Thingiverse

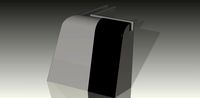

4.7L Mini ITX case, easily printable (2 major pieces), sandwich layout, no extra thread inserts, standoffs or feet required by ecor

by Thingiverse

Last crawled date: 3 years, 3 months ago

Overview

The idea behind this case is to be simple to print in terms of setup, required parts; and designed from scratch with 3d printing in mind versus taking an existing sheet metal case and cloning it.

I took inspiration for the assembly from the ASRock Deskmini series, and the k39 case for the layout and feel (although at a higher volume). Internal volume is about 4.7L

I print relatively slow (35-50mm/s) and use 1.75mm filament, so with my estimated price of ~$28 (high side) per kg of PETG filament

Spine: 170g, $5, 1 day to print

Case: 390g, $11, 2 days to print

GPU support: 5g, $0.15, 30 minutes to print

Not taking labor, parts or electricity into account, you'll pay around $16 for a mini itx case ( plus riser, I know)

Printable area required:

235x110mm for the maximum bed dimensions and ~200mm in height

All the fastener threads can be made with a metal screw (M3 and M4), no need to tap or weld thread inserts, just be careful when threading, and assembling it.

Before you start

Given that this is plastic, you'll need to keep some things in mind before printing and assembling it:

It will flex a little bit, but not enough to wobble when fully assembled and printed correctly

It won't feel like higher end aluminium cases because it's plastic

You'll need to do a good job cleaning up all the orifices and vents before screwing anything onto it, I didn't do great job (see pics) because I'm lazy, but also this is not my main computer, so I don't mind the extra micro strings

It will be more sensitive to overtorquing the fasteners than metal cases, so BE EXTRA careful or risk losing your threads

You'll need to have your printer properly dialed up for tall and long structures which means:

Proper dimensional calibration (failure to do this will result in poor assembly)

Proper flow calibration (over extrusion won't only affect appearance, it will also affect height and the nozzle may touch at the higher layers, which will deform it)

Proper bed leveling (large area is more sensitive to bad leveling)

Just the right bed adhesion (be careful of too much bed adhesion given the big area touching the bed)

Proper first layer height and bed texture/quality when printing the case, as the face of it will reflect your bed surface and first layer quality. Mine didn't came out great because of that, but yours can.

A printer that doesn't wobble/vibrate (tall structures may suffer from vibration, particularly the spine which needs to be somewhat straight and thin)

Print orientations

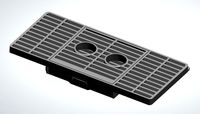

Case orientation: front face down (open cube at the top)

Spine orientation: back face down (IO shield down, tall-thin structure at the top)

GPU bracket: back face down

No supports

Material

Minimum material:

PETG.. particularly DO NOT PRINT SPINE IN PLA!!, the case MAY be more lenient, but I can't recommend it

Let me repeat that for you: DO NOT PRINT THE SPINE IN PLA

Be prepared to clean up a lot of strings (PETG) :)

Requirements

You'll need fasteners (M3 and M4, be very careful with torque), a PCI riser 200mm in cable length, 300 mm total (I tried only 1 but others may be compatible),

a CPU cooler with a max 38mm in height, a GPU that is at most 185mm in length (with a PSU with thin wires or ~175 for bulky wire ones), a Flex ATX PSU, and a MiniITX Motherboard.

This case supports 1 external SSD that is at most 9.5mm in thickness or you can always switch to M.2. I only tested a motherboard with an M.2 on the front, unfortunately the riser MAY interfere with one in the back depending on its position.

Stuff I used

Fasteners:

Set of M3-M5 flat head hex (look better, but you have to be cautious with torquing)https://amzn.to/33jtiRJ

...OR...

M3:https://amzn.to/3l1wN5m

M4 nylon:https://amzn.to/39inUC0

GPU Riser:

Phanteks "300mm" (end to end, cable is 200mm) 180 Degree riserhttps://amzn.to/2V0kSKB

Power Button:

Generic push button with 2 pin 0.1" connector (custom made, link is button only)https://amzn.to/3fDmNOo

If you drill a 12mm hole through the thin wall of the button it will fithttps://amzn.to/37avcVR

.. or similar ~12mm diameter buttons

GPU (max clearance: 2 slots, ~175mm for PSUs with thick wires, ~185mm for modular/thin wire PSUs), I used a GTX 1650:https://amzn.to/3l1x9ZK

PSU (thick and not very flexible cables, this is the worst case scenario IMO and works):

SilverStone, 350 Watt Flex ATXhttps://amzn.to/37ckwWD

CPU:

AMD Ryzen 3100https://amzn.to/3nVLyIK

CPU Cooler (clearance is about 38mm.. not great, I know):

Noctua NH-L9a AM4https://amzn.to/37avgF5

Motherboard:

B520https://amzn.to/3652GWs

Others

Filament:

SUNLU PETG (orange/black combo)https://amzn.to/3m85Iif

Exacto knife for cleaning extra materialhttps://amzn.to/3mc06Ui

My printer is a CR10 V2 and it's able to print the case:https://amzn.to/2V3RQcS

How to assemble/build

Clean up all the stringing and residue from all holes, particularly the ones that require threads

(don't tap, because in my experience this makes the thread too loose in PETG and the hole too wide) Thread the 3 holes in the case (M3), the 2 holes for the riser (M3), the 4 holes for the motherboard (M4) and the one for the GPU bracket (M4), this last one may require a nut given that sometimes one may want to overtighten it trying to secure the GPU, but it may not be necessary if you're careful. Use metal bolts for this, and do it slowly. M3 holes should be ~2.8-2.9 mm in diameter, M4 ones should be ~3.7-3.9mm and you should be ok, if it's less, try to make it the proper diameter, if it's more, you're kinda screwed, try filling up the wholes with baking soda and crazy glue, and redrilling/threading/tapping (never tried this, but it may work). You DON"T need to thread the PSU holes, the hard drive holes, the power button hole. These rely on the component's thread.

Install riser, try to bend it as compact as possible, route it through the back of the motherboard

Install IO shield

Install motherboard with everything attached to it, except cables, this will give rigidity to the spine

Install the GPU and its external bracket to secure it

Install PSU (BUT DON'T LIFT THE ASSEMBLY YET OR YOU RISK DAMAGING IT)

Install your SSD/HDD

Route all the cables to their destinations and bundle the rest at the "front" of the case, try to make it as compact as possible while leaving about 3-4 mm at the very front for the assembly to go into the case

Tie the bundle of cables to the spine tightly too, so that this gives rigidity to the spine/psu assembly

If you have a modular cable PSU, secure it through the back with a zip tie into the spine/assembly, so that it doesn't move from the back.

Insert the whole spine assembly into the case, making sure the top center rail/guide is aligned

Flip the case face side down, so that the spine assembly goes in easier

Make sure the spine is aligned with the "bottom" (in this orientation) "sockets" and push gently from the middle/top (in this orientation) spine, so that it goes all the way in. Depending on your printer tolerances, it may be more or less tight, but if everything lines up it should be no problem.

Fasten the 3 screws at the "top" (in this orientation) once the spine is flush with the case

The idea behind this case is to be simple to print in terms of setup, required parts; and designed from scratch with 3d printing in mind versus taking an existing sheet metal case and cloning it.

I took inspiration for the assembly from the ASRock Deskmini series, and the k39 case for the layout and feel (although at a higher volume). Internal volume is about 4.7L

I print relatively slow (35-50mm/s) and use 1.75mm filament, so with my estimated price of ~$28 (high side) per kg of PETG filament

Spine: 170g, $5, 1 day to print

Case: 390g, $11, 2 days to print

GPU support: 5g, $0.15, 30 minutes to print

Not taking labor, parts or electricity into account, you'll pay around $16 for a mini itx case ( plus riser, I know)

Printable area required:

235x110mm for the maximum bed dimensions and ~200mm in height

All the fastener threads can be made with a metal screw (M3 and M4), no need to tap or weld thread inserts, just be careful when threading, and assembling it.

Before you start

Given that this is plastic, you'll need to keep some things in mind before printing and assembling it:

It will flex a little bit, but not enough to wobble when fully assembled and printed correctly

It won't feel like higher end aluminium cases because it's plastic

You'll need to do a good job cleaning up all the orifices and vents before screwing anything onto it, I didn't do great job (see pics) because I'm lazy, but also this is not my main computer, so I don't mind the extra micro strings

It will be more sensitive to overtorquing the fasteners than metal cases, so BE EXTRA careful or risk losing your threads

You'll need to have your printer properly dialed up for tall and long structures which means:

Proper dimensional calibration (failure to do this will result in poor assembly)

Proper flow calibration (over extrusion won't only affect appearance, it will also affect height and the nozzle may touch at the higher layers, which will deform it)

Proper bed leveling (large area is more sensitive to bad leveling)

Just the right bed adhesion (be careful of too much bed adhesion given the big area touching the bed)

Proper first layer height and bed texture/quality when printing the case, as the face of it will reflect your bed surface and first layer quality. Mine didn't came out great because of that, but yours can.

A printer that doesn't wobble/vibrate (tall structures may suffer from vibration, particularly the spine which needs to be somewhat straight and thin)

Print orientations

Case orientation: front face down (open cube at the top)

Spine orientation: back face down (IO shield down, tall-thin structure at the top)

GPU bracket: back face down

No supports

Material

Minimum material:

PETG.. particularly DO NOT PRINT SPINE IN PLA!!, the case MAY be more lenient, but I can't recommend it

Let me repeat that for you: DO NOT PRINT THE SPINE IN PLA

Be prepared to clean up a lot of strings (PETG) :)

Requirements

You'll need fasteners (M3 and M4, be very careful with torque), a PCI riser 200mm in cable length, 300 mm total (I tried only 1 but others may be compatible),

a CPU cooler with a max 38mm in height, a GPU that is at most 185mm in length (with a PSU with thin wires or ~175 for bulky wire ones), a Flex ATX PSU, and a MiniITX Motherboard.

This case supports 1 external SSD that is at most 9.5mm in thickness or you can always switch to M.2. I only tested a motherboard with an M.2 on the front, unfortunately the riser MAY interfere with one in the back depending on its position.

Stuff I used

Fasteners:

Set of M3-M5 flat head hex (look better, but you have to be cautious with torquing)https://amzn.to/33jtiRJ

...OR...

M3:https://amzn.to/3l1wN5m

M4 nylon:https://amzn.to/39inUC0

GPU Riser:

Phanteks "300mm" (end to end, cable is 200mm) 180 Degree riserhttps://amzn.to/2V0kSKB

Power Button:

Generic push button with 2 pin 0.1" connector (custom made, link is button only)https://amzn.to/3fDmNOo

If you drill a 12mm hole through the thin wall of the button it will fithttps://amzn.to/37avcVR

.. or similar ~12mm diameter buttons

GPU (max clearance: 2 slots, ~175mm for PSUs with thick wires, ~185mm for modular/thin wire PSUs), I used a GTX 1650:https://amzn.to/3l1x9ZK

PSU (thick and not very flexible cables, this is the worst case scenario IMO and works):

SilverStone, 350 Watt Flex ATXhttps://amzn.to/37ckwWD

CPU:

AMD Ryzen 3100https://amzn.to/3nVLyIK

CPU Cooler (clearance is about 38mm.. not great, I know):

Noctua NH-L9a AM4https://amzn.to/37avgF5

Motherboard:

B520https://amzn.to/3652GWs

Others

Filament:

SUNLU PETG (orange/black combo)https://amzn.to/3m85Iif

Exacto knife for cleaning extra materialhttps://amzn.to/3mc06Ui

My printer is a CR10 V2 and it's able to print the case:https://amzn.to/2V3RQcS

How to assemble/build

Clean up all the stringing and residue from all holes, particularly the ones that require threads

(don't tap, because in my experience this makes the thread too loose in PETG and the hole too wide) Thread the 3 holes in the case (M3), the 2 holes for the riser (M3), the 4 holes for the motherboard (M4) and the one for the GPU bracket (M4), this last one may require a nut given that sometimes one may want to overtighten it trying to secure the GPU, but it may not be necessary if you're careful. Use metal bolts for this, and do it slowly. M3 holes should be ~2.8-2.9 mm in diameter, M4 ones should be ~3.7-3.9mm and you should be ok, if it's less, try to make it the proper diameter, if it's more, you're kinda screwed, try filling up the wholes with baking soda and crazy glue, and redrilling/threading/tapping (never tried this, but it may work). You DON"T need to thread the PSU holes, the hard drive holes, the power button hole. These rely on the component's thread.

Install riser, try to bend it as compact as possible, route it through the back of the motherboard

Install IO shield

Install motherboard with everything attached to it, except cables, this will give rigidity to the spine

Install the GPU and its external bracket to secure it

Install PSU (BUT DON'T LIFT THE ASSEMBLY YET OR YOU RISK DAMAGING IT)

Install your SSD/HDD

Route all the cables to their destinations and bundle the rest at the "front" of the case, try to make it as compact as possible while leaving about 3-4 mm at the very front for the assembly to go into the case

Tie the bundle of cables to the spine tightly too, so that this gives rigidity to the spine/psu assembly

If you have a modular cable PSU, secure it through the back with a zip tie into the spine/assembly, so that it doesn't move from the back.

Insert the whole spine assembly into the case, making sure the top center rail/guide is aligned

Flip the case face side down, so that the spine assembly goes in easier

Make sure the spine is aligned with the "bottom" (in this orientation) "sockets" and push gently from the middle/top (in this orientation) spine, so that it goes all the way in. Depending on your printer tolerances, it may be more or less tight, but if everything lines up it should be no problem.

Fasten the 3 screws at the "top" (in this orientation) once the spine is flush with the case

Similar models

thingiverse

free

NR200 PSU lift mod by pebst

...ng off and potentially hitting the motherboard.

the rectangle fixture is optional.

petg recommended for higher material strength.

3dwarehouse

free

Mining Rig

...at genesis mining youtube video. i got psu, gpu, motherboard and risers from warehouse. #miner #rig #gpu #motherboard #psu #riser

thingiverse

free

SSD mount for PCIE risers by somefreak

...oles (if there is none there already)

use 6 hdd screws to attach the mount to the case.

run your cables and plug in your cards :)

thingiverse

free

Slotted Meshify C PSU Shroud Plate by tactical-puke

...he slots to your cable routing needs

printed in pla with the standard cura settings. print with the top down on the build plate.

thingiverse

free

ASUS TUF Gaming GT501 GPU Riser Cover by kidnotorius

.../38tjleo

you should be able to use your slicing software to scale it to your specific needs if your set up is a little different.

thingiverse

free

Hyde, a DIY 3D-printable case by skiphix

...washers

angled ac psu cable

16mm anti vandal momentary button with thread length >= 12mm, pinheader cables, solder, heatshrink

thingiverse

free

Phonon Case - 5.6L APU Case by Makaba

...rews (6-32 thread) for fixing the psu. https://amzn.to/3ln17in

4 motherboard screws. https://amzn.to/3n58yo6

1 16mm power switch.

thingiverse

free

Small and stack miniITX Case by Ren_Dev

...stall "down_case" to "base_case"

install 4x"pad" to "base_case" or "down_case"

thingiverse

free

3D PCI-e Graphics Card GPU Stand by Daox

...02mm apart. i used 'asiahorse 180 degree riser extension cable' from amazon.

uses computer case screws for all hardware.

thingiverse

free

Basic Motherboard Stand - ATX Compatible by jeezy0025

...

2 longs & 1 short

the holes are not threaded but are made small enough to "thread" normal motherboard screws into.

Ecor

turbosquid

$9

ecoreal estate black coin

...y free 3d model ecoreal estate black coin for download as max on turbosquid: 3d models for games, architecture, videos. (1457749)

turbosquid

$9

ecoreal estate gold coin

...ty free 3d model ecoreal estate gold coin for download as max on turbosquid: 3d models for games, architecture, videos. (1457747)

thingiverse

free

Dan A4 SFX (V4+) +16mm side spacer with 2x USB-A by ecor

...he insert if there are requests (maybe just 1 usb?, maybe a blank for mods?, maybe a reset button?), let me know in the comments.

thingiverse

free

Dan A4 SFX (V4+) CPU & GPU Spacer (+16mm) for coolers up to 64mm or extra GPU clearance by ecor

...s that 0.2mm gap. if your gap is larger than 0.2mm, calibrate your printer.

update 2020-08-21

added gpu side for +16mm clearance.

cg_trader

$2

ecorative Stucco 355 - 8K Shader

...k shader

cg trader

ecorative stucco 355 - 8k shader 3d plaster gypsum, available in max, fbx, mat, ready for 3d animation and ot

cg_trader

$3

decorative set 13

...ooks, cup, glasses,...

polys:207436

vertx: 226419

version: 2016

format: max, obj

thank you for choosing my model!

enjoy your use!

cg_trader

$35

Small flowerpot 3 | 3D

...cacti bonsai flowerpot vase house decor artchallenge plant plants ecortion dae flower vase flowers vase flower vase house plant...

cults

free

Customizable Origami Elephant

...geometric geometrical home_decor jewelry lowpoly low_poly necklace origami pendant wall_decortion this is a customizable 2d origami art of a...

3dwarehouse

free

Edificio Ecor VI

...edificio ecor vi

3dwarehouse

edificio ecor vi

7L

turbosquid

$10

Lucente Amak 7L Suspension Light / Chandelier

...ion light / chandelier for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1212167)

3ddd

$1

Ledc c4 L7

...ledc c4 l7 3ddd leds c4 люстра leds c4 7l niagara...

3dfindit

free

RR-7L-3S-240G

...rr-7l-3s-240g

3dfind.it

catalog: usbfirewire

3dfindit

free

RR-7L-7F-05G

...rr-7l-7f-05g

3dfind.it

catalog: usbfirewire

3dfindit

free

RR-7L-7F-12G

...rr-7l-7f-12g

3dfind.it

catalog: usbfirewire

3dfindit

free

RR-7L-7F-24G

...rr-7l-7f-24g

3dfind.it

catalog: usbfirewire

3dfindit

free

RR-7L-3S-24G

...rr-7l-3s-24g

3dfind.it

catalog: usbfirewire

3dfindit

free

RR-7L-3S-72G

...rr-7l-3s-72g

3dfind.it

catalog: usbfirewire

3dfindit

free

RR-7L-3S-12G

...rr-7l-3s-12g

3dfind.it

catalog: usbfirewire

thingiverse

free

Canon NB-7L AC power adapter Powershot G10 etc by oregondesign

... bend them to secure, solder on your power supply. two screws to secure the back, but could be taped/glued if you'd rather.

Itx

3d_export

$56

teenage engineering computer 1 mini itx pc chassis

... get the best results in blender. no extra plugins are required for this model. lights and cameras are not included in the scene.

cg_studio

$9

Mini Computer3d model

...hardware harddisk desktop peripheral component leopard tiger snow small mini-itx pc design .3ds .xsi .obj .max .ma .lxo .lwo...

3d_export

$9

Mini Computer 3D Model

...hardware harddisk desktop peripheral component leopard tiger snow small mini-itx pc design maya supply 3ds max mini computer 3d...

thingiverse

free

ITX by irr1449

...itx by irr1449

thingiverse

itx case

thingiverse

free

Mini-ITX to Nano ITX adapter

...mini-itx to nano itx adapter

thingiverse

this is an adapter to put a nanoitx board in a miniitx case.

3dfindit

free

PICO-ITX

...pico-itx

3dfind.it

catalog: winsystems

3dfindit

free

NANO-ITX

...nano-itx

3dfind.it

catalog: winsystems

thingiverse

free

ITX computer case by hlmjjj1994

...itx computer case by hlmjjj1994

thingiverse

for itx mb only

thingiverse

free

Xbox-ITX

...originally went, mount the mini-itx motherboard on the original xbox mounting holes, and use the original power hole on the case.

thingiverse

free

thin ITX model by Goatee

...thin itx model by goatee

thingiverse

thin itx boards rough model

Standoffs

cg_studio

$30

AGM-154A Joint Standoff Weapon3d model

...

.3ds .c4d .lwo .max - agm-154a joint standoff weapon 3d model, royalty free license available, instant download after purchase.

3d_export

$5

smoke from standoff 2

...m uv.<br>texturs – substanse painter.<br>render - substanse painter iray.<br>model for octane render, unreal 4.

cg_studio

$89

Aim-9M3d model

... radar aim9 aim-9

.3ds .c4d .lw .ma .max .obj - aim-9m 3d model, royalty free license available, instant download after purchase.

3d_export

$60

northrop grumman b-2 spirit

...nuclear bombs. the b-2 is the only acknowledged aircraft that can carry large air-to-surface standoff in a stealth configuration.

3d_export

$15

nimrod anti tank missile

...gt;maps include; base, normal, height, rough, and metal.<br>nose glass is 512 x 512<br>https://stgbooks.blogspot.com/

thingiverse

free

20x20 standoff

...20x20 standoff

thingiverse

standoff for 8mm linear rails.

standoff distance 20mm

thingiverse

free

Standoff by charlespax

...standoff by charlespax

thingiverse

this is a standoff created to hold up a friend's monitor.

thingiverse

free

Standoff Holder by jfaller

...standoff holder by jfaller

thingiverse

holder for for m3x6 standoff.

thingiverse

free

Commodore 64 Standoffs

...odore 64. cut off old standoffs, sand smooth then attach these standoffs with epoxy. be sure to align with the holes in the case.

thingiverse

free

BTS7960 Standoff by AlbaTito

...bts7960 standoff by albatito

thingiverse

standoff for bts7960. m3 hardware

Sandwich

turbosquid

free

Sandwich

...turbosquid

royalty free 3d model sandwich for download as ma on turbosquid: 3d models for games, architecture, videos. (1281718)

3d_ocean

$4

Sandwiches

...ndwiches for your interior scene. model made in 3ds max 2014. render: corona renderer. also included .3ds .fbx .obj files. enjoy!

turbosquid

$25

Sandwich

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Sandwich

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

sandwich

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$19

Sandwiches

...k vray

3d model of two sandwiches in kaiser roll – one is half eaten. 3d scanned from real product. placed on square white plate.

3d_ocean

$19

Sandwiches

...ay

3d model of two sandwiches with fried chicken – one is half eaten. 3d scanned from real product. placed on square white plate.

3d_ocean

$9

Hotdog Sandwich

...hotdog sandwich

3docean

3d model cinema 4d food hotdog sandwich

hotdog sandwich 3d model created in cinema 4d r15

3d_export

$5

SANDWICH

... simple materials are used. the topology of the objects is correct. includes: 127774 polygons; 64070 peaks formats: blender; rar.

3d_export

$5

sandwich

... ray, therefore its lighting is quite professional, it can be used as a complement in a kitchen space, or as a simple decoration.

Major

design_connected

$16

Major majbi-a

...major majbi-a

designconnected

sitia major majbi-a computer generated 3d model. designed by dorigo, florenzo.

design_connected

$16

Major majai-a

...major majai-a

designconnected

sitia major majai-a computer generated 3d model. designed by dorigo, florenzo.

3d_ocean

$16

Marshall Headphones Major

...marshall headphones major

3docean

headphones major marshall

marshall headphones major

turbosquid

$25

Major balustrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Major majbi-h

...major majbi-h

designconnected

sitia major majbi-h computer generated 3d model. designed by dorigo, florenzo.

design_connected

$16

Major majbi-d

...major majbi-d

designconnected

sitia major majbi-d computer generated 3d model. designed by dorigo, florenzo.

design_connected

$16

Major majbi-c

...major majbi-c

designconnected

sitia major majbi-c computer generated 3d model. designed by dorigo, florenzo.

design_connected

$16

Major majai-d

...major majai-d

designconnected

sitia major majai-d computer generated 3d model. designed by dorigo, florenzo.

design_connected

$16

Major majbi-b

...major majbi-b

designconnected

sitia major majbi-b computer generated 3d model. designed by dorigo, florenzo.

design_connected

$16

Major majai-c

...major majai-c

designconnected

sitia major majai-c computer generated 3d model. designed by dorigo, florenzo.

Layout

turbosquid

$30

Layout exhibition

...

royalty free 3d model layout exhibition for download as max on turbosquid: 3d models for games, architecture, videos. (1577107)

turbosquid

$40

food court layout

...

royalty free 3d model food court layout for download as max on turbosquid: 3d models for games, architecture, videos. (1582200)

turbosquid

$20

Layout star decor

...

royalty free 3d model layout star decor for download as max on turbosquid: 3d models for games, architecture, videos. (1576183)

turbosquid

$1

Simple Mug For Layout

... 3d model simple mug for layout for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1332065)

turbosquid

$40

Office Layout Design

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Cafe design layout

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Pyramids of Giza - Layout

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$125

BIG VILLA HOME LAYOUT

...yalty free 3d model big villa home layout for download as skp on turbosquid: 3d models for games, architecture, videos. (1259969)

turbosquid

$90

iconic commercial buildings layout

... model iconic commercial buildings layout for download as skp on turbosquid: 3d models for games, architecture, videos. (1260664)

3ddd

$1

LAYOUT ISOLAGIORNO Easy mono sofa

... isolagiorno , easy

upholstered 3 seater sofa

dimensions: 230cm lenght

Feet

3d_export

$30

Legs and feet High feet 3D Model

...t high feet 3d model

3dexport

feet shoes sandal barefoot leg women

legs and feet high feet 3d model adrianaamerina 96817 3dexport

3ddd

$1

DUCK FEET LAMP

...duck feet lamp

3ddd

утка

duck feet lamp

turbosquid

$19

Feets 01

...3d model feets 01 for download as max, max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1624047)

turbosquid

$2

Robo3D Feet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Hands and Feet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Feet study

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Female Feet 01

...oyalty free 3d model feet 01 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1446069)

turbosquid

$15

Viabizzuno Big Feet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Male Legs and Feet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

container 20 feet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Extra

3d_export

$17

Extra 300

...extra 300

3dexport

extra 300

3ddd

$1

Fidel extra

...fidel extra

3ddd

новый стиль

новый стиль - fidel extra

3ddd

$1

RAPSODY extra

...rapsody extra

3ddd

новый стиль

новый стиль - rapsody extra

3ddd

$1

Столик Extra

...столик extra

3ddd

giannini

столик extra от giannini, италия.

3ddd

free

Extra Long

...ики fantoni, италия. имеет подсветку ( зеленая или белая). передняя панель выполнена из аккустических панелей.

текстуры в архиве.

3ddd

$1

Grammer / Extra

...ло , стул

офисное кресло extra фирмы grammer office. подробнее на www.grammer-office.com

3ddd

$1

Hennesy Paradis Extra

... алкоголь , коньяк

бутылка коньяка hennesy paradis extra

design_connected

$9

Extra Chair Leather

...xtra chair leather

designconnected

cappellini extra chair leather chairs computer generated 3d model. designed by fabien baron.

turbosquid

$30

Extra Beetle Lowpolys

...d model extra beetle lowpolys 3d for download as unitypackage on turbosquid: 3d models for games, architecture, videos. (1483177)

3ddd

$1

NADIR extra CF LB

...nadir extra cf lb

3ddd

новый стиль

новый стиль - nadir extra cf lb

Inserts

turbosquid

$10

insert a bracelet

... 3d model the link element insert for download as max and max on turbosquid: 3d models for games, architecture, videos. (1609593)

turbosquid

$56

Threaded Inserts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Insert for eggs

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$14

drawing of needle inserting machine

...lectronic manufacturers use pin machines to help customers to insert needles, so as to obtain processing costs and obtain wealth.

turbosquid

$5

IKEA Insert drawers

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

IKEA insert with door

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Siemsn EQ 6 Inlet insert

...placed there without any problems. the insert is then straight for normal cups and a square insert can be removed for large cups.

turbosquid

$25

eagle insert on leather or rubber

...eagle insert on leather or rubber for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1342476)

turbosquid

$14

sofa with pillows and decorative inserts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

metal insert for earring rings

...for earring rings for download as 3dm, 3dm, obj, pdf, and stl on turbosquid: 3d models for games, architecture, videos. (1569103)

Thread

3d_export

$5

threaded handle

...threaded handle

3dexport

threaded handle

turbosquid

free

threaded

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Tangle of thread

... tangle thread triangles – 36 in one strand in scene 300 thread includes materials includes 3 colors tangle thread in psd for ...

3d_export

$5

threaded lock handle

...threaded lock handle

3dexport

threaded lock handle

3d_export

$5

threaded machine handle

...threaded machine handle

3dexport

threaded machine handle

3d_export

$5

threaded door knob

...threaded door knob

3dexport

threaded door knob

3d_export

$5

threaded rope ring

...threaded rope ring

3dexport

threaded rope ring

3d_export

$5

threaded door knob

...threaded door knob

3dexport

threaded door knob

turbosquid

$56

Threaded Inserts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

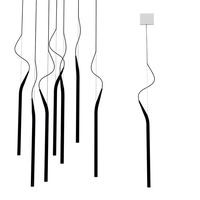

$10

Thread Lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Mini

turbosquid

$10

Mini Mini Luceplan

...

royalty free 3d model mini mini luceplan for download as max on turbosquid: 3d models for games, architecture, videos. (1227359)

3d_ocean

$39

Mini Cooper

...mini cooper

3docean

cabrioler cooper mini

mini cooper cabrioler

3d_export

$30

Mini lathe

...mini lathe

3dexport

mini lathe

3d_export

$5

mini mouse

...mini mouse

3dexport

mini mouse

3d_export

$5

mini house

...mini house

3dexport

mini house

3d_export

free

Mini Mecha

...mini mecha

3dexport

concept of mini mecha

3d_ocean

$20

Mini Gun

...mini gun

3docean

gatling gun gun machine gun mini gun weapon

model of a mini gatling gun.

3ddd

free

Herve mini

... кофейный , herve

http://www.mobiliavenanti.it/ru/products/hervè-mini

3d_export

$5

mini wall

...mini wall

3dexport

mini wall for living room

3d_export

$5

mini bank

...mini bank

3dexport

mini bank 3d model

Easily

3d_export

$5

red flower modeling by blender

...the texture and material of the object can be easily customized in shader view blender and it is easily...

3d_export

$5

curtain modeling by blender

...object is created in blender. this curtain can be easily customized using textures and materials.<br>in blender shader, you can...

3d_export

$7

studio fabric sofa

...studio fabric sofa 3dexport you can easily change the...

3d_export

$5

Cup

...cup 3dexport blue mug, it can also be easily repainted in any...

3d_export

$5

domilli sketchup house plan

...domilli sketchup house plan 3dexport easily editable house plan for students as well as...

3d_export

$40

wood cutting and shredding machine

...wood cutting and shredding machine 3dexport it can easily shred woods up to 20 cm...

3d_export

$29

Pilot Helmet

...ready to use pilot helmet, which can be imported easily and used in...

3d_export

$15

crown splash

...file in the animated .alembic format that you can easily open in any 3d application, cinema 4d, houdini, 3dmax,...

3d_export

$16

womennp2maxfbxobjmb

...womennp2maxfbxobjmb 3dexport polygonal model of a girl.<br>you can easily snap a skeleton for...

3d_export

$7

sofa furniture l

...l 3dexport all components are separate and can be easily changed in volume. materials in the folder are...

Required

turbosquid

$5

Snow chains required

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

cold coffee

...cold coffee 3dexport cold coffee can. any required modifications will be done at...

3d_export

free

Game console

...game console

3dexport

this is a model of a game console that does not require any plug-ins.

3d_export

$5

plummer block

...model of plummer block assembly where seven parts are required to assemble...

3ddd

$1

white table (wood)

...white table (wood) 3ddd обеденный tension mod required fbx and obj included high...

3ddd

$1

Fine Art Lamps 420840 Portobello

...portobello 3ddd fine art lamps no third party plugin required ...

3d_export

$7

kitchenware

...kitchen utensils includes all small electrical appliances that are required for interior...

3d_export

$5

star ball

...sizes. small, medium and original size. adhesive may be required ...

3d_export

$5

shock absorber

...absorber can also provide .stp or .iges format if required ...

3ddd

free

Moon Charme

...3ddd дверная ручка , ручка no third party plugin required hi detailed 3d...

Case

3d_export

$1

case

...case

3dexport

case

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case + cakes - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

showcase show-case glass case

glass-case for chips - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case shelving drawer

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case rack locker

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case drawer kitchen furniture

case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case cupboard shelving

glass case - 3d model for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case handbag suitcase

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

case suitcase

case 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Case

...case

archibase planet

locker case dresser

case - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Pieces

archibase_planet

free

Piece

...piece

archibase planet

sand-box playground

piece 8 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Piece

...piece

archibase planet

smithy forge farriery

piece 12 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$7

piece

...turbosquid

royalty free 3d model piece for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1407696)

archibase_planet

free

Piece

...piece

archibase planet

merry-go-round roundabout carrousel

piece 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

free

Lego piece

...lego piece

3dexport

lego piece<br>.stl

turbosquid

free

Chess Pieces

...es

turbosquid

free 3d model chess pieces for download as fbx on turbosquid: 3d models for games, architecture, videos. (1502330)

turbosquid

$5

Skywalk Piece

...quid

royalty free 3d model skywalk piece for download as max on turbosquid: 3d models for games, architecture, videos. (1422588)

turbosquid

$1

chess pieces

...squid

royalty free 3d model chess pieces for download as obj on turbosquid: 3d models for games, architecture, videos. (1562332)

turbosquid

$1

chess piece

...osquid

royalty free 3d model chess piece for download as fbx on turbosquid: 3d models for games, architecture, videos. (1369649)

turbosquid

free

Chess Pieces

...uid

royalty free 3d model chess pieces for download as blend on turbosquid: 3d models for games, architecture, videos. (1323069)

Printable

turbosquid

$5

printable giraffe

...uid

royalty free 3d model printable giraffe for download as on turbosquid: 3d models for games, architecture, videos. (1504825)

3d_export

$2

printable audi car

...printable audi car

3dexport

printable audi car

turbosquid

$23

Printable Statue

...ty free 3d model printable statue for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1415137)

turbosquid

$1

heart printable

...y free 3d model heart printable for download as stl and sldpr on turbosquid: 3d models for games, architecture, videos. (1209566)

turbosquid

$1

Printable Hook

...

royalty free 3d model 3d printable hook for download as stl on turbosquid: 3d models for games, architecture, videos. (1413683)

turbosquid

$30

Printable support

... model 3d printable support for download as max, 3ds, and stl on turbosquid: 3d models for games, architecture, videos. (1689342)

turbosquid

$24

Printable Dolphin

...el printable dolphin for download as , dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1602353)

turbosquid

$7

Printable Mug

...e 3d model 3d printable mug for download as obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1496940)

turbosquid

$40

Printable cottage

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Printable dice

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

4

turbosquid

$9

Office Chair 4-4

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

doors- 4

...doors- 4

3dexport

doors 4

3d_export

$5

hinge 4

...hinge 4

3dexport

hinge 4

3ddd

$1

Штора №4

...штора №4

3ddd

штора №4

3d_export

free

playstation 4

...playstation 4

3dexport

playstation 4

3ddd

$1

nexus 4

...nexus 4

3ddd

lg , телефон

nexus 4

3ddd

$1

4 Poufs

...4 poufs

3ddd

пуф

4 soft poufs

turbosquid

$12

Calligraphic Digit 4 Number 4

...hic digit 4 number 4 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389332)

3ddd

$1

Dauphin 4+

...dauphin 4+

3ddd

кресло

dauphin 4+ конференц кресло

3ddd

$1

iPhone 4

...

3ddd

apple , iphone , телефон

модель iphone 4.

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

turbosquid

$19

Loft wooden square box chandelier (2) (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

ALPEREN-2

...alperen-2

3ddd

комод , alperen-2

комод с зеркалом alperen-2

design_connected

$27

Confluences 2 2-Seater Sofa

... 2-seater sofa

designconnected

ligne roset confluences 2 2-seater sofa computer generated 3d model. designed by nigro, philippe.