Thingiverse

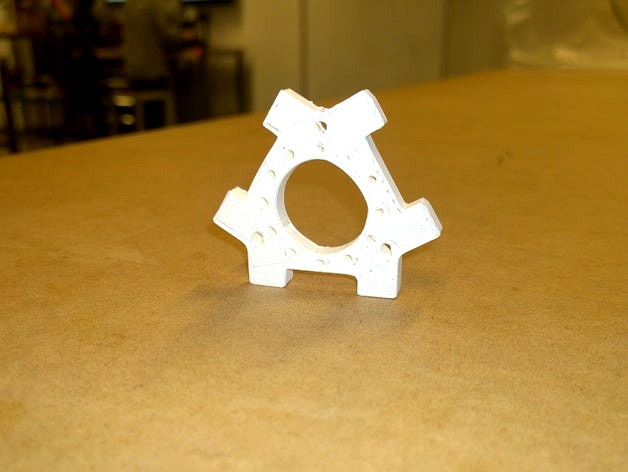

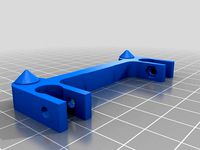

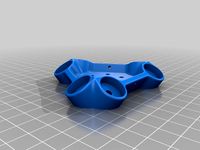

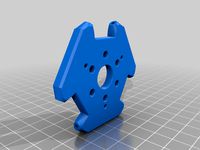

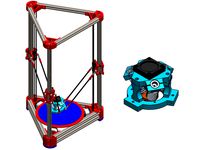

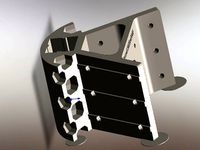

40mm kossel delta rostock E3D v6 metal effector. by ElJefeDSecurit

by Thingiverse

Last crawled date: 3 years ago

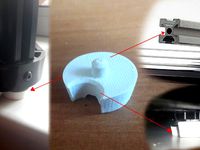

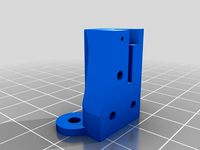

this is a slight remix of Mgx's effector, attempting to re-use dimensions from original Kossel mini mount holes, and align to a more asymmetric 40 mm rod width. I am still working out a 3-d model for machining the M3 mounts.

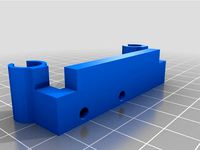

update 4/10/2015: I've since made this latest version. I discovered 2 things. first, the little lip in the middle would get in the way of the screws mounting the arms, and second, the original bracket didn't entirely line up with the holes, and there was just some simple dimension issues I didn't like. it is even bigger still, able to pass the entire hot end through the top. I posted the head bracket in visio for laser cutting out of wood, for example, or if you would rather, there is an stl for the same thing. you may have to adjust the height, as I laser cut mine, not printed, but they are here for your use. enjoy!

update 3/22:2015: i rebuilt it from the ground up... making the holes a little bigger all around...rounded the rod ends in case the angles might cause issues in the extreme edges... but as this is a little bigger head, it will need a recalibration.

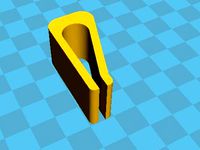

also made a press-clamp for it, as the earlier holes did not line up right. the mod(v2) and the mk3 are different hole lines. so do take note of the file dates.

Update 3/21/2015: I made an ABS print and am pleased enough for the next iteration. It did not come out as expected. all holes were too small for M3 /M4 respectively. the inside hole was 1.5 mm too small after a print. so I added a slight .25 opening on each. and added 3mmm holes all the way around, in case you want to tap, Or just run through in plastic. this should 3d print, and I included the holes for the arms. i'll try a reference print later. made a couple C clamp versions for laser cutting, as I am done with trying to print out anything in plastic to hold something made of metal. :)

Update 3/20/2015: I went back and took out the old kossel diameter and went back to the 25mm hole, to be able to pull a whole hotend thru it as well as open up other head types in the future. took out the ovals because they got in the way, and took out the circles to reduce cnc cutting costs. if anyone has ideas on how to add M3 holes that don't affect the rods at the extreme angles like the orignal model, i'm all eyes/ears, and whether i should just tap for M3, or cut outright to M3.5 and include space for an M3 nylock nut as in the original. if that is the case, i might just instead start up a kickstarter to have a bunch machined, if there's enough interest...

update 4/10/2015: I've since made this latest version. I discovered 2 things. first, the little lip in the middle would get in the way of the screws mounting the arms, and second, the original bracket didn't entirely line up with the holes, and there was just some simple dimension issues I didn't like. it is even bigger still, able to pass the entire hot end through the top. I posted the head bracket in visio for laser cutting out of wood, for example, or if you would rather, there is an stl for the same thing. you may have to adjust the height, as I laser cut mine, not printed, but they are here for your use. enjoy!

update 3/22:2015: i rebuilt it from the ground up... making the holes a little bigger all around...rounded the rod ends in case the angles might cause issues in the extreme edges... but as this is a little bigger head, it will need a recalibration.

also made a press-clamp for it, as the earlier holes did not line up right. the mod(v2) and the mk3 are different hole lines. so do take note of the file dates.

Update 3/21/2015: I made an ABS print and am pleased enough for the next iteration. It did not come out as expected. all holes were too small for M3 /M4 respectively. the inside hole was 1.5 mm too small after a print. so I added a slight .25 opening on each. and added 3mmm holes all the way around, in case you want to tap, Or just run through in plastic. this should 3d print, and I included the holes for the arms. i'll try a reference print later. made a couple C clamp versions for laser cutting, as I am done with trying to print out anything in plastic to hold something made of metal. :)

Update 3/20/2015: I went back and took out the old kossel diameter and went back to the 25mm hole, to be able to pull a whole hotend thru it as well as open up other head types in the future. took out the ovals because they got in the way, and took out the circles to reduce cnc cutting costs. if anyone has ideas on how to add M3 holes that don't affect the rods at the extreme angles like the orignal model, i'm all eyes/ears, and whether i should just tap for M3, or cut outright to M3.5 and include space for an M3 nylock nut as in the original. if that is the case, i might just instead start up a kickstarter to have a bunch machined, if there's enough interest...

Similar models

thingiverse

free

Kossel Igus+v6 Effector by goeland86

...he carriage side just fine. only on the effector were they too close together.

so, space the ending on the effector a bit.

enjoy!

thingiverse

free

Proximity Sensor for Mini Kossel Effector by Hideto

...proximity sensor for mini kossel effector by hideto

thingiverse

use effector m3 hole.

thingiverse

free

Kossel effector with 1/8"BST Pneufit adapter v2 by stone2339

...choll (https://github.com/jcrocholl/kossel/).

this works out very well - screw in the pneufit while it is still hot preferably.

thingiverse

free

Kossel based magnetic effector + self-locking carriages (10 mm magnets) by docpayce

...there is now also a version to accomodate for magnets with 12 mm diameter, check it out: http://www.thingiverse.com/thing:1584513

thingiverse

free

FLSUN Kossel LCD-Case by Geekdad_3D

...e for the pot knob bigger to fit the knob on my flsun kossel xl. also made the "speaker" holes bigger and more of them.

thingiverse

free

Cable stabilizer for 'Kossel effector' by Belgokauf84

...ce on the cables and the ptfe tube!!!

just cut an m4 thread into the 2 unused holes / fix with 2x m4x10mm screws and one m3x20mm.

thingiverse

free

JOEQU kossel effector for E3Dv5 remix by mooninman

...cm fan only want use joequ kossel effector

40mm fan x3

e3dv5 x1

m3 snew little...

add all in one 40mm effector and 42mm effector

thingiverse

free

mini Kossel jSlot mount - OpenSCAD by Jaydmdigital

...th e3d and makergear v3, but if you have a different hotend, you can modify as needed.

the stl has a 0.2mm layer for printing.

thingiverse

free

Kossel Mini SmartLCD-Case cut up for small printbeds by heinzdrei

....

all real work done by: http://www.thingiverse.com/thing:320117

please see there for additional information and instructions.

thingiverse

free

Laser Cut iPhone 4 Case by robyward

...dd a blog on the making of this to www.sharemake.com. i also drew this up on a new free dxf creator draftsight. check it out...

Eljefedsecurit

thingiverse

free

E3D V6 groove mount with BLtouch bracket. by ElJefeDSecurit

...mount...compatible with my magnetic effector mod. nothing special, except that it's measured to spec at 8.3 mm offset. enjoy!

thingiverse

free

LED support ring with bltouch bracket. by ElJefeDSecurit

... also am adding a bl-touch z-probe sensor, so in the interest of simplicity, i added my universal bracket to this as well.

enjoy!

thingiverse

free

RAspberry PI Holders by ElJefeDSecurit

...3d printer xl, but the idea is the same. the last one is the camera experiment, where it would hang off the end of a build plate.

thingiverse

free

kossel magnetic ball stud carriage redux by ElJefeDSecurit

...on.

bored the holes so that you can use 30mm m3 screws with delrin wheels.

also added a tensioner for use with 3 delrin wheels.

thingiverse

free

universal bltouch mount for E3D v6 by ElJefeDSecurit

...mpatible with others. if not, point me to your carriage bracket and i'll see what i can do. :)

if you make one let me know :)

thingiverse

free

Magnetic Kossel effector e3d compatible (45mm centers) -modified by ElJefeDSecurit

...e fact that the led ring would hit the screws and get all warped and out of shape. adding 2 mm height should compensate for that.

thingiverse

free

kossel self-locking carriage for reticulating mounts by ElJefeDSecurit

...me wiggle and play, but it works well and doesn't slip, that is for sure. if there is interest for pics for proof. lemme know

thingiverse

free

Diamond delta magnetic Effector V3 by ElJefeDSecurit

...arms, but i would love to get some feedback on this on how well this works if anyone does give it a try. drop me a line and a pic

thingiverse

free

Diamond hotend Nozzle -Kossel / Delta mod. by ElJefeDSecurit

...nozzle, so if anyone print one and assemble it for proofs, please let me know if you do and any adjustments that need to be made.

Rostock

thingiverse

free

Endstop for Rostock by Raz0neR

...endstop for rostock by raz0ner

thingiverse

endstop for rostock.

thingiverse

free

Rostock Cooling by nobicore

...rostock cooling by nobicore

thingiverse

rostock cooling

thingiverse

free

ROSTOCK PARTS by OC3D

...rostock parts by oc3d

thingiverse

parts for our modified rostock extruder assembly

thingiverse

free

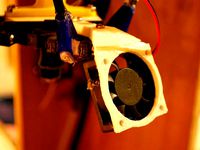

Rostock squirrel fan by MarioPanic

...rostock squirrel fan by mariopanic

thingiverse

rostock squirrel fan

thingiverse

free

FC Hansa Rostock by ron86

...fc hansa rostock by ron86

thingiverse

fc hans rostock logo

thingiverse

free

rostock mini carriage by cjol

...rostock mini carriage by cjol

thingiverse

carriage for my rostock mini project

thingiverse

free

Rostock and Rostock Mini Dual Extruder Mount by westonshakespear

...ht.

sorry about the pictures, my filament jammed for part of the print and i am waiting for a new part to print a better version.

thingiverse

free

Rostock mini clip by Scott_Chen

...rostock mini clip by scott_chen

thingiverse

rostock mini clip for printer base glass

thingiverse

free

Rostock Board holder by drewan

...rostock board holder by drewan

thingiverse

this is a clip for using a rostock board as a print surface.

thingiverse

free

Rostock Fan Bracket by ImprisonedByTime

...rostock fan bracket by imprisonedbytime

thingiverse

this bracket is for a 40mm fan to attach to the rostock 3d printer

Effector

3d_ocean

$5

Radial Sound Effector

...e spheres will expand with your song. fully customisable, change the color, the size of the spheres or even put in different s...

3d_ocean

$12

3D Customizable Puzzle Set (16x10)

...mograph compatible (you can effect the pieces with mograph effector) - included also a non-mograph version with...

thingiverse

free

Effector by olo2000pm

...effector by olo2000pm

thingiverse

effector

thingiverse

free

CERAMBOT-Effector

...cerambot-effector

thingiverse

cerambot-effector

thingiverse

free

modulize effector by candyasdf

...ulize effector by candyasdf

thingiverse

mount things on effector with m3 screws

effector radius : 25.4mm

rod arm distance : 40mm

thingiverse

free

Delta Effector by zavier

...delta effector by zavier

thingiverse

delta effector with radial fan 50 and bltouch

thingiverse

free

D810 Effector by WhiteTiger13

...d810 effector by whitetiger13

thingiverse

this is d810 effector for d810 without autocalibration, and also cap for it.

thingiverse

free

Effector for Delta Printer

...effector for delta printer

thingiverse

effector for delta printer (3 color)

using diamond hotend

thingiverse

free

Delta effector magnetic by fpassos

...delta effector magnetic by fpassos

thingiverse

effector for e3dv6 hotend. i needed put the spheres (10mm) on the effector.

thingiverse

free

End Effector Gripper

...end effector gripper

thingiverse

end effector gripper

for a robotic arm

uses mg995 servo motor

Kossel

thingiverse

free

kossel bottom by keisukelin

...kossel bottom by keisukelin

thingiverse

kossel bottom

thingiverse

free

Leg for kossel by exelon

...leg for kossel by exelon

thingiverse

leg for kossel

thingiverse

free

Extruder for kossel by spencer_chen7

...extruder for kossel by spencer_chen7

thingiverse

extruder for kossel

thingiverse

free

Kossel parts by breezer83

...kossel parts by breezer83

thingiverse

kossel parts

thingiverse

free

Anycubic Kossel PID calibration

...ir mount:

kossel raspberry camera ir mount

extruder pid calibration.

simple extruder temperature calibration of your 3d printer.

thingiverse

free

Kossel Medium by flux83

...kossel medium by flux83

thingiverse

vertex for upgraded kossel mini

thingiverse

free

Kossel Mini by salesmendesandre

...kossel mini by salesmendesandre

thingiverse

custom kossel mini

frame 20x20

thingiverse

free

leg for kossel by ionulet

...leg for kossel by ionulet

thingiverse

leg for kossel with channel for end- stop cables

thingiverse

free

Optical Endstops Mounts for Kossel (with Better Kossel carriages) by dellfer

...stops on the anycubic kossel with better kossel carriages by codefreak https://www.thingiverse.com/thing:2501337

more precission

thingiverse

free

kossel??????? by wangrui19890704

...kossel??????? by wangrui19890704

thingiverse

??2020?2060???

Delta

design_connected

$16

Delta

...delta

designconnected

arflex international spa delta computer generated 3d model. designed by koivisto, eero.

design_connected

$16

Delta

...delta

designconnected

lj lamps delta computer generated 3d model. designed by janowski-lenhart, sasha.

design_connected

$13

Delta

...delta

designconnected

emu group delta armchairs computer generated 3d model. designed by marin chiaramonte .

3ddd

$1

Delta Light

...delta light

3ddd

delta light , you-turn reo 3033

точечний светильник delta light

3ddd

$1

Blanco / delta

...blanco / delta

3ddd

blanco , мойка

мойка blanco delta со смесителем

3ddd

$1

Delta Light Spot

...delta light spot

3ddd

delta light

светильник фирмы delta light

3ddd

free

Bianchi Delta LVMDLT200100

...i delta lvmdlt200100

3ddd

bianchi delta , смеситель

смеситель bianchi delta lvmdlt200100

design_connected

free

Delta 190

...delta 190

designconnected

free 3d model of delta 190 by zanotta designed by progetti, emaf.

design_connected

$27

Delta 211

...delta 211

designconnected

zanotta delta 211 computer generated 3d model. designed by progetti, emaf.

design_connected

$27

Delta 234

...delta 234

designconnected

zanotta delta 234 computer generated 3d model. designed by progetti, emaf.

E3D

turbosquid

$23

E3D - Google Home

... 3d model e3d - google home for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1192509)

cg_studio

free

e3d model

...e3d model

cgstudio

- e 3d model, royalty free license available, instant download after purchase.

turbosquid

$2

Syringe C4D (E3D Ready)

...lty free 3d model syringe c4d (e3d ready) for download as c4d on turbosquid: 3d models for games, architecture, videos. (1336720)

turbosquid

$12

Microphone USB E3D and C4D

...ree 3d model microphone usb e3d & c4d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1568216)

turbosquid

$29

E3D - OnePlus 6 Black

...model e3d - oneplus 6 black for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358534)

turbosquid

$29

E3D - Motorola One 2018

...del e3d - motorola one 2018 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1358533)

turbosquid

$29

E3D - Disney MagicBands 2

...l e3d - disney magicbands 2 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1355515)

turbosquid

$29

E3D - Samsung Z4 Smartphone

...e3d - samsung z4 smartphone for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1182179)

turbosquid

$23

E3D - Razer Phone model

...del e3d - razer phone model for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1231207)

turbosquid

$23

E3D - Alcatel Idol 5

... model e3d - alcatel idol 5 for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1212799)

V6

3d_export

$100

v6 engine

...engine

3dexport

complete v6 engine modeled on solidworks 2017 along with .stl, .sldprt and .sldasm of all th parts and assembly.

3d_export

$10

V6 engine

... the first v6 engines were designed and produced independently by marmon motor car company, deutz gasmotoren fabrik and delahaye.

3d_export

$35

v6 engine

...s a complete model of a v6 engine containing over 400 components. you can contact me for a video of all the components assembling

3d_export

$10

v6 engine

...v6 engine

3dexport

turbosquid

$25

Bed1001-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Chair2-v6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

V6.mb

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

V6 engine

...rovided in this package is all the parts in sldprt format and assembly in sldasm format. i can also convert the format on demand.

3ddd

$1

Стол V6

...6" в стиле дизельпанк изготовлен из блока двигателя, 4х поршней и 4х шатунов.

столешница изготовлена из стекла толщиной 8мм.

cg_studio

$199

V6 VVTi3d model

...v6 vvti3d model

cgstudio

.3ds - v6 vvti 3d model, royalty free license available, instant download after purchase.

40Mm

turbosquid

$10

40MM Bullet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

40mm Vickers-Terni

... free 3d model 40mm vickers-terni for download as lwo and obj on turbosquid: 3d models for games, architecture, videos. (1260063)

turbosquid

$3

40mm grenade M9XX

...y free 3d model 40mm grenade m9xx for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1408150)

turbosquid

$3

40mm grenade M3XX

...y free 3d model 40mm grenade m3xx for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1408145)

turbosquid

$3

40mm grenade M1XX

...y free 3d model 40mm grenade m1xx for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1408144)

turbosquid

$8

40mm Smith & Wesson

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Free 40mm grenade M433

...e 3d model free 40mm grenade m433 for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1404768)

turbosquid

$98

40mm 6G30 grenade launcher

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Famas G2 M203 40mm.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

40mm Bofors TNT-11606

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Metal

3d_ocean

$10

Metal Barrel

...metal barrel

3docean

barrel barrels metal metal barrel wood barrel

metal barrel

turbosquid

$14

Metals

...als

turbosquid

royalty free 3d model metals for download as on turbosquid: 3d models for games, architecture, videos. (1486252)

3d_ocean

$18

Metal Furniture

...metal furniture

3docean

design desk indoor industrial metal metal furniture restoration table

metal furniture 3d model

3d_export

$5

metal table

...metal table

3dexport

metal table.blend

3d_export

$5

Metal Shelf

...metal shelf

3dexport

metal shelf

3d_export

free

metal detector

...metal detector

3dexport

metal detector

3ddd

$1

metal lux

...metal lux

3ddd

dedalo , metal lux

люстра и бра metal lux коллекция dedalo.

3ddd

$1

bonded metal

...bonded metal

3ddd

https://www.forms-surfaces.com/bonded-metal

boded tiled metal

3ddd

$1

Metal

...metal

3ddd

1280-1024 бесшовный 8-)

3d_export

$5

cgaxis metal

...cgaxis metal

3dexport

notebook cgaxis metal