Thingiverse

40mm Extruder fan grille (Wanhao Di3/Maker Select) by Dracos

by Thingiverse

Last crawled date: 2 years, 12 months ago

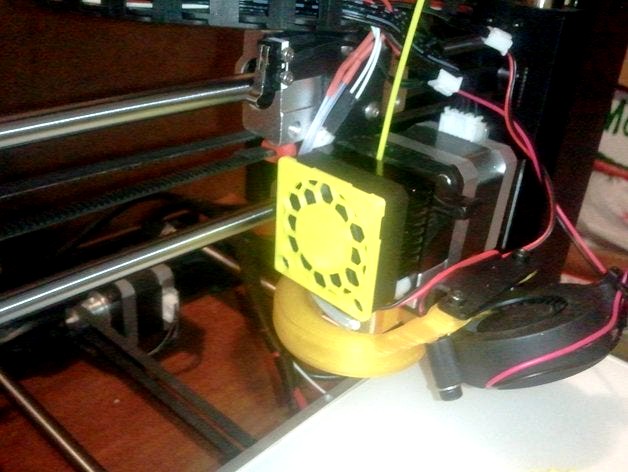

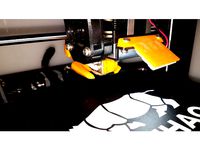

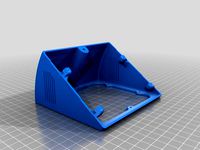

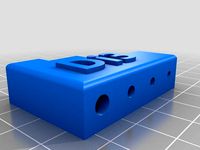

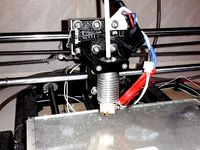

I was looking at extruder fan grilles for my Maker Select, and considered a few, but they all seemed to have one or another near-fatal flaw. This is my attempt to combine ideas from all the grilles I looked at and solve their flaws.

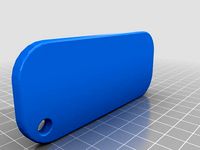

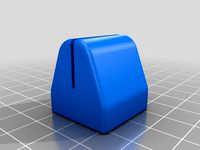

The hexagon pattern is specifically made with ribs .8mm wide to ensure two nozzle passes using the stock .4mm nozzle, and to restrict a minimum of airflow. Orignially the hex pattern went all the way across, but then I remembered why we use these: to protect the fan while giving us a place to push the carriage. This is where the central disk came in.

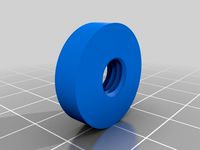

The next problem to solve was mounting it. Other designs have their own well for the screw head, which can affect how much thread engages with the motor body. M3x55 or M3x60 screws can he hard to find, so I avoided that possibility altogether by just making the holes for the screws to pass through.

Some other designs use slotted pins. I printed two iterations with slotted pins, and the pins broke off of both of them. Another option I considered and discarded was to integrate small clips into the design. I considered the bottom side a hot zone unsuitable for PLA, and the heat sink severely limits clip size. So that was out.

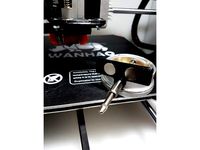

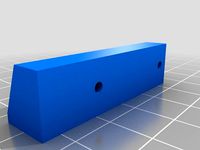

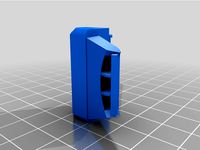

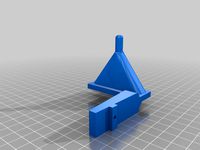

The only mounting soliution left was press fit. That is, solid pins that are just oversize for an M3 hole to hold the grille in place by friction. The pin diameters match the screw size at the ends, but bulge out to .25mm more than the screw size in the middle. The narrow end helps with insertion, and because some fans have head wells on one or both sizes of the fan chassis, the only reliable hold area was the middle, hence the bulge.

The slots around the back edge are to aid in removing the grille if the fit is tight. Insert a flat screwdriver and twist so that the side of the slot near the pin gets pulled away.

Variation in fan design is why there are two versions. Some fans have M3 holes, other have M4. Each file is named for the screw size that matches the pins. If you have a stock fan, use the M3 version.

The M3 grille I printed fits with barely any force required, yet doesn't rattle and hasn't fallen off.

EDIT: The 'b' files add .05mm diameter to the thick part of the pins (to nominal + .3mm), which should make for a tighter fit.

The hexagon pattern is specifically made with ribs .8mm wide to ensure two nozzle passes using the stock .4mm nozzle, and to restrict a minimum of airflow. Orignially the hex pattern went all the way across, but then I remembered why we use these: to protect the fan while giving us a place to push the carriage. This is where the central disk came in.

The next problem to solve was mounting it. Other designs have their own well for the screw head, which can affect how much thread engages with the motor body. M3x55 or M3x60 screws can he hard to find, so I avoided that possibility altogether by just making the holes for the screws to pass through.

Some other designs use slotted pins. I printed two iterations with slotted pins, and the pins broke off of both of them. Another option I considered and discarded was to integrate small clips into the design. I considered the bottom side a hot zone unsuitable for PLA, and the heat sink severely limits clip size. So that was out.

The only mounting soliution left was press fit. That is, solid pins that are just oversize for an M3 hole to hold the grille in place by friction. The pin diameters match the screw size at the ends, but bulge out to .25mm more than the screw size in the middle. The narrow end helps with insertion, and because some fans have head wells on one or both sizes of the fan chassis, the only reliable hold area was the middle, hence the bulge.

The slots around the back edge are to aid in removing the grille if the fit is tight. Insert a flat screwdriver and twist so that the side of the slot near the pin gets pulled away.

Variation in fan design is why there are two versions. Some fans have M3 holes, other have M4. Each file is named for the screw size that matches the pins. If you have a stock fan, use the M3 version.

The M3 grille I printed fits with barely any force required, yet doesn't rattle and hasn't fallen off.

EDIT: The 'b' files add .05mm diameter to the thick part of the pins (to nominal + .3mm), which should make for a tighter fit.

Similar models

thingiverse

free

Anet A8 50mm extruder fan adapter + heatsink hole cover by yclee126

...tock nozzle size)

tight one is barely possible for inserting screws, i recommend loose one.

designed in freecad, rotated in cura.

thingiverse

free

Gauge holder on 40x40 fan

...uder on my anet a8 but the gauge holder is designed to fit any extruder using 40x40 fan for cooling (e.g. the stock mk8 extruder)

thingiverse

free

Solve "Fan Nozzle Droop" with this Original Prusa i3 MK2 Part Cooling Fan Shroud with Integrated Nozzle by riskable

... real thing in the video :)

edit: separated the fan shroud w/nozzle and the "mk2" grill/cover into separate .stl files.

thingiverse

free

fan m150 screwhole by jkemi

...0 screwhole by jkemi

thingiverse

fan (40x40) nozzle with screw holes. intentionally tight m3 screw holes (drill for desired fit)

thingiverse

free

Fan mount FT-5 (Stock) by warkoskib

...n mount are flushinstall mount using m3 10mm screws and flat square bolt as found in kitreinstall extruder motor

adjust as needed

thingiverse

free

PrintrBoard Case by Lord_Vader

...ue to warping (case) and abs (lid).

the holes for the lid and the fan are for m3 (threading) but you can use selftapping screws

thingiverse

free

Coldend / Hotend Fan Holder Tevo Tornado by pemic

....12.2017:

jerrymcmackin created a remix of the grill for dual layer fans, i added his stl and his photo (thanks jerrymcmackin !).

thingiverse

free

Cowboy Bebop Fan Grill by TinkerMan92

...e from cowboy bebop

no supports

screw holes are smaller to allow different size screws, recommend drilling hole to fit screw size

thingiverse

free

R3 Volcano Adaptor V2 by martinrwolfe

...t the part with a skirt.

it can be used to fit the r3 print fan nozzle to the r1, r2 and r3 extruder cover and body if requiered.

thingiverse

free

east3D Gecko Remix E3D fan with integrated layer-fan by delukart

... !hot! to gecko) and opened up the thru-hole a bit to allow the m3 screw to fit easier. (needs to be positioned letter side down)

Di3

thingiverse

free

Wanhao Di3 v2 Light / Wanhao Di3 v2 Beleuchtung by JMDesigns

...wanhao di3 v2 light / wanhao di3 v2 beleuchtung by jmdesigns

thingiverse

wanhao di3 v2 light / wanhao di3 v2 beleuchtung

thingiverse

free

Wanhao Di3 MagFix System by JMDesigns

...wanhao di3 magfix system by jmdesigns

thingiverse

wanhao di3 magfix system

thingiverse

free

Wanhao Di3 Silicone Softgrip by JMDesigns

...wanhao di3 silicone softgrip by jmdesigns

thingiverse

wanhao di3 silicone softgrip

thingiverse

free

Di3 rotary dial by 3Dplanner

...hingiverse

original model of jo3ri http://www.thingiverse.com/thing:33286 , adjusted for the di3.

layer 0.2

shell 2

fill 50%

pla

thingiverse

free

Di3 LCD Angler ( With Air Vents ) by diamonddrake

...3 lcd angler ( with air vents ) by diamonddrake

thingiverse

this is a remix of rtideas di3 lcd angler, i simply added air vents.

thingiverse

free

Di3 Hex Wrench Holder by BliNDF123

...de a hex wrench holder for the ones that come with the di3, stuck it to the side frame of my printer with some double sided tape.

thingiverse

free

E3D v6 mount for Wanhao Di3 by slimc

...w design http://www.thingiverse.com/thing:1657971

set of components that allow the e3d v6 hotend to be mounted on the wanhao di3.

thingiverse

free

Wanhao Di3 V2.1 Knob Grip by Hyperlinks

...

thingiverse

this is a remix for the di3 v2.1. it did not fit properly on my printer (too tall), so i scaled it down minus 7 mm.

thingiverse

free

Wanhao Di3+ filament cleaner by Alpin3D

...wanhao di3+ filament cleaner by alpin3d

thingiverse

v1.1

filament cleaner / sponge

v1.2

better filament control

thingiverse

free

Di3 Nozzle LED Mount by sprfly

...e cooler. uses a 3 led section of self adhesive strip leds. i tapped into the always on hotend fan to provide the 12v to my leds.

Dracos

turbosquid

$150

Draco

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Draco

...draco

3ddd

дракон , дракон profi

игрушка, мягкая, дракон

3d_export

$10

Toy Draco 3D Model

...toy draco 3d model

3dexport

toy draco

toy draco 3d model nlena1208 64516 3dexport

turbosquid

$5

Little Draco

...odel little draco for download as c4d, obj, dae, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1708340)

3d_export

$10

dracaena draco dragon tree

...dracaena draco dragon tree

3dexport

dracaena draco | dragon tree

turbosquid

$20

BC Rich Draco Guitar

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$69

Electric guitar B C Rich DRACO

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Dracaena Draco trees

...00 cm<br>formats<br>3ds max - vray / corona<br>cinema4d<br>blender<br>obj<br>fbx<br>stl

3d_export

$5

Red Dragon 3D Model

...red dragon 3d model

3dexport

red dragon monster skyrim draco dragons

red dragon 3d model liquidsunproductions 63440 3dexport

3d_export

$99

Dragon skeleton 3D Model

...ture winged wings flying fantasy tower bones animal foot leg arm skull ribs castle

dragon skeleton 3d model rembex 27923 3dexport

Wanhao

thingiverse

free

Wanhao Logo Plate / Wanhao Logo Schild by JMDesigns

...wanhao logo plate / wanhao logo schild by jmdesigns

thingiverse

wanhao logo plate / wanhao logo schild

thingiverse

free

Wanhao logo by nebtio

...wanhao logo by nebtio

thingiverse

wanhao logo

thingiverse

free

Wanhao keychain by Rein3003

...wanhao keychain by rein3003

thingiverse

a keychain with the logo of wanhao

thingiverse

free

Wanhao Di3 v2 Light / Wanhao Di3 v2 Beleuchtung by JMDesigns

...wanhao di3 v2 light / wanhao di3 v2 beleuchtung by jmdesigns

thingiverse

wanhao di3 v2 light / wanhao di3 v2 beleuchtung

thingiverse

free

TUSH For Wanhao by wtmi1992

...tush for wanhao by wtmi1992

thingiverse

the ultimate spool holder, modified for the top of the wanhao control box. fits snug.

thingiverse

free

fanduct wanhao d12 by theopoilmek

...fanduct wanhao d12 by theopoilmek

thingiverse

fanduct pour wanhao d12

thingiverse

free

Wanhao i3 Marlin by johan21

...wanhao i3 marlin by johan21

thingiverse

marlin for wanhao i3 rampsboard 1.4.

thingiverse

free

Wanhao Duplicator i3 by imagineering4

...wanhao duplicator i3 by imagineering4

thingiverse

these are the stl files for the improvements to the wanhao duplicator i3, v2

thingiverse

free

Wanhao D6 filament guard

...wanhao d6 filament guard

thingiverse

this is a filament guard for wanhao d6 machine to avoid the filament unrolling

thingiverse

free

Wanhao Duplicator i3 Model by Hilde3D

...wanhao duplicator i3 model by hilde3d

thingiverse

wanhao duplicator i3 model

Grille

archibase_planet

free

Grill

...grill

archibase planet

grill brazier

grill n010807- 3d model for interior 3d visualization.

archibase_planet

free

Grill

...grill

archibase planet

barbecue grill

gas grill n080908 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Grill

...grill

archibase planet

grill equipment

kolagrill n211009 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$10

grill

...rill

turbosquid

royalty free 3d model grill for download as on turbosquid: 3d models for games, architecture, videos. (1448747)

3d_export

$25

Balcony grills and ornamental grills 3D Model

...amental grills 3d model

3dexport

balcony grills ornamental

balcony grills and ornamental grills 3d model rameshknd 72140 3dexport

turbosquid

$12

Grill

...l

turbosquid

royalty free 3d model grill for download as max on turbosquid: 3d models for games, architecture, videos. (1209288)

3d_export

$5

grill

...grill

3dexport

3ddd

free

Grill

...grill

3ddd

гриль

гриль

turbosquid

$25

Grill

...royalty free 3d model grill for download as 3ds, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1288849)

turbosquid

$39

Grill

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

40Mm

turbosquid

$10

40MM Bullet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

40mm Vickers-Terni

... free 3d model 40mm vickers-terni for download as lwo and obj on turbosquid: 3d models for games, architecture, videos. (1260063)

turbosquid

$3

40mm grenade M9XX

...y free 3d model 40mm grenade m9xx for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1408150)

turbosquid

$3

40mm grenade M3XX

...y free 3d model 40mm grenade m3xx for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1408145)

turbosquid

$3

40mm grenade M1XX

...y free 3d model 40mm grenade m1xx for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1408144)

turbosquid

$8

40mm Smith & Wesson

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Free 40mm grenade M433

...e 3d model free 40mm grenade m433 for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1404768)

turbosquid

$98

40mm 6G30 grenade launcher

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Famas G2 M203 40mm.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

40mm Bofors TNT-11606

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Select

3ddd

$1

TUBADZIN SELECT

...max 2014, 2011.

fbx 2014, 2013, 2011,

obj

_____________________________________http://www.tubadzin.pl/en/collection/324

3ddd

$1

Плитка Selection

... supergres , плитка

плитка selection - supergres ceramiche

turbosquid

$15

Christmas Selection

...royalty free 3d model christmas selection for download as fbx on turbosquid: 3d models for games, architecture, videos. (1696333)

turbosquid

$39

Vases selection

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

SELECTIVE RACKING SYSTEM

...yalty free 3d model selective racking system for download as on turbosquid: 3d models for games, architecture, videos. (1282512)

turbosquid

$10

Hansgrohe ShowerTablet Select

...ee 3d model hansgrohe showertablet select for download as max on turbosquid: 3d models for games, architecture, videos. (1336955)

turbosquid

$29

Chill selectional sofa

...odel chill selectional sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1465691)

3ddd

free

Lunaria - Nova, ASA Selection

... asa selection , dried flowers

ветка лунарии в вазе nova, asa selection

3ddd

$1

inno SELECT SLIM chair

...inno select slim chair

3ddd

inno

high detailed inno select slim chair

turbosquid

$29

Select Chaise Lounge

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

3d_export

$13

extruded table

...ed to give you the highest possible quality for up to 4k renders. there is no post-production used on any of the renders you see.

3d_export

$13

extruded chair

...for high-quality render results. no extra plugins are required for this model. lights and cameras are not included in the scenes.

3d_export

$13

extruded table 2

...for high-quality render results. no extra plugins are required for this model. lights and cameras are not included in the scenes.

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)

Maker

3d_ocean

$17

Coffee Maker

...coffee maker

3docean

breakfast coffee drip electric maker morning

detailed coffee maker and a plug.

3ddd

$1

coffee maker

...coffee maker

3ddd

кофемашина

coffee maker

3d_export

$10

chapati maker

...chapati maker

3dexport

it is a indian traditional chapati maker

archibase_planet

free

Coffee maker

...aker

archibase planet

percolator coffee-machine coffee maker

coffee maker - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee maker

...aker

archibase planet

percolator coffee-machine coffee maker

coffee maker - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee maker

...aker

archibase planet

percolator coffee-machine coffee maker

coffee maker - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Сoffee maker

...er

archibase planet

coffee maker percolator coffee-machine

сoffee maker n020112 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee maker

...aker

archibase planet

coffee maker percolator coffee-machine

coffee maker - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Juice Maker

...juice maker

3ddd

соковыжималка

fully detailed kenwood juice maker

archibase_planet

free

Coffee maker

...hibase planet

coffee maker percolator coffee-machine

coffee maker n140611 - 3d model (*.gsm+*.3ds) for interior 3d visualization.