GrabCAD

24" Explosion Proof Exhaust Fan - 6860 CFM - 1HP, 230-480V AC Three Phase - Roof Mounted

by GrabCAD

Last crawled date: 1 year, 11 months ago

https://www.larsonelectronics.com/product/276785/24-explosion-proof-exhaust-fan-6860-cfm-1hp-230-480v-ac-three-phase-roof-mounted

The EPF-RME-24-1HP-3P from Larson Electronics is an Explosion Proof Exhaust Fan for use in flammable environments. Equipped with a built-in bird screen, this unit operates on 3-phase 230-480 V AC. The 1 horsepower (HP) explosion proof fan is constructed of non-sparking/spun aluminum and is compatible with roof/ceiling mounting applications.

The EPF-RME-24-1HP-3P explosion proof fan is rated for Class I, Group D and Class II, Groups F & G hazardous environments. This 3-phase explosion proof ventilation fan has a 1 HP fully enclosed motor that can spin the propeller at a rate of 1,750 rotations per minute (RPM). Capable of achieving 6,860 cubic feet per minute (CFM), the explosion proof exhaust fan features a built-in bird screen.

The explosion proof fan is constructed of non-sparking and spun aluminum, resulting in a lightweight unit. The 24" diameter propeller on this explosion proof high pressure ventilation fan resists sparking, further increasing the safety of the hazardous environment in which the fan is being utilized.

Voltage: The EPF-RME-24-1HP-3P is multi-voltage capable and can operate on voltages ranging from 230-480 V AC.

Wiring: The explosion proof exhaust fan is a hard-wired unit that should be installed according to national, state and local electrical and mechanical codes.

Mounting: Operators may mount the fan on ceilings or roofings during installation.

Applications: Class I, Group D and Class II, Groups F & G hazardous areas that require ventilation including but not limited to the following: clean rooms, marijuana extraction rooms, laboratory hoods, oil refineries, grain mills, chemical plants, welding shops, chemical storage areas and battery changing areas.

The EPF-RME-24-1HP-3P from Larson Electronics is an Explosion Proof Exhaust Fan for use in flammable environments. Equipped with a built-in bird screen, this unit operates on 3-phase 230-480 V AC. The 1 horsepower (HP) explosion proof fan is constructed of non-sparking/spun aluminum and is compatible with roof/ceiling mounting applications.

The EPF-RME-24-1HP-3P explosion proof fan is rated for Class I, Group D and Class II, Groups F & G hazardous environments. This 3-phase explosion proof ventilation fan has a 1 HP fully enclosed motor that can spin the propeller at a rate of 1,750 rotations per minute (RPM). Capable of achieving 6,860 cubic feet per minute (CFM), the explosion proof exhaust fan features a built-in bird screen.

The explosion proof fan is constructed of non-sparking and spun aluminum, resulting in a lightweight unit. The 24" diameter propeller on this explosion proof high pressure ventilation fan resists sparking, further increasing the safety of the hazardous environment in which the fan is being utilized.

Voltage: The EPF-RME-24-1HP-3P is multi-voltage capable and can operate on voltages ranging from 230-480 V AC.

Wiring: The explosion proof exhaust fan is a hard-wired unit that should be installed according to national, state and local electrical and mechanical codes.

Mounting: Operators may mount the fan on ceilings or roofings during installation.

Applications: Class I, Group D and Class II, Groups F & G hazardous areas that require ventilation including but not limited to the following: clean rooms, marijuana extraction rooms, laboratory hoods, oil refineries, grain mills, chemical plants, welding shops, chemical storage areas and battery changing areas.

Similar models

grabcad

free

24" Explosion Proof Exhaust Fan - 7820 CFM - 1HP, 115-230V AC Single Phase - Roof Mounted

...laboratory hoods, oil refineries, grain mills, chemical plants, welding shops, chemical storage areas and battery changing areas.

grabcad

free

36" Explosion Proof Exhaust Fan - 18,500 CFM - 3HP, 230-460V AC Three Phase - Roof Mounted

...laboratory hoods, oil refineries, grain mills, chemical plants, welding shops, chemical storage areas and battery changing areas.

grabcad

free

16" Explosion Proof Exhaust Fan - 2,950 CFM - 1/4 HP, 115V AC 1PH - Roof Mounted

...laboratory hoods, oil refineries, grain mills, chemical plants, welding shops, chemical storage areas and battery changing areas.

grabcad

free

18" Explosion Proof Low Pressure Fan - 2600 CFM - 1/4 HP - 230/460V 3P - C1 Group D, C2 Groups F & G

...ady to install.

cfm static pressure (sp) ratings

1. 0" sp - 2600 cfm

2. 1/8" sp - 2200 cfm

3. 1/4" sp - 1000 cfm

grabcad

free

18" Explosion Proof Low Pressure Fan - 2600 CFM - 1/4 HP - 115V/230V - C1 Group D & C2 Groups F & G

...ady to install.

cfm static pressure (sp) ratings

1. 0" sp - 2600 cfm

2. 1/8" sp - 2200 cfm

3. 1/4" sp - 1000 cfm

grabcad

free

3000W Explosion Proof Heater - Forced Fan Heater - C1D1, C2D1 - 480V 3PH - 580 CFM

...chemical processing, cold-temperature facilities, farming operations, agricultural sites, flour processing, grain silos and more.

grabcad

free

30" Electric Explosion Proof Fan on 4' Stand - 8723 CFM - 30 inch - Pedestal Mount - 50' Cord - C1D1

...ug for use with 120v explosion proof outlets, or a 6-20 20 amp straight blade plug for use with 220-240v explosion proof outlets.

grabcad

free

24" Electric Explosion Proof Fan on Stand - 7980 CFM - 24 inch - Pedestal Mount - 50' Cord - C1D1 - CPP516 Pin/Sleeve Cord Cap

...al sites, oil and gas facilities, processing plants, construction, aerospace facilities, indoor/outdoor cooling systems and more.

grabcad

free

24" Electric Explosion Proof Fan on Stand - C1D1 - 7980 CFM - 24 inch - Pedestal Mount - 6' Cord

...al sites, oil and gas facilities, processing plants, construction, aerospace facilities, indoor/outdoor cooling systems and more.

grabcad

free

24" Electric Explosion Proof Fan on Stand - 7980 CFM - 24 inch - Pedestal Mount - 150' Cord - C1D1

...al sites, oil and gas facilities, processing plants, construction, aerospace facilities, indoor/outdoor cooling systems and more.

6860

3ddd

$1

KITCHEN 03

...barazza варочная поверхность siemens eh775me21e духовка - miele h 6860 bp посуд все под сглаживания с открытым turbosmooth turbosmooth...

3ddd

$1

KITCHEN 02

...- smeg kdd 90 vx духовка - miele h 6860 bp кастрюли и посуда все под сглаживания с открытым...

3ddd

$1

KITCHEN 05

...1950mm варочная поверхность miele km 6388 духовка miele h 6860 bp вытяжка miele da 2690 подогреватель посуды miele esw...

3d_export

$19

muuto workshop chair

...high-res film close-ups, advertising, design visualization, etc.<br>the model contains 6860 polygons.<br>model is built to real-world scale. units used: centimeters.<br>lengths:...

3ddd

$2

KITCHEN 06

...2400mm варочная поверхность miele km 6388 духовка miele h 6860 bp вытяжка miele da 2690 подогреватель посуды miele esw...

3dfindit

free

6760, 6762, 6860, 6862, 6760-Black, 6762-Black, 6860-Black, 6862-Black

...6760, 6762, 6860, 6862, 6760-black, 6762-black, 6860-black, 6862-black

3dfind.it

catalog: 80/20

3dfindit

free

25-6760, 25-6762, 40-6860, 40-6862, 25-6760-Black, 25-6762-Black, 40-6860-Black, 40-6862-Black

...25-6760, 25-6762, 40-6860, 40-6862, 25-6760-black, 25-6762-black, 40-6860-black, 40-6862-black

3dfind.it

catalog: 80/20

blendswap

free

Toilet High Poly

...source 3d art high poly toilet based on ifoâ 6860 model. cycles material, white glossy porcelain and dull white...

3d_sky

$8

02 KITCHEN

...- smeg kdd 90 vx oven - miele h 6860 bp pans and utensils are all under the smoothing...

thingiverse

free

1405 Simple X Expanded (Single/Double Precision) by iamjonlawrence

...those ideas into a 3d model. please review the conversation:http://www.printrbottalk.com/forum/viewtopic.php?f=21&t=6860 ...

1Hp

thingiverse

free

Adapter for 1HP QP bomb to intex hose by Teleldo

...adapter for 1hp qp bomb to intex hose by teleldo

thingiverse

adapter for 1hp qp bomb to intex hose

thingiverse

free

MPCNC Primo J Bosch Colt 1HP Mount by truglodite

...ready to print. flipping it over will increase support material and print time, and make the more visible top surface look nasty.

thingiverse

free

Improved Eurorack Parametric Panel by mdroberts1243

...this remix i changed the openscad code to handle 1hp and 2hp panel widths. i fixed the vertical hole...

thingiverse

free

1.25 inch Pool Nozzle by rlegault

...much less power than the main filter pump of 1hp filter pump is on when we swim and also...

thingiverse

free

Plastic Extruder by laughingman

...spec'ed at 1/2hp 1640rpm 4.5amps the gearbox is 11:1 1hp ...

thingiverse

free

100mm vacuum hose gate by ois_face

...i use these to ensure maximum vacuum from my 1hp shop vac that has two vacuum hoses coming from...

thingiverse

free

Eurorack M3 Rail System

...parameters can be adjusted within fcstd files. to achieve 1hp - 30hp (x+) rail lengths. body 30 hp rails...

thingiverse

free

Bosch PR20EVS Router Base by twuelfing

...the tool's axle. i made this for my little 1hp bosch router. i can use laser cut templates out...

grabcad

free

Air compressor 1HP

...air compressor 1hp

grabcad

air compressor 1hp

grabcad

free

motor eléctrico 1hp

...motor eléctrico 1hp

grabcad

motor eléctrico 1hp

480V

3dfindit

free

ACH550-BC 480V

...ach550-bc 480v

3dfind.it

catalog: abb

3dfindit

free

ACH550-BCR 480V

...ach550-bcr 480v

3dfind.it

catalog: abb

3dfindit

free

ACH550-BD 480V

...ach550-bd 480v

3dfind.it

catalog: abb

3dfindit

free

ACH550-PC 480V

...ach550-pc 480v

3dfind.it

catalog: abb

3dfindit

free

ACH550-PDR 480V

...ach550-pdr 480v

3dfind.it

catalog: abb

3dfindit

free

ACH550-PD 480V

...ach550-pd 480v

3dfind.it

catalog: abb

3dfindit

free

ACH550-CD 480V

...ach550-cd 480v

3dfind.it

catalog: abb

3dfindit

free

ACQ580-34 480V

...acq580-34 480v

3dfind.it

catalog: abb

3dfindit

free

ACQ580-PC 480V

...acq580-pc 480v

3dfind.it

catalog: abb

3dfindit

free

ACH550-PCR 480V

...ach550-pcr 480v

3dfind.it

catalog: abb

Cfm

3d_export

$60

Airbus A320 CFM 3D Model

...airbus a320 cfm 3d model

3dexport

airbus a320 a-320 jet aircraft

airbus a320 cfm 3d model denokan 30378 3dexport

3d_export

$12

whirlpool hood collection

..."concave glass wall mount range hood -gold® 30-inch vented 300-cfm under-cabinet hood -30 "convertible under-cabinet hood -gold® 36-inch vented...

3ddd

$1

CHEHOMA LAMPE SILVERSTONE NICKEL

..., chehoma модель сделана для vray и corona render. магазинhttp://www.decoetcompagnie.com/lamp-silverstone-pm,us,4,54500900.cfmamp;nbsp; ...

3ddd

$1

Модульные полки Adonde

..., полка модульные металлические полки французской фирмы adonde. сайт производителя:http://www.adonde.fr/3d-etagere-modulable-metal-plie-origami,fr,4,939000.cfm931016 ...

3d_export

$10

shelby gt500 1967

...topped with an aluminum mid-rise intake and 2x4-barrel 600 cfm holley carburetors producing 355 bhp (360 ps; 265 kw)...

3d_export

$10

air cooler

...with low water alarm air flow : powerful 300 cfm air flow speeds : 4 speed include high, medium,...

3dfindit

free

TLD-200ECM (100 to180 CFM) ( 1.3Sones 0.10S.P)

...tld-200ecm (100 to180 cfm) ( 1.3sones 0.10s.p)

3dfind.it

catalog: reversomatic manufacturing

3dfindit

free

RCF100-3 (64 to 150 CFM)( 80CFM 1.3Sones 0.10S.P)

...rcf100-3 (64 to 150 cfm)( 80cfm 1.3sones 0.10s.p)

3dfind.it

catalog: reversomatic manufacturing

thingiverse

free

CFM Frame for Movement by Zeakfury

...ad of everywhere.

version 2 will have spikes similar to https://www.thingiverse.com/thing:4262131 for easy replacement material.

thingiverse

free

Grow Tent 16mm High CFM Support Brace Clips by Killavolt

...el into place to add support.

print flat on build plate, but add support down the middle to prevent deformation of the flat spot.

Proof

turbosquid

$6

bullet proof jacket

...el bullet proof jacket for download as 3ds, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1193147)

turbosquid

$1

Sound Proofing Foam

... sound proofing foam for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1289027)

turbosquid

$25

Flame proof fibricks_lit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$149

Bullet Proof Vest with molle attachments

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$40

chevrolet nova ss 70 death proof

...chevrolet nova ss 70 death proof

3dexport

3d_export

$9

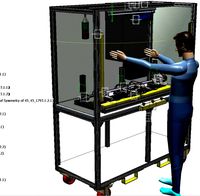

of automobile component error proofing system

...cific product defects; the other is to check the products one by one through cheap means to determine whether they are qualified.

turbosquid

$29

Nikon Coolpix AW110 rugged and proof digital camera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Armoured fighting vehicles armoured vehicles with explosion-proof wheels

...ured vehicles with explosion-proof wheels for download as max on turbosquid: 3d models for games, architecture, videos. (1629664)

turbosquid

$27

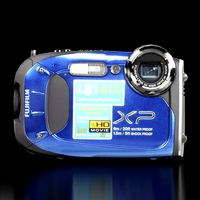

Fujifilm FinePix XP60 Blue rugged and proof digital camera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$23

Panasonic Lumix DMC-TS5 rugged and proof digital gamera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

230

3ddd

$1

Sven 230

... колонки

бюджетные компьютерные колонки sven 230. размеры 65×60×200мм. текстура в комплекте.

design_connected

$27

Mr.Jones Sofa 230

...mr.jones sofa 230

designconnected

adea mr.jones sofa 230 computer generated 3d model. designed by lervik, alexander.

design_connected

$11

Shade 230 Sideboard

...shade 230 sideboard

designconnected

bonaldo shade 230 sideboard computer generated 3d model. designed by viganò, giuseppe.

3ddd

$1

Christopher Guy 60-230

...christopher guy 60-230

3ddd

christopher guy

christopher guy 60-230

design_connected

$27

Lars 230 Low

...onnected

photo-realistic 3d models of the lars 230 low sofa from bonaldo for 3d architectural and interior design presentations.

turbosquid

$7

Rug Set 230

...y free 3d model rug set 230 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1501131)

turbosquid

$14

230 Carpenter 230 Sofa C Sofa-Bed 3-seats 2350x1005x1150

...c sofa-bed 3-seats 2350x1005x1150 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1186112)

turbosquid

$39

Nokia Asha 230

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Nokia 230 White

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Nokia 230 Black

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Explosion

3d_export

$6

explosion

...explosion

3dexport

3 d of explosion

3d_export

$10

explosion

...explosion

3dexport

3d model of explosion for 3d printing

turbosquid

$5

Explosion

...rbosquid

royalty free 3d model explosion for download as max on turbosquid: 3d models for games, architecture, videos. (1202603)

3d_export

$10

Explosion

...explosion

3dexport

turbosquid

$14

Explosion

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Explosive

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Explosive Barrel

...explosive barrel 3docean barrel decoration explosion explosive industrial low low poly metal object old poly...

3ddd

free

KOLARZ Serie Explosion

... serie explosion , австрия

kolarz serie explosion 0109.118.5.kot. врай. текстуры.

3d_export

$5

atomic bomb explosion

...atomic bomb explosion

3dexport

atomic bomb explosion

turbosquid

$1

explosives pack

...squid

royalty free 3d model explosives pack for download as on turbosquid: 3d models for games, architecture, videos. (1316376)

Phase

3d_export

$10

three-phase and single-phase transformer - brazilian style

... and single-phase transformers, very popular in the brazilian power distribution network.<br>they were made in blender 2.82

turbosquid

$20

PHASE COMPARATOR

...ee 3d model phase comparator for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1176216)

turbosquid

$15

Phase Screwdriver

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Phase Pistol

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Phase Primi Personal Chair

...ase - primi personal chair in 3dsmax 2011 vray scene with maps & materials carefully unwrapped, fbx & obj format included

turbosquid

$9

Sofa Cannes Phase

... 3d model sofa cannes phase for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1230512)

turbosquid

free

Longmire phase shotgun

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$16

Phase Brides Veil Stool

...

royalty free 3d model phase brides veil for download as 3ds on turbosquid: 3d models for games, architecture, videos. (1168728)

turbosquid

$2

3 PHASE METER KOHLER

...free 3d model 3 phase meter kohler for download as and sldas on turbosquid: 3d models for games, architecture, videos. (1362953)

turbosquid

$18

3 Phase Circuit Breaker

... phase circuit breaker for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1369078)

Exhaust

turbosquid

$2

Exhaust

...id

royalty free 3d model exhaust for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1603373)

turbosquid

$1

Exhaust

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

exhaust

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

exhaust

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$25

exhaust manifold

...exhaust manifold

3dexport

this is a 3d design of an exhaust manifold used in automobile.

archive3d

free

Exhauster 3D Model

... air exhauster hoover

exhauster n101015 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$13

Exhaust 3D Model

...exhaust 3d model

3dexport

exhaust smoke engine motor bike car detail detailed

exhaust 3d model cesar_vonc 12007 3dexport

turbosquid

free

MSX EXHAUSTS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

exhaust sport

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

car exhaust

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Ac

3d_export

$59

AC Ace 3D Model

...ac ace 3d model

3dexport

car classic ac ace british roadster

ac ace 3d model desmonster 41277 3dexport

turbosquid

$9

Ace(ACE) black coin

...royalty free 3d model ace(ace) black coin for download as max on turbosquid: 3d models for games, architecture, videos. (1593428)

design_connected

$18

Ace soft

...ace soft

designconnected

viccarbe habitat ace soft computer generated 3d model. designed by massaud, jean-marie.

turbosquid

$240

AC 130

...

turbosquid

royalty free 3d model ac 130 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1366260)

turbosquid

$5

AC PLUG

...rbosquid

royalty free 3d model ac plug for download as sldas on turbosquid: 3d models for games, architecture, videos. (1199446)

turbosquid

$2

ac 02

...2

turbosquid

free 3d model ac 02 for download as 3ds and obj on turbosquid: 3d models for games, architecture, videos. (1710322)

turbosquid

$1

AC Socket

...osquid

royalty free 3d model ac socket for download as blend on turbosquid: 3d models for games, architecture, videos. (1562405)

turbosquid

$30

Motor AC

...d

royalty free 3d model motor ac for download as ipt and iam on turbosquid: 3d models for games, architecture, videos. (1361968)

turbosquid

$2

AC unit

...

royalty free 3d model ac unit for download as fbx and blend on turbosquid: 3d models for games, architecture, videos. (1487700)

3ddd

$1

AC SPLIT

...ac split

3ddd

3dmax / vray

Roof

3ddd

$1

Roof

...roof

3ddd

kare , roof

kare кресло roof.

archibase_planet

free

Roof

...roof

archibase planet

roof iron roof

fence roof - 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Roof

...roof

archibase planet

roof iron roof

fence roof-3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Roof

...roof

archibase planet

roof iron roof

fence roof-5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Roof

...roof

archibase planet

roof iron roof

fence roof-6 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Roof

...roof

archibase planet

roof iron roof

fence roof-1- 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

free

roof

...roof

3dexport

roof construct

archibase_planet

free

Roof

...roof

archibase planet

roof skylight

fence roof-7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Roof

...roof

archibase planet

roof skylight

fence roof-8 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Roof

...roof

archibase planet

roof house-top

roof n070211 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

24

3d_export

$15

rocks 24

...rocks 24

3dexport

rocks 3d model 24

design_connected

$18

Dezza 24

...dezza 24

designconnected

dezza 24 computer generated 3d model. designed by ponti, gio.

3ddd

$1

Bed 24

...bed 24

3ddd

постельное белье

bed 24

news bed. i hope you like it

design_connected

$18

Gray 24

...gray 24

designconnected

gervasoni gray 24 chairs computer generated 3d model. designed by paola navone.

design_connected

$9

SMTR 24

...smtr 24

designconnected

maxalto smtr 24 dining tables computer generated 3d model. designed by antonio citterio.

3ddd

$1

Curtains 24

...curtains 24

3ddd

curtains 24

polys: 150755

my other models:http://3ddd.ru/users/brast

3d_export

$6

tap-24

...tap-24

3dexport

turbosquid

$10

Earrings 24

...osquid

royalty free 3d model earrings 24 for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1549235)

turbosquid

$10

Decor 24

...urbosquid

royalty free 3d model decor 24 for download as stl on turbosquid: 3d models for games, architecture, videos. (1678186)

turbosquid

$10

Bedcloth 24

...osquid

royalty free 3d model bedcloth 24 for download as max on turbosquid: 3d models for games, architecture, videos. (1522762)

Three

turbosquid

$5

three

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

three tiger

...three tiger

3dexport

three tank tiger move in attack.

3d_export

$5

three trees

...three trees

3dexport

three trees tri dereva vegetation

design_connected

$16

Three Skin

...three skin

designconnected

moroso three skin computer generated 3d model. designed by arad, ron.

turbosquid

$1

Three vases

...s

turbosquid

free 3d model three vases for download as blend on turbosquid: 3d models for games, architecture, videos. (1214567)

turbosquid

$2

three rings

...quid

royalty free 3d model three rings for download as blend on turbosquid: 3d models for games, architecture, videos. (1327579)

turbosquid

$2

three candlesticks

...

royalty free 3d model three candlesticks for download as dwg on turbosquid: 3d models for games, architecture, videos. (1479291)

3d_export

free

Three free cans

...three free cans

3dexport

three free cans

turbosquid

$10

Satsumas three

...ree 3d model satsumas three for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1378138)

turbosquid

$3

Three trees

...y free 3d model three trees for download as c4d, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1709095)

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)

Mounted

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)