GrabCAD

100W Explosion Proof Ultraviolet LED Light Fixture - Class I, II, III - Paint Spray Booth Approved - 180° Beam Angle

by GrabCAD

Last crawled date: 1 year, 10 months ago

https://www.larsonelectronics.com/product/104729/100w-explosion-proof-ultraviolet-led-light-fixture-class-i-ii-iii-paint-spray-booth-approved-180-beam-angle

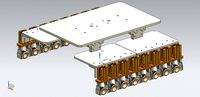

The EPL-HB-100LED-RT-UVA from Larson Electronics is an Explosion Proof Ultraviolet Light Fixture that provides operators with a powerful and energy efficient alternative to traditional hazardous location luminaries with UV cutoff filters. LED technology and compact design makes this lamp an excellent replacement upgrade option for bulky and high maintenance cost older incandescent, metal halide and high pressure sodium lights. This fixture uses advanced LED light technology to produce ultraviolet light and is T6 rated for hazardous locations where UV lamps are used in paint and adhesive curing, food inspection, or for non-destructive testing. The EPL-HB-100LED-RT-UVA features a 180° beam angle.

This Class I Divisions 1 & 2, Class II Divisions 1 & 2 explosion proof UV light fixture provides 46,550 mW of high quality ultraviolet light while drawing only 100 watts. This high output UV LED fixture provides a 6,384 µW/cm2 center beam maximum intensity at 12" while providing a minimum 2,660 µW/cm2 intensity over a 14" by 14" area. The EPL-HB-100LED-RT-UVA is typically used for curing coatings or adhesives and for non-destructive testing applications. This fixture has been thoroughly tested with the DuPont line of ultraviolet curable paint and primers, accelerating the cure times over metal halide fixtures with surface temperatures as low at 55°F.

The copper free aluminum alloy body is powder coated for added durability and an attractive aesthetic appearance. Special heat dissipating design in conjunction with LED technology helps this fixture to achieve an excellent 50,000 hour rated lifespan with 80% intensity retention. Light weight and a low profile make this unit an attractive alternative to larger and heavier older fixtures and requires less hardware to install. This fixture can operate on voltages ranging from 120V-277 V AC, 50/60 Hz and is ETL approved for use in hazardous environments, paint spray booths, wet environments, and areas where UV lamps are used in paint and adhesive curing, food inspection, and for non-destructive testing.

The explosion proof LED light fixture features multiple LED drivers which helps to increase the operational life of the fixture. With traditional LED lights, in the event an LED array or driver fails, the entire fixture no longer illuminates. This new series of LED lamps contains twelve individual LED boards configured in a series of banks. Each bank contains two LED boards with an individual driver. In the event of a driver failure, only one bank of LEDs will be effected while the other banks will continue to operate. In the event that of an LED failure, the mating LED will continue to operate.

The EPL-HB-100LED-RT-UVA uses ultraviolet LED light technology, a technology that is far better in energy saving than traditional fluorescent bulbs used for the same purposes. Traditional ultraviolet lights require a coating to block out visible light or a special composition of gases and chemicals used to create a higher concentration of ultraviolet light. This process, however, also produces many other wavelengths of light which go unused and end up as wasted energy. LED lights are unique in that they have a narrower wavelength band than traditional ultraviolet sources and therefore do not require these special coatings. As a result, LED lights do not produce unused, wasted light and therefore consume less energy than traditional UV lights on the market. LED lights have the added benefit of being capable of producing very specific wavelengths with tighter curves and are more durable and light weight as well. This eliminates harmful UV-B and UV-C wavelengths from being emitted from the light source, adding in productivity and safety during operation.

LED Benefits: Unlike gas burning and arc type lamps that have glass bulbs, LEDs have no filaments or fragile housings to break during operation and/or transportation. Instead of heating a small filament or using a combination of gases to produce light, light emitting diodes (LEDs) use semi-conductive materials that illuminate when electric current is applied, providing instant illumination with no warm up or cool down time before re-striking. Because there is no warm up period, this light can be cycled on and off with no reduction in lamp life.

LED lights run at significantly cooler temperatures than traditional metal halide and high pressure sodium lights and contain no harmful gases, vapors, or mercury, making them both safer and more energy efficient. No extra energy is wasted in cooling enclosed work areas due to external heat emissions from bulb type lights, and the operator risks associated with traditional lighting methods, such as accidental burns and exposure to hazardous substances contained in the glass bulbs, are eliminated. In addition, LEDs are also safer for the environment as they are 100% recyclable, which eliminates the need for costly special disposal services required with traditional gas burning and arc type lamps.

400W MH

100W LED

Wattage

400 watts

100 watts

Amp Draw @ 120V AC

3.34 amps

0.84 amps

Amp Draw @ 24V DC

16.67 amps

4.17 amps

Lamp Life Expectancy

15,000

50,000+ Hours

Wavelength

320-400NM

350-380NM

Operation Cost per Year (8hs/day @ 11c/kWh)

$138.12

$32.12

The Class I & II, Divisions 1 & 2 LED ultraviolet light fixture can be used for non-destructive testing in aviation and manufacturing, food processing and inspection, and in paint, coating, and adhesive curing. The EPL-HB-100LED-RT-UVA provides operators in hazardous locations with a reliable and durable UV lighting solution that combines effective production of UV light with explosion proof protection and is applicable for leak detection, paint spray booths, ink, coatings, and adhesive curing, non-destructive testing, inspection, and food processing.

This light is universal voltage capable and can be operated with 100-277 V AC, 50/60 Hz. We also offer a low voltage version of this LED fixture that operates on AC/DC voltages from 11-25 Volts. This explosion proof LED light fixture is IP67 rated, dust-proof, and protected against high pressure jets and temporary submersion. The cast aluminum body and LED lamp give this light excellent durability and resistance to vibration and impacts. The housing is specially designed to dissipate heat which increases the efficiency and lifespan of the LEDs and electronics.

This LED light produces 46,550 mW with a wavelength curve of 350-380NM. The EPL-HB-100LED-RT-UVA offers several mounting options including ceiling mounting, pendant mounting, wall mounting and cable mounting. The standard version of this explosion proof LED fixture includes a pendant mount and a surface mount option.

The EPL-HB-100LED-RT-UVA from Larson Electronics is an Explosion Proof Ultraviolet Light Fixture that provides operators with a powerful and energy efficient alternative to traditional hazardous location luminaries with UV cutoff filters. LED technology and compact design makes this lamp an excellent replacement upgrade option for bulky and high maintenance cost older incandescent, metal halide and high pressure sodium lights. This fixture uses advanced LED light technology to produce ultraviolet light and is T6 rated for hazardous locations where UV lamps are used in paint and adhesive curing, food inspection, or for non-destructive testing. The EPL-HB-100LED-RT-UVA features a 180° beam angle.

This Class I Divisions 1 & 2, Class II Divisions 1 & 2 explosion proof UV light fixture provides 46,550 mW of high quality ultraviolet light while drawing only 100 watts. This high output UV LED fixture provides a 6,384 µW/cm2 center beam maximum intensity at 12" while providing a minimum 2,660 µW/cm2 intensity over a 14" by 14" area. The EPL-HB-100LED-RT-UVA is typically used for curing coatings or adhesives and for non-destructive testing applications. This fixture has been thoroughly tested with the DuPont line of ultraviolet curable paint and primers, accelerating the cure times over metal halide fixtures with surface temperatures as low at 55°F.

The copper free aluminum alloy body is powder coated for added durability and an attractive aesthetic appearance. Special heat dissipating design in conjunction with LED technology helps this fixture to achieve an excellent 50,000 hour rated lifespan with 80% intensity retention. Light weight and a low profile make this unit an attractive alternative to larger and heavier older fixtures and requires less hardware to install. This fixture can operate on voltages ranging from 120V-277 V AC, 50/60 Hz and is ETL approved for use in hazardous environments, paint spray booths, wet environments, and areas where UV lamps are used in paint and adhesive curing, food inspection, and for non-destructive testing.

The explosion proof LED light fixture features multiple LED drivers which helps to increase the operational life of the fixture. With traditional LED lights, in the event an LED array or driver fails, the entire fixture no longer illuminates. This new series of LED lamps contains twelve individual LED boards configured in a series of banks. Each bank contains two LED boards with an individual driver. In the event of a driver failure, only one bank of LEDs will be effected while the other banks will continue to operate. In the event that of an LED failure, the mating LED will continue to operate.

The EPL-HB-100LED-RT-UVA uses ultraviolet LED light technology, a technology that is far better in energy saving than traditional fluorescent bulbs used for the same purposes. Traditional ultraviolet lights require a coating to block out visible light or a special composition of gases and chemicals used to create a higher concentration of ultraviolet light. This process, however, also produces many other wavelengths of light which go unused and end up as wasted energy. LED lights are unique in that they have a narrower wavelength band than traditional ultraviolet sources and therefore do not require these special coatings. As a result, LED lights do not produce unused, wasted light and therefore consume less energy than traditional UV lights on the market. LED lights have the added benefit of being capable of producing very specific wavelengths with tighter curves and are more durable and light weight as well. This eliminates harmful UV-B and UV-C wavelengths from being emitted from the light source, adding in productivity and safety during operation.

LED Benefits: Unlike gas burning and arc type lamps that have glass bulbs, LEDs have no filaments or fragile housings to break during operation and/or transportation. Instead of heating a small filament or using a combination of gases to produce light, light emitting diodes (LEDs) use semi-conductive materials that illuminate when electric current is applied, providing instant illumination with no warm up or cool down time before re-striking. Because there is no warm up period, this light can be cycled on and off with no reduction in lamp life.

LED lights run at significantly cooler temperatures than traditional metal halide and high pressure sodium lights and contain no harmful gases, vapors, or mercury, making them both safer and more energy efficient. No extra energy is wasted in cooling enclosed work areas due to external heat emissions from bulb type lights, and the operator risks associated with traditional lighting methods, such as accidental burns and exposure to hazardous substances contained in the glass bulbs, are eliminated. In addition, LEDs are also safer for the environment as they are 100% recyclable, which eliminates the need for costly special disposal services required with traditional gas burning and arc type lamps.

400W MH

100W LED

Wattage

400 watts

100 watts

Amp Draw @ 120V AC

3.34 amps

0.84 amps

Amp Draw @ 24V DC

16.67 amps

4.17 amps

Lamp Life Expectancy

15,000

50,000+ Hours

Wavelength

320-400NM

350-380NM

Operation Cost per Year (8hs/day @ 11c/kWh)

$138.12

$32.12

The Class I & II, Divisions 1 & 2 LED ultraviolet light fixture can be used for non-destructive testing in aviation and manufacturing, food processing and inspection, and in paint, coating, and adhesive curing. The EPL-HB-100LED-RT-UVA provides operators in hazardous locations with a reliable and durable UV lighting solution that combines effective production of UV light with explosion proof protection and is applicable for leak detection, paint spray booths, ink, coatings, and adhesive curing, non-destructive testing, inspection, and food processing.

This light is universal voltage capable and can be operated with 100-277 V AC, 50/60 Hz. We also offer a low voltage version of this LED fixture that operates on AC/DC voltages from 11-25 Volts. This explosion proof LED light fixture is IP67 rated, dust-proof, and protected against high pressure jets and temporary submersion. The cast aluminum body and LED lamp give this light excellent durability and resistance to vibration and impacts. The housing is specially designed to dissipate heat which increases the efficiency and lifespan of the LEDs and electronics.

This LED light produces 46,550 mW with a wavelength curve of 350-380NM. The EPL-HB-100LED-RT-UVA offers several mounting options including ceiling mounting, pendant mounting, wall mounting and cable mounting. The standard version of this explosion proof LED fixture includes a pendant mount and a surface mount option.

Similar models

grabcad

free

150W Explosion Proof Ultraviolet LED Light Fixture - C1D2/C2D1 - Paint Spray Booth Approved

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

grabcad

free

Explosion Proof 33.5 Watt LED Ultraviolet Light - Class 1 Div 1&2, Class 2 Div 1&2

...bration/impact resistant.

13. significantly cooler operation.

14. less frequent outages, higher output improves workplace safety.

grabcad

free

Explosion Proof Fluorescent Ultraviolet Light - Class 1 & 2 - 4' 2 lamp - Paint Booths, Rigs, Marine

...n our uv fluorescent fixtures are unique to uv applications.

uva(-a) 400nm - 315nm

uvb (-b) 315nm - 280nm

uvc (-c) 280nm - 100nm

grabcad

free

Explosion Proof Ultraviolet LED Light - Base Stand Mount - 100 Watt LED - Class I Div 1 C&D

... the led light head retains 80% of its light output after 60,000 hours of use, far longer than incandescent or fluorescent lamps.

grabcad

free

Explosion Proof 160 W Class 1 & 2 Fluorescent UV Light With 4 Lamps - Class 1 Division 1

...n our uv fluorescent fixtures are unique to uv applications.

uva(-a) 400nm - 315nm

uvb (-b) 315nm - 280nm

uvc (-c) 280nm - 100nm

grabcad

free

Class 1 & Class 2 Division 1 Explosion Proof UV Fluorescent Light - two foot two lamp

...n our uv fluorescent fixtures are unique to uv applications.

uva(-a) 400nm - 315nm

uvb (-b) 315nm - 280nm

uvc (-c) 280nm - 100nm

grabcad

free

C1D1 Explosion Proof 150 Watt LED Light Fixture - 50ft 16/3 Steel Braided Cable - EXP Plug

...ng. this particular fixture ships with a swivel bracket and safety cables to suspend the light within grain towers and elevators.

grabcad

free

Explosion Proof 150 Watt Low Bay LED Light Fixture - 140° Spread - Paint Booth Approved - C1D1

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

grabcad

free

150W Explosion Proof High Bay LED Light Fixture - 21000 Lumens - C1D1 - Paint Spray Booth Approved - 180° Beam Angle

...eas, waste treatment plants, and woodworking. click here to read the nec description for explosion proof and hazardous locations.

grabcad

free

Class II Division 1 Explosion Proof 100 Watt High Bay LED Light Fixture 11,667 Lumens - CID2 / CIID1

...and cable mounting. the standard version of this explosion proof led fixture includes a pendant mount and a surface mount option.

Ultraviolet

cg_studio

$18

Ultraviolet Sword3d model

...iolet sword3d model

cgstudio

.max - ultraviolet sword 3d model, royalty free license available, instant download after purchase.

3d_export

$18

Ultraviolet Sword 3D Model

...razor blade battle ready gameready game fight fighter fighting king queen

ultraviolet sword 3d model martialartist 23245 3dexport

3d_export

$15

ultraviolet germicidal antibacterial lamp

...t;br>if you have some questions, write to me!<br>thanks for your choosing! hope for a successful cooperation! good luck!

3d_export

$10

league of legends - akali kda

...series of unlocked characters. this special edition includes an ultraviolet flashlight that shows off the neon details of the...

3d_export

$6

fluorescent bulb

...in the gas excites mercury vapor, which produces short-wave ultraviolet light that then causes a phosphor coating on the...

3d_export

$10

Automatic circuit board UV curing machine

...machine is a mechanical device that emits available strong ultraviolet rays. it has been widely used in printing, electronics,...

3d_export

$5

PENCIL LOW POLY GAME READY

...easily erased, but otherwise resistant to moisture, most chemicals, ultraviolet radiation and natural aging. other types of pencil cores,...

thingiverse

free

Aqua Ultraviolet Mount by philadkins

... print in petg so it's flexible enough to fit over the outside without breaking. i used 4 perimeters for increased strength.

blendswap

free

Cycles Ultraviolet Shader Node

...under a blacklight.source of uv poster used in the scene: https://psy-amb.blogspot.com/2013/05/36-amazing-blacklight-posters.html

thingiverse

free

Ultraviolet Germicidal sponge cleaner plus. by jameswakefield

...it over the cleaned cutting board and knife

then put the wand back on the stand the sponge in the sponge holder

and zap that too.

100W

turbosquid

$22

Marshall 100w - High detailed.

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Светильник Lucitalia Krisma H B (max 100W)

... lucitalia krisma h b (max 100w)

3ddd

прожектор фабрики lucitalia - krisma h b (e27, 220v, max 100w) для интерьерного освещения.

3ddd

free

Progress P4036-20 - 5-100W MED CHANDELIER

...progress p4036-20 - 5-100w med chandelier

3ddd

classic chandelier

3ddd

$1

Бильярдная люстра Тиффани

...тиффани 3ddd tiffany , светильник бильярдная люстра тиффани 3xe27 100w высота: 110мм длина:...

3ddd

$1

searchlight 4052

...54 мм количество ламп: 1 тип лампы: e27 мощность: 100w производитель:...

cg_studio

$19

Marshall 100w3d model

...3d model

cgstudio

.3ds .fbx .max .obj - marshall 100w 3d model, royalty free license available, instant download after purchase.

3ddd

$1

Feiss URBANRWL

...feiss каталог: elstead 2013 коллекция: urbanrwl мощность: 1 х 100w цвет: кованное железо ширина: 254 высота:...

3ddd

$1

Люстра Prearo KOMPASSI 2173/50/S

...2173/50/s 50 x 40-140 h e27 x 1 max 100w ...

3ddd

$1

Aurora

...65 см; длина - 65 см. мощность - 7xe27 max.100w материалы - металл никель сатин /опаловое...

3ddd

$1

Prearo KOMPASSI 2173/120X60/S

...x 60 x 40-140 h e27 x 5 max 100w ...

Approved

3d_export

$30

Stamp 3D Model

...stamp invoice wooden handle office supply tool ink stamper approved documents letter form paper stamp 3d model tartino 27989...

cg_studio

$30

Stamp3d model

...rubber stamp invoice wooden handle supply tool ink stamper approved documents letter form paper .3ds .c4d .dxf .obj -...

3d_ocean

$12

Pumpkin Package

... stability and has earned the aethereal studios game ready stamp of approval. the autumn pumpkin package is optimized for both...

3ddd

$1

FREDERICIA FURNITURE 3Seats sofa No.1

...ard fabrics according to current price list. customer specified fabrics (com) upon factory approval.

dimensions in cm

206х86х83

3d_ocean

$9

Catwalk for structures

...for structures, heavy duty, aisc 360 and can/csa 16 approved used in mine plants and construction infrastructure, scale 1:1,...

3ddd

$1

FREDERICIA FURNITURE 2Seats sofa No.1

...rd fabrics according to current price list. customer specified fabrics (com) upon factory approval.

dimensions in cm

143x86x 83

3d_ocean

$8

Adidas Conext15 Official match ball

...adidas conext15 official match ball 3docean adidas approved ball brazuca conext conext15 field fifa football goal match...

3d_ocean

$8

Adidas Finale 2014/2015 Champions League Ball

...adidas finale 2014/2015 champions league ball 3docean adidas approved ball champions fifa finale football goal league net score...

3d_ocean

$8

Adidas Finale Berlin 2015

...adidas finale berlin 2015 3docean adidas approved ball berlin champions fifa final finale football goal league...

3d_ocean

$8

Puma evoPower 1 Statement and Statement 15

...puma evopower 1 statement and statement 15 3docean approved ball evo evopower fifa football goal kick official power...

Proof

turbosquid

$6

bullet proof jacket

...el bullet proof jacket for download as 3ds, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1193147)

turbosquid

$1

Sound Proofing Foam

... sound proofing foam for download as ige, obj, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1289027)

turbosquid

$25

Flame proof fibricks_lit

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$149

Bullet Proof Vest with molle attachments

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$40

chevrolet nova ss 70 death proof

...chevrolet nova ss 70 death proof

3dexport

3d_export

$9

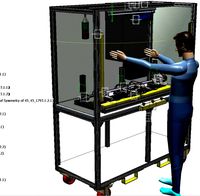

of automobile component error proofing system

...cific product defects; the other is to check the products one by one through cheap means to determine whether they are qualified.

turbosquid

$29

Nikon Coolpix AW110 rugged and proof digital camera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Armoured fighting vehicles armoured vehicles with explosion-proof wheels

...ured vehicles with explosion-proof wheels for download as max on turbosquid: 3d models for games, architecture, videos. (1629664)

turbosquid

$27

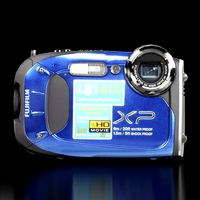

Fujifilm FinePix XP60 Blue rugged and proof digital camera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$23

Panasonic Lumix DMC-TS5 rugged and proof digital gamera

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Explosion

3d_export

$6

explosion

...explosion

3dexport

3 d of explosion

3d_export

$10

explosion

...explosion

3dexport

3d model of explosion for 3d printing

turbosquid

$5

Explosion

...rbosquid

royalty free 3d model explosion for download as max on turbosquid: 3d models for games, architecture, videos. (1202603)

3d_export

$10

Explosion

...explosion

3dexport

turbosquid

$14

Explosion

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Explosive

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Explosive Barrel

...explosive barrel 3docean barrel decoration explosion explosive industrial low low poly metal object old poly...

3ddd

free

KOLARZ Serie Explosion

... serie explosion , австрия

kolarz serie explosion 0109.118.5.kot. врай. текстуры.

3d_export

$5

atomic bomb explosion

...atomic bomb explosion

3dexport

atomic bomb explosion

turbosquid

$1

explosives pack

...squid

royalty free 3d model explosives pack for download as on turbosquid: 3d models for games, architecture, videos. (1316376)

Iii

3d_export

$17

JetRanger III

...jetranger iii

3dexport

jetranger iii

3ddd

$1

Jarron III

...jarron iii

3ddd

jarron iii

decorative glass vase

cg_studio

$139

Panzer III - PzKpfw III - Ausf.G3d model

....3ds .c4d .lwo .obj - panzer iii - pzkpfw iii - ausf.g 3d model, royalty free license available, instant download after purchase.

cg_studio

$139

StuG III - Sturmgeschutz III - Ausf.D3d model

....c4d .lwo .obj - stug iii - sturmgeschutz iii - ausf.d 3d model, royalty free license available, instant download after purchase.

3ddd

free

Velashape III

... syneron , candela

velashape iii — аппарат для лечения целлюлита

3d_ocean

$8

Inoplanet III

...inoplanet iii

3docean

3ds arman3dg games inoplanet low max poly trees

inoplanet iii

design_connected

$16

Richard III

...richard iii

designconnected

baleri italia richard iii armchairs computer generated 3d model. designed by philippe starck.

3d_export

$199

cinderella iii

...cinderella iii

3dexport

3d_export

$119

lara iii

...lara iii

3dexport

3ddd

$1

Towel Collection III

...towel collection iii

3ddd

полотенце

towel collection iii

Spray

3d_export

$5

spray

...spray

3dexport

spray paint can

archibase_planet

free

Spray

...spray

archibase planet

spray bathroom ware

spray - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spray

...spray

archibase planet

sanitary ware spray

spray - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spray

...spray

archibase planet

spray sanitary ware

spray - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spray

...spray

archibase planet

spray sanitary ware

spray n260911 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Spray

...spray

archibase planet

spray bottle

spray n050313 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spray

...spray

archibase planet

hair spray makeup preparation

spray 1- 3d model for interior 3d visualization.

archibase_planet

free

Spray

...spray

archibase planet

hair spray makeup preparation

spray 2 - 3d model for interior 3d visualization.

archibase_planet

free

Spray

...spray

archibase planet

hair spray makeup preparation

spray 3 - 3d model for interior 3d visualization.

archibase_planet

free

Spray

...spray

archibase planet

spray sanitary ware aerosol

spray - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Booth

3d_export

$10

Booth Devassa

...booth devassa

3dexport

booth 10x10

3d_export

$10

Booth VENEZA

...booth veneza

3dexport

booth 12x10

3d_export

$10

Booth MSD

...booth msd

3dexport

booth 8.00x6.00

3d_export

$10

Booth Oncoclincas

...booth oncoclincas

3dexport

booth 14.00x11.00

3d_export

$10

Booth SOLINFTEC

...booth solinftec

3dexport

booth 11.00x5.00

3d_export

$7

Booth Janssen

...booth janssen

3dexport

booth 6.00x6.00

3d_export

$7

Booth Astellas

...booth astellas

3dexport

booth 6.00x6.00

3d_export

$7

Booth Galvani

...booth galvani

3dexport

booth 4.00x4.50

3d_export

$5

exhibition booth

...exhibition booth

3dexport

exhibition booth

3d_export

$5

Booth Camil

...booth camil

3dexport

booth 6x3

Beam

archibase_planet

free

Beam

...beam

archibase planet

beam camber-beam hammer-beam

balance beam 2 - 3d model for interior 3d visualization.

design_connected

$16

Beam

...beam

designconnected

van rossum beam computer generated 3d model. designed by rossum, van.

design_connected

$11

Beam

...beam

designconnected

mdf italia beam computer generated 3d model. designed by arrivillaga, luis alberto.

turbosquid

$25

beam

...am

turbosquid

royalty free 3d model beam for download as stl on turbosquid: 3d models for games, architecture, videos. (1674400)

turbosquid

free

beam

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

ZERO, BEAM

...zero, beam

3ddd

zero

поворотная люстра zero , beam

archive3d

free

Beam 3D Model

...archive3d

beam camber-beam hammer-beam

balance beam 2 - 3d model for interior 3d visualization.

3ddd

free

Studio Beam

... navy

светильники studio beam

модели: mariner, ocean mariner, navy.

могут быть в разных цветах

3ddd

$1

Studio Beam

...grupius

производитель studio beam

модели: edison’s rocket pendant, edison’s rocket table lamp,romanov,elena pendant,grupius 1919.

design_connected

$11

I-Beam

...i-beam

designconnected

glas italia i-beam computer generated 3d model. designed by massaud, jean-marie.

180°

3ddd

$1

Ванная POLLSPA-Corazon-180-180

...dd

corazon , pollspa

ванная pollspa-corazon-180-180 примерно по каталогу. текстуры есть.

3ddd

$1

TENSO 180

...ddd

formina , ванна , джакузи

jakuzzi tenso 180

design_connected

$11

Bolero 180

...bolero 180

designconnected

poltrona frau bolero 180 computer generated 3d model. designed by lazzeroni, roberto.

design_connected

$20

Delta 180

...delta 180

designconnected

zanotta delta 180 2-seater computer generated 3d model. designed by emaf progetti.

design_connected

$27

Sayonara 180

...sayonara 180

designconnected

bbb emmebonacina sayonara 180 2-seater computer generated 3d model. designed by giorgio decursu.

turbosquid

$9

Office 180

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Chair 180

...d model chair 180 for download as max, max, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1631404)

design_connected

$25

La Mise 180

...la mise 180

designconnected

la mise 180 computer generated 3d model. designed by nichetto, luca.

3ddd

$1

Rishar R-180

...ar r-180

3ddd

rishar , стол

кабинет rishar

стол руководителя r-180

размеры: 1800х880х790

3ddd

free

Riho / MONTREAL 180

...и

ванна riho montreal 180

длина 180

ширина 90

высота 47,5

объем 275

цвет euro white (европейский белый)

страна голландия / чехия

Fixture

turbosquid

$5

Fixture

...turbosquid

royalty free 3d model fixture for download as max on turbosquid: 3d models for games, architecture, videos. (1160462)

turbosquid

$39

FIXTURE

...id

royalty free 3d model fixture for download as ige and obj on turbosquid: 3d models for games, architecture, videos. (1332983)

turbosquid

$2

Fixture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

fixture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

fixture

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

ROBOT FIXTURE

...fixture

3dexport

it is a robot fixture. it is used to pick the insert from the table and place that insert into the mold cavity.

turbosquid

free

lighting fixtures

...odel lighting fixtures for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1428616)

3d_ocean

$2

Light Fixture 02

...reat for any game enviroment. the light fixture has texture with both lid bulb, and unlid bulb. low poly (238 polygons – 245 v...

turbosquid

$29

bathroom fixtures

...odel bathroom fixtures for download as 3ds, max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1180328)

turbosquid

$20

Wall Fixture

... 3d model wall fixture for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1270353)

Ii

3d_ocean

$5

inoplanet II

...inoplanet ii

3docean

3ds arman3dg games ii inoplanet low max poly trees

inoplanet ii

3ddd

$1

Novecento II

...novecento ii

3ddd

консоль

консоль: ii novecento

дизайнер: elia monterosso

3ddd

$1

Спальня VENERO II

...d

venero ii , venero , hulsta

спальня venero ii

3ddd

$1

PROPORTION II

...proportion ii

3ddd

malabar emotional

консоль proportion ii

malabar emotional design

коллекция euphoria

3ddd

$1

Regina II

...ltrona frau , капитоне

this is a custom version of the poltrona frau regina ii armchair.

3d_export

$119

cinderella ii

...cinderella ii

3dexport

3d_export

$119

lara ii

...lara ii

3dexport

3d_export

$119

doris ii

...doris ii

3dexport

3ddd

$1

Heracleum II

...s endless technical possibilities,

making this new version much more efficient while providing unique and sparkling illumination.

3ddd

$1

Towel Collection II

...towel collection ii

3ddd

полотенце

towel collection ii

Angle

design_connected

$25

Angle

...angle

designconnected

flou angle sleep furniture computer generated 3d model. designed by rodolfo dordoni.

3ddd

$1

FLOU / Angle

...flou / angle

3ddd

flou

кровать flou angle. все карты процедурные.

3ddd

free

Кровать ANGLE flou

...le , flou , постельное белье

кровать angle flou

design_connected

$16

Calin Angle

...calin angle

designconnected

ligne roset calin angle computer generated 3d model. designed by mourgue, pascal.

3d_export

$5

angle grease nipple

...angle grease nipple

3dexport

angle grease nipple

3ddd

$1

Двуспальная кровать Angle

...ngle. двуспальную кровать с подъемным механизмом angle оценят и те, кто любит практичность: кровать имеет объемый ящик для белья.

turbosquid

$10

Angle Wardrobe

...e 3d model angle wardrobe for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1301544)

turbosquid

$9

Angle Stool

...y free 3d model angle stool for download as max, skp, and skp on turbosquid: 3d models for games, architecture, videos. (1694318)

3d_export

free

angle bracket

...t 3d model part. it is the combination of a bra and ket (bra+ket = bracket) which represents the inner product of two functions.

turbosquid

$6

Angles Pouf

...e 3d model angles pouf for download as max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1577097)

Class

3d_export

free

Class room

...class room

3dexport

class room 3d model

3ddd

free

Capellini / Class

...capellini / class

3ddd

capellini

стул class фирмы capellini

3ddd

free

Valmori - Class

...valmori - class

3ddd

valmori

bed from valmori model class

3ddd

$1

LUCECREA CLASS

...lucecrea class

3ddd

lucecrea class

торшер фабрики lucecrea class_коллекция

bakara contract_art.376351 da a

turbosquid

$15

BaikaL class Frigate and UraL class Corvette

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

vibieffe class armchair

...vibieffe class armchair

3ddd

vibieffe

vibieffe class armchair

3ddd

$1

Baccarat Glass Class

...

источник:http://www.select-interiormarket.com/en/baccarat-glass-class-chair-2601025-philippe-starck

текстуры имеются

turbosquid

$85

Class Brooklyn

...alty free 3d model class brooklyn for download as jpg and max on turbosquid: 3d models for games, architecture, videos. (1461215)

3d_export

$5

class room

...class room

3dexport

turbosquid

$69

Mercedes Class

...d model mercedes class for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1440493)

Led

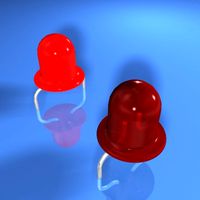

3d_export

$5

led

...led

3dexport

the led is cut with all the parts.

3ddd

$1

Monacor / PARL56DMX / LED-320RGBW / LED-345RGBW / LED-300RGB

... прожектор

http://www.monacor.dk/

parl56dmx

led-320rgbw

led-345rgbw

led-300rgb

turbosquid

$10

LED

...led

turbosquid

free 3d model led for download as blend on turbosquid: 3d models for games, architecture, videos. (1691856)

3d_export

$5

led lamp

...led lamp

3dexport

led lamp, brightness animation

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

современный торшер

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

настольный лампа

turbosquid

$19

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Led

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Paint

archibase_planet

free

Paints

...paints

archibase planet

paints paint

paints n241211 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Paint

...paint

archibase planet

jar of paint paint can

paint - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

paint

...paint

3ddd

paint

archibase_planet

free

Paint

...paint

archibase planet

paint

paint - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Painting

...painting

3ddd

картина

painting in double wooden frame decorated antique

3ddd

$1

The collection of paintings

...

картина , фото

collection of modern and contemporary paintings.

contemporary paintings.

turbosquid

$1

Painting

...ee 3d model painting for download as 3ds, obj, md3, and blend on turbosquid: 3d models for games, architecture, videos. (1207611)

turbosquid

free

Painting

... 3d model painting for download as ma, 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1219609)

3ddd

$1

PAINTINGS

...paintings

3ddd

панно

размеры:

1170х900

3ddd

$1

Paintings Frame

...paintings frame

3ddd

картины

paintings frame

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...