Thingiverse

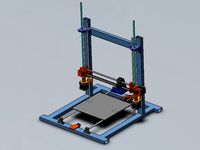

1200 x 1200 Large scale DIY 3D printer - Sub33D v3.07 by sschm9

by Thingiverse

Last crawled date: 3 years ago

Please check out the Build progress and test print preview video:https://www.youtube.com/watch?v=eUf5-UCVueU

There is a playlist of full build progress updates and test print videos:https://www.youtube.com/playlist?list=PLW8e88EbKrS-baD0ZTySmq4-q1nxtejUq

800mm Ledgend of Zelda Master Sword test print:https://www.youtube.com/watch?v=uNQMUBLKr4Y

T-Rex skull test print:https://www.youtube.com/watch?v=X6_i6DHRLhA

You can also check us out on Facebook:https://www.facebook.com/Sub33D/

Filament for the printer is created on our own modified Lyman / Mulier version 5 Filament Extruder:https://www.youtube.com/watch?v=RwAdB6rVrKg

This printer was designed to print very large scale using recycled ABS plastic (we also recycle, shred and produce recycled ABS filament).

Most of the other very large scale printers out there tend to print in PLA which is a lot less problematic at large scale.

Main features:

Build volume 1200mm x 1200mm x 600mm

H bot layout with fixed heat-bed (4 x z-axis motors to move the light weight H frame rather than the insanely heavy heat-bed)

1mm nozzle, double volcano extruder hot end to increase flow rate (80W total heater power)

2400W heatbed using 4 x 230V 600W 400mm x 400mm silicone heating pads (controlled with 25A solid state relay)

2 x Recycled Nema23 stepper motors for y-axis, driven by single 5A TB600 CNC type stepper driver

4 x Recycled Nema23 stepper motors for z-axis, driven by single 5A TB600 CNC type stepper driver

1 x Recycled Nema23 stepper motor for x-axis, driven by standard DRV8825 2.5A stepper driver

1 x Recycled Nema17 stepper motor for extruder, driven by standard DRV8825 2.5A stepper driver

Modified Ultimaker 1.5.7 PCB main board

4 x 150W IR heaters to reduce heat-bed deformation and maintain consistent heat on printed ABS parts.

Designed in Sketchup Make 2017, design file included in downloads (Sub33D v3.07.09.skp), I have also uploaded Sub33D v3.07.09.stl which is a common intermediate format used by Sketchup and other CAD formats.

Frame built from 50mm x 50mm x 2mm box section aluminium

Total build cost is close to $2000 AUD, aproximately add another $500 AUD if your not using recycled components.

Marlin-RC firmware also included in downloads (Marlin-RC.zip)

If anyone is thinking to build something like this I would recommend using a 12mm heat-bed plate (rather than 6mm) as the aluminium plate deforms up to 5mm when heated to 90 deg C, I am using 9 x 9 point auto-bed leveling to pick up the deformation shape).

Also the 400mm x 400m 600W silicone heaters are a little small as the distance between them causes around a 10 deg C difference on the heat-bed surface between the heaters and above them).

I'm Currently building a new dual 100mm stack extruder with 8 x 40W heater cartridges to allow for a 4 x increase in flow rate over the current design, as the printing speed at this volume is way to slow, once this is done I will share some more of the design details.

There is an image of the wiring (Sub33d_v3.07_stepper_and_heatbed_wiring_diagram_v1.00.zip), which can be used to connect many different 3D printer boards to external CNC type drivers, I used the RAMPS 1.4 in the wiring diagram as this seems to be one of the most common boards.

An old server ATX power supply was used which was around 1000W, although a 500W supply would have been fine.

Only the 12V output was used.

The max current draw is the sum of the following:

4 x z-axis Nema23's at 4A total

2 x y-axis Nema23's at 4A total

1 x x-axis Nema23 at 2A total

1 x extruder Nema17 at 1.5A total

2 x volcano hotend heaters at 6A total

several 12V fans, approx 2A total

Which comes to around 19.5A peak at 12V, (please note this does not include the heatbed, which runs off 230V AC mains power at 2400W)

Special thanks to Substation33 for all the support and recycled materials.

There is a playlist of full build progress updates and test print videos:https://www.youtube.com/playlist?list=PLW8e88EbKrS-baD0ZTySmq4-q1nxtejUq

800mm Ledgend of Zelda Master Sword test print:https://www.youtube.com/watch?v=uNQMUBLKr4Y

T-Rex skull test print:https://www.youtube.com/watch?v=X6_i6DHRLhA

You can also check us out on Facebook:https://www.facebook.com/Sub33D/

Filament for the printer is created on our own modified Lyman / Mulier version 5 Filament Extruder:https://www.youtube.com/watch?v=RwAdB6rVrKg

This printer was designed to print very large scale using recycled ABS plastic (we also recycle, shred and produce recycled ABS filament).

Most of the other very large scale printers out there tend to print in PLA which is a lot less problematic at large scale.

Main features:

Build volume 1200mm x 1200mm x 600mm

H bot layout with fixed heat-bed (4 x z-axis motors to move the light weight H frame rather than the insanely heavy heat-bed)

1mm nozzle, double volcano extruder hot end to increase flow rate (80W total heater power)

2400W heatbed using 4 x 230V 600W 400mm x 400mm silicone heating pads (controlled with 25A solid state relay)

2 x Recycled Nema23 stepper motors for y-axis, driven by single 5A TB600 CNC type stepper driver

4 x Recycled Nema23 stepper motors for z-axis, driven by single 5A TB600 CNC type stepper driver

1 x Recycled Nema23 stepper motor for x-axis, driven by standard DRV8825 2.5A stepper driver

1 x Recycled Nema17 stepper motor for extruder, driven by standard DRV8825 2.5A stepper driver

Modified Ultimaker 1.5.7 PCB main board

4 x 150W IR heaters to reduce heat-bed deformation and maintain consistent heat on printed ABS parts.

Designed in Sketchup Make 2017, design file included in downloads (Sub33D v3.07.09.skp), I have also uploaded Sub33D v3.07.09.stl which is a common intermediate format used by Sketchup and other CAD formats.

Frame built from 50mm x 50mm x 2mm box section aluminium

Total build cost is close to $2000 AUD, aproximately add another $500 AUD if your not using recycled components.

Marlin-RC firmware also included in downloads (Marlin-RC.zip)

If anyone is thinking to build something like this I would recommend using a 12mm heat-bed plate (rather than 6mm) as the aluminium plate deforms up to 5mm when heated to 90 deg C, I am using 9 x 9 point auto-bed leveling to pick up the deformation shape).

Also the 400mm x 400m 600W silicone heaters are a little small as the distance between them causes around a 10 deg C difference on the heat-bed surface between the heaters and above them).

I'm Currently building a new dual 100mm stack extruder with 8 x 40W heater cartridges to allow for a 4 x increase in flow rate over the current design, as the printing speed at this volume is way to slow, once this is done I will share some more of the design details.

There is an image of the wiring (Sub33d_v3.07_stepper_and_heatbed_wiring_diagram_v1.00.zip), which can be used to connect many different 3D printer boards to external CNC type drivers, I used the RAMPS 1.4 in the wiring diagram as this seems to be one of the most common boards.

An old server ATX power supply was used which was around 1000W, although a 500W supply would have been fine.

Only the 12V output was used.

The max current draw is the sum of the following:

4 x z-axis Nema23's at 4A total

2 x y-axis Nema23's at 4A total

1 x x-axis Nema23 at 2A total

1 x extruder Nema17 at 1.5A total

2 x volcano hotend heaters at 6A total

several 12V fans, approx 2A total

Which comes to around 19.5A peak at 12V, (please note this does not include the heatbed, which runs off 230V AC mains power at 2400W)

Special thanks to Substation33 for all the support and recycled materials.

Similar models

thingiverse

free

PASTE EXTRUDER / STEPPER MOTOR DRIVEN by OliverReinecke

...4

the thing is finished ... but the preparation of the right paste is a work in progress as you might see in the short video ;)

grabcad

free

NEMA23 STEPPER MOTOR BRACKET FOR 20x40 V SLOT Z AXIS ACTUATOR

...nema23 stepper motor bracket for 20x40 v slot z axis actuator

grabcad

nema23 stepper motor bracket for z axis actuator

thingiverse

free

Sub33D v2.06 sub $100 AUD recycled e-waste 3D printer by sschm9

... instructions (still under construction):

https://www.youtube.com/watch?v=0ecutgj9l7u&list=plw8e88ebkrs9l1py1hj-ydup7o0o1gqak

thingiverse

free

nightliner - ikea "trysil" based 3d printer by alexsilver

...n"

add some more cable ducts

some optimizations..

add construction manual if anyone is interested in rebuilding this printer

thingiverse

free

Nema 17 Stepper motor mount MGFA for exturnal driven extruders by MGFA

...t mgfa for exturnal driven extruders by mgfa

thingiverse

stepper motor mount for stepper motor, ready rod style printers mgfa.ca

grabcad

free

3 Axis Stepper Motor Driver

...3 axis stepper motor driver

grabcad

3 axis stepper motor driver

thingiverse

free

MK 3D Printer Full Printable Frame by KRMICH29

... sensor

the bed fit 214mm x 214mm heated bed.

( optional ) added modular extruder motor holder to be glued on base left or right.

grabcad

free

Microstep Driver

...microstep driver

grabcad

this one is from china for nema23 stepper motor. use it.

all likes are also welcome;)

grabcad

free

Stepper motor NEMA23 23hs5628

...tepper motor with some more details than the https://grabcad.com/library/nema23-stepper-motor-1, which i downloaded and modified.

thingiverse

free

Change your stepper by a servo DC motor on Prusa i3 x-axis by misan

...ou can see the servo working before being installed in the printer in the next video: https://www.youtube.com/watch?v=jb6cartgrn8

Sub33D

thingiverse

free

Sub33D v2.06 sub $100 AUD recycled e-waste 3D printer by sschm9

... instructions (still under construction):

https://www.youtube.com/watch?v=0ecutgj9l7u&list=plw8e88ebkrs9l1py1hj-ydup7o0o1gqak

thingiverse

free

Sub33D recycled e-waste 3D printer v1.02 (large format, low cost) by sschm9

...s, office printers and general e-waste turned into 3d printers, enabling disadvantaged people access to very low cost 3d printers

thingiverse

free

18650 LiPo battery module assembly for Ryobi One+ tools utilising recycled e-waste laptop cells by sschm9

...18650 cells (e.g. from dead laptop batteries) printed on sub33d v1.02 printer 4 x perimiters (0.5mm nozzle) 25% infill...

thingiverse

free

Generic 18v 18650 LiPo battery module assembly for 18v tools utilising recycled e-waste laptop cells by sschm9

...18650 cells (e.g. from dead laptop batteries) printed on sub33d v1.02 printer 4 x perimiters (0.5mm nozzle) 25% infill...

thingiverse

free

$65 3D printer made from recycled electronic waste by sschm9

...items ~$10.00 total (inc delivery) $64.22 please checkout file "sub33d price info v2.07.pdf" for links to online components and...

Sschm9

thingiverse

free

Power Jack inverter mounting bracket by sschm9

...'s tend to be extremely heavy due to the large ferrite transformers)

also added a third bracket under the inverter for safety

thingiverse

free

18650 LiPo battery module assembly for Ryobi One+ tools utilising recycled e-waste laptop cells by sschm9

...5mm nozzle)

25% infill

10mm brim

recommended ebay components:

1 x deans plug

1 x 5s jst-xh cable

1 x imax b6 (1s-6s lipo charger)

thingiverse

free

Heavy Duty - Enclosed Bearing - Tri Fidget Spinner Toy by sschm9

...et me know if anyone tries this design with pla, i am guessing it would still crack if dropped onto concrete from several meters?

thingiverse

free

Generic 18v 18650 LiPo battery module assembly for 18v tools utilising recycled e-waste laptop cells by sschm9

...5mm nozzle)

25% infill

10mm brim

recommended ebay components:

1 x deans plug

1 x 5s jst-xh cable

1 x imax b6 (1s-6s lipo charger)

thingiverse

free

Solar PV or EV (Electric Vehicle) 18650 modular battery pack from recycled e-waste laptop batteries by sschm9

...station 33 (www.substation33.com.au), special thanks to tony sharp

31 mary st, kingston qld 4114, australia

ph +61 (07) 3826 1533

thingiverse

free

Electric bike (e-bike) or scooter 18650 modular battery pack from recycled e-waste laptop batteries by sschm9

...station 33 (www.substation33.com.au), special thanks to tony sharp

31 mary st, kingston qld 4114, australia

ph +61 (07) 3826 1533

thingiverse

free

Sub33D recycled e-waste 3D printer v1.02 (large format, low cost) by sschm9

...s, office printers and general e-waste turned into 3d printers, enabling disadvantaged people access to very low cost 3d printers

thingiverse

free

Sub33D v2.06 sub $100 AUD recycled e-waste 3D printer by sschm9

... instructions (still under construction):

https://www.youtube.com/watch?v=0ecutgj9l7u&list=plw8e88ebkrs9l1py1hj-ydup7o0o1gqak

thingiverse

free

$65 3D printer made from recycled electronic waste by sschm9

... instructions (still under construction):

https://www.youtube.com/watch?v=0ecutgj9l7u&list=plw8e88ebkrs9l1py1hj-ydup7o0o1gqak

1200

turbosquid

$12

HUMAN-1200

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

LAUFEN / CASE 1200

...laufen / case 1200

3ddd

laufen

модель мебели для ванной laufen серия case 1200, max2012+fbx+obj+3ds

3ddd

$1

RAVAK Unity 1200

...unity , suzan

умывальник ravak unity 1200

смеситель ravak suzan sn 012

полигонов 77 000

design_connected

$18

Pictofocus 1200 Gas Fireplace

...00 gas fireplace

designconnected

focus pictofocus 1200 gas fireplace computer generated 3d model. designed by imbert, dominique.

3ddd

$1

Kappellini Intagli 1200 PS

... капитоне , кресло

компютерне крісло kappellini intagli 1200 ps.159538 полігонів

turbosquid

$35

Kitchen Stove Bertazzoni 1200

...ee 3d model kitchen stove bertazzoni 1200 for download as upk on turbosquid: 3d models for games, architecture, videos. (1258217)

turbosquid

$35

Medieval Tower 1200 3D

...y free 3d model medieval tower 1200 3d for download as blend on turbosquid: 3d models for games, architecture, videos. (1454112)

turbosquid

$79

Ducati Monster 1200(1)

...model ducati monster 1200(1) for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1376659)

turbosquid

$6

Classic wood table 1200

...del classic wood table 1200 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1459507)

turbosquid

$6

Wooden table with veneers 1200

...den table with veneers 1200 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1469151)

V3

3d_export

$5

Poison-v3

...poison-v3

3dexport

poison-v3

3ddd

$1

Curtain v3

...curtain v3

3ddd

полупрозрачная штора v3

turbosquid

free

v3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

potato v3

...potato v3

3dexport

turbosquid

$69

Skeletor v3

...royalty free 3d model skeletor v3 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1712713)

turbosquid

$49

Zombie v3

...

royalty free 3d model zombie v3 for download as obj and ztl on turbosquid: 3d models for games, architecture, videos. (1342458)

turbosquid

$2

Bitcoin v3

...

royalty free 3d model bitcoin v3 for download as c4d and prj on turbosquid: 3d models for games, architecture, videos. (1182845)

turbosquid

$29

Turret V3

...alty free 3d model turret v3 for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1217498)

turbosquid

$20

Radiators v3

... free 3d model radiators v3 for download as max, max, and obj on turbosquid: 3d models for games, architecture, videos. (1607437)

turbosquid

$10

Wheel V3S

...e 3d model wheel v3s for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1344250)

Diy

3d_export

free

DIY 3D Printer

...diy 3d printer

3dexport

diy 3d printer model

turbosquid

$10

Diy tiered

...l diy tiered for download as max, max, max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1603709)

turbosquid

$3

Diy Desk to Bench

...odel diy desk to bench for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1506589)

turbosquid

$2

DIY Moon Light

...model diy moon light for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1501170)

3d_export

$8

DIY CNC Router 3D Model

...diy cnc router 3d model

3dexport

cnc; router; diy; homemade

diy cnc router 3d model maikeru86 58463 3dexport

turbosquid

$5

Diy Kitchen Cabinets

...itchen cabinets for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1197373)

3d_export

free

Download free Diying Plant 3D Model

...download free diying plant 3d model

3dexport

diying plant blender

diying plant 3d model visitorsama 98607 3dexport

3ddd

$1

DIY coffee table + decor

... рамка для фото

кофейный столик diy 400х350х600(h) мм. моделился по фото. внимание: материалы - corona.

turbosquid

$3

Diy Wire Lamp Shade

...free 3d model diy wire lamp shade for download as 3ds and fbx on turbosquid: 3d models for games, architecture, videos. (1347605)

cg_studio

$12

DIY MONGOLIAN LAMB STOOLS3d model

... hair soft pile white

.max - diy mongolian lamb stools 3d model, royalty free license available, instant download after purchase.

07

turbosquid

$6

Classic cabinet 07 07

...sic cabinet 07 07 for download as max, max, dwg, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1669541)

3ddd

$1

Bed 07

...bed 07

3ddd

постельное белье

bed 07

evermotion

$25

Scene 07 Archexteriors vol. 07

...downtowns public's

take a look at textured and shadered visualization scene ready to be rendered.. evermotion 3d models shop.

turbosquid

$20

07

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

chair 07

...chair 07

designconnected

chair 07 computer generated 3d model.

design_connected

$16

chair 07

...chair 07

designconnected

chair 07 computer generated 3d model.

design_connected

$27

Gamma 07

...gamma 07

designconnected

zanotta gamma 07 computer generated 3d model. designed by progetti, emaf.

design_connected

$20

Gray 07

...gray 07

designconnected

gervasoni gray 07 computer generated 3d model. designed by navone, paola.

design_connected

$20

Kilt 07

...kilt 07

designconnected

zanotta kilt 07 computer generated 3d model. designed by progetti, emaf.

3ddd

$1

Net 07

...net 07

3ddd

ротанг , gervasoni

диван net 07 от gervasoni.

габариты: 2000*850*680

Large

3d_export

$15

large excavator

...large excavator

3dexport

large excavator

design_connected

$22

Daydream large

...daydream large

designconnected

dedon daydream large computer generated 3d model. designed by frinier, richard.

design_connected

$7

Laccio Large

...laccio large

designconnected

knoll laccio large computer generated 3d model. designed by breuer, marcel.

3ddd

$1

MOLTENI LARGE

... подушка , плед

диван molteni&c; модель large

3ddd

$1

Molteni Large

... подушка , плед

диван molteni&c; модель large

3ddd

$1

CLAUDINE LARGE

...audine large

3ddd

claudine large , arflex

модель сделана в размерах и цветах аналога ...

design_connected

$11

Ovo Large

...ovo large

designconnected

cor ovo large armchairs computer generated 3d model. designed by studio vertijet.

design_connected

$4

Cu Large

...cu large

designconnected

kristalia cu large coffee tables computer generated 3d model. designed by monica graffeo.

3d_ocean

$18

Large sausage

...rge meat mental ray obj photorealistic sausage scanned vray

scanned 3d model of large sausage placed on rectangular wooden board.

design_connected

$16

Filly Large

...onnected

photo-realistic 3d models of the filly large chair from bonaldo for 3d architectural and interior design presentations.

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Scale

turbosquid

$20

Weight scale or Bathroom Scale

...ght scale or bathroom scale for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1664576)

turbosquid

$19

Scale

...e

turbosquid

royalty free 3d model scale for download as fbx on turbosquid: 3d models for games, architecture, videos. (1411722)

turbosquid

$5

Scales

...s

turbosquid

royalty free 3d model scales for download as ma on turbosquid: 3d models for games, architecture, videos. (1393439)

turbosquid

$40

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$17

Scales

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Scale

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$7

of scales

...s have a flat point of support. the samples are rendered in the standard cinema 4d renderer. enjoy your use and creative success.

3d_export

$5

scale knob

...scale knob

3dexport

scale knob

3d_export

$20

cartoon weight scale or bathroom scale

...cartoon weight scale or bathroom scale

3dexport

texture size:512px number of texture:1 texture format: png