip 6

3dexport

tulip 6

3d_export

$5

hinge 6

...hinge 6

3dexport

hinge 6

3ddd

$1

MASIERO / FLASHWOOD STL 6 + 6

...6

3ddd

masiero

торшер flashwood stl 6 + 6 фабрики masiero

http://www.masierogroup.com/c87_697/it/flashwood%20stl%206%20+%206.ashx

turbosquid

$110

Atmos Cannon 2000 6*6

...yalty free 3d model atmos cannon 2000 6*6 for download as skp on turbosquid: 3d models for games, architecture, videos. (1528591)

turbosquid

$1

ae 6 6 electric locomotive

... free 3d model ae 6 6 electric locomotive for download as obj on turbosquid: 3d models for games, architecture, videos. (1707537)

turbosquid

$39

A-6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

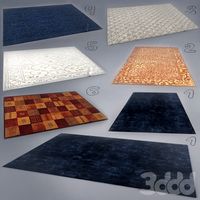

6 ковров

...6 ковров

3ddd

ковры , ковер

6 ковров

turbosquid

$12

Calligraphic Digit 6 Number 6

...hic digit 6 number 6 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389336)

turbosquid

$19

Case For Phone 6 Girl 6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

Iphone 6 & 6 Plus All

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

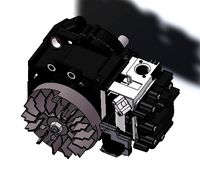

Engine

3d_export

$5

engine

...engine

3dexport

engine

3d_export

free

Engine

...engine

3dexport

engine

archibase_planet

free

Engine

...engine

archibase planet

motor engine

engine - 3d model for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

motor engine mover

engine n170708 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

engine locomotive train

locomotive - 3d model for interior 3d visualization.

turbosquid

$49

ENGINE

...

turbosquid

royalty free 3d model engine for download as max on turbosquid: 3d models for games, architecture, videos. (1206116)

turbosquid

$1

ENGINE

...osquid

royalty free 3d model ic engine for download as sldas on turbosquid: 3d models for games, architecture, videos. (1382781)

3d_export

$5

engine

...engine

3dexport

3d_export

free

engine

...engine

3dexport

turbosquid

$7

Engine

...d model animated engine mograph element3d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1380716)