Thingiverse

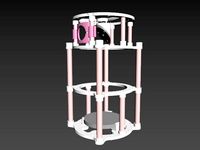

ZWO EAF Mounting Bracket for Meade LX90 8inch by TrevOinAus

by Thingiverse

Last crawled date: 3 years, 3 months ago

This is a remix of the ZWO EAF Holder for Celestron Nexstar 6/8/9 by jamesdedij (February 29, 2020) for the Celstron SCTs and I thank him for sharing the editable design files with me.

I have modified all of the parts in Fusion 360 to fit the geometry of the Meade LX90 8inch SCT and possibly other Meade SCTs depending on the Focus Knob used.

The EAF positioning allows adjustment and removal of the EAF for transport and avoids collision with the LX90 fork arms

It also makes it possible to remove the EAF quickly or to "disengage it" to perform manual focusing.

To improve the gearing between the EAF and the Focus knob, I have added a 32 tooth gear wheel to replace the 16 tooth Alloy gear wheel used initially. To accommodate the new larger gear wheel, a 158mm or 160mm loop belt should be used instead of the 140mm or 142mm belt used with the alloy gear.

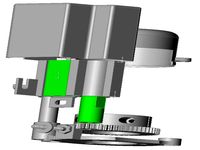

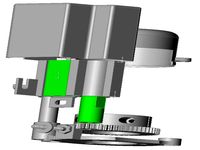

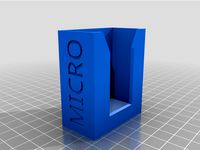

I printed all parts in ABS to avoid warping in use, with 70% infill, layer height of 0.15mm. Only the Angled Motor Base may need supports. Recommended 3D print orientation is in the images.

Installation:

After testing for fit and alignment with the Hex Screws, Glue the M4 nuts into the recesses in the Angled Base Bracket

Set the Telescope Tube Horizontal to avoid parts moving when screws are removed.

Wind the Mirror to the rear of the Telescope (Clockwise) and back off half a turn anticlockwise.

Carefully remove the three screws holding the Focus assembly to the telescope rear plate. (Image 1)

Mount the Angled Base Bracket to the telescope rear plate with the new 6-32 UNC 5/8inch screws. (Image 2)

The Focus Collar should be squarely and firmly pressed onto the Focus knob past the knurled finger grip. (It will be tight and it may be necessary to remove any irregularities from the inside of the Focus Collar for it to fit past the Knurled finger grip.)

Carefully rap about 1.5 turns of electrical tape around the base of the Focus Knob to take up the slack and centre to Focus Knob and Focus collar.

The Collar should be located on the focus knob, so that it is close to, but does not rub, on the Angled Base Bracket when the Focus knob is turned.

If the collar is too high on the Focus Knob, the top of it will foul against the chrome faceplate of the EAF during assembly for operation.

Tighten the Headless Screws firmly, so there is no movement between the knob and collar. (Image 3)

Mount the 16 or 32 teeth pulley on the EAF drive shaft so that the centre line of the pully teeth matches the centre line of the Focus collar teeth when assembled. You may need to try this a few times with the EAF not screwed to the Motor base before you tighten the headless screws firmly.

Fasten the EAF to the Angled Motor Base with the 2 CHC M4x12 screws

Glue the Knob-M4s onto the 2 hex screws M4x20. These are used to attach and adjust the Motor Base to the Angled Bracket.

Extra Parts:

GT2 pulley 16 teeth for 5mm axle (to fit on EAF drive shaft)

and

142 (or 140) mm GT2 Loop belt

or

3D Printed 32 teeth pulley for 5mm axle (to fit on EAF drive shaft)

and

158 or 160 mm GT2 Loop belt

3 x Cross Head or Hex 6-32 x 5/8inch) UNC Button Head screws (To secure Angled Base Bracket to LX90)

3 x M4x8 headless screws (From EAF Kit) (To secure Focus Collar to Focus Knob)

2 x CHC M4x12 screws (From EAF Kit) (To secure EAF to Angled Motor Base)

2 Hex M4x20 screws (For use with printed knobs to secure Motor Base to Bracket)

2 M4 nuts (Glued into Angled Base Bracket)

I have modified all of the parts in Fusion 360 to fit the geometry of the Meade LX90 8inch SCT and possibly other Meade SCTs depending on the Focus Knob used.

The EAF positioning allows adjustment and removal of the EAF for transport and avoids collision with the LX90 fork arms

It also makes it possible to remove the EAF quickly or to "disengage it" to perform manual focusing.

To improve the gearing between the EAF and the Focus knob, I have added a 32 tooth gear wheel to replace the 16 tooth Alloy gear wheel used initially. To accommodate the new larger gear wheel, a 158mm or 160mm loop belt should be used instead of the 140mm or 142mm belt used with the alloy gear.

I printed all parts in ABS to avoid warping in use, with 70% infill, layer height of 0.15mm. Only the Angled Motor Base may need supports. Recommended 3D print orientation is in the images.

Installation:

After testing for fit and alignment with the Hex Screws, Glue the M4 nuts into the recesses in the Angled Base Bracket

Set the Telescope Tube Horizontal to avoid parts moving when screws are removed.

Wind the Mirror to the rear of the Telescope (Clockwise) and back off half a turn anticlockwise.

Carefully remove the three screws holding the Focus assembly to the telescope rear plate. (Image 1)

Mount the Angled Base Bracket to the telescope rear plate with the new 6-32 UNC 5/8inch screws. (Image 2)

The Focus Collar should be squarely and firmly pressed onto the Focus knob past the knurled finger grip. (It will be tight and it may be necessary to remove any irregularities from the inside of the Focus Collar for it to fit past the Knurled finger grip.)

Carefully rap about 1.5 turns of electrical tape around the base of the Focus Knob to take up the slack and centre to Focus Knob and Focus collar.

The Collar should be located on the focus knob, so that it is close to, but does not rub, on the Angled Base Bracket when the Focus knob is turned.

If the collar is too high on the Focus Knob, the top of it will foul against the chrome faceplate of the EAF during assembly for operation.

Tighten the Headless Screws firmly, so there is no movement between the knob and collar. (Image 3)

Mount the 16 or 32 teeth pulley on the EAF drive shaft so that the centre line of the pully teeth matches the centre line of the Focus collar teeth when assembled. You may need to try this a few times with the EAF not screwed to the Motor base before you tighten the headless screws firmly.

Fasten the EAF to the Angled Motor Base with the 2 CHC M4x12 screws

Glue the Knob-M4s onto the 2 hex screws M4x20. These are used to attach and adjust the Motor Base to the Angled Bracket.

Extra Parts:

GT2 pulley 16 teeth for 5mm axle (to fit on EAF drive shaft)

and

142 (or 140) mm GT2 Loop belt

or

3D Printed 32 teeth pulley for 5mm axle (to fit on EAF drive shaft)

and

158 or 160 mm GT2 Loop belt

3 x Cross Head or Hex 6-32 x 5/8inch) UNC Button Head screws (To secure Angled Base Bracket to LX90)

3 x M4x8 headless screws (From EAF Kit) (To secure Focus Collar to Focus Knob)

2 x CHC M4x12 screws (From EAF Kit) (To secure EAF to Angled Motor Base)

2 Hex M4x20 screws (For use with printed knobs to secure Motor Base to Bracket)

2 M4 nuts (Glued into Angled Base Bracket)

Similar models

grabcad

free

GT2 Kit for autofocus Sky-Watcher Evoguide 50ED with ZWO EAF electronic focuser

...ith sky-watcher evoguide 50ed dedicated flattener. i suppose it can work with starizona flattener as is or with small adjustment.

thingiverse

free

ZWO EAF mount for William Optics RedCat 51 (SpaceCat) by domino89

...extra stability. it is optional. two m4 screws are probably enough.

bracket is secured to the telescope mount by two m3x45 bolts.

thingiverse

free

Focuser for my Meade LX90 Telescope

...he #1244 focuser for the etx-90 telescope, removed the stepper motor and circuit board to build a focuser that works for my lx90.

grabcad

free

ZWO EAF Motor bracket

...zwo eaf motor bracket

grabcad

zwo eaf electronic automatic focuser motor bracket

thingiverse

free

Dew Shield for ZWO EAF by Hackschnitzel

...dew shield for zwo eaf by hackschnitzel

thingiverse

dew shield for the zwo focus motor eaf

thingiverse

free

Samyang 135mm f/2.0 ED for astronomy with EAF by RomanHujer

... 16teeth/bore 5mm

4x m3x10mm imbus screew

4x self tapping screw 2x6

1x rj45 - pcb on easyeda

update

2021-01-01 add beld tensioner

thingiverse

free

ZWO EAF Adapter for GSO Linear Bearing Crayford Focuser by johnnyturpin

...ing the four screws of the focuser plate - remove the screws but keep holding the piece in place when screwing in the base-plate.

thingiverse

free

Telescope Dovetail Rail. iOptron to Meade 8inch SCT by toguan

...n instead of the standard. not a perfect solution, but better than the nothing that was had previously.

have a good day.

bill.

3dwarehouse

free

ZWO EAF Meade LX65 6 inch mount

...de lx65 6 inch mount

3dwarehouse

mount for attaching a zwo electric automatic focuser to a meade lx65 6' maksutov-cassegrain

grabcad

free

Tri-bahtinov mask for MEADE 10'' telescope

...tri-bahtinov mask for meade 10'' telescope

grabcad

tri-bahtinov mask for meade lx90 10" telescope.

Trevoinaus

thingiverse

free

Tape Dispenser Spindle by TrevOinAus

...sticky tape) dispenser.

this is the part that often gets lost or accidentally thrown away when the first spool of tape is emptied

thingiverse

free

LX200 ACF Stepper Motor Mounting Bracket by smitchelus

...design for the c8 (https://www.thingiverse.com/thing:4191869) i then started from trevoinaus#39;s design for the lx90 (https://www.thingiverse.com/thing:4592948) which needed to be...

Lx90

thingiverse

free

Focuser for my Meade LX90 Telescope

...he #1244 focuser for the etx-90 telescope, removed the stepper motor and circuit board to build a focuser that works for my lx90.

thingiverse

free

Meade Autostar holder for LXD75/LX90 mount by Nicolas_T

...meade autostar holder for lxd75/lx90 mount by nicolas_t

thingiverse

this holder is made for the 50mm tube of the lxd75 mount.

thingiverse

free

Remix of Meade Autostar holder for LXD75/LX90 mount by GeoDave

... added 1mm extra around the holes.

i used 2 - m3x16mm screws with locknuts & printed at 40% infill with esun silver pla pro.

thingiverse

free

Remix of JMI focuser Holder by tannenba

...m6 hammerhead t-nuts. remix of jmi microfocuser handbox meade lx90 tripod mount : 3192372 by zlatko84 i needed a...

thingiverse

free

LX200 ACF Stepper Motor Mounting Bracket by smitchelus

...(https://www.thingiverse.com/thing:4191869) i then started from trevoinaus's design for the lx90 (https://www.thingiverse.com/thing:4592948) which needed to be adjusted to work with...

thingiverse

free

Laser Holder by FChirico

...i cercatori. questo disegno è ottimizzato per un meade lx90 ma si fissa semplicemente con delle fettucce intorno al...

grabcad

free

Tri-bahtinov mask for MEADE 10'' telescope

...for meade 10'' telescope grabcad tri-bahtinov mask for meade lx90 10"...

3dwarehouse

free

Pioneer SUSANO High Definition Amplifier SC-LX90

...icepower аппарат обладает выдающимися способностями, которые позволяют реализовать общую выходную мощность 1400 вт на 10 каналов.

Eaf

3d_export

$120

Ch47 EAF Helicopter 3D Model

...licopter desert transport military heavy lift tandem rotoa textures materials

ch47 eaf helicopter 3d model tartino 38054 3dexport

thingiverse

free

EAF Mount for C5 by green_spider

...eaf mount for c5 by green_spider

thingiverse

simple bracket to mount the zwo eaf onto a celestron c5

thingiverse

free

Dew Shield for ZWO EAF by Hackschnitzel

...dew shield for zwo eaf by hackschnitzel

thingiverse

dew shield for the zwo focus motor eaf

thingiverse

free

Zwo EAF 3D Model by icimdengelen

...zwo eaf 3d model by icimdengelen

thingiverse

zwo eaf 3d model

i did it to develop accessories on it.

thingiverse

free

Skywatcher 150750 EAF rack by reticyte

... skywatcher 150750 eaf-compatible with my astroberry. inspired by astroberry focusor: https://github.com/rkaczorek/astroberry-diy

thingiverse

free

ZWO EAF RAP2,5 Mount by K_Bahr

...e zwo eaf on the ts optics 2.5" rap draw tube

additional material used:

grub screws,

t5/200 belt

two thin but strong springs

thingiverse

free

EAF adapter for ES127 FCD100 focuser

... telescope. it only uses the original locking screw from the focuser for attachment, and allows access to the adjustment screws.

thingiverse

free

ZWO EAF RAP2,5 Mount by K_Bahr

...rub screws (to attach the gears)

2 long screws e.g. (60mm x 4mm) or 4 grub screws to attach the cover

2 small but strong springs

thingiverse

free

EAF bracket for Explore Scientific 102 Telescope by skislalom1

... addition, it provides a hole for the optional temperature sensor and a slotted hole for a wire tie to hold excess wire in place.

thingiverse

free

ZWO EAF adapter for Celestron C9.25 by latunen

...own in slicer to get right dimensions.

this model doesn't fit to c8 of edgehd8 but i will make models for these scopes soon.

Zwo

3d_export

$10

gerb zwo rf

...gerb zwo rf

3dexport

emblem of the western military district of the russian federation

thingiverse

free

Finderscope to ZWO by Galvenize

...finderscope to zwo by galvenize

thingiverse

adapts a zwo to a skywatcher (and alike) stock finderscope

thingiverse

free

ZWO asi 120 mc by Maniaquera

...zwo asi 120 mc by maniaquera

thingiverse

scale model of the zwo camera.

thingiverse

free

Dew Shield for ZWO EAF by Hackschnitzel

...dew shield for zwo eaf by hackschnitzel

thingiverse

dew shield for the zwo focus motor eaf

thingiverse

free

Dovetail Camera ZWO ASI by dester

...dovetail camera zwo asi by dester

thingiverse

dovetail camera zwo asi without fan

thingiverse

free

ZWO ASI Nikon Adapter by andrea_carminati

...zwo asi nikon adapter by andrea_carminati

thingiverse

zwo asi nikon adapter with 1,25" filter

thingiverse

free

ZWO ASI 294 Pro support by Gh14Cc10

...294 pro support by gh14cc10

thingiverse

remix of the great swiss body support for zwo asi2600mc pro, modified for zwo asi294 pro

thingiverse

free

ZWO 2600MM Cable Support by tooth_dr

...zwo 2600mm cable support by tooth_dr

thingiverse

zwo 2600mc cable support updated with '2600mm' lettering.

thingiverse

free

Zwo EAF 3D Model by icimdengelen

...zwo eaf 3d model by icimdengelen

thingiverse

zwo eaf 3d model

i did it to develop accessories on it.

thingiverse

free

ZWO ASi 294MCPRO Halter Schelle_78mm by rabit9

...zwo asi 294mcpro halter schelle_78mm by rabit9

thingiverse

zwo asi 294mcprohalter schelle_78mm

8Inch

3d_export

$49

Samsung Galaxy Tab 3 8inch 3D Model

...droid droid ipad mobile cellular smartphone touchscreen touch screen

samsung galaxy tab 3 8inch 3d model humster3d 79975 3dexport

3d_export

$25

KHE TripleThreat BMX complete 3D Model

...threat pro 21inch, sanko crmo, midbbfork: cirrus, sanko crmohandlebar: 8inch anchor, sanko crmocrank: hindenburg, crmo, 2-pc, s/b,sprocket: ninja, 25tpedals:...

thingiverse

free

5mm to 3/8inch (9.525mm) coupler by Flytech81

...r by flytech81

thingiverse

this is meant for a 5mm stepper motor shaft to 3/8inch (9.525mm) threaded rod conversion. z - coupler

thingiverse

free

Tablet holder - Joyfar 8inches

...tablet holder - joyfar 8inches

thingiverse

allows to hold the tablet against a tubular ik*a lamp

needs two screws

thingiverse

free

knife sharpening for 20cm/8inch grinding machine by arturas123

...knife sharpening for 20cm/8inch grinding machine by arturas123

thingiverse

a support for sharpening knifes with grinding

thingiverse

free

Dobsonian 8Inch 3D Modeling by knoxxr

...1ea , 25cm/1m x 4

25cm bar length is different by primary mirror focus length

this modeling is need to least 20x20cm print stage.

thingiverse

free

SR Suntour FAA122 for 3/8inch Ratchet by Kaskadeur111

...suntour faa122 for 3/8inch ratchet by kaskadeur111

thingiverse

remix to fit a 3/8 inch ratchet. perfect fit no upscaling needed.

thingiverse

free

Telescope Dovetail Rail. iOptron to Meade 8inch SCT by toguan

...n instead of the standard. not a perfect solution, but better than the nothing that was had previously.

have a good day.

bill.

thingiverse

free

Beyma 8ag/n 8inch Protection Cover by sogidaned

...protection cover by sogidaned

thingiverse

protection cover for 8 inch loudspeaker.

two 6 mm x 215 mm stainless steel rods needed

thingiverse

free

Wide Backscratcher 3/8inch (9.5mm) rod by FuzzyMetal

... better scratch power to body curvature.

also the angle minimizes the edge tong from digging into your skin when slightly turned.

Meade

3ddd

$1

Телескоп Meade LX 200

...аботка материалов в 2014 г.

габариты: 845 х 2400 мм

аналогhttp://www.telescopeplanet.co.uk/meade-lx200-acf-gps/20168

turbosquid

free

Syd Mead Entertainment center Home

...yd mead entertainment center home for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1523167)

3ddd

$1

Axel Occasional Table Belle Meade

...ble belle meade

•dimensions: 24d 22h

•features: acrylic base with satin brass hub

•starphire glass top with flat polished edge

3d_export

$200

Telescope 3D Model

...model 3dexport telescope telescop scop scope lunette glass astronomy meade space star stars galaxy observatory zoom optic detail detailed...

3d_export

$7

brooklyn museum

...tain its building and collection, only to be revitalized in the late 20th century, thanks to major renovations. source: wikipedia

unrealengine

$35

Mead Hall UE5

...mead hall ue5

unreal engine marketplace

mead hall. 44 unique assets + interior

thingiverse

free

Meade Eyepiece Cover by lanemaxwell

...meade eyepiece cover by lanemaxwell

thingiverse

eyepiece dust cap for meade etx telescopes

3dcadbrowser

free

MEADS

...e system.this 3d object can be downloaded in .max, .obj, .3ds, .fbx, .dxf, .lwo, .stl, .wrl, .ma, .dae, .x and .asc file formats.

thingiverse

free

Meade Spotting Scope Mount by RobertCL

...potting scope on the side of the meade etx125 scope body rather than using the standard mount point that tends to get in the way.

sketchfab

$10

Ornate Medieval Mead Tankard

...

polygons 3,602

vertices 3,600

textures png 4k - ornate medieval mead tankard - buy royalty free 3d model by getdeadentertainment

Bracket

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel console

bracket 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel holder bracket

bracket 6 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel console

bracket 8 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket n280911 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

holder corbel bracket

bracket 9 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel holder bracket

bracket 10 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel console bracket

bracket 11 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

holder console bracket

bracket 12 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket 13 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Mounting

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)