GrabCAD

2 Cavity Compression Mould for coffee lid

by GrabCAD

Last crawled date: 1 year, 10 months ago

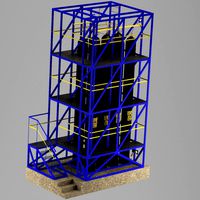

This is a class project. We were challenged to build a mould and die using the same shoe. The other teams are following along the assigned agenda. My group has decided to kick it up several notches. We decided to actually try out the part. A decision was made to make it a compression mold since no injection machine is availabvle. The blank part is 0.02 thick polystyrene sheet cut into a specific size. The blank is loaded into the job and held in place by a ring that clamps it in location. Next heat is added by a heat gun. When the plastic is drooping and soft, the two halfs come together using a verticle spotting press.

The second part is to trim the two lids from the plastic part. I am up to this point on the design, Dies are going to fit in the same pockets in the aluminm inserts and also uses the press to cut them out.

This set of tools will stay at St Clair college for them to teach their future CADCAM students about inovation and to showcase the program. Mould and Die training programs were cut a few years back when substancial work was offshored. Fortunately it is returning to the Mould Capital of the WORLD, Windsor Ontario rocks !!!

More updates as this progresses. I inteand to make a video of the tryouts and also some of th manufacting processes used. The job is entrely designed in NX8.0. ALL cutterpaths are generated using Mastercam X7 and cut on a Cincinati VMC 500 and a Robodrill. The other machines used will be drill press, Anilam controlled milling machines, and also Manual Lathes, Sink EDM and Robowire EDM

The second part is to trim the two lids from the plastic part. I am up to this point on the design, Dies are going to fit in the same pockets in the aluminm inserts and also uses the press to cut them out.

This set of tools will stay at St Clair college for them to teach their future CADCAM students about inovation and to showcase the program. Mould and Die training programs were cut a few years back when substancial work was offshored. Fortunately it is returning to the Mould Capital of the WORLD, Windsor Ontario rocks !!!

More updates as this progresses. I inteand to make a video of the tryouts and also some of th manufacting processes used. The job is entrely designed in NX8.0. ALL cutterpaths are generated using Mastercam X7 and cut on a Cincinati VMC 500 and a Robodrill. The other machines used will be drill press, Anilam controlled milling machines, and also Manual Lathes, Sink EDM and Robowire EDM

Similar models

grabcad

free

Compression Mold Die

...compression mold die

grabcad

plastic formation process dies moulding compression machining system.

thingiverse

free

Precious Plastic Compression Machine (Metric) by robksawyer

...suited for making large and more solid objects. the oven itself is also a great machine for prototyping and making plastic tests.

grabcad

free

Plastic injection moulding machine

...acturing plastic products by the injection molding process. it consists of two main parts, an injection unit and a clamping unit.

thingiverse

free

Flower Press by MattS

...a flower or two. i decided it would be a fun idea to make a printable flower press. it's pretty basic but it will do the job.

thingiverse

free

Dovetail Test fits

...l fit will be press however as the two parts move it will expand to a slip fit.

if you have any questions, dont hesitate to ask.

grabcad

free

Mould press tools

...mould press tools

grabcad

forming tool die to press heated acrylic

grabcad

free

J-Bolt die

...s designed it when we were in educational internship in metec (fabrication) for production of j-bolts for great renaissance dam.

grabcad

free

Fishing Lure Punch and Die to Arbor Press

...cnc mill. "give someone a fish, you'll feed them for a day. teach someone to fish, you'll feed them for life"

grabcad

free

compression moulding dies for fiber

...ber reinforced composite of 3mm thickness can be optained simply by applying load and testing can be carried out on the composite

thingiverse

free

Putty Knife Handle by BrencelJ

...handle. with the putty part you heat the part you will press into the handle and then when it's hot you press it in the hole.

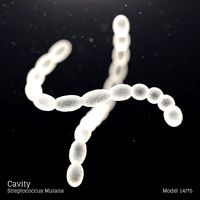

Cavity

turbosquid

$10

oral cavity

...osquid

royalty free 3d model oral cavity for download as fbx on turbosquid: 3d models for games, architecture, videos. (1512365)

turbosquid

$20

Cavity Rock

...y free 3d model cavity rock for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1397880)

turbosquid

$29

Cavity - Streptococcus Mutans

...vity - streptococcus mutans for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1626152)

turbosquid

$24

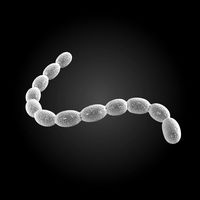

cavity - streptococcus mutans

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Bootie Spice Shaker - Double Cavity

...model bootie spice shaker - double cavity for download as stl on turbosquid: 3d models for games, architecture, videos. (1338377)

turbosquid

$7

Bootie Music Shaker - Dual Cavity

...d model bootie music shaker - dual cavity for download as stl on turbosquid: 3d models for games, architecture, videos. (1338127)

turbosquid

$5

Bootie Spice Shaker - Single Cavity

...model bootie spice shaker - single cavity for download as stl on turbosquid: 3d models for games, architecture, videos. (1338123)

turbosquid

$5

Bootie Music Shaker - Single Cavity

...model bootie music shaker - single cavity for download as stl on turbosquid: 3d models for games, architecture, videos. (1338116)

turbosquid

$14

Signal Cavity Protection Toothpaste 100ml 2019

...l cavity protection toothpaste 100ml 2019 for download as max on turbosquid: 3d models for games, architecture, videos. (1417738)

3d_export

free

ender 3 frame cavity covers

... of the creality ender 3 - makes it look a bit more attractive it just slides into the open channels of the aluminium framework

Mould

3ddd

$1

moulding

...moulding

3ddd

moulding classic plaster ornament

moulding

turbosquid

$35

mould

...ty free 3d model mould for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1438489)

turbosquid

$29

moulding

...free 3d model moulding for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1467257)

turbosquid

$27

Moulding

...free 3d model moulding for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1239199)

turbosquid

$21

Moulding

...free 3d model moulding for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1367303)

turbosquid

$17

moulding

...free 3d model moulding for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1438701)

turbosquid

$7

Moulding

...free 3d model moulding for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1466555)

turbosquid

$40

Moulding

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Moulding

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Moulding

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Compression

turbosquid

$20

compresser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Compression Tap

...for download as blend, gltf, obj, stl, dae, fbx, wrl, and usd on turbosquid: 3d models for games, architecture, videos. (1650763)

turbosquid

$7

Compression reducing tee

...ty free 3d model compression reducing tee for download as max on turbosquid: 3d models for games, architecture, videos. (1540313)

3d_export

$5

Mustang Compressed blend

...mustang compressed blend

3dexport

turbosquid

$19

Compression hips trainer

... compression hips trainer for download as , fbx, stl, and obj on turbosquid: 3d models for games, architecture, videos. (1684685)

turbosquid

$10

Compressed air station

...compressed air station for download as max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1598414)

turbosquid

$35

Compressed-air Engine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Concrete Compression Tester

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

Compression TAP worn

...for download as blend, usd, dae, gltf, fbx, obj, stl, and wrl on turbosquid: 3d models for games, architecture, videos. (1652641)

turbosquid

$49

Compressed Gas Cylinder and Regulator

...odel compressed gas cylinder and regulator for download as ma on turbosquid: 3d models for games, architecture, videos. (1170670)

Lid

3d_export

$5

plastic lid

...plastic lid

3dexport

plastic lid

turbosquid

$4

Sewer lid

...osquid

royalty free 3d model sewer lid for download as blend on turbosquid: 3d models for games, architecture, videos. (1460159)

turbosquid

$15

Lid planter

...y free 3d model lid planter for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1462865)

turbosquid

$1

Bootle (with Lid)

...e 3d model bootle (with lid) for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1362012)

turbosquid

$7

Box Lid

... free 3d model box lid for download as fbx, stl, dae, and obj on turbosquid: 3d models for games, architecture, videos. (1694087)

turbosquid

$30

Sewer Lid

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

SportsBottle4Latches-Lid

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

lid dispenser.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Bucket with lid

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

sewer lid

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Coffee

archibase_planet

free

Coffee

...e planet

coffee iced coffee coffee drink cold coffee

coffee drink n170614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee

... planet

coffee packet of coffee pack of coffee

packet of coffee 1 n190614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

coffee

...coffee

3dexport

coffee

3d_export

$5

coffee

...coffee

3dexport

cartoon cup of coffee

3ddd

free

Coffee

...coffee

3ddd

кофе , книга

coffee, book

archibase_planet

free

Coffee

...coffee

archibase planet

coffee black coffee

nescafe n091007 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Coffee Table

...e table

3ddd

coffee , table , wood

coffee table

archibase_planet

free

Coffee mill

...base planet

coffee mill coffee-grinder coffee grinder

coffee mill n200515 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee mill

...base planet

coffee mill coffee-grinder coffee grinder

coffee mill n300111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_ocean

$2

Starbucks coffee

...starbucks coffee

3docean

coffee starbucks

a high quality starbucks coffee.

2

design_connected

$11

No 2

...no 2

designconnected

sibast no 2 computer generated 3d model. designed by sibast, helge.

turbosquid

$6

Cliff Rock 2-2

...uid

royalty free 3d model cliff rock 2-2 for download as obj on turbosquid: 3d models for games, architecture, videos. (1619161)

turbosquid

$29

Book variation 2 2

...3d model book variation 2 2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1366868)

turbosquid

$22

Classic baluster (2) (2)

...assic baluster (2) (2) for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1483789)

turbosquid

$99

Smilodon 2 Pose 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Barrel Barricade 2-2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Wall Trophy (2) (2)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Tire label 2 of 2

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур

3ddd

free

Кровать, 2 тумбочки, 2 светильника

...кровать, 2 тумбочки, 2 светильника

3ddd

кровать, 2 тумбочки, 2 светильника

нормальное качество

формат 3ds max

без текстур