Thingiverse

1/8" mini phone splice shell by elhalpern

by Thingiverse

Last crawled date: 4 years, 7 months ago

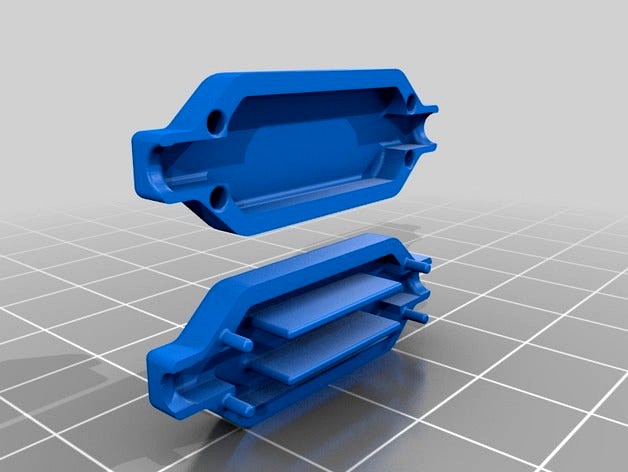

I needed to join a 1/8" stereo mini phone male with a 3/16" mini phone female using a pair of molded cables. In the past I would have butt spliced, soldered, used electrical tape (or heat shrink) and created a large rope-like knot to act as a strain relief.

This shell separates the three conductors and splices and provides strain relief when filled with 5-minute epoxy. The internal walls made it so I didn't need to use heat shrink and my solder joints didn't have to be pretty.

The modeling isn't my best work and the four alignment holes will likely have openings on outside surfaces when printed on most FDM printers. But, a drop of epoxy on each hole and the four mating pins during potting fills the side breakouts and the overall look and function is spot on.

After soldering, dressing the wiring in the three channels and filling it with epoxy I use a small spring loaded clamp to hold it tightly closed while the epoxy cures.

This shell separates the three conductors and splices and provides strain relief when filled with 5-minute epoxy. The internal walls made it so I didn't need to use heat shrink and my solder joints didn't have to be pretty.

The modeling isn't my best work and the four alignment holes will likely have openings on outside surfaces when printed on most FDM printers. But, a drop of epoxy on each hole and the four mating pins during potting fills the side breakouts and the overall look and function is spot on.

After soldering, dressing the wiring in the three channels and filling it with epoxy I use a small spring loaded clamp to hold it tightly closed while the epoxy cures.