Thingiverse

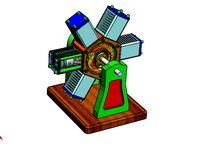

Zortrax M200 dual airflow radial fan duct by liftbag

by Thingiverse

Last crawled date: 3 years ago

Important

For a completely revised version, move here: https://www.thingiverse.com/thing:2797152

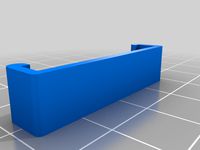

Description (dual_flow_extr_shroud_V7B.stl)

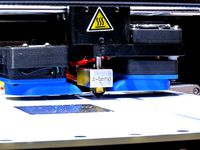

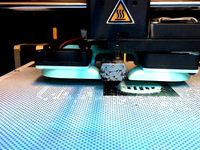

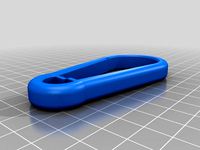

This is an alternative way to having a double cooling flow on the area of extrusion.

The most popular way is to use a second axial fan installed on one of the many special bracket that can be found here on Thingiverse. I myself have published one here: http://www.thingiverse.com/thing:1901911

Later I saw an anular shroud for Wanhao D6 by ZincBoy and I really liked the idea ( http://www.thingiverse.com/thing:1666096 ).

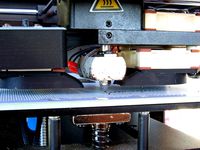

The use of a radial fan is almost mandatory for this application, either for lack of space, both because the axial fans are characterized by a too low working pressure. The problem with the radial fan that I have chosen and which is the same used by ZincBoy is that it does not survive to the 24V PWM with which is powered.

Another problem is that if powered at 12V is so effective that the printing aborts due excessive extruder cooling.

So a small divider/filter circuit is necessary. The divider that I use allows you to print without problems up to 60% fan speed. If you want to print at a higher air flow you must isolate the hotend, for example with cotton coats that can be found on the market or you can use smaller heating block.

The circuit can be easily accommodated in the tray below the fan.

You can find the radial fan here: http://www.digikey.com/product-detail/en/delta-electronics/BFB0412HHA-A117/603-1840-ND/5022816

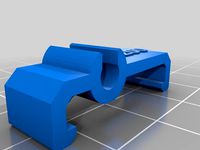

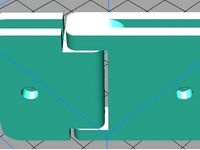

The design is meant to be printed without supports. Because of supportless design it might seem that the air flow is directed towards the hotend. Instead, the output ducts are designed to direct the air flow with a good downward angle.

You need a heat-resistant filament and that does not collapse with long bridges. The best results can be obtained with PBT filament and annealing in the oven, one hour at 60° C, one hour at 95° C, one hour at 60° C and then left to cool in the oven.

Also, three M3x25mm screws are necessary to secure the fan duct to the cooling block.

[EDIT 11/22/2017]

Well, you can now completely avoid electronics.

The radial fans shown at the link below tolerate the 24V PWM signal of the Zortrax M200, turn slower, are very silent and with the correct air volume.https://it.aliexpress.com/item/2PCS-Gdstime-3D-Printer-Fan-40mm-12V-4010-Turbo-Blower-Cooling-Fans-with-120cm-Cable/32811510363.html?spm=a2g0y.10010108.1000023.9.19306e00p907zT

[EDIT 12/06/2017]

Z-VENT_SLP_V4b.stl added.

If you use the radial fan of aliexpress and do not need any adaptation electronics, this is a lightened variant and optimized in various aspects:

> the main air duct has fewer obstacles, in particular the air intake window

> an area that created strong turbulence was eliminated

> to free the entry obstruction, I removed the third fixing front screw

> to improve the solidity of the assembly I have expanded the support base of the two rear supports

> added a curved fin at the entrance that supports the long bridge

> added two cable supports

The downside is the fact that this time it is necessary to put some supports. This is not possible with Zsuite V1, because the supports would also be generated inside the air duct. It should be possible to slice with Zsuite beta2.2 which has a more advanced support management, but I got the best results with Simplify3D, translating the gcode into zcode using ZTool.

For those interested in using third-party slicers with the Zortrax M200 this page may interest you: https://www.stampa3d-forum.it/forum/topic/4107-zdump-is-dead-long-live-ztool /

[EDIT 02/03/2018]

Z-VENT_SLP_V4b.stl has been replaced with Z-VENT_V9.stl.

The main improvement concerns the distance from bed of the rear area, to avoid collision with the perforated bed connector. Minimum adjustments to the inclinations of unsupported areas.

For a completely revised version, move here: https://www.thingiverse.com/thing:2797152

Description (dual_flow_extr_shroud_V7B.stl)

This is an alternative way to having a double cooling flow on the area of extrusion.

The most popular way is to use a second axial fan installed on one of the many special bracket that can be found here on Thingiverse. I myself have published one here: http://www.thingiverse.com/thing:1901911

Later I saw an anular shroud for Wanhao D6 by ZincBoy and I really liked the idea ( http://www.thingiverse.com/thing:1666096 ).

The use of a radial fan is almost mandatory for this application, either for lack of space, both because the axial fans are characterized by a too low working pressure. The problem with the radial fan that I have chosen and which is the same used by ZincBoy is that it does not survive to the 24V PWM with which is powered.

Another problem is that if powered at 12V is so effective that the printing aborts due excessive extruder cooling.

So a small divider/filter circuit is necessary. The divider that I use allows you to print without problems up to 60% fan speed. If you want to print at a higher air flow you must isolate the hotend, for example with cotton coats that can be found on the market or you can use smaller heating block.

The circuit can be easily accommodated in the tray below the fan.

You can find the radial fan here: http://www.digikey.com/product-detail/en/delta-electronics/BFB0412HHA-A117/603-1840-ND/5022816

The design is meant to be printed without supports. Because of supportless design it might seem that the air flow is directed towards the hotend. Instead, the output ducts are designed to direct the air flow with a good downward angle.

You need a heat-resistant filament and that does not collapse with long bridges. The best results can be obtained with PBT filament and annealing in the oven, one hour at 60° C, one hour at 95° C, one hour at 60° C and then left to cool in the oven.

Also, three M3x25mm screws are necessary to secure the fan duct to the cooling block.

[EDIT 11/22/2017]

Well, you can now completely avoid electronics.

The radial fans shown at the link below tolerate the 24V PWM signal of the Zortrax M200, turn slower, are very silent and with the correct air volume.https://it.aliexpress.com/item/2PCS-Gdstime-3D-Printer-Fan-40mm-12V-4010-Turbo-Blower-Cooling-Fans-with-120cm-Cable/32811510363.html?spm=a2g0y.10010108.1000023.9.19306e00p907zT

[EDIT 12/06/2017]

Z-VENT_SLP_V4b.stl added.

If you use the radial fan of aliexpress and do not need any adaptation electronics, this is a lightened variant and optimized in various aspects:

> the main air duct has fewer obstacles, in particular the air intake window

> an area that created strong turbulence was eliminated

> to free the entry obstruction, I removed the third fixing front screw

> to improve the solidity of the assembly I have expanded the support base of the two rear supports

> added a curved fin at the entrance that supports the long bridge

> added two cable supports

The downside is the fact that this time it is necessary to put some supports. This is not possible with Zsuite V1, because the supports would also be generated inside the air duct. It should be possible to slice with Zsuite beta2.2 which has a more advanced support management, but I got the best results with Simplify3D, translating the gcode into zcode using ZTool.

For those interested in using third-party slicers with the Zortrax M200 this page may interest you: https://www.stampa3d-forum.it/forum/topic/4107-zdump-is-dead-long-live-ztool /

[EDIT 02/03/2018]

Z-VENT_SLP_V4b.stl has been replaced with Z-VENT_V9.stl.

The main improvement concerns the distance from bed of the rear area, to avoid collision with the perforated bed connector. Minimum adjustments to the inclinations of unsupported areas.

Similar models

thingiverse

free

Zortrax M200 taller fan duct by liftbag

...ft one is for any dual fan m200 mod.

[edit]

v2 added. the airflow is improved and it's better directed to the extrusion area.

thingiverse

free

Mendel90 - Dual Radial Fan Duct by ps915

...ts no problem for you, you can print it.

i will search for some other radial blower fans to improve the cooling with my mendel90.

thingiverse

free

Micromake C1 Cooling Airduct_ver1.1 by Carrot159

...ct for micromake c1, simple version without duct only mount for radial fan. which solve the problem of poor air flow and leakage.

thingiverse

free

JGAurora A5 Hot'n Cold duct and Tube mount by CarstenD

...ans. you can use any part cooling duct of your liking - the duct i prefere is this one: https://www.thingiverse.com/thing:2788702

thingiverse

free

Hepa filter holder for 80mm fan Zortrax M200 by Skyraf

...nsions 115 x 115 x 20 mm to a standard 80 mm fan. this object can be used for 3d printers like the zortrax m200 or air purifiers.

thingiverse

free

Zortrax m200 dual fan duct by paulo76

...ouble fans duct but felt it got in the way of the cables too much and was a little flimsy. hopefully someone will find it useful.

thingiverse

free

Radial Fan Mount + Fan Duct by davi4pant

... stop air flow like the one i used before, so it don't overheat the rotor of the fan and the amount of air blowed is improved

thingiverse

free

Sapphire Fan Duct for radial fan by stegis

...g-fan-p-980653.html?rmmds=myorder&cur_warehouse=cn

no supports are needed to print this, bechause the supports are builid in.

thingiverse

free

Geeetech I3 Pro B fan (zortrax) by poviliukas20

...for distance, if the air duct is to close to the nozzle.

material: abs

support: yes

the design idea is from zortrax m200 printer.

thingiverse

free

Geeetech Prusa i3 Pro B Air Duct for Titan radial fan by elpago93

...design adding a larger intake capable to fit my fan: i also added a support to secure the fan to the mount (using a single bolt).

Liftbag

thingiverse

free

Zortrax M200 knob by liftbag

...zortrax m200 knob by liftbag

thingiverse

a larger knob.

thingiverse

free

Zortrax M200 ducted fan by liftbag

...ucted fan by liftbag

thingiverse

redesigned from my previous taller design in order to be used with the stock hotend (v1 or v2).

thingiverse

free

Atas Defiance 265 tiny landing skids by liftbag

...atas defiance 265 tiny landing skids by liftbag

thingiverse

small size and low weight landing skids.

thingiverse

free

Atas Defiance 265 top protective shield. by liftbag

...nce 265 top protective shield. by liftbag

thingiverse

a lightweight shield to protect your receiver or other electronic devices.

thingiverse

free

RunCam HD 20° mount for RD290 mini hex by liftbag

...runcam hd 20° mount for rd290 mini hex by liftbag

thingiverse

easy fit on pre-existing holes.

thingiverse

free

Mini CC3D 30.5mm adapter by liftbag

...mount the mini cc3d on standard 30.5 holes pattern.

for those who do not like to use the double-sided tape directly on the frame.

thingiverse

free

Zortrax M200 V4 ribbon cable body holder by liftbag

...zortrax m200 v4 ribbon cable body holder by liftbag

thingiverse

a support that not bend the ribbon cable as the stock bands.

thingiverse

free

Zortrax M200 V4 clip filament to ribbon cable by liftbag

...zortrax m200 v4 clip filament to ribbon cable by liftbag

thingiverse

just another filament guide clip to ribbon cable.

thingiverse

free

Atas Defiance 265 - 5mm camera raiser by liftbag

...i-holder to raise the flight controller deck of 5mm.

this gives more battery choice.

35mm spacers are required to use this thing.

thingiverse

free

Water bottle stand by liftbag

...s of 80 mm diameter.

it must be printed in tpu or rubbery filaments.

maybe good results can be obtained with taulman3d pctpe too.

Zortrax

thingiverse

free

Zortrax M200

...zortrax m200

thingiverse

pipe holder for zortrax m200 and m300

thingiverse

free

Zortrax button by SaintBrieucFactory

...zortrax button by saintbrieucfactory

thingiverse

zortrax button

thingiverse

free

Zortrax M200 Clip

...zortrax m200 clip

thingiverse

zortrax m200 clip

thingiverse

free

porte-clef ZORTRAX by steftroisd

...porte-clef zortrax by steftroisd

thingiverse

porte-clef zortrax

thingiverse

free

Zortrax door-knob by snakehessman

...zortrax door-knob by snakehessman

thingiverse

zortrax door-knob

thingiverse

free

Zortrax Tool Holder by Terranova

...zortrax tool holder by terranova

thingiverse

this is a holder for the tools of the zortrax m200.

have fun!

thingiverse

free

Hinge for Zortrax M200 by snakehessman

...hinge for zortrax m200 by snakehessman

thingiverse

hinge for zortrax m200 with laser-cut doors!

thingiverse

free

Zortrax M300 Hinge by honeybeeprints

...acement hinge for the zortrax m300 printer.

at the time of creation, zortrax does not sell replacement hinges for their printers.

thingiverse

free

filament holder for zortrax by albo86

...filament holder for zortrax by albo86

thingiverse

a simple filament holder for zortrax spool

--working in progress--

thingiverse

free

Zortrax Carabiner with separator by palawanisland

...ortrax carabiner with separator by palawanisland

thingiverse

zortrax carabiner with separator, so that key wont fall out easily.

M200

turbosquid

$2

M200

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Cheytac M200

...squid

royalty free 3d model cheytac m200 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1537657)

turbosquid

$4

CheyTac M200

...oyalty free 3d model cheytac m200 for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1259577)

turbosquid

$49

Microlab M200

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

M200 Intervention

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

cheytac m200

...cheytac m200

3dexport

low poly sniper rifle (11k poly)

turbosquid

$5

cheytac m200 intervension

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$25

CheyTac M200 Intervention Sniper Rifle

...n different format (obj, fbx, max and 3ds ) along with its textures and uv layouts. it is low poly and is available along with...

3d_export

$10

CheyTac

...cheytac 3dexport fbx cheytac m200 ...

3d_export

$19

cheytac m200 intervention sniper rifle

...500 yd (2,286 m), one of the longest ranges of all modern-day sniper rifles. it is based on the edm arms windrunner. (<br>)

Airflow

turbosquid

$19

Airflow Caracole chair

...odel airflow caracole chair for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1658991)

design_connected

$21

AIRFLOW COLLECTIBLES Sky King Tricycle

...airflow collectibles sky king tricycle

designconnected

airflow collectibles sky king tricycle computer generated 3d model.

3ddd

$1

Вытяжной вентилятор Airflow ICON 15

...t is stylish and unobtrusive, even in the smallest space. the quiet, powerful axial fan has been designed with simplicity in mind

humster3d

$75

3D model of Chrysler Imperial Airflow 1934

... model of chrysler imperial airflow 1934 in various file formats. all our 3d models were created maximally close to the original.

humster3d

$75

3D model of Dodge Airflow Tank Truck 1938

...d model of dodge airflow tank truck 1938 in various file formats. all our 3d models were created maximally close to the original.

3d_export

$10

Fan Blade 3D Model

...mechanical household propeller plastic air wind impeller rotor runner airflow fans turbine fan blade 3d model firdz3d 99449...

3d_export

free

laser air nozzle 43mm spindle adapter

...focus of an engraving and cutting laser. without appropriate airflow the sample may develop defects such as uneven cutting...

3d_export

$15

Bladeless Fan 3D Model

...blade air multiplier breeze blows electric electrical appliance home airflow electronic wind bladeless fan 3d model download .c4d .max...

3d_export

$10

Paper Hand Fan 3D Model

...paper hand fan 3d model 3dexport paper hand fan airflow cooling refreshing folding fold classic vintage held woman accessories...

3d_export

free

cnc 3dp laser nozzle for 2w laser opt lasers

...head. this nozzle can be utilized to direct the airflow from the fan of a cutting and engraving laser...

Radial

3d_ocean

$5

Radial engine

...dial engine

3docean

engine radial

this is a radial engine used by the old airplanes. it is made in autodesk inventor and autocad.

3d_export

$5

radial engine

...ne , clearly shows how a radial engine works and all the parts present in it for a student or an engineer to have a glans on it .

3d_export

$5

shaft radial bearing

...shaft radial bearing

3dexport

shaft radial bearing

turbosquid

$7

Radial engine

...bosquid

royalty free 3d model radial engine for download as on turbosquid: 3d models for games, architecture, videos. (1672376)

turbosquid

$7

Radial Tyre

...osquid

royalty free 3d model radial tyre for download as max on turbosquid: 3d models for games, architecture, videos. (1433150)

turbosquid

$60

Radial engine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

VOITH RADIAL PROPELLER

...alty free 3d model voith radial propeller for download as max on turbosquid: 3d models for games, architecture, videos. (1338129)

3d_export

$20

radial engine assembly

...radial engine assembly

3dexport

turbosquid

$4

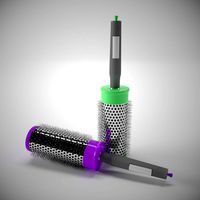

Radial Hair Brush

... 3d model radial hair brush for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1183870)

turbosquid

$39

Wheel ATS Radial

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Duct

turbosquid

$19

Duct Set

...d

royalty free 3d model duct set for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1145038)

turbosquid

$10

Duct Tape

...id

royalty free 3d model duct tape for download as ma and ma on turbosquid: 3d models for games, architecture, videos. (1580351)

turbosquid

free

Duct Tape

...

free 3d model duct tape for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1486518)

3d_ocean

$7

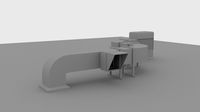

Air-duct

... ventilation

high quality industrial air duct ventilation model. created in cinema 4d but comes in various other formats as well.

turbosquid

$20

Air ducts

...lty free 3d model air ducts for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1262476)

3d_export

$10

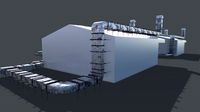

Supply air duct

...supply air duct

3dexport

supply air duct with two axial fans and hangers

turbosquid

$2

Duct Tape

...e 3d model duct tape for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1473972)

turbosquid

free

Duct Tape

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Duct tape

...polys. includes: cinema 4d project. model in 3 formats (obj, fbx, 3ds). 6 .tga texture maps (albedo, ambient occlusion, diffus...

turbosquid

$40

Ventilation Duct PACK

...tion duct pack for download as ma, obj, fbx, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1287068)

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)