Thingiverse

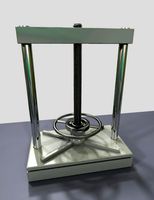

3D Printed Heat-Set Insert Press by 3DAnarchy

by Thingiverse

Last crawled date: 3 years, 1 month ago

This is a 3D printed press for inerting heat-set threaded inserts. It utilizes a cheap soldering iron as the heat source, a rotary dimmer to allow the user to throttle the heat output to tailor to a variety of plastics, and a drawer slider as part of the plunger assembly that pushes down onto the part.

This project was designed out of necessity while working on another big project that utilizes quite a few of these heat-set inserts. Using this press rather than just a soldering iron itself ensures that the inserts get installed accurately, with the correct temperature and in far less time.

These presses go for hundreds or even thousands of dollars so they are beyond the price range of most hobbyist, yet they are very useful in the 3D printing and DIY hobby community. I wanted to design and build a high quality and affordable unit that can be 3D printed within a few days and built for well under $100.

Please take the time to read the print settings.

What you'll need:

-1kg spool of PLA filament

-30w soldering iron similar to the one in the pictures

-Rotary dimmer switch

-Heavy-duty 12" drawer slider (ensure that the inner slide "the one that comes out" has a width of around 24.6mm)

-Assorted M4 machine screws from 6mm to 25mm in length

-M4 Nuts

-M2 self-tapping screws 8mm, 10mm, and 12mm in length

-16 gauge wire

-16 gauge electrical connectors

-6.5" light duty spring

-1-1/2" 10-24 threaded eye hooks (This holds the soldering iron to the drawer slider)

-10-24 nuts for the eye hooks

-Fender washers (These are heatsinks on the threaded eye hooks to slow down heat transfer to the plunger assembly)

-Small hose clamp to fit over the soldering iron barrel

Instructions should be available soon via Instructables. I'll post the link in here when I get around to making them. Visit the 3DAnarchy Facebook group for questions, discussion and info on this and upcoming projects: https://www.facebook.com/groups/1358672314201686/

Please remember to tip your designers. These big projects take a lot of time, money and dedication.

This project was designed out of necessity while working on another big project that utilizes quite a few of these heat-set inserts. Using this press rather than just a soldering iron itself ensures that the inserts get installed accurately, with the correct temperature and in far less time.

These presses go for hundreds or even thousands of dollars so they are beyond the price range of most hobbyist, yet they are very useful in the 3D printing and DIY hobby community. I wanted to design and build a high quality and affordable unit that can be 3D printed within a few days and built for well under $100.

Please take the time to read the print settings.

What you'll need:

-1kg spool of PLA filament

-30w soldering iron similar to the one in the pictures

-Rotary dimmer switch

-Heavy-duty 12" drawer slider (ensure that the inner slide "the one that comes out" has a width of around 24.6mm)

-Assorted M4 machine screws from 6mm to 25mm in length

-M4 Nuts

-M2 self-tapping screws 8mm, 10mm, and 12mm in length

-16 gauge wire

-16 gauge electrical connectors

-6.5" light duty spring

-1-1/2" 10-24 threaded eye hooks (This holds the soldering iron to the drawer slider)

-10-24 nuts for the eye hooks

-Fender washers (These are heatsinks on the threaded eye hooks to slow down heat transfer to the plunger assembly)

-Small hose clamp to fit over the soldering iron barrel

Instructions should be available soon via Instructables. I'll post the link in here when I get around to making them. Visit the 3DAnarchy Facebook group for questions, discussion and info on this and upcoming projects: https://www.facebook.com/groups/1358672314201686/

Please remember to tip your designers. These big projects take a lot of time, money and dedication.

Similar models

grabcad

free

soldering iron collar

...readed insert press brass posts: https://www.amazon.de/gp/product/b09bmk4bk1/ref=ppx_yo_dt_b_asin_title_o09_s00?ie=utf8&psc=1

thingiverse

free

Dremel Drill Press Soldering Iron Adapter by astronoob_com

...a dremel tool station drill press.

it requires 2x m3x20mm bolts and 2x m3 inserts. but feel free to remix to add hex-nut fitting.

thingiverse

free

Drill Press Heat Set Insert Tool by Zoybert

...10pcs-hakko-soldering-station/dp/b07kxy3bcb/ref=sr_1_8?dchild=1&keywords=heat+set+tips&qid=1620145455&s=hi&sr=1-8

thingiverse

free

Soldering iron Drill Press Adapter by kurtschaefer

...roduct/b0192pzd1y

i have a little write up about it athttps://retrotechjournal.com/2016/06/21/soldering-iron-drill-press-adaptor/

thingiverse

free

Clamp Cover for Soldering Iron with Dial by JeffB42

... so i made my own. this part is meant to be used with the remaining other parts in the heat-set insert press with spring return.

thingiverse

free

Modified Heat Set Press Base by TheKojent

...hekojent

thingiverse

taller base with a holder for the in-line soldering iron controller and two small bins for holding inserts.

grabcad

free

3D Printed heat press tool for threaded brass inserts

...3d printed heat press tool for threaded brass inserts

grabcad

heat press tool does perfect insert

thingiverse

free

Universal / modular Nerf Rainbow Catch system for high powered homemade Nerf blasters by NortheastDesigns

...thread size. be sure to place a spring on top of the catch as shown, and thread two medium length screws into the catch as shown.

grabcad

free

1/4-20 X 1/2" Brass Heat Set Insert

... for hole diameter .332". install on soldering iron tip to heat up prior to installation. knurled surface prevents rotation.

grabcad

free

8-32 Brass Heat Set Insert

..." (#5 drill bit) hole using soldering iron tip to heat up prior to installation. knurled od prevents rotation after cooling.

3Danarchy

thingiverse

free

T-Case_housing_mod for Ossum Jeep by 3DAnarchy by Guenter

...hier wieder zur verfügung stellen.

für den zusammenbau des getriebes, wie es von 3danarchy geplant wurde, finde ich keine lösung.

thingiverse

free

Servo mount bumper for the OSSUM Jeep by 3DAnarchy

...as the ossum group on facebook:https://www.facebook.com/groups/1358672314201686/https://www.facebook.com/groups/1883252011928341/

thingiverse

free

3D Printed Willys RC 4X4 by 3DAnarchy

...as the ossum group on facebook:https://www.facebook.com/groups/1358672314201686/https://www.facebook.com/groups/1883252011928341/

thingiverse

free

Prusa i3 MK3 Spool Holder Adapter and Filament Guide for IKEA Lack Enclosure by 3DAnarchy

...gh to create a channel on both sides of the table.the finish will be rough but no worries, the filament guide will cover it up :)

thingiverse

free

Ossum Jeep leaf springs and the axle holders by Guenter

...axle holders, which are screwed in the original by 3danarchy so that these can be printed as a part....

thingiverse

free

Ossum_Jeep_Cockpit_Instruments by Guenter

...to make the ossum jeep cockpit more realistic by 3danarchy for this i looked for pictures from the original...

thingiverse

free

Frame_Mod for Ultra_Realistic_Ossum_Jeep by Guenter

...by guenter thingiverse hello, i like the jeep of 3danarchy (www.thingiverse.com/thing:2475075)and so i wanted to do the replica, so...

thingiverse

free

Ossum_Jeep_Instruments_backlight by Guenter

...you want more reality at the ossum jeep by 3danarchy for the instruments (thing: 2511807) i have now created...

Press

archibase_planet

free

Press

...ibase planet

press squeezer masher

press garment heat press n131213 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Press

...press

archibase planet

newspaper daily paper magazine

press - 3d model for interior 3d visualization.

archibase_planet

free

Press

...press

archibase planet

gymnastic apparatus gym

gym leg press - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Press bench

...press bench

archibase planet

bench press press bench gym

press bench - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3d_export

$20

iron press

...iron press

3dexport

iron press

3d_export

$15

punch press

...punch press

3dexport

punch press

3d_export

$10

Grape press

...grape press

3dexport

grape press

3d_ocean

$9

Fruit Press

...fruit press

3docean

food and drinks fruit press furnishing

fruit press,food and drinks, furnishing

turbosquid

$20

Press

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Press

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Heat

3d_export

$5

heat

...heat

3dexport

heat tool

3ddd

$1

electric heating

...electric heating

3ddd

обогреватель

electric heating

3d_export

$6

The heating module

...any questions also you can email to me. designed with solidworks 2017, render with keyshot **************************************

turbosquid

free

Heating Rod

...rod

turbosquid

free 3d model heating rod for download as obj on turbosquid: 3d models for games, architecture, videos. (1482690)

turbosquid

$2

Heating Radiator

...

royalty free 3d model heating radiator for download as blend on turbosquid: 3d models for games, architecture, videos. (1561908)

3d_export

$35

heating instalation with heat pump and solar system

...el , please contact me. before buying a model, you can try to download one of my free models and testing. thank you for watching.

turbosquid

$29

Heating Mantle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Heating Radiator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

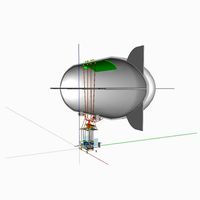

AT_airship_control_stand_(heated)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

AT_airship_(heated)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Insert

turbosquid

$10

insert a bracelet

... 3d model the link element insert for download as max and max on turbosquid: 3d models for games, architecture, videos. (1609593)

turbosquid

$56

Threaded Inserts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Insert for eggs

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$14

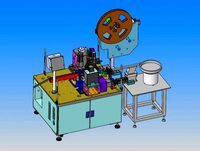

drawing of needle inserting machine

...lectronic manufacturers use pin machines to help customers to insert needles, so as to obtain processing costs and obtain wealth.

turbosquid

$5

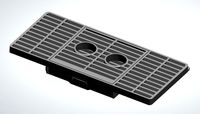

IKEA Insert drawers

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

IKEA insert with door

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Siemsn EQ 6 Inlet insert

...placed there without any problems. the insert is then straight for normal cups and a square insert can be removed for large cups.

turbosquid

$25

eagle insert on leather or rubber

...eagle insert on leather or rubber for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1342476)

turbosquid

$22

Fireplace Stovax - Knightsbridge Insert

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$22

Fireplaces Stovax - Knightsbridge Insert

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Set

archibase_planet

free

Setting

...setting

archibase planet

setting cover place setting

setting - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Setting

...setting

archibase planet

setting place setting cover

setting - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Setting

...setting

archibase planet

setting place setting cover

setting - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$8

decorative set mens set

...decorative set mens set

3dexport

decorative set men's set

archibase_planet

free

Set

...anet

set kitchen ware kitchen set kitchen tools

set kitchen tools n281114 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

beer set bar equipment

beer set - 3d model for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

cover place setting

set - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

kitchen set kitchen ware

set - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

set cup glass kitchen ware

set - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Set

...set

archibase planet

flatware cover place setting

set n311210 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Printed

design_connected

$27

...print

designconnected

moroso print computer generated 3d model. designed by wanders, marcel.

3ddd

free

Eichholtz Prints

...- eichholtz print central station i

13 - eichholtz print central station ii

14 - eichholtz print marisa

15 - eichholtz print tish

3ddd

$1

Eichholtz Prints

...print abstract - set of 2

10 - eichholtz print orange abstract

11 - eichholtz print buddha right

12 - eichholtz print buddha left

turbosquid

$1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Eichholtz Prints

...of 4

2 - print dunbar 2 set of 4

3 - print guadeloupe 1 set of 4

4 - print guadeloupe 2 set of 4

5 - print giles

6 - print trett

3ddd

$1

Eichholtz Prints

...nt tutti frutti

3 - eichholtz prints watson - set of 2

4 - eichholtz prints antique nautilus - set of 2

5 - eichholtz print tiara

3d_export

$5

Monster for printing

...monster for printing

3dexport

monster 3d model printing

3ddd

free

printed rug

...printed rug

3ddd

ковер

very creative printed rug

3ddd

free

Eichholtz Prints

...иал: бумага

габариты (вхш): 72 x 62 см

описание: print sweetmeat - постер в деревянной раме.

3 - prints varsity set of 2

арти

3ddd

free

Art Print Posters

...art print posters

3ddd

прованс

art print posters by patrician prints