GrabCAD

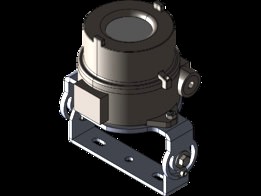

25W Explosion Proof Red Crane LED Warning Light- C1D1-2 - C2D1-2 - Aluminum Housing - 9-60V DC

by GrabCAD

Last crawled date: 1 year, 10 months ago

http://www.larsonelectronics.com/p-147128-25w-explosion-proof-red-crane-led-warning-light-c1d1-2-c2d1-2-aluminum-housing-9-60v-dc.aspx

Made in Texas

The EXHL-TRN-LE4-CRN-RED-1224 from Larson Electronics is an Explosion Proof Red Crane LED Warning Light that produces 2,250 lumens while drawing only 25 watts. Crane operators may use this compact luminary to notify nearby pedestrians and workers about ongoing crane operations. The EXHL-TRN-LE4-CRN-RED-1224 is Class I, Divisions 1 & 2, Groups A, B, C, D, Class I, Zones 1 & 2, Groups IIB+H2, IIA, Class II, Divisions 1 & 2, Groups E, F ,G and Class III Divisions 1 & 2 rated for hazardous areas and is listed for use worldwide including the United States, Canada, Europe and Asia. This explosion proof LED light offers 9 to 60-volt universal compatibility, which includes commonly used 12V DC and 24V DC voltages.

The EXHL-TRN-LE4-CRN-RED-1224 produces 2,250 lumens of intense LED light for real-time visual notification of crane operations. This 25-watt unit, which operates on universal 9-60V DC, features a small form factor (SFF) design for easy installation in tight spaces, making it ideal for applications where electrical power and mounting space is at a premium. Five 5-watt red LEDs provides a high intensity center beam which is visible during daytime and nighttime operations. An adjustable surface mount mechanism allows operators to control the direction of the beam by tilting the unit towards the desired target.

Standard crane warning systems consist of strobe lights or audible alarms. Strobe lights may not always be visible with high illumination settings. The strobe lights on cranes, depending on the position of the light, can be a hindrance to the crane operator by reducing the visibility due to continual contrasting from the strobe light. Audible alarms are the most disliked warning system for cranes, especially operators and pedestrians within work forces that have to listen to this alarm continually throughout the work day. Both strobe lights and audible alarms are often ignored due to conditioning of the warning system from day to day exposure. The EXHL-TRN-LE4-CRN-RED-1224 addresses both of the above issues, providing a new system that is not obnoxious and will not get on the nerves of employees, while providing the warning indication required by OSHA to keep employees and pedestrians within the work force safe.

LED Benefits: Unlike gas burning and arc type lamps that have glass bulbs, LEDs have no filaments or fragile housings to break during operation and/or transportation. Instead of heating a small filament or using a combination of gases to produce light, light emitting diodes (LEDs) use semi-conductive materials that illuminate when electric current is applied, providing instant illumination with no warm up or cool down time before re-striking. Because there is no warm up period, this light can be cycled on and off with no reduction in lamp life.

LED lights run at significantly cooler temperatures than traditional metal halide and high pressure sodium lights and contain no harmful gases, vapors, or mercury, making them both safer and more energy efficient. No extra energy is wasted in cooling enclosed work areas due to external heat emissions from bulb type lights, and the operator risks associated with traditional lighting methods, such as accidental burns and exposure to hazardous substances contained in the glass bulbs, are eliminated. In addition, LEDs are also safer for the environment as they are 100% recyclable, which eliminates the need for costly special disposal services required with traditional gas burning and arc type lamps.

Heat Management: Heat is the single largest factor in premature LED failure and color shifting. These LED units contain advanced drivers which use pulse width modulation to control heat buildup rather than simple voltage regulators which are typically harsh on sensitive electronics and can contribute to early LED failure. These units automatically sense the temperature of each LED and adjust the energy frequency or "duty cycle" accordingly to maintain heat levels within acceptable ranges. This system in essence flashes current at an extremely fast on and off rate to each LED based upon the LED's core temperature. This flash rate is too fast to detect with the human eye, but provides precise control of the current flowing to each LED and thus the heat it generates. This allows the LEDs to be driven at up to 100% capacity without overheating or visible loss of light output. The LEDs are always driven at the same voltage but the duty cycle, however, is changed to alter how long the LEDs are actually on or off. The end result is more light with less heat and longer LED life with an average 70% lumen maintenance after 50,000 hours.

Durability: The EXHL-TRN-LE4-CRN-RED-1224 explosion proof LED light fixture from Larson Electronics is rated NEMA Type 3, 4, 4X, 7 (B,C,D) and 9 (E,F,G) and designed to withstand the rigors of demanding environmental and operating conditions while remaining lightweight and easy to use. These units can operate in temperatures of -40° Celsius to 60° Celsius, are waterproof to 3 meter and resist ingress of dust, dirt and humidity. The housings are formed from extruded aluminum and the lenses are unbreakable polycarbonate. The LEDs offer inherent LED resistance to shocks and vibrations.

Mounting: This explosion proof LED warning light features an adjustable surface mount bracket for seamless control. The included adjustable flat surface bracket has two set screws on the bracket, allowing operators to loosen the mounting bracket, adjust the light's tilt orientation, and retighten to hold the luminary in position. A single thru-hole mounting bolt allows operators to adjust the rotation of the fixture by loosening one bolt.

Wiring: Terminal strips inside the fixture allow operators to make electrical connections. Wiring is fed through rigid pipe to the 3/4" NPT hubs on either side of the fixture and tied in to the fixture’s terminal strips, completing the electrical connection.

Made in Texas

The EXHL-TRN-LE4-CRN-RED-1224 from Larson Electronics is an Explosion Proof Red Crane LED Warning Light that produces 2,250 lumens while drawing only 25 watts. Crane operators may use this compact luminary to notify nearby pedestrians and workers about ongoing crane operations. The EXHL-TRN-LE4-CRN-RED-1224 is Class I, Divisions 1 & 2, Groups A, B, C, D, Class I, Zones 1 & 2, Groups IIB+H2, IIA, Class II, Divisions 1 & 2, Groups E, F ,G and Class III Divisions 1 & 2 rated for hazardous areas and is listed for use worldwide including the United States, Canada, Europe and Asia. This explosion proof LED light offers 9 to 60-volt universal compatibility, which includes commonly used 12V DC and 24V DC voltages.

The EXHL-TRN-LE4-CRN-RED-1224 produces 2,250 lumens of intense LED light for real-time visual notification of crane operations. This 25-watt unit, which operates on universal 9-60V DC, features a small form factor (SFF) design for easy installation in tight spaces, making it ideal for applications where electrical power and mounting space is at a premium. Five 5-watt red LEDs provides a high intensity center beam which is visible during daytime and nighttime operations. An adjustable surface mount mechanism allows operators to control the direction of the beam by tilting the unit towards the desired target.

Standard crane warning systems consist of strobe lights or audible alarms. Strobe lights may not always be visible with high illumination settings. The strobe lights on cranes, depending on the position of the light, can be a hindrance to the crane operator by reducing the visibility due to continual contrasting from the strobe light. Audible alarms are the most disliked warning system for cranes, especially operators and pedestrians within work forces that have to listen to this alarm continually throughout the work day. Both strobe lights and audible alarms are often ignored due to conditioning of the warning system from day to day exposure. The EXHL-TRN-LE4-CRN-RED-1224 addresses both of the above issues, providing a new system that is not obnoxious and will not get on the nerves of employees, while providing the warning indication required by OSHA to keep employees and pedestrians within the work force safe.

LED Benefits: Unlike gas burning and arc type lamps that have glass bulbs, LEDs have no filaments or fragile housings to break during operation and/or transportation. Instead of heating a small filament or using a combination of gases to produce light, light emitting diodes (LEDs) use semi-conductive materials that illuminate when electric current is applied, providing instant illumination with no warm up or cool down time before re-striking. Because there is no warm up period, this light can be cycled on and off with no reduction in lamp life.

LED lights run at significantly cooler temperatures than traditional metal halide and high pressure sodium lights and contain no harmful gases, vapors, or mercury, making them both safer and more energy efficient. No extra energy is wasted in cooling enclosed work areas due to external heat emissions from bulb type lights, and the operator risks associated with traditional lighting methods, such as accidental burns and exposure to hazardous substances contained in the glass bulbs, are eliminated. In addition, LEDs are also safer for the environment as they are 100% recyclable, which eliminates the need for costly special disposal services required with traditional gas burning and arc type lamps.

Heat Management: Heat is the single largest factor in premature LED failure and color shifting. These LED units contain advanced drivers which use pulse width modulation to control heat buildup rather than simple voltage regulators which are typically harsh on sensitive electronics and can contribute to early LED failure. These units automatically sense the temperature of each LED and adjust the energy frequency or "duty cycle" accordingly to maintain heat levels within acceptable ranges. This system in essence flashes current at an extremely fast on and off rate to each LED based upon the LED's core temperature. This flash rate is too fast to detect with the human eye, but provides precise control of the current flowing to each LED and thus the heat it generates. This allows the LEDs to be driven at up to 100% capacity without overheating or visible loss of light output. The LEDs are always driven at the same voltage but the duty cycle, however, is changed to alter how long the LEDs are actually on or off. The end result is more light with less heat and longer LED life with an average 70% lumen maintenance after 50,000 hours.

Durability: The EXHL-TRN-LE4-CRN-RED-1224 explosion proof LED light fixture from Larson Electronics is rated NEMA Type 3, 4, 4X, 7 (B,C,D) and 9 (E,F,G) and designed to withstand the rigors of demanding environmental and operating conditions while remaining lightweight and easy to use. These units can operate in temperatures of -40° Celsius to 60° Celsius, are waterproof to 3 meter and resist ingress of dust, dirt and humidity. The housings are formed from extruded aluminum and the lenses are unbreakable polycarbonate. The LEDs offer inherent LED resistance to shocks and vibrations.

Mounting: This explosion proof LED warning light features an adjustable surface mount bracket for seamless control. The included adjustable flat surface bracket has two set screws on the bracket, allowing operators to loosen the mounting bracket, adjust the light's tilt orientation, and retighten to hold the luminary in position. A single thru-hole mounting bolt allows operators to adjust the rotation of the fixture by loosening one bolt.

Wiring: Terminal strips inside the fixture allow operators to make electrical connections. Wiring is fed through rigid pipe to the 3/4" NPT hubs on either side of the fixture and tied in to the fixture’s terminal strips, completing the electrical connection.

Similar models

grabcad

free

25W Explosion Proof Amber Crane LED Warning Light- C1D1-2 - C2D1-2 - Aluminum Housing - 9-60V DC

...pplications: crane warning systems, crane notifications, crane safety systems in hazardous locations and industrial environments.

grabcad

free

50mW Explosion Proof Red Crane Warning Laser- C1D1-2 - C2D1-2 - Aluminum Housing - 12V DC

...manufacturing applications and anywhere requiring overhead crane safety lights. similar to forklift safety lights, this product will add an...

grabcad

free

Explosion Proof Red Crane Warning Laser- C1D1-2 - C2D1-2 - Aluminum Housing - 12-24V DC

...manufacturing applications and anywhere requiring overhead crane safety lights. similar to forklift safety lights, this product will add an...

grabcad

free

25W Explosion Proof Blue Forklift LED Warning Light- C1D1-2 - C2D1-2 - Aluminum Housing - 9-60V DC

..." npt hubs on either side of the fixture and tied in to the fixture’s terminal strips, completing the electrical connection.

grabcad

free

Explosion Proof Red Crane Warning Laser- C1D1-2 - C2D1-2 - Surface Mount - 12-24V DC - Aluminum

...manufacturing applications and anywhere requiring overhead crane safety lights. similar to forklift safety lights, this product will add an...

grabcad

free

50mW Explosion Proof Green Crane Warning Laser- C1D1-2 - C2D1-2 - Aluminum Housing - 12V DC

...manufacturing applications and anywhere requiring overhead crane safety lights. similar to forklift safety lights, this product will add an...

grabcad

free

50mW Explosion Proof Red Crane Warning Laser- C1D1-2 - C2D1-2 - Surface Mount - 12V DC - Aluminum

...manufacturing applications and anywhere requiring overhead crane safety lights. similar to forklift safety lights, this product will add an...

grabcad

free

25W Explosion Proof Red LED Warning Strobe Light - C1D1 - Magnetic Mount - Aluminum - 9-60V DC

...cations: industrial warning systems, industrial notifications, safety systems in hazardous locations and industrial environments.

grabcad

free

25W Explosion Proof Red LED Indicator Light- C1D1-2 - C2D1-2 - Aluminum Housing- 9-60VDC - 10' Cord

...tion to low voltage power sources.

applications: situations that require a reliable led indicator light inside a hazardous area.

grabcad

free

25W Explosion Proof Amber LED Warning Strobe Light - C1D1 - Magnetic Mount - Aluminum - 9-60V DC

...cations: industrial warning systems, industrial notifications, safety systems in hazardous locations and industrial environments.

C2D1

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 480V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 208V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 208V 1PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

5000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 480V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 240V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 240V 1PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

Explosion Proof Control Station - C1D1/C2D1 - Local/Off/Auto 3-Pos Switch - 10k Ohm Potentiometer

...int spray booths, food manufacturing buildings, agricultural sites, grain storage centers, small motors, manual control and more.

grabcad

free

Explosion Proof SPST Three Phase Starter Switch - Copper Free Aluminum - 30 Amp Rated - C1D1 C2D1

...applications: manufacturing, industrial, warehouse, lighting, lighting, wet areas or locations where combustible dust is present.

grabcad

free

Hazardous Location Exit Sign - C1D2 - C2D1&2 - IP65 - 120V/277VAC - Green or Red Exit Sign

...rants making identification and location of exits in emergency situations easier than with typical self illuminated exit markers.

grabcad

free

Explosion Proof Red Crane Warning Laser- C1D1-2 - C2D1-2 - Surface Mount - 12-24V DC - Aluminum

...nal strips, completing the electrical connection.

applications: crane safety, crane measurements, crane warning system and more.

60V

thingiverse

free

Greenworks 60v max - Dewalt 60v Flexvolt converter (Incomplete) by TurboUSMC

...e anyway in case someone else out there wants to try figuring that part of it out. i'm not an expert on electronics. go nuts.

thingiverse

free

Ubiquiti POE 50W/60V Adapter Skadis Mount by RaihaX

...ubiquiti poe 50w/60v adapter skadis mount by raihax

thingiverse

needed to mount my poe adapter for my flex switch.

thingiverse

free

Ubiquiti POE 50W/60V Adapter Skadis Mount by RaihaX

...ti poe 50w/60v adapter skadis mount by raihax

thingiverse

remix to allow for mounting on a skadis pegboard - use universal hook.

thingiverse

free

Wall Mount For DeWalt 12, 20 & 60V MAX Batteries. by cmadson

...printed this in polymaker polylite pla with the settings that you can find in the attached .gcode and simplify3d .factory files.

thingiverse

free

DeWalt Battery holder (All 20v / 60v) by TurboUSMC

...h petg because i like the gray color matching.

hole in the bottom is to ensure any potential moisture can drain from the holder.

thingiverse

free

DPT9010 600W (IN 0-60V / OUT 0-90V) Step Up Power Module Case

...dpt9010 600w (in 0-60v / out 0-90v) step up power module case

thingiverse

step upo power supply module case .

thingiverse

free

Case for "1200W DC-DC Boost Converter Power Supply 8-60V 12V Step up to 12-83V 24V 48V 20A" by took

...er power supply 8-60v 12v step up to 12-83v 24v 48v 20a" by took

thingiverse

case for a step up converter i bought on ebay.

thingiverse

free

Infento battery box for 60V 15Ah Li Ion + Controller by teamwittholz

...the 2 parts need to be connected using 6x m6 threaded rods and big washer and locknuts.

no overhangs, big base, is easy to print.

thingiverse

free

Dewalt 20v Tool Holder by dpmakestuff

...thingiverse this is a simple mount for storing 20v (60v flexvolt) dewalt tools while the batteries are charging. two...

thingiverse

free

Motor board din rail mount by Xplode85

...rail mount for a motor controller sold as "dc 10v-60v reversible motor driver speed control governor soft start h-bridge"...

C1D1

grabcad

free

Explosion Proof Enclosure, C1D1, 8'' x 12'' x 6'' Internal Dims, Surface Mount, N3R

...; in height. a removable backplate for easy mounting of equipment outside of the enclosure can be provided at an additional cost.

grabcad

free

Explosion Proof Cable Gland, 2" NPT, Nickel Plated Brass, 1.40-1.73" OD, C1D1 ATEX IEC Ex N4X

...ctions, cable fittings, explosive work sites, hazardous locations, instrumentation, telecommunication, cable management and more.

grabcad

free

Explosion Proof Cable Gland, 1" NPT, Nickel Plated Brass, 0.67-1.03" OD, C1D1 ATEX IEC Ex N4X

...ctions, cable fittings, explosive work sites, hazardous locations, instrumentation, telecommunication, cable management and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 480V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 208V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 208V 1PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

5000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 480V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 240V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 240V 1PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

Explosion Proof Cable Gland, 3/4" NPT, Nickel Plated Brass, 0.44-0.78" OD, C1D1 ATEX IEC Ex N4X

...ctions, cable fittings, explosive work sites, hazardous locations, instrumentation, telecommunication, cable management and more.

25W

3ddd

$1

Massive - 41633/11/10

..., massive , бельгия , металл , хрусталь мощность: 25w цоколь: 7xg9 размеры:...

3ddd

$1

triad 15 pendant

...lamping: 15 type a g25 bulbs max 60w each 25w matte white bulbs...

3ddd

$1

Favourite 1155-2W бра

..., om 1155-2w настенный светильник размер светильника: w370*d210*h110 лампы: e14*2*25w цвет, отделка: античная...

3ddd

$1

Willow Chair

...3ddd lexington , willow willow chair item: 1563-11 dimensions: 25w x 33½d x 50½h in. inside depth: 21 in....

3ddd

$1

Favourite 1155-1W бра

..., om 1155-1w настенный светильник размер светильника: w240*d210*h110 лампы: e14*1*25w цвет, отделка: античная...

3ddd

$1

Favourite 1155-4W картинная подстветка

..., om 1155-4w настенный светильник размер светильника: w720*d210*h110 лампы: e14*4*25w цвет, отделка: античная...

3ddd

$1

Favourite 1150-1W картинная подсветка

..., om 1150-1w настенный светильник размер светильника: w270*h125*d220 лампы: 1*e14*25w цвет, отделка: в основании гипсовый медальон, античная...

3ddd

free

Favourite 1150-2W картинная подстветка

..., om 1150-2w настенный светильник размер светильника: w400*h125*d220 лампы: 2*e14*25w цвет, отделка: в основании гипсовый медальон, античная...

3ddd

$1

19TH C. ROCOCO IRON & SMOKE CRYSTAL SCONCE 18"

...rococo iron & smoke crystal sconce 18" uses three 25w max. bulbs (four bulbs...

3ddd

free

Мини-прожектор на шинопроводе Milo L 110 33213

...фабрики martini название: milo l 110 артикул: 33213 мощность: 25w источник света: led оптика: 64° poly: 6 441, verts:...

Proof

turbosquid

$6

bullet proof jacket

...el bullet proof jacket for download as 3ds, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1193147)

turbosquid

$1

Sound Proofing Foam

... sound proofing foam for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1289027)

turbosquid

$25

Flame proof fibricks_lit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$149

Bullet Proof Vest with molle attachments

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$40

chevrolet nova ss 70 death proof

...chevrolet nova ss 70 death proof

3dexport

3d_export

$9

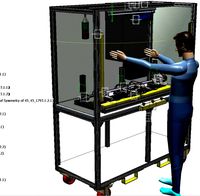

of automobile component error proofing system

...cific product defects; the other is to check the products one by one through cheap means to determine whether they are qualified.

turbosquid

$29

Nikon Coolpix AW110 rugged and proof digital camera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Armoured fighting vehicles armoured vehicles with explosion-proof wheels

...ured vehicles with explosion-proof wheels for download as max on turbosquid: 3d models for games, architecture, videos. (1629664)

turbosquid

$27

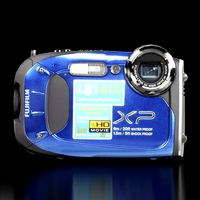

Fujifilm FinePix XP60 Blue rugged and proof digital camera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$23

Panasonic Lumix DMC-TS5 rugged and proof digital gamera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Explosion

3d_export

$6

explosion

...explosion

3dexport

3 d of explosion

3d_export

$10

explosion

...explosion

3dexport

3d model of explosion for 3d printing

turbosquid

$5

Explosion

...rbosquid

royalty free 3d model explosion for download as max on turbosquid: 3d models for games, architecture, videos. (1202603)

3d_export

$10

Explosion

...explosion

3dexport

turbosquid

$14

Explosion

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Explosive

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Explosive Barrel

...explosive barrel 3docean barrel decoration explosion explosive industrial low low poly metal object old poly...

3ddd

free

KOLARZ Serie Explosion

... serie explosion , австрия

kolarz serie explosion 0109.118.5.kot. врай. текстуры.

3d_export

$5

atomic bomb explosion

...atomic bomb explosion

3dexport

atomic bomb explosion

turbosquid

$1

explosives pack

...squid

royalty free 3d model explosives pack for download as on turbosquid: 3d models for games, architecture, videos. (1316376)

Crane

archibase_planet

free

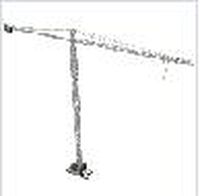

Crane

...rane

archibase planet

crane harbor crane lifting crane port crane

crane 1 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Crane

...rane

archibase planet

crane port crane lifting crane harbor crane

crane 4 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Crane

...rane

archibase planet

crane port crane lifting crane harbor crane

crane 2 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Crane

...rane

archibase planet

crane harbor crane lifting crane port crane

crane 3 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

Crane

...crane

archibase planet

crane lifting crane hoisting crane

crane mob n080708 - 3d model for interior 3d visualization.

archibase_planet

free

Crane

...e

archibase planet

crane lifting crane hoisting crane

crane n110314 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

archibase_planet

free

Crane

...base planet

crane lifting crane hoisting crane gibbet

crane n100713 - 3d model (*.gsm+*.3ds+*.max) for exterior 3d visualization.

3d_export

$29

Crane

...crane

3dexport

a cute crane

3d_ocean

$18

Crane

...crane

3docean

crane lift loader machine work

this is a high poly 3d model crane

archibase_planet

free

Crane

...crane

archibase planet

crane

saddle jib crane cel - 3d model. free download.

Warning

turbosquid

$10

Warning Flammable

...model warning flammable for download as ma, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1628354)

turbosquid

$15

Warning Symbol

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Warning Barrier

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

warning triangle

...ady. with blender and photoshop .psd files for personal customization!<br>verts: 332<br>faces: 222<br>tris: 648

3d_export

$20

Warning Signs 3D Model

...warning signs 3d model

3dexport

sign warning traffic road roadway european

warning signs 3d model supermegamau 18750 3dexport

turbosquid

$29

5 Warning Light

...id

royalty free 3d model 5 warning light for download as c4d on turbosquid: 3d models for games, architecture, videos. (1538332)

turbosquid

free

Radiation Warning Sign

...alty free 3d model radiation warning sign for download as fbx on turbosquid: 3d models for games, architecture, videos. (1446692)

turbosquid

$20

Radar Warning Reciever

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Plastic Warning Drum

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

signs-warning-001

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Dc

design_connected

$27

DC 290

...dc 290

designconnected

ceccotti collezioni dc 290 computer generated 3d model. designed by de cotiis, vincenzo.

design_connected

$27

DC 300

...dc 300

designconnected

ceccotti collezioni dc 300 computer generated 3d model. designed by de cotiis, vincenzo.

design_connected

$27

DC Bed

...dc bed

designconnected

ceccotti collezioni dc bed sleep furniture computer generated 3d model. designed by vincenzo de cotiis.

turbosquid

$1

DC motor

...urbosquid

royalty free 3d model dc motor for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1188219)

3ddd

$1

Ceccotti | DC

...ceccotti | dc

3ddd

ceccotti

фабрика ceccotti

turbosquid

$35

DC Skateboard

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$13

DC Motor

...l dc motor for download as max, ige, obj, fbx, stl, and sldas on turbosquid: 3d models for games, architecture, videos. (1493908)

3ddd

free

Ceccotti / DC Bed

...://freshome.com/2009/05/12/dc-bed-by-ceccotti-collezioni/ http://www.switchmodern.com/beds/ceccotti-dc-bed.asp

3ddd

$1

Кресло CECCOTTI DC 90

...кресло ceccotti dc 90

3ddd

ceccotti

кресло ceccotti dc 90

3ddd

$1

Ceccotti Collezioni DC 90

... кресло , armchair

кресло ceccotti collezioni dc 90. размеры:850-800-406.7

Aluminum

3d_export

$5

aluminum crutch

...aluminum crutch

3dexport

aluminum crutch

3d_export

free

aluminum cane

...aluminum cane

3dexport

aluminum cane

3d_export

$5

the aluminum canister

...

3dexport

the aluminum canister is designed for storing and transporting liquids( water), fuels and lubricants (gasoline, oils).

turbosquid

$2

Aluminum Wheel

...uid

royalty free 3d model aluminum wheel for download as fbx on turbosquid: 3d models for games, architecture, videos. (1371918)

turbosquid

$2

aluminum pulley

...

royalty free 3d model aluminum pulley for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1671716)

turbosquid

$40

Aluminum Can

... free 3d model aluminum can for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1301606)

turbosquid

$15

Curved aluminum

...ee 3d model curved aluminum for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1260293)

turbosquid

$12

Aluminum pot

... free 3d model aluminum pot for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1653492)

3d_export

$5

Aluminum Bottle

... for shampoo, conditioner or any liquids (500ml 17floz) separated all parts, able to customize any color, material and finishing.

turbosquid

$19

Aluminum windows

...model aluminum windows for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1646740)

Led

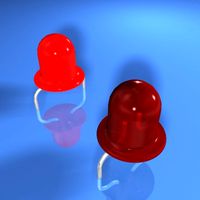

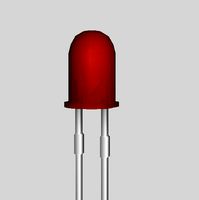

3d_export

$5

led

...led

3dexport

the led is cut with all the parts.

3ddd

$1

Monacor / PARL56DMX / LED-320RGBW / LED-345RGBW / LED-300RGB

... прожектор

http://www.monacor.dk/

parl56dmx

led-320rgbw

led-345rgbw

led-300rgb

turbosquid

$10

LED

...led

turbosquid

free 3d model led for download as blend on turbosquid: 3d models for games, architecture, videos. (1691856)

3d_export

$5

led lamp

...led lamp

3dexport

led lamp, brightness animation

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

современный торшер

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

настольный лампа

turbosquid

$19

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Led

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

9

3ddd

$1

9

...9

3ddd

консоль

9

turbosquid

$40

Apple iPhone 9 & 9+

...del apple iphone 9 & 9+ for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1284550)

turbosquid

$12

Calligraphic Digit 9 Number 9

...hic digit 9 number 9 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389349)

3ddd

$1

PLANTS 9

...plants 9

3ddd

папоротник , кашпо

plant 9.. hope u all like it

design_connected

$11

194 9

...194 9

designconnected

194 9 computer generated 3d model. designed by lissoni, piero.

design_connected

free

Tangram 9

...tangram 9

designconnected

free 3d model of tangram 9 by lago designed by lago, daniele.

design_connected

$11

Domino 9

...domino 9

designconnected

zanotta domino 9 computer generated 3d model. designed by progetti, emaf.

design_connected

$20

Docks 9

...docks 9

designconnected

gandia blasco docks 9 computer generated 3d model. designed by romero vallejo.

3d_export

$80

mq-9

...mq-9

3dexport

3d_export

$6

washbasin-9

...washbasin-9

3dexport

Red

3ddd

$1

red bull

...red bull

3ddd

red bull

red bull can

3d_ocean

$4

Red brick

...red brick

3docean

brick low poly red

red brick

3d_export

$40

red panda

...red panda

3dexport

red panda

3d_export

$5

eggchair red

...eggchair red

3dexport

a red eggchair

3ddd

$1

Red curtain

...red curtain

3ddd

red curtain

3d_export

$5

Red barrel

...red barrel

3dexport

its a red barrel

3ddd

$1

Red bicycle

...red bicycle

3ddd

велосипед

red bicycle

3ddd

$1

RED COLLECTION

...red collection

3ddd

витрина

red collection

3ddd

$1

RED COLLECTION

...red collection

3ddd

обеденный

red collection

3ddd

$1

RED COLLECTION

...red collection

3ddd

витрина

red collection

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...

Housing

archibase_planet

free

House

...t

house residential house private house wooden house

house wooden n290815 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...use residential house private house wooden house

house wood stone n140815 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n050615 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n030615 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n230715 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n240615 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n290815 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n110915 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n120915 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

archibase_planet

free

House

...ibase planet

house residential house building private house

house n210915 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$6

Cliff Rock 2-2

...uid

royalty free 3d model cliff rock 2-2 for download as obj on turbosquid: 3d models for games, architecture, videos. (1619161)

turbosquid

$22

Classic baluster (2) (2)

...assic baluster (2) (2) for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1483789)

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

turbosquid

$19

Loft wooden square box chandelier (2) (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.