Thingiverse

3TSS: 30mm Tube Spool System by wavexx

by Thingiverse

Last crawled date: 3 years, 4 months ago

3TSS: 30mm Tube Spool System

This is a complete solution to convert a regular 30mm tube into a horizontal/vertical (suspended!) spool holder for one or more rolls.

It includes:

Fixed spool hub adapter

Axial bearing spool adapter using 6mm softair pellets

Filament guide for perpendicular feeding (doubles as clamp)

Plain 30mm tube clamp

M3 drill helper (for the safety endstop)

Flush tube cap

Requires:

30mm tube of any lenght (in this case, a 30x500mm foot used for furniture, ceiling mounted)

M3x10 cylinder head screw (for the safety end-stop)

M5x20 hex-head + M5 butterfly nut (for both the clamp or filament guide)

32 6mm softair pellets (for the axial bearing)

01/2021 Update

Updated filament guide (filament guide v2): improved bend and larger internal diameter. The hole now fits an (optional) 4mm bowden tube, press-fit. The bowden tube reduces friction with some materials (such as CF filaments).

Printing

All parts are optimized for a 0.2 layer height, 0.4mm nozzle, 2+ perimeters.

PETG or ABS is highly recommended for the simple clamp and for the filament guide (due to the flex applied by the butterfly nut). I've used PETG for all parts.

No supports are required, although the filament guide could use a little to improve the quality of the lower part of the upward bend.

Very good dimensional accuracy is required for the axial bearing in order to have good loading strength.

Safety gravity end-stop

Since I've mounted my tube suspended, I've included a safety end-stop in the design. This can be omitted in horizontal or floor-mounted setups.

An M3x10 socket-head screw needs to be drilled at the end of the tube. A drill-helper is included to make a perfectly centered/perpendicular hole. When drilling remember to leave enough space for the cap.

All parts have a special slot which fits the head of the screw when aligned. When inserting components into the suspended system you should turn each part slightly so that the safety can catch a loose part.

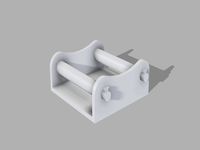

Axial bearing

In most cases, for a single 1kg spool, the fixed spool adapter is enough, prints faster and uses less material as well.

For heavier spools, or in a vertical design, the friction required to pull the filament can become significant. In these cases the axial bearing can offer butter-smooth motion:

https://youtu.be/TrgeDNtn97A

I checked my softair pellets to have an effective 5.95+/-0.01mm diameter. The inner spacing is 6mm exactly. With these tolerances I tested up to 10kg of axial load without issues, so a single axial bearing can be used for up to 2-3 spools. The radial loading is probably even higher.

If you need higher loads (for more spools) use multiple bearings separated by a regular clamp.

In any case, on a vertical system, the axial bearing is only needed on the bottom of the spool. A fixed adapter is always sufficient on the top since it just needs to keep the spool balanced.

When using a safety end-stop, the radial bearing needs to be aligned in order to be removed. There is a special notch on the outer perimeter to indicate where the opening is, and whether it is aligned:

Axial bearing assembly

To assemble the axial bearing first combine the bottom and top parts together. Flip the bearing so that you're looking at the bottom. Align the special notch, then rotate 20 degrees counter-clockwise (until a regular notch aligns) to find the special loading slot:

Push from 30 to 32 6mm airsoft pellets. Some force is required to push the pellets in.

Once about 3/4 of the pellets are inserted the two parts of the bearing should be locked together and cannot be separated anymore.

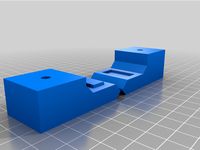

Clamp / filament guide

The clamp can be seen in detail here:

https://www.thingiverse.com/thing:3418776

The filament guide uses an identical design.Do not over-tighten these: very little tightening is actually required.

Tube cap

The tube cap is designed to fit an inner diameter of 28mm and might not work for all tubes. It can be scaled down, but not up, since the border of the tube needs to be perfectly flush in order to let the components pass.

This is a complete solution to convert a regular 30mm tube into a horizontal/vertical (suspended!) spool holder for one or more rolls.

It includes:

Fixed spool hub adapter

Axial bearing spool adapter using 6mm softair pellets

Filament guide for perpendicular feeding (doubles as clamp)

Plain 30mm tube clamp

M3 drill helper (for the safety endstop)

Flush tube cap

Requires:

30mm tube of any lenght (in this case, a 30x500mm foot used for furniture, ceiling mounted)

M3x10 cylinder head screw (for the safety end-stop)

M5x20 hex-head + M5 butterfly nut (for both the clamp or filament guide)

32 6mm softair pellets (for the axial bearing)

01/2021 Update

Updated filament guide (filament guide v2): improved bend and larger internal diameter. The hole now fits an (optional) 4mm bowden tube, press-fit. The bowden tube reduces friction with some materials (such as CF filaments).

Printing

All parts are optimized for a 0.2 layer height, 0.4mm nozzle, 2+ perimeters.

PETG or ABS is highly recommended for the simple clamp and for the filament guide (due to the flex applied by the butterfly nut). I've used PETG for all parts.

No supports are required, although the filament guide could use a little to improve the quality of the lower part of the upward bend.

Very good dimensional accuracy is required for the axial bearing in order to have good loading strength.

Safety gravity end-stop

Since I've mounted my tube suspended, I've included a safety end-stop in the design. This can be omitted in horizontal or floor-mounted setups.

An M3x10 socket-head screw needs to be drilled at the end of the tube. A drill-helper is included to make a perfectly centered/perpendicular hole. When drilling remember to leave enough space for the cap.

All parts have a special slot which fits the head of the screw when aligned. When inserting components into the suspended system you should turn each part slightly so that the safety can catch a loose part.

Axial bearing

In most cases, for a single 1kg spool, the fixed spool adapter is enough, prints faster and uses less material as well.

For heavier spools, or in a vertical design, the friction required to pull the filament can become significant. In these cases the axial bearing can offer butter-smooth motion:

https://youtu.be/TrgeDNtn97A

I checked my softair pellets to have an effective 5.95+/-0.01mm diameter. The inner spacing is 6mm exactly. With these tolerances I tested up to 10kg of axial load without issues, so a single axial bearing can be used for up to 2-3 spools. The radial loading is probably even higher.

If you need higher loads (for more spools) use multiple bearings separated by a regular clamp.

In any case, on a vertical system, the axial bearing is only needed on the bottom of the spool. A fixed adapter is always sufficient on the top since it just needs to keep the spool balanced.

When using a safety end-stop, the radial bearing needs to be aligned in order to be removed. There is a special notch on the outer perimeter to indicate where the opening is, and whether it is aligned:

Axial bearing assembly

To assemble the axial bearing first combine the bottom and top parts together. Flip the bearing so that you're looking at the bottom. Align the special notch, then rotate 20 degrees counter-clockwise (until a regular notch aligns) to find the special loading slot:

Push from 30 to 32 6mm airsoft pellets. Some force is required to push the pellets in.

Once about 3/4 of the pellets are inserted the two parts of the bearing should be locked together and cannot be separated anymore.

Clamp / filament guide

The clamp can be seen in detail here:

https://www.thingiverse.com/thing:3418776

The filament guide uses an identical design.Do not over-tighten these: very little tightening is actually required.

Tube cap

The tube cap is designed to fit an inner diameter of 28mm and might not work for all tubes. It can be scaled down, but not up, since the border of the tube needs to be perfectly flush in order to let the components pass.

Similar models

thingiverse

free

Filament Spool Bearing using 6mm airsoft by joesturge

...his filament spool holder uses 6mm airsoft pellets incorporated in the bearing. the operation of the bearing is pretty dam smooth

thingiverse

free

Wanhao D9 Filament Guide Tube Holder by jamesarm97

...p fits over the d9 extruder top above the filament hole. the extruder cap will fit either the tube or a ptfe press fit connector.

thingiverse

free

softair bb deep groove ball thrust bearing / axial bearing / Axialrillenkugellager by UncleBens

...work as well.

if you don t want to to have a holding ring around one of the bearing race you can print the opposite part twice.

thingiverse

free

mh-Filament Guide by mh8

...;s function is to maintain a little flexibility on the filament by maintaining the exit part of the guide-tube above the printer.

thingiverse

free

Linear Spool Bearing, Filament Guide & Spool End Cap by SimonSaysMake

...hould fit filament spools purchased from filaments.ca. a filament guide and end cap are included.

thanks , hope it works well!

thingiverse

free

Filament bearing by ogi1888

...filament bearing by ogi1888

thingiverse

filament bearing using 6mm airsoft pellets

thingiverse

free

2016 FlashForge Creator Pro Filament Alignment Bracket by eclipsen

...tube stop to prevent the guide tubes from extending out the bottom of the bracket. this can be printed without supports. enjoy!

thingiverse

free

filament end stop/guide by bandit-ed

...filament end stop/guide by bandit-ed

thingiverse

a filament end stop/guide for a spool holder i have made

thingiverse

free

Ender 3 / Pro Filament spool 3D printed Bearing by Easy_maker

...g have slight draft, to position and fix the filament spool on the bearing.

cover was glued on the housing, to close the bearing.

thingiverse

free

Filament Tube Guide for Prusa I3 MK2 by ProjectB2

...er. slide on this guide.

note: must use with teflon tubing. filament have feeding issue with normal tubing due to high friction.

Wavexx

thingiverse

free

Petri Dish Cap by wavexx

...cap by wavexx

thingiverse

a simple cap for a standard petri dish.

in this case it was printed in black to act as a light shield.

thingiverse

free

STM32 Nucleo F4 / F4* bumper by wavexx

...stm32 nucleo f4 / f4* bumper by wavexx

thingiverse

super-simple, minimal bumper for the st nucleo f4* boards.

thingiverse

free

Tarantula display hanging hooks by wavexx

...arantula display to a vertical surface, such as the side of a cabinet. the hooks must be glued (i used strong double-sided tape).

thingiverse

free

Cat Stand for IPhone 5 by wavexx

...r it wins on cuteness alone.

stretch on z as desired. might hold other mobiles, however getting the right fit can be challenging.

thingiverse

free

Piston Keychain (press-fit version) by wavexx

...required! i used a vice:

https://youtu.be/d8rxq-3lft8

tested with petg, 0.2 layers, 0.4 nozzle, 2 perimeters, no infill required.

thingiverse

free

GM328 Transistor-tester battery holder by wavexx

...around the pcb (<0.1mm gap). push firmly the pcb until it snaps into place. m3 screws can be directly fastened on the support.

thingiverse

free

Sausage Dipole Antenna mount by wavexx

...up. when satisfied, line the interior with silicone and close shut.

be sure to take an action shot during the first comm-check ;)

thingiverse

free

Zassenhaus coffee grinder Sliding Cap by wavexx

...ate freely, with just a little bit of friction.

petg with 0.4 nozzle, 0.2 layer height, 4 perimeters and 100% infill recommended.

thingiverse

free

Orange Scientific Comfopette screw-cap v2 by wavexx

...ue. please note the correct orientation of the teeth by looking at the images (same as provided in the model: teeth lining down).

thingiverse

free

IFlight XL5 BN-880 GPS holder by wavexx

... support holes (these are press-fit) until the bottom faces are flush. once screwed back in place the holder/gps is fully locked.

30Mm

thingiverse

free

30mm by astorck

...30mm by astorck

thingiverse

30mm

thingiverse

free

30mm by astorck

...30mm by astorck

thingiverse

30mm

thingiverse

free

30mm plug by jaxda1

...30mm plug by jaxda1

thingiverse

30mm plugs

thingiverse

free

30mm plug by jaxda1

...30mm plug by jaxda1

thingiverse

30mm plug

thingiverse

free

30mm arrow by jaxda1

...30mm arrow by jaxda1

thingiverse

30mm arrow plug

thingiverse

free

30mm Hinge by BigFunkyMan

...30mm hinge by bigfunkyman

thingiverse

30mm hinge for litle boxes

thingiverse

free

30mm no! plug by jaxda1

...30mm no! plug by jaxda1

thingiverse

30mm no1 ear plugs

thingiverse

free

Corner Guard (30mm x 30mm x 30mm) by BG32940

...his one is smaller but more effective and less obtrusive. i printed this in harchbox dark wood pla to match our kitchen cabinets.

thingiverse

free

30mm fan shield

...30mm fan shield

thingiverse

it's a fairly beefy 30mm fan shroud.

thingiverse

free

30mm Tube Clamp by RCTESTFLIGHT

...30mm tube clamp by rctestflight

thingiverse

30mm tube clamp for clamping 30mm tubes

System

thingiverse

free

Coordinate system

...coordinate system

thingiverse

coordinate system

thingiverse

free

ACRO SYSTEMS DRAG CHAIN SYSTEM by dragonfire81m

...acro systems drag chain system by dragonfire81m

thingiverse

chain link mounting system for acro system openbuilds

thingiverse

free

Circulatory System

...circulatory system

thingiverse

made in a 3d design software

designed for students

circulatory system based on images

thingiverse

free

Clutch system

...clutch system

thingiverse

clutch system inspired from lego technics kit

print with default settings

thingiverse

free

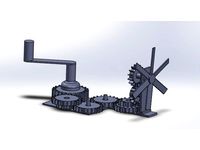

Gear system test-Systeme d'engrenage Test by CPS007

...gear system test-systeme d'engrenage test by cps007

thingiverse

gear system test-systeme d'engrenage test

13cm7cm7cm

thingiverse

free

Pulley System by LeapFrog_3D

...pulley system by leapfrog_3d

thingiverse

pulley system

thingiverse

free

System Block by CryoShift

...system block by cryoshift

thingiverse

system block

thingiverse

free

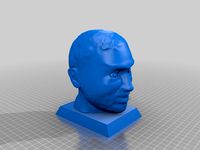

System administrator by Diodmag

...system administrator by diodmag

thingiverse

system administrator, sculpting

thingiverse

free

L.A. Systems by Bjorn175

...l.a. systems by bjorn175

thingiverse

l.a. systems mold

thingiverse

free

Decken Montage-system

...decken montage-system

thingiverse

decken montage-system

Spool

thingiverse

free

Spool Support For Anycubic Spool Holder and AMZ3D Spools by Kobaratsu

... amz3d spools by kobaratsu

thingiverse

spool axis support to avoid jerks on spool, using anycubic spool holder and amz3d spools

thingiverse

free

Spool adapter for Warhorse spool

...spool adapter for warhorse spool

thingiverse

a simple spool adapter to use abs warhorse spool with a 72 mm hole diameter.

thingiverse

free

Spool holder for 1KG Spools by angkor

...spool holder for 1kg spools by angkor

thingiverse

spool holder for 1kg spools

thingiverse

free

Spool holder

...spool holder

thingiverse

i use this spool holder for up to 1kg spools and should fit all spools.

thingiverse

free

Spool assembler

... empty spool with this spool assembler

just cut an empty spool in half , put your filament and assemble with this spool assembler

thingiverse

free

Small Spool and Spool Stand by Beckman13

...ool holder are meant for 50 gram flexible filaments. the two sides of the spool holder are meant to slide together and interlock.

thingiverse

free

spool spindle cap for 25mm spools by Seadevil

...spool spindle cap for 25mm spools by seadevil

thingiverse

spool spindle cap for 25mm spools

thingiverse

free

spool ! by St0rmingBr4in

...spool ! by st0rmingbr4in

thingiverse

this is a spool !

thingiverse

free

Spool Holder for large spools by dmonkey

...y

thingiverse

a spool holder that you can attach to the back of a makerbot replicator that can hold large filament spools (1kg)

thingiverse

free

Spool roll

...spool roll

thingiverse

spool roll

Tube

thingiverse

free

tubes by

...tubes by

thingiverse

tube time

thingiverse

free

Edrio Two Tubes (Tubes) by Sidejoebob

...edrio two tubes (tubes) by sidejoebob

thingiverse

tube for the edrio two tubes helmet

thingiverse

free

Tube Racks

...tube racks

thingiverse

tube racks for 15ml & 50ml falcon tubes and 20mm round-bottom tubes

thingiverse

free

A tube squeezer for aluminum tubes by joergkrause

...rinted with pla. no support required. suitable for tubes up to 50mm

update 03.07.2018 better version uploadet. tube squeezer2.stl

thingiverse

free

Tube by williandb

...tube by williandb

thingiverse

tube

thingiverse

free

tube by shvanmajd

...tube by shvanmajd

thingiverse

tube

thingiverse

free

Tube by vovkachuk

...tube by vovkachuk

thingiverse

tube

thingiverse

free

tube by baramon

...tube by baramon

thingiverse

tube

thingiverse

free

Sliding tube cap or tube foot for 0.85" OD tube by DBQGrips

...f a tube leg to assist in sliding across the floor.

this was designed for 0.85" od tube but can be scaled for similar sizes.

thingiverse

free

Tubing straightener (4,8mm tubes)

... brake lines for example).

all you need is 8x 608 ball bearing, 8x m8 screw and 8x m8 nut.

print list:

2x body

8x roller

1x shims