GrabCAD

25W Explosion Proof LED Light - C1D1-2 - C2D1-2 - Adjustable Table Arm Mount - 50' Cord w/ EXP Plug

by GrabCAD

Last crawled date: 1 year, 10 months ago

https://www.larsonelectronics.com/product/148376/25w-explosion-proof-led-light-c1d1-2-c2d1-2-adjustable-table-arm-mount-50-cord-w-exp-plug

Made in Texas

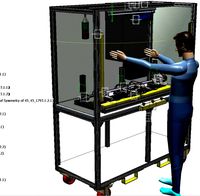

The EXHL-TBL-LE1-50C-1227-EPP from Larson Electronics is an Explosion Proof LED Fixture that features an adjustable table arm mount for inspections in hazardous locations. This LED lamp operates on 120-277V AC and produces 1,320 lumens while drawing only 25 watts. The EXHL-TBL-LE1-50C-1227-EPP is Class I, Divisions 1 & 2, Groups B, C, D, Class I, Zones 1 & 2, Groups IIB+H2, IIA, Class II, Divisions 1 & 2, Groups E, F ,G and Class III Divisions 1 & 2 rated for hazardous areas and is listed for use worldwide including the United States, Canada, Europe and Asia. This explosion proof LED light fixture is offered in a choice of spot or flood beam configuration and operates on 120-277V AC.

The EXHL-TBL-LE1-50C-1227-EPP produces 1,320 lumens of high-intensity LED light for illumination within hazardous areas and potentially explosive work environments. This explosion proof LED light fixture operates on 120-277V AC. The EXHL-TBL-LE1-50C-1227-EPP is available in two lighting configurations: spot or flood. The spot configuration features a 10° beam that measures 800`L and 140` W. The flood configuration throws a 40° beam that measures 300`L and 225`W. An adjustable table arm mount offers hands-free operation and flexible positioning during operation.

LED Benefits: Unlike gas burning and arc type lamps that have glass bulbs, LEDs have no filaments or fragile housings to break during operation and/or transportation. Instead of heating a small filament or using a combination of gases to produce light, light emitting diodes (LEDs) use semi-conductive materials that illuminate when electric current is applied, providing instant illumination with no warm up or cool down time before re-striking. Because there is no warm up period, this light can be cycled on and off with no reduction in lamp life.

LED lights run at significantly cooler temperatures than traditional metal halide and high pressure sodium lights and contain no harmful gases, vapors, or mercury, making them both safer and more energy efficient. No extra energy is wasted in cooling enclosed work areas due to external heat emissions from bulb type lights, and the operator risks associated with traditional lighting methods, such as accidental burns and exposure to hazardous substances contained in the glass bulbs, are eliminated. In addition, LEDs are also safer for the environment as they are 100% recyclable, which eliminates the need for costly special disposal services required with traditional gas burning and arc type lamps.

Heat Management: Heat is the single largest factor in premature LED failure and color shifting. These LED units contain advanced drivers which use pulse width modulation to control heat buildup rather than simple voltage regulators which are typically harsh on sensitive electronics and can contribute to early LED failure. These units automatically sense the temperature of each LED and adjust the energy frequency or "duty cycle" accordingly to maintain heat levels within acceptable ranges. This system in essence flashes current at an extremely fast on and off rate to each LED based upon the LED`s core temperature. This flash rate is too fast to detect with the human eye, but provides precise control of the current flowing to each LED and thus the heat it generates. This allows the LEDs to be driven at up to 100% capacity without overheating or visible loss of light output. The LEDs are always driven at the same voltage but the duty cycle, however, is changed to alter how long the LEDs are actually on or off. The end result is more light with less heat and longer LED life with an average 70% lumen maintenance after 50,000 hours.

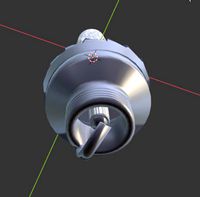

Durability: The EXHL-TBL-LE1-50C-1227-EPP explosion proof LED light fixture from Larson Electronics is rated NEMA Type 3, 4, 4X, 7 (B,C,D) and 9 (E,F,G) and designed to withstand the rigors of demanding environmental and operating conditions while remaining lightweight and easy to use. These units can operate in temperatures of -40° Celsius to 85° Celsius, are waterproof to 3 meter and resist ingress of dust, dirt and humidity. The housings are formed from cast copper free aluminum and the lenses are tempered glass. The LEDs offer inherent LED resistance to shocks and vibrations.

Mounting: This explosion proof LED light can be installed on flat surfaces, such as desks and platforms, using an adjustable table arm mounting system. The mounting component, which is constructed of aircraft-grade aluminum, supports 360 degrees of rotation, 180 degrees of swivel, as well as 15 degrees (up) and 85 degrees (down) of tilt. The LED lamp does not need to be removed when positioning the unit. For elevated illumination, the mounting component is adjustable at height of 16". The arm is gas spring-powered for accurate positioning of the luminary. During installation, operators may either clamp the base of the mount at the end of the platform (does not require holes) or secure the foundational component into the surface with screws.

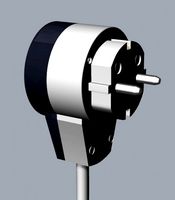

Wiring & Plug: The EXHL-TBL-LE1-50C-1227-EPP is equipped with 50` of chemical and abrasion resistant SOOW cord that is fitted with an explosion proof cord cap for easy connection to explosion proof outlets. Plug options include a 5-15 15 amp straight blade plug for use with 120V explosion proof outlets, a 5-20 20 amp straight blade plug for use with 120V explosion proof outlets, or a 6-20 20 amp straight blade plug for use with 220-240V explosion proof outlets. Cables can be fed through the mounting arm for a clean installation. **PLEASE NOTE** voltage ratings on plugs and outlets are MAXIMUM voltage. For low voltage applications, proper voltage must be applied to the outlet or damage to the light fixture will occur.

High Quality Features

1. Low power consumption

2. Instant on/off operation

3. Fixture constructed of extruded corrosion resistant copper free aluminum alloy

4. Superior color rendering compared to HPS, LPS, MH

5. Retains 70% lumen output after 50,000 operating hours

6. Powder coated aluminum fixture body

7. Adjustable table arm mount

8. Low profile - light weight

9. 1,320 lumen output from 25 watts

Superior LED Benefits

1. 50,000+ hour lifespan.

2. Can SAVE 50% or more on energy.

3. Qualifies retrofit projects for financial incentives, including utility rebates, tax credits and energy loan programs.

4. Reduces energy use and prolongs life-spans of peripheral cooling units (A/C, refrigeration)

5. 100% recyclable.

6. No toxins-lead, mercury.

7. No UV light, infrared radiation or CO2 emissions.

8. Qualifies buildings for LED and other sustainable business certifications.

9. Bright, even light maintains consistent color over time.

10. Instant on/off - No flickering, delays or buzzing.

11. Very good color rendering.

12. Vibration/impact resistant.

13. Significantly cooler operation.

14. Less frequent outages, higher output improves workplace safety.

Applications: Inspections, detailed tasks, labs, soldering, petroleum refineries, chemical and petrochemical plants, paint spray booths, food manufacturing buildings, hazardous locations and more.

Made in Texas

The EXHL-TBL-LE1-50C-1227-EPP from Larson Electronics is an Explosion Proof LED Fixture that features an adjustable table arm mount for inspections in hazardous locations. This LED lamp operates on 120-277V AC and produces 1,320 lumens while drawing only 25 watts. The EXHL-TBL-LE1-50C-1227-EPP is Class I, Divisions 1 & 2, Groups B, C, D, Class I, Zones 1 & 2, Groups IIB+H2, IIA, Class II, Divisions 1 & 2, Groups E, F ,G and Class III Divisions 1 & 2 rated for hazardous areas and is listed for use worldwide including the United States, Canada, Europe and Asia. This explosion proof LED light fixture is offered in a choice of spot or flood beam configuration and operates on 120-277V AC.

The EXHL-TBL-LE1-50C-1227-EPP produces 1,320 lumens of high-intensity LED light for illumination within hazardous areas and potentially explosive work environments. This explosion proof LED light fixture operates on 120-277V AC. The EXHL-TBL-LE1-50C-1227-EPP is available in two lighting configurations: spot or flood. The spot configuration features a 10° beam that measures 800`L and 140` W. The flood configuration throws a 40° beam that measures 300`L and 225`W. An adjustable table arm mount offers hands-free operation and flexible positioning during operation.

LED Benefits: Unlike gas burning and arc type lamps that have glass bulbs, LEDs have no filaments or fragile housings to break during operation and/or transportation. Instead of heating a small filament or using a combination of gases to produce light, light emitting diodes (LEDs) use semi-conductive materials that illuminate when electric current is applied, providing instant illumination with no warm up or cool down time before re-striking. Because there is no warm up period, this light can be cycled on and off with no reduction in lamp life.

LED lights run at significantly cooler temperatures than traditional metal halide and high pressure sodium lights and contain no harmful gases, vapors, or mercury, making them both safer and more energy efficient. No extra energy is wasted in cooling enclosed work areas due to external heat emissions from bulb type lights, and the operator risks associated with traditional lighting methods, such as accidental burns and exposure to hazardous substances contained in the glass bulbs, are eliminated. In addition, LEDs are also safer for the environment as they are 100% recyclable, which eliminates the need for costly special disposal services required with traditional gas burning and arc type lamps.

Heat Management: Heat is the single largest factor in premature LED failure and color shifting. These LED units contain advanced drivers which use pulse width modulation to control heat buildup rather than simple voltage regulators which are typically harsh on sensitive electronics and can contribute to early LED failure. These units automatically sense the temperature of each LED and adjust the energy frequency or "duty cycle" accordingly to maintain heat levels within acceptable ranges. This system in essence flashes current at an extremely fast on and off rate to each LED based upon the LED`s core temperature. This flash rate is too fast to detect with the human eye, but provides precise control of the current flowing to each LED and thus the heat it generates. This allows the LEDs to be driven at up to 100% capacity without overheating or visible loss of light output. The LEDs are always driven at the same voltage but the duty cycle, however, is changed to alter how long the LEDs are actually on or off. The end result is more light with less heat and longer LED life with an average 70% lumen maintenance after 50,000 hours.

Durability: The EXHL-TBL-LE1-50C-1227-EPP explosion proof LED light fixture from Larson Electronics is rated NEMA Type 3, 4, 4X, 7 (B,C,D) and 9 (E,F,G) and designed to withstand the rigors of demanding environmental and operating conditions while remaining lightweight and easy to use. These units can operate in temperatures of -40° Celsius to 85° Celsius, are waterproof to 3 meter and resist ingress of dust, dirt and humidity. The housings are formed from cast copper free aluminum and the lenses are tempered glass. The LEDs offer inherent LED resistance to shocks and vibrations.

Mounting: This explosion proof LED light can be installed on flat surfaces, such as desks and platforms, using an adjustable table arm mounting system. The mounting component, which is constructed of aircraft-grade aluminum, supports 360 degrees of rotation, 180 degrees of swivel, as well as 15 degrees (up) and 85 degrees (down) of tilt. The LED lamp does not need to be removed when positioning the unit. For elevated illumination, the mounting component is adjustable at height of 16". The arm is gas spring-powered for accurate positioning of the luminary. During installation, operators may either clamp the base of the mount at the end of the platform (does not require holes) or secure the foundational component into the surface with screws.

Wiring & Plug: The EXHL-TBL-LE1-50C-1227-EPP is equipped with 50` of chemical and abrasion resistant SOOW cord that is fitted with an explosion proof cord cap for easy connection to explosion proof outlets. Plug options include a 5-15 15 amp straight blade plug for use with 120V explosion proof outlets, a 5-20 20 amp straight blade plug for use with 120V explosion proof outlets, or a 6-20 20 amp straight blade plug for use with 220-240V explosion proof outlets. Cables can be fed through the mounting arm for a clean installation. **PLEASE NOTE** voltage ratings on plugs and outlets are MAXIMUM voltage. For low voltage applications, proper voltage must be applied to the outlet or damage to the light fixture will occur.

High Quality Features

1. Low power consumption

2. Instant on/off operation

3. Fixture constructed of extruded corrosion resistant copper free aluminum alloy

4. Superior color rendering compared to HPS, LPS, MH

5. Retains 70% lumen output after 50,000 operating hours

6. Powder coated aluminum fixture body

7. Adjustable table arm mount

8. Low profile - light weight

9. 1,320 lumen output from 25 watts

Superior LED Benefits

1. 50,000+ hour lifespan.

2. Can SAVE 50% or more on energy.

3. Qualifies retrofit projects for financial incentives, including utility rebates, tax credits and energy loan programs.

4. Reduces energy use and prolongs life-spans of peripheral cooling units (A/C, refrigeration)

5. 100% recyclable.

6. No toxins-lead, mercury.

7. No UV light, infrared radiation or CO2 emissions.

8. Qualifies buildings for LED and other sustainable business certifications.

9. Bright, even light maintains consistent color over time.

10. Instant on/off - No flickering, delays or buzzing.

11. Very good color rendering.

12. Vibration/impact resistant.

13. Significantly cooler operation.

14. Less frequent outages, higher output improves workplace safety.

Applications: Inspections, detailed tasks, labs, soldering, petroleum refineries, chemical and petrochemical plants, paint spray booths, food manufacturing buildings, hazardous locations and more.

Similar models

grabcad

free

12W Explosion Proof LED Light - C1D1-2 - C2D1-2 - Adjustable Table Arm Mount - 120-240V AC

...um refineries, chemical and petrochemical plants, paint spray booths, food manufacturing buildings, hazardous locations and more.

grabcad

free

12W Explosion Proof LED Light - C1D1-2 - C2D1-2 - Adjustable Table Arm Mount - 12V or 24V

...um refineries, chemical and petrochemical plants, paint spray booths, food manufacturing buildings, hazardous locations and more.

grabcad

free

12W Explosion Proof Surface Mount LED Light - C1D1-2 - C2D1-2 - Aluminum Frame - 12-24V DC

..." npt hubs on either side of the fixture and tied in to the fixture’s terminal strips, completing the electrical connection.

grabcad

free

12W Explosion Proof Surface Mount Red LED Light - C1D1-2 - C2D1-2 - Aluminum Frame - 12-24V DC

...t; npt hubs on either side of the fixture and tied in to the fixture's terminal strips, completing the electrical connection.

grabcad

free

12W Explosion Proof Handheld LED Light - 120-277VAC Stepped Down 12/24VDC - Trunnion Mount

...bration/impact resistant.

13. significantly cooler operation.

14. less frequent outages, higher output improves workplace safety.

grabcad

free

25W Explosion Proof Surface Mount LED Light - C1D1-2 - C2D1-2 - Aluminum Frame - 120-277V AC

...bration/impact resistant.

13. significantly cooler operation.

14. less frequent outages, higher output improves workplace safety.

grabcad

free

12W Explosion Proof Handheld LED Light - 120-277VAC Stepped Down 12/24VDC - Magnetic Trunnion Mount

...bration/impact resistant.

13. significantly cooler operation.

14. less frequent outages, higher output improves workplace safety.

grabcad

free

12W Explosion Proof Surface Mount Blue LED Light - C1D1-2 - C2D1-2 - Aluminum Frame - 12-24V DC

...bration/impact resistant.

13. significantly cooler operation.

14. less frequent outages, higher output improves workplace safety.

grabcad

free

C1D1 Explosion Proof 150 Watt High Bay LED Light Fixture-140°-Paint Booth Approved -150' w/ EXP Plug

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

grabcad

free

C1D1 Explosion Proof 150 Watt High Bay LED Light Fixture-140°-Paint Booth Approved -250' w/ EXP Plug

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

C2D1

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 480V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 208V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 208V 1PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

5000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 480V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 240V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 240V 1PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

Explosion Proof Control Station - C1D1/C2D1 - Local/Off/Auto 3-Pos Switch - 10k Ohm Potentiometer

...int spray booths, food manufacturing buildings, agricultural sites, grain storage centers, small motors, manual control and more.

grabcad

free

Explosion Proof SPST Three Phase Starter Switch - Copper Free Aluminum - 30 Amp Rated - C1D1 C2D1

...applications: manufacturing, industrial, warehouse, lighting, lighting, wet areas or locations where combustible dust is present.

grabcad

free

Hazardous Location Exit Sign - C1D2 - C2D1&2 - IP65 - 120V/277VAC - Green or Red Exit Sign

...rants making identification and location of exits in emergency situations easier than with typical self illuminated exit markers.

grabcad

free

Explosion Proof Red Crane Warning Laser- C1D1-2 - C2D1-2 - Surface Mount - 12-24V DC - Aluminum

...nal strips, completing the electrical connection.

applications: crane safety, crane measurements, crane warning system and more.

C1D1

grabcad

free

Explosion Proof Enclosure, C1D1, 8'' x 12'' x 6'' Internal Dims, Surface Mount, N3R

...; in height. a removable backplate for easy mounting of equipment outside of the enclosure can be provided at an additional cost.

grabcad

free

Explosion Proof Cable Gland, 2" NPT, Nickel Plated Brass, 1.40-1.73" OD, C1D1 ATEX IEC Ex N4X

...ctions, cable fittings, explosive work sites, hazardous locations, instrumentation, telecommunication, cable management and more.

grabcad

free

Explosion Proof Cable Gland, 1" NPT, Nickel Plated Brass, 0.67-1.03" OD, C1D1 ATEX IEC Ex N4X

...ctions, cable fittings, explosive work sites, hazardous locations, instrumentation, telecommunication, cable management and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 480V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 208V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 208V 1PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

5000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 480V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 240V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 240V 1PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

Explosion Proof Cable Gland, 3/4" NPT, Nickel Plated Brass, 0.44-0.78" OD, C1D1 ATEX IEC Ex N4X

...ctions, cable fittings, explosive work sites, hazardous locations, instrumentation, telecommunication, cable management and more.

25W

3ddd

$1

Massive - 41633/11/10

..., massive , бельгия , металл , хрусталь мощность: 25w цоколь: 7xg9 размеры:...

3ddd

$1

triad 15 pendant

...lamping: 15 type a g25 bulbs max 60w each 25w matte white bulbs...

3ddd

$1

Favourite 1155-2W бра

..., om 1155-2w настенный светильник размер светильника: w370*d210*h110 лампы: e14*2*25w цвет, отделка: античная...

3ddd

$1

Willow Chair

...3ddd lexington , willow willow chair item: 1563-11 dimensions: 25w x 33½d x 50½h in. inside depth: 21 in....

3ddd

$1

Favourite 1155-1W бра

..., om 1155-1w настенный светильник размер светильника: w240*d210*h110 лампы: e14*1*25w цвет, отделка: античная...

3ddd

$1

Favourite 1155-4W картинная подстветка

..., om 1155-4w настенный светильник размер светильника: w720*d210*h110 лампы: e14*4*25w цвет, отделка: античная...

3ddd

$1

Favourite 1150-1W картинная подсветка

..., om 1150-1w настенный светильник размер светильника: w270*h125*d220 лампы: 1*e14*25w цвет, отделка: в основании гипсовый медальон, античная...

3ddd

free

Favourite 1150-2W картинная подстветка

..., om 1150-2w настенный светильник размер светильника: w400*h125*d220 лампы: 2*e14*25w цвет, отделка: в основании гипсовый медальон, античная...

3ddd

$1

19TH C. ROCOCO IRON & SMOKE CRYSTAL SCONCE 18"

...rococo iron & smoke crystal sconce 18" uses three 25w max. bulbs (four bulbs...

3ddd

free

Мини-прожектор на шинопроводе Milo L 110 33213

...фабрики martini название: milo l 110 артикул: 33213 мощность: 25w источник света: led оптика: 64° poly: 6 441, verts:...

Exp

turbosquid

$800

EXP Banbury 6W1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Superficial Tension Exp. Image.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$39

Bentley EXP 10 Speed 6 Concept

...oncept

3dexport

bentley exp 10 speed 6 concept, year 2015.<br>model with high quality finishing on the outside and inside.

3d_export

$129

Tony Kart Rocky EXP 2014 3D Model

...g japan japanese

tony kart rocky exp 2014 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl humster3d 113606 3dexport

3d_export

$199

Bentley Exp Speed 8 2001 3D Model

...bentley exp speed 8 2001 3d model

3dexport

nurbs bentley poly model tyio

bentley exp speed 8 2001 3d model tyio 1582 3dexport

humster3d

$15

Bentley EXP 9 F 2012 Blueprint

...12 blueprint 3d model in the format you need. all our 3d models was created on real car base and maximally close to the original.

humster3d

$15

Tony Kart Rocky EXP 2014 Blueprint

...14 blueprint 3d model in the format you need. all our 3d models was created on real car base and maximally close to the original.

humster3d

$75

3D model of Bentley EXP 9 F 2012

...etailed 3d model of bentley exp 9 f 2012 in various file formats. all our 3d models were created maximally close to the original.

humster3d

$75

3D model of Tony Kart Rocky EXP 2014

...led 3d model of tony kart rocky exp 2014 in various file formats. all our 3d models were created maximally close to the original.

cg_studio

$199

Bentley EXP Speed 8, 2001, nurbs to poly3d model

...tudio

.max - bentley exp speed 8, 2001, nurbs to poly 3d model, royalty free license available, instant download after purchase.

Proof

turbosquid

$6

bullet proof jacket

...el bullet proof jacket for download as 3ds, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1193147)

turbosquid

$1

Sound Proofing Foam

... sound proofing foam for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1289027)

turbosquid

$149

Bullet Proof Vest with molle attachments

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$40

chevrolet nova ss 70 death proof

...chevrolet nova ss 70 death proof

3dexport

3d_export

$9

of automobile component error proofing system

...cific product defects; the other is to check the products one by one through cheap means to determine whether they are qualified.

turbosquid

$12

Armoured fighting vehicles armoured vehicles with explosion-proof wheels

...ured vehicles with explosion-proof wheels for download as max on turbosquid: 3d models for games, architecture, videos. (1629664)

3d_export

$16

yb2 high voltage explosion proof series three phase asynchronous motor 9 specifications in total

...cifications in total

3dexport

yb2 high voltage explosion proof series three phase asynchronous motor (9 specifications in total)

turbosquid

$2

Replacement RC Car Shock Proof Plank SJ11 Accessory Spare Parts 15-SJ11 for GPTOYS S911 S912 And Others

...1 for gptoys s911 s912 and others for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1193732)

3d_ocean

$1

Insulation Felt Seamless Pattern Background

...background 3docean background carpet ceilings closeup cloth cover dust proof fabric felt fiber fleece gray insulation insulation felt material...

3d_export

$20

Passport Collection 3D Model

...3dexport passport us usa united states travel document citizenship proof booklet realistic textures russia uk great britain france collection...

Explosion

3d_export

$6

explosion

...explosion

3dexport

3 d of explosion

3d_export

$10

explosion

...explosion

3dexport

3d model of explosion for 3d printing

turbosquid

$5

Explosion

...rbosquid

royalty free 3d model explosion for download as max on turbosquid: 3d models for games, architecture, videos. (1202603)

3d_export

$10

Explosion

...explosion

3dexport

turbosquid

$14

Explosion

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Explosive

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Explosive Barrel

...explosive barrel 3docean barrel decoration explosion explosive industrial low low poly metal object old poly...

3ddd

free

KOLARZ Serie Explosion

... serie explosion , австрия

kolarz serie explosion 0109.118.5.kot. врай. текстуры.

3d_export

$5

atomic bomb explosion

...atomic bomb explosion

3dexport

atomic bomb explosion

turbosquid

$1

explosives pack

...squid

royalty free 3d model explosives pack for download as on turbosquid: 3d models for games, architecture, videos. (1316376)

Cord

3ddd

$1

Softline / Cord

...softline / cord

3ddd

cord , softline

диван cord (фира softline)

3d_export

$5

Cord 3D Model

...cord 3d model

3dexport

cord

cord 3d model gaj15 61441 3dexport

3ddd

$1

Sofa CORD

...sofa cord

3ddd

cosmo , cord

3ds max 2010.v-ray 2.40.03.file formats fbx,obj

3d_ocean

$18

Texture Pack Cord

...texture pack cord

3docean

clothing cord corduroy fabric

20 cord textures with bump and normal map.

3ddd

$1

Cord Chair

...ecame a prominent craft geek way before craft geekery was cool and produced a series of graphic fabrics based on canadian foliage

design_connected

$13

Cord Lamp

...cord lamp

designconnected

design house stockholm cord lamp computer generated 3d model. designed by form us with love.

3ddd

$1

Кресло Cord

...cord

3ddd

cosmo , cord

высота (см)76

высота седалища (см)38

ширина (см)95

глубина (см)96

3ddd

$1

Minotti Aston Cord

...minotti aston cord

3ddd

minotti

minotti aston cord indoor chair

3ddd

$1

Кресло Minotti Aston Cord

...кресло minotti aston cord

3ddd

minotti , aston cord

кресло minotti aston cord

3ddd

$1

Диван Minotti Aston Cord

...диван minotti aston cord

3ddd

minotti , aston cord

диван minotti aston cord

Plug

3d_export

$5

plug

...plug

3dexport

3d_export

$5

plug cover

...plug cover

3dexport

plug cover

3d_export

$5

spark plug

...spark plug

3dexport

spark plug

3d_export

free

spark plug

...spark plug

3dexport

spark plug

turbosquid

$30

plug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

plug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Plug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Plug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Plug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

plug

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Arm

archibase_planet

free

Arm

...ase planet

arm hand right hand skeleton

arm human skeleton right arm n030515 - 3d model (*.gsm+*.3ds+*.max) for 3d visualization.

3ddd

$1

arm chair

...arm chair

3ddd

arm chair , пуф

arm chair

turbosquid

$5

arm

...arm

turbosquid

royalty free 3d model arm for download as obj on turbosquid: 3d models for games, architecture, videos. (1306158)

turbosquid

free

Arm

...arm

turbosquid

free 3d model arm for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1346955)

turbosquid

$29

Arm

...osquid

royalty free 3d model arm for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1382436)

3d_export

$5

coat of arms

...coat of arms

3dexport

coat of arms

3ddd

$1

ARM SOFA

...arm sofa

3ddd

arm sofa

3ddd

$1

Arm chair

...arm chair

3ddd

arm chair

3ddd

$1

Arm chair

...arm chair

3ddd

угловое

arm chair

3ddd

$1

ARM CHAIR

...arm chair

3ddd

arm chair clothes

Led

3d_export

$5

led

...led

3dexport

the led is cut with all the parts.

3ddd

$1

Monacor / PARL56DMX / LED-320RGBW / LED-345RGBW / LED-300RGB

... прожектор

http://www.monacor.dk/

parl56dmx

led-320rgbw

led-345rgbw

led-300rgb

turbosquid

$10

LED

...led

turbosquid

free 3d model led for download as blend on turbosquid: 3d models for games, architecture, videos. (1691856)

3d_export

$5

led lamp

...led lamp

3dexport

led lamp, brightness animation

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

современный торшер

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

настольный лампа

turbosquid

$19

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Led

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

50

3d_export

$500

50

...50

3dexport

flanged ball valve dn 50 detailed made in compass 17

3ddd

free

Life 50-50-170

...life 50-50-170

3ddd

life

автор модели: aroslon

3ddd

$1

Pillows 50

...pillows 50

3ddd

подушка

pillows 50

turbosquid

$27

50

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$18

plants 50

...plants 50

3dexport

plants 50 is a monstera plants or swiss cheese plant,, best suit in both indoor and outdoor.

3d_export

$17

Sukhoi T-50

...sukhoi t-50

3dexport

sukhoi t-50

3ddd

$1

Aqwella Espresso 50

...aqwella espresso 50

3ddd

aqwella espresso 50

3ddd

$1

ELEYUS LINE 50

...тяжка , eleyus

вытяжка eleyus, модель eleyus line 50 ( белый, коричневый) ширина - 50 см

turbosquid

$99

AMX-50

...

turbosquid

royalty free 3d model amx-50 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1521461)

3d_export

$20

Vespa 50s

...vespa 50s

3dexport

vespa obj

Adjustable

3d_ocean

$7

Adjustable Wrench

...adjustable wrench

3docean

adjustable wrench highly detailed wrench

highly detailed adjustable wrench.

3ddd

$1

Adjustable Stool

...adjustable stool

3ddd

табурет

wooden adjustable stool.

3d_ocean

$20

Adjustable Gym Bench

...st adjustable bench black equipement gym gymnastic indoor silver sport workout

3d model of black and silver adjustable gym bench.

3d_ocean

$20

Adjustable Gym Bench

...st adjustable bench black equipement gym gymnastic indoor silver sport workout

3d model of black and silver adjustable gym bench.

3d_ocean

$16

Adjustable Weight Bench

...arbell bench black equipement gym gymnastic indoor sport weight workout

3d model of black adjustable weight bench with a barbell.

turbosquid

$5

Adjustable wrench

...

royalty free 3d model adjustable wrench for download as fbx on turbosquid: 3d models for games, architecture, videos. (1313414)

3d_export

$5

adjustable tension lock

...adjustable tension lock

3dexport

adjustable tension lock

turbosquid

$1

Adjustable Wrench

...free 3d model adjustable wrench for download as obj and blend on turbosquid: 3d models for games, architecture, videos. (1446736)

turbosquid

$1

Adjustable Wrench

...y free 3d model adjustable wrench for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1379022)

3d_export

$5

Adjustable key

...adjustable key

3dexport

W

3ddd

$1

chair W

...chair w

3ddd

chair w

3ddd

$1

кресло w

...кресло w

3ddd

капитоне

кресло w

3ddd

$1

KUTEK (W) W-ZW-5

...kutek (w) w-zw-5

3ddd

kutek

3d модель люстри (w) w-zw-5 фабрики kutek. в архиве: max2012, obj, fbx, mat.(два варианта металла)

3ddd

$1

KUTEK (W) W-ZW-3

...kutek (w) w-zw-3

3ddd

kutek

3d модель люстри (w) w-zw-3 фабрики kutek. в архиве: max2012, obj, fbx, mat. (два варианта металла)

3ddd

$1

KUTEK (W) W-ZW-1

...kutek (w) w-zw-1

3ddd

kutek

3d модель люстри (w) w-zw-1 фабрики kutek. в архиве: max2012, obj, fbx, mat (два варианта металла).

3ddd

free

aneken W&W

...aneken w&w

3ddd

2 женских манекена, ценники и фолио. материалы и текстуры прилагаются.

design_connected

$9

KTribe W

...ktribe w

designconnected

ktribe w computer generated 3d model. designed by starck, philippe.

design_connected

$16

Troy W

...troy w

designconnected

magis troy w computer generated 3d model. designed by wanders, marcel.

turbosquid

$9

Menu - Benjamin Hubert - W W Carafe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Menu - Benjamin Hubert - W W Carafe

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Mount

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...

Table

3ddd

free

Table

...table

3ddd

table

table

archibase_planet

free

Table

...table

archibase planet

table glass-table round table glass table

table n240311 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...e

archibase planet

table dining-room table dinner table round table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

table

...table

3dexport

table classic-table

archibase_planet

free

Table

...se planet

table glass table round table glass-table

table tonin habitat n280111 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table dining-room table dinner table

table - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table coffee table glass table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table glass-table coffee table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Table

...table

archibase planet

table writing table office table

table - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$5

Table

...table

3docean

dining table furniture home kitchen table

simple wooden table.

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

turbosquid

$19

Loft wooden square box chandelier (2) (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

ALPEREN-2

...alperen-2

3ddd

комод , alperen-2

комод с зеркалом alperen-2

design_connected

$27

Confluences 2 2-Seater Sofa

... 2-seater sofa

designconnected

ligne roset confluences 2 2-seater sofa computer generated 3d model. designed by nigro, philippe.