3dExport

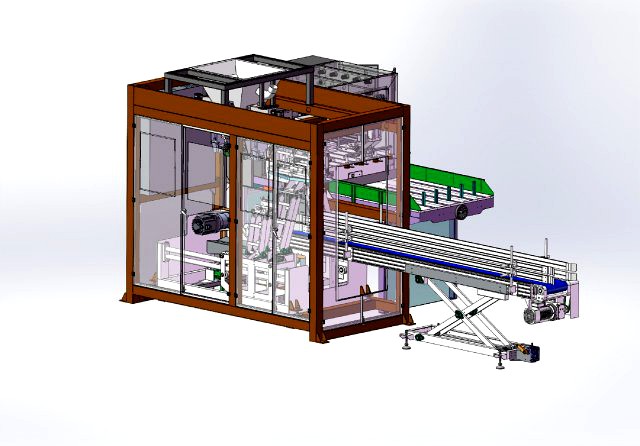

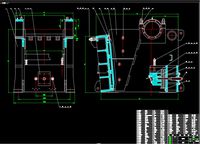

3d drawings bom list for fully automated pocket packing machines

by 3dExport

Last crawled date: 1 year, 10 months ago

the model of automatic bag-packing machine includes: bag-packing, out-packing, bag-holding, pocket-packing, feeding, feeder, bag-packing, bag-packing, bag-picking, bag-picking, bag-drawing, outer frame assembly, presser, guide, shock bag, etc.contains list bom and 3d models

the automatic bagging machine adopts the industry leading design thought, it is ideal equipment for 25kg packaging, strong flexible production, simple operation, stable use and low maintenance. it is suitable not only for the conventional environment, but also for the dusty environment, widely used in food, chemical, fertilizer and mobile protection.and feedstuffs industries suitable packaging material: fine granular or granular material. productivity: 18 tons/h. (25kg/bag according to packing specifications). packaging material automatically enters automatic weighing machine storage through feeder. packing bags are automatically loaded to the down position by manipulator, and the weighing machine is automatically downloaded into the packing bag.the weighing bag is automatically run to the sewing machine, and the machine automatically folds the edge.compact equipment arrangement, low energy consumption, energy saving and high efficiency.convenient operation and maintenance, stable performance, low failure rate and reliable operation.the pneumatic gripper device automatically bag, pneumatic gripper bag, automatically drop bagwith the function of self-testing, it can automatically detect the state of each action of fast, medium, slow, weighing, stabilizing, gripping, unloading and dropping bags.forced packing function in manual mode, the automatic control program is broken, the packing process can be accomplished manually without interrupting production. "the automatic bag-packing machine consists of the following components: bag-packing platform, bag-packing and pre-opening, mechanical hand-holding system, pocket-packing and bag-packing system, pocket-packing and transportation system, external frame assembly, control cabinet, and electrical control system." features: a. suitable for automatic bag, open bag and cover bag packing of flat plastic bag, paper plastic bag, etc. b) it has no bag and no splint detection, no bag or if the straps are not firmly packed.avoid dropping materials to ensure clean environment and continuity of production line. c) the bagging device adopts the completely closed design and the separation technology of the underfeed channel and the dust-removing channel to minimize the dust spillage.the entire perimeter of the machine is fully. set up vibration device, hold the bottom of the bag after loading, shake the material in the bag, remove part of the gas, and make sure the seal is intact. e) precision components are all sealed and installed without nudity. they are suitable for dust environment. this ensures long life of equipment. f) all the components of the packaging machine are made of famous domestic and international company products, which can ensure the long-term, stable and reliable operation of the equipments. g) the fault self-diagnosis function and the sound and light alarm system are used to alert the problem.where there is a safe place for operation, there is a protective device for opening doors and stopping machines to protect the safety of operators. h) designed special out-of-the-bag auxiliary exhaust mechanism to reduce bag opening and vent some air into the bag before filling, so as to increase packing speed. bag storage: double disc automatic switching operation. each plate can store more than 200 empty bags (knitted or paper bags) with a vacuum inspection system.the placement of empty bags is checked by the detector. fill position: automatic bagging function can automatically continuously take out bags, open bags, automatic check, automatic bag packing, etc.the material released from the electronic weighing scale is put into the bag via transition hopper and transferred to the vertical bag conveyor.this machine can perform pneumatic claw hand gripping bag, vacuum suction cup opening bag, positive and negative pressure detection, automatic disposing bag, etc. clamp finisher: complete the closing of a full-fill bag to ensure smooth entry into the folding machine.

the automatic bagging machine adopts the industry leading design thought, it is ideal equipment for 25kg packaging, strong flexible production, simple operation, stable use and low maintenance. it is suitable not only for the conventional environment, but also for the dusty environment, widely used in food, chemical, fertilizer and mobile protection.and feedstuffs industries suitable packaging material: fine granular or granular material. productivity: 18 tons/h. (25kg/bag according to packing specifications). packaging material automatically enters automatic weighing machine storage through feeder. packing bags are automatically loaded to the down position by manipulator, and the weighing machine is automatically downloaded into the packing bag.the weighing bag is automatically run to the sewing machine, and the machine automatically folds the edge.compact equipment arrangement, low energy consumption, energy saving and high efficiency.convenient operation and maintenance, stable performance, low failure rate and reliable operation.the pneumatic gripper device automatically bag, pneumatic gripper bag, automatically drop bagwith the function of self-testing, it can automatically detect the state of each action of fast, medium, slow, weighing, stabilizing, gripping, unloading and dropping bags.forced packing function in manual mode, the automatic control program is broken, the packing process can be accomplished manually without interrupting production. "the automatic bag-packing machine consists of the following components: bag-packing platform, bag-packing and pre-opening, mechanical hand-holding system, pocket-packing and bag-packing system, pocket-packing and transportation system, external frame assembly, control cabinet, and electrical control system." features: a. suitable for automatic bag, open bag and cover bag packing of flat plastic bag, paper plastic bag, etc. b) it has no bag and no splint detection, no bag or if the straps are not firmly packed.avoid dropping materials to ensure clean environment and continuity of production line. c) the bagging device adopts the completely closed design and the separation technology of the underfeed channel and the dust-removing channel to minimize the dust spillage.the entire perimeter of the machine is fully. set up vibration device, hold the bottom of the bag after loading, shake the material in the bag, remove part of the gas, and make sure the seal is intact. e) precision components are all sealed and installed without nudity. they are suitable for dust environment. this ensures long life of equipment. f) all the components of the packaging machine are made of famous domestic and international company products, which can ensure the long-term, stable and reliable operation of the equipments. g) the fault self-diagnosis function and the sound and light alarm system are used to alert the problem.where there is a safe place for operation, there is a protective device for opening doors and stopping machines to protect the safety of operators. h) designed special out-of-the-bag auxiliary exhaust mechanism to reduce bag opening and vent some air into the bag before filling, so as to increase packing speed. bag storage: double disc automatic switching operation. each plate can store more than 200 empty bags (knitted or paper bags) with a vacuum inspection system.the placement of empty bags is checked by the detector. fill position: automatic bagging function can automatically continuously take out bags, open bags, automatic check, automatic bag packing, etc.the material released from the electronic weighing scale is put into the bag via transition hopper and transferred to the vertical bag conveyor.this machine can perform pneumatic claw hand gripping bag, vacuum suction cup opening bag, positive and negative pressure detection, automatic disposing bag, etc. clamp finisher: complete the closing of a full-fill bag to ensure smooth entry into the folding machine.

Similar models

3d_export

$12

sorting and quantitative packaging machine

...dopted to ensure the speed and accuracy;; the structure is stable, the floor area is small, and it is easy to clean and maintain;

cg_trader

$46

Packaging scale and automatic bagging for open pocket woven bag

...s the automatic packaging process of automatic weighing, automatic bag loading, automatic filling, automatic folding and sealing.

grabcad

free

big bag ton dolum hattı ( big bag ton filling line )

...e. the ton bag packaging machine has a high degree of automation, high packaging accuracy, and the packaging speed is adjustable.

grabcad

free

KRAFT BAG, BIG BAG WEIGHING-PACKAGING MACHINE AND DIVERTING CLUTCH FOR GRANULAR MATERIAL

...ng clutch for granular material

grabcad

kraft bag, big bag weighing-packaging machine and diverting clutch for granular material

cg_trader

$65

Full automatic bag-making packing machine

...and powder materials. the equipment can be made a similar packaging machine design reference, welcome to download. ************************************** polygons:...

grabcad

free

Automatic bag feeding vacuum packaging machine

...e monitoring function, if the heating pipe or thermocouple is damaged, it will be displayed on the touch screen to give an alarm.

grabcad

free

industrial 3D model weighing packing machine

...ne #labelingmachine #screenprintingmachine #screw #robotarm #cupmakingmachine #cupmachine #polishingmachine

#assembly #car #cars

cg_trader

$190

Automatic weighing and packing machine

... assembly factory automatic mechanic engine tool device robot conveyor packing packaging weigh package robotic industrial machine

grabcad

free

weighing packing machine

...ne #labelingmachine #screenprintingmachine #screw #robotarm #cupmakingmachine #cupmachine #polishingmachine

#assembly #car #cars

cg_trader

$16

3D Design of Automatic Paper Box Filling and Opening Machine

... box sealing detection function. packaging package box models sorting filling machine automatically industrial industrial machine

Bom

3d_export

$27

n95 folding mask ear band welding machine 3d engineering drawing bom

...original parameters, all parts engineering drawings, has been mass produced many sets, for mature equipment, welcome to download!

3d_export

$20

high-speed tabletting machine n95 full servo 3d 2d bom 120 pieces per minute

...servo 3d 2d bom 120 pieces per minute

3dexport

high-speed tabletting machine n95 full servo 3d + 2d + bom, 120 pieces per minute

3d_export

$10

new version of semi-automatic rotating mask ear strap welding machine 3d engineering drawing bom

...ngineering drawing bom

3dexport

new version of semi-automatic rotating mask ear strap welding machine 3d engineering drawing bom

3d_export

$250

production of needle inserts including dfm-bom

...ctional feed, sectional pin, grab mouldclip into pin, pin cut-off module;<br>3. check for assembly after insertingin place;

3d_export

$49

source file engineering drawing bom of generation 2 one drag two mask machine

... mass production, the most common in the market, with stable production and high efficiency. the drawings are for reference only.

3d_export

$200

automatic lab device - cell phone case shell transparent film packaging with bom list s

...ce a transparent film package outside the mobile phone box, an automatic film cutting film four angles cut and then heat sealing.

3d_export

$10

meltblown cloth production equipment full set of 3d engineering drawings bom electrical

...technical support for mask manufacturers and provide a basis for market supervision, so that consumers can choose suitable masks.

3d_export

$50

3d engineering drawing of cup mask production line list bom

...ools, cutting edges and oily <br>4. integrated manufacturing of several processes, reasonable planning and higher power2

3d_export

$50

semi auto earloop welding machine

...made sw2019 and step , dwg , pdf , bom ...

3d_export

$5

Grenade 3D Model

...grenade 3d model 3dexport fire bom grenade granaat uzrgm concept firearm frag grenade 3d model...

Automated

turbosquid

$19

Automation for gates

... model automation for gates for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1600153)

turbosquid

$5

Automated Teller Machine

...tomated teller machine for download as c4d, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1677841)

turbosquid

$30

AUTOMATED GUARD STATION

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$19

Drink Automate New

...w office old red retro rust soda store vending vintage

old rusty drink machine, and new shiny. xsi and lvo exported from blender.

evermotion

$10

home automation system 32 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 35 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 38 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 24 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 30 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

evermotion

$10

home automation system 27 am95

...ion system with all textures, shaders and materials.

it is ready to use, just put it into your scene.. evermotion 3d models shop.

3d_export

$12

pocket stove

...pocket stove

3dexport

pocket stove

3d_ocean

$6

Pocket Watch

...calendar chain clock gear gold golden jewelry luxury old-fashioned pocket pocket watch time watch

pocket watch on a 2009 calendar

3d_export

$5

Pocket Watch

...pocket watch

3dexport

pocket watch old style

3d_ocean

$15

pocket watch

... calendar chain clock gear gold golden jewelry luxury old-fashioned pocket pocket watch time watch

high poly ancient pocket watch

3d_export

$8

Pocket watch

...pocket watch

3dexport

pocket watch with a photo of new york in the 1900s

turbosquid

$5

Pocket flashlight

...uid

royalty free 3d model pocket flashlight for download as on turbosquid: 3d models for games, architecture, videos. (1271804)

3d_export

free

Pocket flashlight

...this is a 3d model of a pocket flashlight. it is quite realistic and you can add this model to your project and enjoy the result.

archive3d

free

Pocket 3D Model

...e3d

bag pocket paper bag

pocket n040608 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$29

Pocket Watch

...squid

royalty free 3d model pocket watch for download as max on turbosquid: 3d models for games, architecture, videos. (1346695)

turbosquid

$20

Pocket Watch

...squid

royalty free 3d model pocket watch for download as c4d on turbosquid: 3d models for games, architecture, videos. (1352289)

List

3ddd

$1

LIST

...list

3ddd

папоротник

растение[size=xx-small][/size][font=arial][/font][color=000000][/color] :-)

turbosquid

$4

List paint

...

royalty free 3d model list paint for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1536512)

turbosquid

$30

Dolphin Listed

... dolphin listed for download as 3ds, fbx, blend, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1394939)

turbosquid

$20

Vintage Wooden Bucket With List

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

wood Grocery List Holder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Деревянные вазы The Wish List

...x+fbx, +obj

corona renderhttp://www.rdh.ru/site/dizayn/3798--derevyannye_vazy_the_wish_list_gareta_nila_i_zakhi_khadid/

3ddd

$1

LAMPE LISTE ROUGE 298

...d

ralphpucci

illimitee rouge/blanc

33.1h x 18.5d x 8.3hhttp://ralphpucci.net/lighting/herve-van-der-straeten/collection

3d_export

$200

automatic lab device - cell phone case shell transparent film packaging with bom list s

...ce a transparent film package outside the mobile phone box, an automatic film cutting film four angles cut and then heat sealing.

3d_export

$50

3d engineering drawing of cup mask production line list bom

...ools, cutting edges and oily <br>4. integrated manufacturing of several processes, reasonable planning and higher power2

3ddd

free

Городская мебель

...ствол , дерево , урна , скамья , вазон http://www.stimex-trade.ru/catalog/list722 http://www.stimex-trade.ru/catalog/list/614 http://www.stimex-trade.ru/catalog/list/467 http://www.stimex-trade.ru/catalog/list/300 http://www.stimex-trade.ru/catalog/list/466 http://www.stimex-trade.ru/catalog/list/581 http://www.stimex-trade.ru/catalog/list/755 ...

Drawings

archibase_planet

free

Drawing

...drawing

archibase planet

cooking hood kitchen furniture

drawing air - 3d model for interior 3d visualization.

3d_export

$35

house drawing

...house drawing

3dexport

house drawing

3d_export

$5

drawing of planter

...drawing of planter

3dexport

drawing of planter

turbosquid

$15

Draws

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

draws

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$13

Draw Table

...draw table

designconnected

rex kralj draw table computer generated 3d model. designed by studio rex kralj.

3d_export

$22

750x1060 jaw crusher set drawing 105 CAD drawings

...750x1060 jaw crusher set drawing 105 cad drawings

3dexport

750x1060 jaw crusher set drawing (105 cad drawings)

turbosquid

$5

Table with draw

...id

royalty free 3d model table with draw for download as max on turbosquid: 3d models for games, architecture, videos. (1232200)

turbosquid

$2

Drawing Wire

...uid

royalty free 3d model drawing wire for download as blend on turbosquid: 3d models for games, architecture, videos. (1462970)

turbosquid

$1

Drawing Table

...quid

royalty free 3d model drawing table for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1310235)

Fully

turbosquid

$50

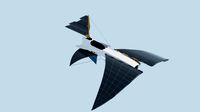

Drone fully rigged

...

royalty free 3d model drone fully rigged for download as max on turbosquid: 3d models for games, architecture, videos. (1282280)

turbosquid

$12

FULLY PARAMETRIC CHAIR

...alty free 3d model fully parametric chair for download as rvt on turbosquid: 3d models for games, architecture, videos. (1280209)

turbosquid

$10

firetruck-fully-rigged

...yalty free 3d model firetruck-fully-rigged for download as ma on turbosquid: 3d models for games, architecture, videos. (1653811)

turbosquid

$6

Fully rigged character

...ty free 3d model fully rigged character for download as blend on turbosquid: 3d models for games, architecture, videos. (1486076)

turbosquid

$3

Fully Rigged shark

...ee 3d model fully rigged 3d shark model for download as blend on turbosquid: 3d models for games, architecture, videos. (1517695)

turbosquid

$75

Fully Customizable Hospital

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Fully Rigged Link

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Troy W Fully Covered

...troy w fully covered

designconnected

magis troy w fully covered computer generated 3d model. designed by wanders, marcel.

cg_studio

$99

Pepe fully rigged3d model

...ully rigged3d model

cgstudio

.max - pepe fully rigged 3d model, royalty free license available, instant download after purchase.

3d_export

$60

Ankylosaur 8K - fully animated

...ankylosaur 8k - fully animated

3dexport

Machines

archibase_planet

free

Machine

...machine

archibase planet

sewing-machine sewing machine equipment

singer machine- 3d model for interior 3d visualization.

archibase_planet

free

Machine

...hine

archibase planet

percolator equipment coffee-machine

machine n230708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Machine

...chibase planet

percolator coffee-machine kitchen equipment

coffee machine - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Slot machine

...ase planet

slot machine slot-machine playing machine

slot machine n260311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$7

Machine

...ne

turbosquid

royalty free 3d model machine for download as on turbosquid: 3d models for games, architecture, videos. (1391792)

3d_ocean

$10

War machine

...war machine

3docean

camuflage machine robot war war machine

war machine created in 3dmax 2009 15.497-poly count

turbosquid

$7

machine

...turbosquid

royalty free 3d model machine for download as obj on turbosquid: 3d models for games, architecture, videos. (1452674)

3d_ocean

$12

Weighing-machine

...weighing-machine

3docean

market shop weighing-machine

3d model weighing-machine

archibase_planet

free

Sewing machine

...ine

archibase planet

sewing machine sewing-machine

sewing machine n080311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee machine

...se planet

coffee machine percolator coffee-machine

coffee machine n010715 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Packing

3d_export

$5

pack

...pack

3dexport

low poly pack

archibase_planet

free

Packing

...packing

archibase planet

wrapping wrapper packing

packing 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Packing

...packing

archibase planet

packaging wrapping packing

packing 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Packing

...packing

archibase planet

wrapper packing packaging

packing 4 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Packing

...packing

archibase planet

packaging wrapping packing

packing 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Packing

...packing

archibase planet

packing packaging wrapper

packing 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$7

Health Pack Armor Pack and Ammo Pack 3D Model

...pack 3d model

3dexport

health armor ammo pack check point game

health pack armor pack and ammo pack 3d model u2501 99166 3dexport

3d_ocean

$79

Turrets Pack - Tower Defense Pack

...be used in any sf type of game, especially in tower defense games. the pack includes: - flack cannon: 6239 polygons - chain gu...

3d_export

$7

arbalet pack

...arbalet pack

3dexport

arbalet pack

3d_export

$5

rocks pack

...rocks pack

3dexport

rocks pack