Thingiverse

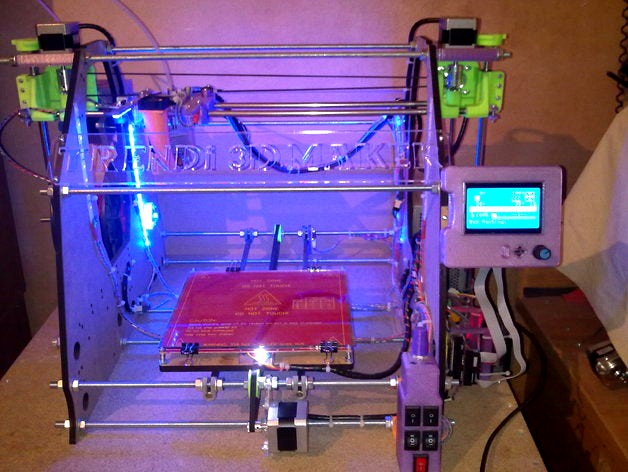

3D Printer Mendel Type Small (relatively) by TRENDi77

by Thingiverse

Last crawled date: 3 years ago

This is my next homemade project for 3D printer.

Single homemade hotend or E3D compatible - 0,4 mm nozzle, bowden type extruder.

400W PC ATX PSU.

Electronics - Mega2560 + RAMPs 1,4 + Full_Graphic_Smart_LCD_Controller + 5 NEMA 17 motors. Malrin Fimware.

Expecting very small or none backlash effect with 5 mm rods for Z axis.

Working area with 220x200x3mm glass- XYZ - 220/186/148 mm;

Manual control for 40 mm fan for hotend/always ON by default/ and manual control for 30 mm fan duct with 500 oM potentiometer.

Short video: https://youtu.be/aaMdQ0u-Osc

Source files added for laser cutting and references (AutoCad 2010 or above). Also if You want to change ot remake anything.

Clamp for E3D clone also is present in .stl files. Will do 30 mm fanduct for it soon.

I was close to start with leveling and calibration, but found some drama with the LCD. Probably, I have damaged it during the flash of the mainboard. So things won`t develope very fast, untill I replace it.

BOM ~270-275 €

20.09.2015

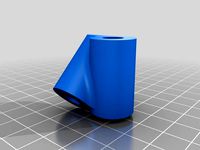

Uploaded 30 mm Fan Duct for E3D type hotend -> + 10 mm on Z print area.

Source files reuploaded + 2 pics with E3D type hotend look.

28.09.2015

Printer is leveled and calibrated. Waiting only for new LCD controler to complete it. Thing is final.

Will post video and pictures, when LCD is here (after ~2 weeks).

21.10.2015

New 2 pictures added with new lcd controller.

Link to video of secont test print - https://youtu.be/R7v5BBhPvtYTest is made with the worst 1.75 mm ABS filament I have ever used - it is badly calibrated and got a lot of air bubbles. 0.2 mm layer hight

I got some things to improve mostly on print setting + got a layer shift on Y axis on the 3rd print test (some bridge test cube).

As it can be seen on the video no such thing as "massive Z wobble" here, on the contraty - You have to use expensive optic tools to see it :)

23.10.2015

Added photos of the result of the 3rd and last printer test - herringbone gears - at the end of the gallery. 0.2 mm layer hight, and better fillament used. A little bit to close start to table but the result is OK.

It is ready and complete at 100%. There will not be any update anymore.

10.12.2015

Added patrs #32 and #33 on request.

Did upgrade of left and right X axis holders to fit for Tr8 leadscrew. It is for 4 hole nut (holes situated on 16.2 diameter of the nut - http://g04.a.alicdn.com/kf/HTB1hqsXKpXXXXb_XVXXq6xXFXXX2/3D-Printer-Part-THSL-300-8D-Lead-Screw-Rod-brass-nut-for-3D-Printer-.jpg). So, prepare additional 8 M3 nuts, 8 M3x12mm bolts and change the couplers to 5to8mm.

25.12.2016

Uploaded versions for Air2 3D printer for X axis. Distances between center of the nut and the vertical smooth rod for Z movement - 30.5 mm.https://www.youtube.com/watch?v=Mx8ncfCHZms

Single homemade hotend or E3D compatible - 0,4 mm nozzle, bowden type extruder.

400W PC ATX PSU.

Electronics - Mega2560 + RAMPs 1,4 + Full_Graphic_Smart_LCD_Controller + 5 NEMA 17 motors. Malrin Fimware.

Expecting very small or none backlash effect with 5 mm rods for Z axis.

Working area with 220x200x3mm glass- XYZ - 220/186/148 mm;

Manual control for 40 mm fan for hotend/always ON by default/ and manual control for 30 mm fan duct with 500 oM potentiometer.

Short video: https://youtu.be/aaMdQ0u-Osc

Source files added for laser cutting and references (AutoCad 2010 or above). Also if You want to change ot remake anything.

Clamp for E3D clone also is present in .stl files. Will do 30 mm fanduct for it soon.

I was close to start with leveling and calibration, but found some drama with the LCD. Probably, I have damaged it during the flash of the mainboard. So things won`t develope very fast, untill I replace it.

BOM ~270-275 €

20.09.2015

Uploaded 30 mm Fan Duct for E3D type hotend -> + 10 mm on Z print area.

Source files reuploaded + 2 pics with E3D type hotend look.

28.09.2015

Printer is leveled and calibrated. Waiting only for new LCD controler to complete it. Thing is final.

Will post video and pictures, when LCD is here (after ~2 weeks).

21.10.2015

New 2 pictures added with new lcd controller.

Link to video of secont test print - https://youtu.be/R7v5BBhPvtYTest is made with the worst 1.75 mm ABS filament I have ever used - it is badly calibrated and got a lot of air bubbles. 0.2 mm layer hight

I got some things to improve mostly on print setting + got a layer shift on Y axis on the 3rd print test (some bridge test cube).

As it can be seen on the video no such thing as "massive Z wobble" here, on the contraty - You have to use expensive optic tools to see it :)

23.10.2015

Added photos of the result of the 3rd and last printer test - herringbone gears - at the end of the gallery. 0.2 mm layer hight, and better fillament used. A little bit to close start to table but the result is OK.

It is ready and complete at 100%. There will not be any update anymore.

10.12.2015

Added patrs #32 and #33 on request.

Did upgrade of left and right X axis holders to fit for Tr8 leadscrew. It is for 4 hole nut (holes situated on 16.2 diameter of the nut - http://g04.a.alicdn.com/kf/HTB1hqsXKpXXXXb_XVXXq6xXFXXX2/3D-Printer-Part-THSL-300-8D-Lead-Screw-Rod-brass-nut-for-3D-Printer-.jpg). So, prepare additional 8 M3 nuts, 8 M3x12mm bolts and change the couplers to 5to8mm.

25.12.2016

Uploaded versions for Air2 3D printer for X axis. Distances between center of the nut and the vertical smooth rod for Z movement - 30.5 mm.https://www.youtube.com/watch?v=Mx8ncfCHZms

Similar models

thingiverse

free

Fan Duct for E3D all metal HotEnds by stepava

....ipt (autodesk inventor) file provided allow to customize easily the center distance by changing the first block extrusion width.

thingiverse

free

Dual E3D V6 (or clone) fan duct by FernandoGarcia

...360 file is available.

layer fan: https://www.thingiverse.com/thing:2375978

update 1: added holes to allow assembly of layer fan.

thingiverse

free

Prusa i3 mount for MK8 extruder and an E3D hotend NOW WITH LAYER COOLING by StevenQ-NE-UK

...the duct.

you can see why a layer cooling fan is good for pla in my youtube video herehttps://www.youtube.com/watch?v=gtdwd6tbnqk

thingiverse

free

fan duct for E3D hotend by Intector

...for e3d hotend by intector

thingiverse

this is a test air duct for my new printer. it's designed to fit on a e3d v6 hotend.

thingiverse

free

E3D V6 fan duct for bed and hotend by HgArgen

...3d v6 fan duct for bed and hotend.

it allows to install in all positions.

for 40 mm fan and m3 screws and nuts.

work in progress!

thingiverse

free

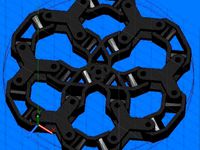

Delta Effector for E3D V6 by Osechi

...effector offset : 25mm

i use the following parts,

・lj12a3-4-z-bx

・e3d v6 hotend

・3010 fans

・3010 blower fan

・m3 screws & nuts

thingiverse

free

ZAV Printer E3D Volcano 40mm fan duct by pasha5584

...d and 40mm fans. i did test it. and it works perfectly. there is project file for solidworks2015, so everyone can customize that.

thingiverse

free

E3D fan duct for prusa I2 by film4rk

...e3d fan duct for prusa i2 by film4rk

thingiverse

this is a fan duct for e3d hotend in a prusa i2 printer.

thingiverse

free

Mendel90 Radial Fan Duct E3D by Hackbert

...mendel90 radial fan duct e3d by hackbert

thingiverse

fan duct for e3d hotend

screws and nuts m3

radial fan titan 60x60x15

thingiverse

free

E3D bowden hotend mount for Prusa i3 by hackermagnet

...ct. it works with the fan duct from here.

i designed it for my e3d clone and i haven't tested it with an original e3d hotend.

Trendi77

thingiverse

free

4X SpoolHolder by TRENDi77

...4x spoolholder by trendi77

thingiverse

for m8 rod.

thingiverse

free

50Xx50Yx30Z_1mmWall_Calibrator by TRENDi77

...irst layer/

1 mm walls;

short arm just for support. made it after problems with z, shown on the pics with the object on the left.

thingiverse

free

GT2 idler for 608 bearing by TRENDi77

...gt2 idler for 608 bearing by trendi77

thingiverse

for nozzles >0,3 mm additional filing may be needed.

thingiverse

free

Simple Mega2560 mount by TRENDi77

...a2560 mount by trendi77

thingiverse

75 mm x 69 mm frame holes(for m3 bolts).

remake from http://www.thingiverse.com/thing:279296

thingiverse

free

GT2 idler for 605 bearing by TRENDi77

...or 605 bearing by trendi77

thingiverse

for nozzles >0,3 mm additional filing may be needed.

it is for 2 605 bearings inside!

thingiverse

free

Cable Chain by TRENDi77

... w=12 mm, h=9 mm;

180 degree turn - ~7 segments.

15.05.2017

small (unnoticeable) change in chain segment.

19.05.2017

some pics...

thingiverse

free

Front Panel Cover for Dell precision by TRENDi77

... front panel cover. fits 490, 690, т5400 т3500, t7400, etc...

these are abs made, but if you want to avoid warping drama use pla.

thingiverse

free

HDDCaddy 1x2.5 or 3.5 to 5.25 by TRENDi77

....2 mm layer hight. 10-15% infill. pla for caddy. pla or abs for front panels.

if you like my work, donate on my web site, please.

thingiverse

free

ReWorked Spoolinsert 4 Chinese filament by TRENDi77

...he hole of the spool :).

very tight, you may have to file a little bit 1 of the legs to fit.

for 56-7 mm spool hole and 8 mm rod.

thingiverse

free

Homemade hotend for 1.75 mm filament by TRENDi77

...ith wade`s or bowden type extruder.

short video in operation - https://www.youtube.com/watch?v=cdxr_oypl2u&feature=youtu.be

Mendel

thingiverse

free

Mendel Foot with pad for Alloy Mendel by maza250

...d for alloy mendel by maza250

thingiverse

40 mm high corner foot with base pad for use with 30x30mm extrusion - in alloy mendel.

thingiverse

free

Rigid Prusa mendel/mendel Bar clamp by wakalics

...iverse

original prusa mendel bar clamp is so weak.

i remade the bar clamp by idea from sells mendel.

www.wakalics.blogspot.kr

thingiverse

free

Mendel Squashfeet by superdoek

...mendel squashfeet by superdoek

thingiverse

shoes for your mendel (original vertex)

thingiverse

free

RepRap Mendel Stabilizer by g0nz00

...tabilizer by g0nz00

thingiverse

a stabilizer for reprap mendel, i use it for a bigger version of the reprappro tricolour mendel.

thingiverse

free

Fan Prusa Mendel by Rafertech

...fan prusa mendel by rafertech

thingiverse

fan prusa mendel.

thingiverse

free

Mendel Inspired Snowflake by flintols

...mendel inspired snowflake by flintols

thingiverse

holiday fun with mendel corners!

thingiverse

free

Tweezer Holder for Mendel (or Prusa Mendel) by MakerCubed

...opping mine, so if there's a spot for it, it won't get lost.

it's parametric in openscad to set it for left or right.

thingiverse

free

Fan holder - Mendel by rafaellsi

...fan holder - mendel by rafaellsi

thingiverse

experimental for 40x40mm fan - mendel reprappro

thingiverse

free

Mendel Feet by tonokip

...mendel feet by tonokip

thingiverse

thingiverse

free

Mendel Z tensioner by timschmidt

...rse

openscad remake of mendel's z tensioner. part of the mendel openscad re-work being done here: thingiverse.com/thing:3118

Relatively

3ddd

free

04 Remont Rels

...04 remont rels

3ddd

рельсы , ремонт

обновил в архиве obj - теперь ок.

turbosquid

$20

REL Tzero Gloss White Lacquer

...l tzero gloss white lacquer for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1145679)

turbosquid

$20

REL Habitat1 Gloss White Lacquer

...abitat1 gloss white lacquer for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1145677)

turbosquid

$20

REL Habitat1 Gloss Piano Black

... habitat1 gloss piano black for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1145676)

turbosquid

$60

Bathroom furniture set Panta Rel 6

...m furniture set panta rel 6 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1192539)

turbosquid

$60

Bathroom furniture set Panta Rel 5

...m furniture set panta rel 5 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1190928)

turbosquid

$60

Bathroom furniture set Panta Rel 3

...m furniture set panta rel 3 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1171360)

turbosquid

$60

Bathroom furniture set Panta Rel 2

...m furniture set panta rel 2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1167055)

3d_export

$5

Glock

...glock 3dexport a relatively common...

3ddd

free

OASIS

...oasis

3ddd

oasis

oasis of rbg 175 rel

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Type

3d_export

$5

s type

...s type

3dexport

s type formats max 3ds obj stl

3d_export

$5

l-type conveyor

...l-type conveyor

3dexport

l-type conveyor

3d_export

$5

volkswagen type 2

...volkswagen type 2

3dexport

volkswagen type 2

turbosquid

$150

RBC types

...osquid

royalty free 3d model rbc types for download as blend on turbosquid: 3d models for games, architecture, videos. (1343563)

turbosquid

$1

B-Type

...urbosquid

royalty free 3d model b-type for download as blend on turbosquid: 3d models for games, architecture, videos. (1609608)

3ddd

$1

shoes type A

...shoes type a

3ddd

туфли

shoes

turbosquid

$39

R-type

...oyalty free 3d model r-type for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1303675)

turbosquid

$5

melon type

...ee 3d model melon galia type for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1557188)

3d_export

free

three different type

...three different type

3dexport

three different type: mace, axe, sword

turbosquid

$49

Types of Placentation

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Small

3d_export

$10

small bed

...small bed

3dexport

small bed design for small house or small room with storage

3d_export

$10

small house

...small house

3dexport

a small house. the project of a small country house.

3d_ocean

$4

Small Cake

...small cake

3docean

cake food small

just a small cake ready for render

3d_export

$6

small armchair

...small armchair

3dexport

small armchair

3d_export

$5

a small world

...a small world

3dexport

a small world

3d_export

$5

small room

...small room

3dexport

small cozy room

3d_export

$5

small tank

...small tank

3dexport

small tank modeling in blender

design_connected

free

small lounge

...small lounge

designconnected

free 3d model of small lounge

design_connected

$11

Watermelons Small

...watermelons small

designconnected

watermelons small computer generated 3d model.

3d_export

$5

small house

...small house

3dexport

a small cozy house on the foundation, the interior is missing.