CG Trader

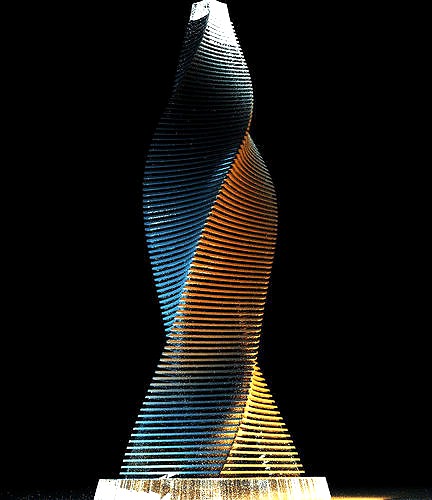

3D Building

by CG Trader

Last crawled date: 3 years, 2 months ago

Construction 3D printing is a method for manufacturing construction elements or entire buildings by means of a 3D printer printing concrete, polymer, metal, or other materials, layer-by-layer. The most common type of printer is based on a robotic arm that moves back and forth while extruding concrete. 3D printing technology has had a revolutionary impact on enterprises around the world. It enables businesses to quickly develop models and prototypes, expediting their ability to test and fine-tune new products. It also makes it easy and affordable to manufacture pieces and components that keep important machinery working as intended, such as medical testing and diagnostic equipment. According to a Forbes report, more than half of all enterprises say they are actively using 3D printing in product development and production. Here is the ultimate guide to 3D printing in construction. We will tell you more about the benefits of 3D printing for the construction industry, and we will see the different technologies developed to revolutionize this sector. Is 3D printing the future of construction? Can it become an alternative to traditional construction techniques in the future? That’s also what we are going to see! You will find some information about the first experiments of 3D printed houses or 3D printed buildings. Still, more importantly, we will see how additive manufacturing could be helpful for you and your projects. How could you use it at your scale? For which projects? We hope all these tremendous architectural projects will inspire you. The advantages of 3D printing start with using the correct 3D software. Finding the right architecture software can be complicated. From ArchiCAD to Revit, many programs are dedicated to architecture and offer great toolsets. Why are these software so useful? Even if you are not planning on using 3D printing, these programs can help you better visualize your projects for yourself and your customers. You will be able to produce a photorealistic rendering and do and re-do your 3D models until it matches your expectations. Thanks to these advanced software, you can turn any of your ideas into detailed models and designs. Moreover, a 3D modeling software using the Cloud will allow you to optimize your team’s collaboration and communication. Your work will be accessible to anybody, and you’ll all be able to work on the same model. Now that you know a little about how it’s done let’s discuss why we do it. One might think we have suitable technologies for building different structures, we make stable houses, apartments, and offices, is there still room for improvement? Oh yes. Rebuilding whole cities after a natural disaster, giving shelter to homeless people, and generally building more sustainable habitats- are only a few problems that 3D printing can help with. The main advantage of using 3D printing in the construction industry is saving many production costs on material waste. That’s because a 3D printer, such as robotic arms, uses precisely the amount of material they need. Producing buildings layer by layer and with lattice structures inside allows for a considerable cost reduction. Not only that, but they are also capable of using recycled materials. With Topology Optimization, creating even more material-efficient models is possible. This software helps to eject not necessary material sections out of a model without interfering with the functionality. This factor also benefits the environment. 3D printing has a much smaller impact than traditional ways of manufacturing. An Italian company called WASP took 3D printing into a significant development and designed one of the largest 3D printers in the world capable of producing homes out of local materials and using green energy (hydro, wind, or solar power). This means much smaller emissions, a big problem in today’s construction industry. Last year we talked about the first family to move into a 3D printed house. The house in question was produced in Nantes, France, and is called the Yhnova project. It took only 54 hours to print the house, and the overall cost was about 20% cheaper than building a traditional home. Additive Manufacturing can help to build a better future for the construction industry.

As mentioned above, using Additive Manufacturing allows for less material usage and involves fewer people working on the construction. 3D printing is also a much faster technology. Those factors radically reduce the costs of building any 3D printed construction. While 3D printing structures, we use just the amount of material we need, therefore, we are eco-friendly and save money. This aspect can really bring the costs down. 3D technologies also reduce supply costs. We can also save a lot of time, 3D printers don’t need to eat or sleep, their working hours are more adjustable, and they are much faster than people. And the faster you build, the more money you save.. .

. . .

.

. .

.

. .

. . comfort computer equipment footwear basketball court building life empire state buildings a new hut assault rifle land rover rococo giusti biology stylish peppermint candy scanned 3d models various

As mentioned above, using Additive Manufacturing allows for less material usage and involves fewer people working on the construction. 3D printing is also a much faster technology. Those factors radically reduce the costs of building any 3D printed construction. While 3D printing structures, we use just the amount of material we need, therefore, we are eco-friendly and save money. This aspect can really bring the costs down. 3D technologies also reduce supply costs. We can also save a lot of time, 3D printers don’t need to eat or sleep, their working hours are more adjustable, and they are much faster than people. And the faster you build, the more money you save.. .

. . .

.

. .

.

. .

. . comfort computer equipment footwear basketball court building life empire state buildings a new hut assault rifle land rover rococo giusti biology stylish peppermint candy scanned 3d models various