Thingiverse

5015 fan silencer by FullPlasticScientist

by Thingiverse

Last crawled date: 3 years, 3 months ago

Inlet silencer for 5015 blowers.

See bottom for original listing.

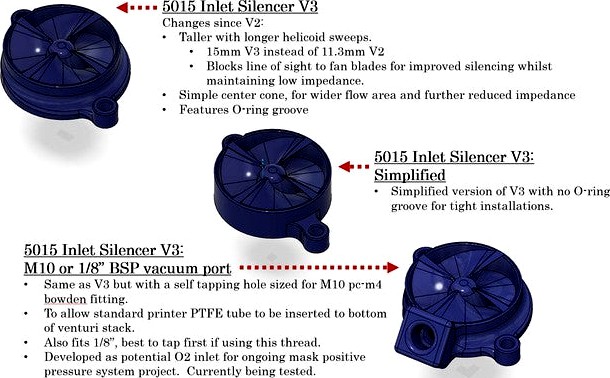

----V3 DESIGN UPDATE 2020-11-18---

Another version, same as V2 except:

15mm tall instead of 11.3mm for longer helocid to block line of sight to fan blades completely.

Simplified inner cone for wider flow area and lowest impedance.

some fine geometric refinements to fan inlet, eg smaller cone base.

Made a simplified version with no damping o-ring.

Made a M10 or 1/8thBSP vacuum port inlet version. Experimental for use as as 02 delivery system. Treat as untested/unsafe and use with extreme caution. Potential fire hazard!

----V2 DESIGN UPDATE 2020-11-06---

Made a V2 simplified option with no o-ring groove feature and minimal footprint to allow it to be fitted to a greater variety of printer setups.

----V2 DESIGN UPDATE 2020-10-31----

Thanks to detailed and constructive feedback from esoterik, see comments, I have produced an updated design. Optimised for lower impedance and hence less impact on fan output.

-Modal barrier removed, 4 resonant modes now down from 8

-Velocity stack/venturi OD flared for lower flow impedance

-Toroidal blades wider for lower flow impedance

-2.7mm shorter for tight installation requirements

----FUTURE WORK----

Build flowrate, pressure and acoustic testrig. Using arduino, custom printed venturi flow meter fitted with an RC plane differential sensor MPXV7002DP. Acoustically silenced chamber (eg old fridge turned off) to measure noise (Db) without background interference. May also add accelerometer to characterise spectrograms/scaleograms of resonant modes. So that designs can be made to manipulate resonant modes precisely.

--Test microporous toroidal blades

--Radially patterned angular flared holes around stack OD

--Resonant hidden side chambers in stack OD and cone body, see paper ref at end of listing.

--Different number of toroidal blades for more modes

--Construct a table of flow impedance vs acoustic damping so users can select appropriate levels for their application.

--Adapt for other fan sizes and types

--Make adjustable outlet, eg plane aircon nozzle, using best techniques.

----ROUND 2 FIGHT!----

This is a backburner project as part of a clear mask pressure and flow regulated ventilation system. All critical and constructive feedback is greatly appreciated. If I am not replying immediately its because I'm currently mustering my remaining resources to face Corona head on, one more time, to protect my family and community in the UK. When the opponent is exponential our efforts to counter attack must also be exponential.

Join me #CoronaSlayers for one last push to #HackThePandemic

PRINT & SHARE, until Corona is done!

----ORIGINAL LISTING----

Designed for a clear mask positive pressure system being developed for the https://www.thingiverse.com/thing:4598055

That application required near silent operation at greater than 100% rated voltages. In order to achieve pressure necessary to blow air through a highly restrictive clear mask inlet filter and develop net positive pressure inside the mask trapped volume. A mini PAPR system. In use for several weeks in an office environment with no complains from co workers.

So should work for noisy 5015 3D printer fans too. Check your airflow after fitting.

Features:

Short venturi / velocity stack cone inlet

Modal barrier to break up resonance into 8 separate modes, thus reducing peak intensity of primary fan resonance.

4 way toroid with no sight line to fan

Converts linear airflow to radial as the blower wants

Gap at inlet to fan blades matched to radius of blower fan.

Smooth transition into fan blade leading edge to reduce local high pressure pockets that generate resonance.

Cut out at bottom of toroid to allow air mixing void just before blower fan blades.

Increases efficiency whilst also reducing resonant noise.

O-ring seal groove for a 1.5mm cross section 40mm ID 43mm OD o-ring

Dampens vibration and improves inlet seal

Reduces contact area on first printing layer, no more torn borosilicate using petG!

O-ring optional, silencer will still mount and work fine if not fitted.

Small chamfers on bottom of part, to compensate for elephants foot.

Oversized holes for M4 cap heads to account for differences in blower housing manufacture.

No supports or bridging required. Part is its own support. If toroidal vanes are not 100 solid it may be microporous, this is an advantage as micro porous acoustic silencers are far more effective.

Material doesn't really matter

I print in 0.2 layer height but best results will be 0.1 or nearest magic number. Relatively quick to print. All other settings as per your preferences.

Best used with a dual ball bearing or sleeved bearing fan variant. Avoid cheap winsinn hydraulic bearing fans. Unreliable and the hydraulic bearings give off a high pitched whine this silencer cannot combat. The ball and sleeved bearing 5015 blowers types do not.

This review paper and related literature on toroidal silencers made with additive manufacturing techniques as inspiration.

"Assessment on the use of additive manufacturing technologies for acoustic applications"https://link.springer.com/article/10.1007/s00170-020-05853-2

See bottom for original listing.

----V3 DESIGN UPDATE 2020-11-18---

Another version, same as V2 except:

15mm tall instead of 11.3mm for longer helocid to block line of sight to fan blades completely.

Simplified inner cone for wider flow area and lowest impedance.

some fine geometric refinements to fan inlet, eg smaller cone base.

Made a simplified version with no damping o-ring.

Made a M10 or 1/8thBSP vacuum port inlet version. Experimental for use as as 02 delivery system. Treat as untested/unsafe and use with extreme caution. Potential fire hazard!

----V2 DESIGN UPDATE 2020-11-06---

Made a V2 simplified option with no o-ring groove feature and minimal footprint to allow it to be fitted to a greater variety of printer setups.

----V2 DESIGN UPDATE 2020-10-31----

Thanks to detailed and constructive feedback from esoterik, see comments, I have produced an updated design. Optimised for lower impedance and hence less impact on fan output.

-Modal barrier removed, 4 resonant modes now down from 8

-Velocity stack/venturi OD flared for lower flow impedance

-Toroidal blades wider for lower flow impedance

-2.7mm shorter for tight installation requirements

----FUTURE WORK----

Build flowrate, pressure and acoustic testrig. Using arduino, custom printed venturi flow meter fitted with an RC plane differential sensor MPXV7002DP. Acoustically silenced chamber (eg old fridge turned off) to measure noise (Db) without background interference. May also add accelerometer to characterise spectrograms/scaleograms of resonant modes. So that designs can be made to manipulate resonant modes precisely.

--Test microporous toroidal blades

--Radially patterned angular flared holes around stack OD

--Resonant hidden side chambers in stack OD and cone body, see paper ref at end of listing.

--Different number of toroidal blades for more modes

--Construct a table of flow impedance vs acoustic damping so users can select appropriate levels for their application.

--Adapt for other fan sizes and types

--Make adjustable outlet, eg plane aircon nozzle, using best techniques.

----ROUND 2 FIGHT!----

This is a backburner project as part of a clear mask pressure and flow regulated ventilation system. All critical and constructive feedback is greatly appreciated. If I am not replying immediately its because I'm currently mustering my remaining resources to face Corona head on, one more time, to protect my family and community in the UK. When the opponent is exponential our efforts to counter attack must also be exponential.

Join me #CoronaSlayers for one last push to #HackThePandemic

PRINT & SHARE, until Corona is done!

----ORIGINAL LISTING----

Designed for a clear mask positive pressure system being developed for the https://www.thingiverse.com/thing:4598055

That application required near silent operation at greater than 100% rated voltages. In order to achieve pressure necessary to blow air through a highly restrictive clear mask inlet filter and develop net positive pressure inside the mask trapped volume. A mini PAPR system. In use for several weeks in an office environment with no complains from co workers.

So should work for noisy 5015 3D printer fans too. Check your airflow after fitting.

Features:

Short venturi / velocity stack cone inlet

Modal barrier to break up resonance into 8 separate modes, thus reducing peak intensity of primary fan resonance.

4 way toroid with no sight line to fan

Converts linear airflow to radial as the blower wants

Gap at inlet to fan blades matched to radius of blower fan.

Smooth transition into fan blade leading edge to reduce local high pressure pockets that generate resonance.

Cut out at bottom of toroid to allow air mixing void just before blower fan blades.

Increases efficiency whilst also reducing resonant noise.

O-ring seal groove for a 1.5mm cross section 40mm ID 43mm OD o-ring

Dampens vibration and improves inlet seal

Reduces contact area on first printing layer, no more torn borosilicate using petG!

O-ring optional, silencer will still mount and work fine if not fitted.

Small chamfers on bottom of part, to compensate for elephants foot.

Oversized holes for M4 cap heads to account for differences in blower housing manufacture.

No supports or bridging required. Part is its own support. If toroidal vanes are not 100 solid it may be microporous, this is an advantage as micro porous acoustic silencers are far more effective.

Material doesn't really matter

I print in 0.2 layer height but best results will be 0.1 or nearest magic number. Relatively quick to print. All other settings as per your preferences.

Best used with a dual ball bearing or sleeved bearing fan variant. Avoid cheap winsinn hydraulic bearing fans. Unreliable and the hydraulic bearings give off a high pitched whine this silencer cannot combat. The ball and sleeved bearing 5015 blowers types do not.

This review paper and related literature on toroidal silencers made with additive manufacturing techniques as inspiration.

"Assessment on the use of additive manufacturing technologies for acoustic applications"https://link.springer.com/article/10.1007/s00170-020-05853-2

Similar models

cults

$1

5015 Blower fan static pressure booster!

...booster 5015 50 15 fan blower centrifugal

increases output of air 10% or more.

boosts pressure when using as a print cooling fan.

thingiverse

free

Tarantula cover for 5015 radial blower fan by Joshfitz

...tarantula cover for 5015 radial blower fan by joshfitz

thingiverse

5015 / 50mm radial fan inlet cover with tarantula on it.

grabcad

free

Venturi mask inlet

...venturi mask inlet

grabcad

variable venturi mask inlet.

thingiverse

free

Blower fan silencer 5015 and fan grill by Kallee

...s of the fan a little bit.

additionally it's a good fan grill.

feel free to contact me, if you've ideas for optimization.

thingiverse

free

30mm Fan Inlet Stack Noise Reducer by mbrady6

...randassociates.com/pdfs/ret_bellmouth_sept.pdf

also check out my designs for 40mm fans: https://www.thingiverse.com/thing:4794537

thingiverse

free

Single 5015 Blower Duct by uniformxray

...ower duct by uniformxray

thingiverse

a 5015 blower duct for one single fan and added a vane to guide the most of the flow to x/y

grabcad

free

Blower Industrial

...ir into the inlet of the blower housing while an axial flow fan or industrial axial fan uses a propeller to draw the air into it.

thingiverse

free

5015-4010 blower adapter for Satsana E3V2 fan duct by alantch

...gogler. temporary solution with the intent to upgrade to a 5015 blower at a later stage without having to reprint a new fan duct.

thingiverse

free

5015 Fan Blower Velocity Stack Intake Guard by roznerd

...see how i made it or make your own tweaks.

check out my other designs for other cool useful stuff for around the garage.........

thingiverse

free

QQS 5015 (50mm) blower fan to 4010 (40mm) blower fan by dewthehue

...) blower fan by dewthehue

thingiverse

use as an adapter for 5015 blower fan to 4010, this is mounted vertically on the flsun qqs

Fullplasticscientist

thingiverse

free

The CuLAW by FullPlasticScientist

... can also be used to open simple door handles

scale by ~70-80% in xy for children's size. listing is for generic adult size.

thingiverse

free

Axial fan exhaust covers by FullPlasticScientist

...sideways as part of the clear mask usb mask dryer. see my other designs.

leave a comment if you would like a different fan size.

thingiverse

free

Anti-Microbial general purpose handles by FullPlasticScientist

.... designed for optimal strength whilst using minimal material. see the original listing if you want to customize your own size.

thingiverse

free

Cu NANO Pen by FullPlasticScientist

...lock and let ink flow. small enough so if the ink cartridge leaks it should remain within the pen body and struggle to leak out.

thingiverse

free

Cu NANO Clip V1 by FullPlasticScientist

...nd width as necessary. prototype in normal pla first if scaling for other sizes to avoid wasting any plactive on printer tuning.

thingiverse

free

Mask Dryer V2 by FullPlasticScientist

... particles. this is an unproven concept device intended to aid development of clear mask technology and should be viewed as such.

thingiverse

free

Cu NANO Pen V2 by FullPlasticScientist

...m magnets or 2 off 10x3mm magnets)

-design for manufacture geometry optimisations

-optimised interference fit for biro ink insert

thingiverse

free

Helping hands phone tripod mount armor 9 by FullPlasticScientist

...one in place.

-optional fibre stick on pads for smaller phones such as old iphone 6. from anti scuff furniture leg sticker pads.

thingiverse

free

Antimicrobial filter mesh by FullPlasticScientist

...and produce better disease outcomes for all...

*the time has come to awaken him.... i command you to rise stribog! coming soon ;)

5015

3ddd

$1

Скамья RUGIANO - COPERTINA BRONZA, 5015/130GL

...a bronza, 5015/130gl

3ddd

rugiano , скамья

скамья rugiano - copertina bronza, 5015/130gl

3d_export

$15

3d hair style for girl v94

...: 4811 - edges : 9836 - faces : 5015 - tris : 9642 - uvs : 5364 file...

thingiverse

free

5015 fan duct

...5015 fan duct

thingiverse

5015 fan duct

thingiverse

free

5015 Fan Guard

...5015 fan guard

thingiverse

5015 fan guard

3dfindit

free

294-5015

...294-5015

3dfind.it

catalog: wago

thingiverse

free

40MM to 5015 Adapter by 360alaska

...by 360alaska

thingiverse

this will adapt a 5015 fan to a 40mm fan mount. the 5015 fan mounts at a right angle and rotates fully.

thingiverse

free

Chiron 5015 blower by DK_Davis

...chiron 5015 blower by dk_davis

thingiverse

anycubic chiron 5015 blower

thingiverse

free

single 5015 to 50mnm by Kyledavis417

...single 5015 to 50mnm by kyledavis417

thingiverse

single 5015 to 50mm for tevo controller box

thingiverse

free

Cetus 3D 5015 Duct

...cetus 3d 5015 duct

thingiverse

twisted 5015 fan duct for cetus 3d mk2

thingiverse

free

Dual 5015 to 50mm by Kyledavis417

...dual 5015 to 50mm by kyledavis417

thingiverse

dual 5015 fan adapter for tevo tornado controller box

Silencer

turbosquid

$5

Silencer

...alty free 3d model silencer for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1288625)

turbosquid

$10

Silencer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

silencer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Silencer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Silencer 3D Model

...silencer 3d model

3dexport

silencer

silencer 3d model sargent99 63624 3dexport

3d_export

$10

Silencer 3D Model

...ssault rifle sniper machine gatling gun pistol handgun weapon game ready gameready

silencer 3d model martialartist 22621 3dexport

turbosquid

$5

Silenced Revolver

...e 3d model silenced revolver for download as ma, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1355044)

turbosquid

$9

Silencer V5

...3d model silencer v5 for download as blend, obj, dae, and fbx on turbosquid: 3d models for games, architecture, videos. (1711483)

turbosquid

$9

silencer v4

...3d model silencer v4 for download as blend, dae, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1711410)

turbosquid

$9

Silencer V3

...del silencer v3 for download as blend, stl, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1711395)

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)