Thingiverse

Zortrax fumes extraction by mrh85

by Thingiverse

Last crawled date: 2 years, 12 months ago

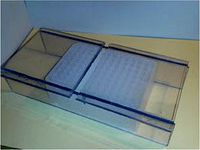

Main features:

Front side can be easy removed for maintenance tasks

Chamber has thermometer measuring temperature inside the printer

Back side has a hole for cable and filament tube

Pipe is connected by a brace that can be easily disconnected and it should be disconnected when the extractor is switched off

Chamber has many useful tool holders

This is only an example how you can extend your Zortrax machine.

Please be aware that this is work in progress.

Background history of the project:

I was looking for a solution to problem with fumes generated by 3d Printers.

I was surprised by the indifference of people to fumes generated by their devices.

So as any regular further of a infant child I decided that I will build my own solution for fumes extraction to protect our health.

Before I bought a 3D printer I decided that this will be my first project :)

I hope that example presented in the instruction bellow can save us from fumes that are not fully examined.

Printed parts:

2 x Window-pipe adapter - ( symbol:WPA )

Bottom parts for chamber:

2 x Bottom Right Corner ( symbol: CBR )

2 x Bottom Left Corner ( symbol: CBL )

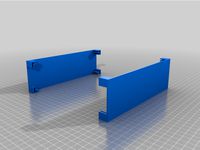

2 x 8 cm Front female connectors ( symbol: FFC8 )

2 x 8 cm Side female connectors ( symbol: SFC8 )

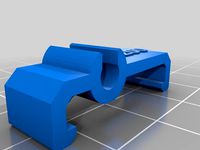

4 x 1 cm Front male connectors ( symbol: FMC1 )

4 x 1 cm Side male connectors ( symbol: SMC1 )

2 x 1 cm Middle male connectors ( symbol: MMC1 )

1 x Back side adapter ( symbol: BSA )

Top parts for chamber:

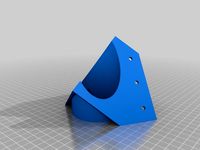

2 x Top Right Corner ( symbol:CTR )

2 x Top Left Corner ( symbol:CTL )

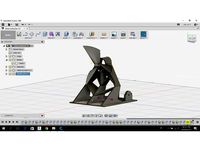

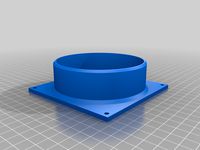

2 x Extractor holder ( symbol: EH )

1 x Thermometer housing ( symbol: TH )

Printing parameters:

Material: Z-ULTRAT (Exception: male connectors should be printed with more flexible Z-ABS)

Layer thickness: 0.19 mm

Infill: Light (Exception: Extractor holders should have full infill)

Support: 10 degrees light

Corners description:

They can warp so I use side covers and try to keep warm air in the room

Use mixture with Z-ABS or Z-Ultrat residues and pure Acetone - it creates glue for the surface

Circular holes are designed for support removal with help of a scalpel handle (scalpel that is in default toolbox)

Circular holes can be also used for screws

Male connectors description:

they are so small because sticks are very fragile, so it will be easy to replace them

print sticks horizontally ( otherwise they will break ! )

print with more flexible Z-ABS material

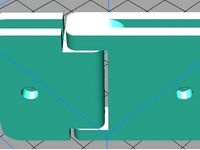

Female connectors description:

these parts are printed in various orientations, therefore you can expect some discrepancies between the results and the design

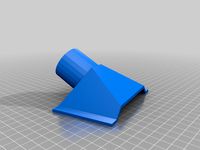

Window-pipe adapter description:

unfortunately I had to print it horizontally, so I can warp

I connected 2 parts with ABS slurry

Parts that you need to buy in a hardware store:

Flexible pipe 3 m (radius 5 cm)

2 x Metal braces for pipe

Dark shelfs cut into rectangles:

2 x 16x200x340 (left and right site)

1 x 16x235x340 (front side)

1 x 16x285x340 (back side)

2 x 16x97x340 (roof)

Dark protective film

Dark insulating tape

Electronic devices used in the project:

TOOLCRAFT ZD-153A Soldering Fume Extractor

Thermometer with probe 1.5 m BLOW TH001

Front side can be easy removed for maintenance tasks

Chamber has thermometer measuring temperature inside the printer

Back side has a hole for cable and filament tube

Pipe is connected by a brace that can be easily disconnected and it should be disconnected when the extractor is switched off

Chamber has many useful tool holders

This is only an example how you can extend your Zortrax machine.

Please be aware that this is work in progress.

Background history of the project:

I was looking for a solution to problem with fumes generated by 3d Printers.

I was surprised by the indifference of people to fumes generated by their devices.

So as any regular further of a infant child I decided that I will build my own solution for fumes extraction to protect our health.

Before I bought a 3D printer I decided that this will be my first project :)

I hope that example presented in the instruction bellow can save us from fumes that are not fully examined.

Printed parts:

2 x Window-pipe adapter - ( symbol:WPA )

Bottom parts for chamber:

2 x Bottom Right Corner ( symbol: CBR )

2 x Bottom Left Corner ( symbol: CBL )

2 x 8 cm Front female connectors ( symbol: FFC8 )

2 x 8 cm Side female connectors ( symbol: SFC8 )

4 x 1 cm Front male connectors ( symbol: FMC1 )

4 x 1 cm Side male connectors ( symbol: SMC1 )

2 x 1 cm Middle male connectors ( symbol: MMC1 )

1 x Back side adapter ( symbol: BSA )

Top parts for chamber:

2 x Top Right Corner ( symbol:CTR )

2 x Top Left Corner ( symbol:CTL )

2 x Extractor holder ( symbol: EH )

1 x Thermometer housing ( symbol: TH )

Printing parameters:

Material: Z-ULTRAT (Exception: male connectors should be printed with more flexible Z-ABS)

Layer thickness: 0.19 mm

Infill: Light (Exception: Extractor holders should have full infill)

Support: 10 degrees light

Corners description:

They can warp so I use side covers and try to keep warm air in the room

Use mixture with Z-ABS or Z-Ultrat residues and pure Acetone - it creates glue for the surface

Circular holes are designed for support removal with help of a scalpel handle (scalpel that is in default toolbox)

Circular holes can be also used for screws

Male connectors description:

they are so small because sticks are very fragile, so it will be easy to replace them

print sticks horizontally ( otherwise they will break ! )

print with more flexible Z-ABS material

Female connectors description:

these parts are printed in various orientations, therefore you can expect some discrepancies between the results and the design

Window-pipe adapter description:

unfortunately I had to print it horizontally, so I can warp

I connected 2 parts with ABS slurry

Parts that you need to buy in a hardware store:

Flexible pipe 3 m (radius 5 cm)

2 x Metal braces for pipe

Dark shelfs cut into rectangles:

2 x 16x200x340 (left and right site)

1 x 16x235x340 (front side)

1 x 16x285x340 (back side)

2 x 16x97x340 (roof)

Dark protective film

Dark insulating tape

Electronic devices used in the project:

TOOLCRAFT ZD-153A Soldering Fume Extractor

Thermometer with probe 1.5 m BLOW TH001

Similar models

thingiverse

free

Mini kitchen cabinet with drawers by Mewalela

...ne drawer because i was out of pink ultrat :(.

this is a link to all miniature furniture for dollhouse i've designed so far.

thingiverse

free

Classic Mini Pickup B pillar cover by amarravnen

...by amarravnen

thingiverse

cover for the b pillar on a classic mini pickup.

i printed it using zortrax z ultrat on a zortrax m200

thingiverse

free

1" BSP to 25mm pond pipe fitting by tsh2

...d i'm getting a fairly good seal without any gaskets. i already had the male-male 1" bsp, so that part here is untested.

thingiverse

free

80mm fan extractor adaptor by JB1

...t the side of a solidoodle 2 case to get rid of the abs fumes. it adapts to an 80mm fan. i assume it can be used for other tasks.

thingiverse

free

Fume extractor with 12 cm fan

...aced.

for the 12 v power supply, a barrel connector can be press-fitted or glued in the hole on the right side (diameter: 13 mm).

thingiverse

free

Fume Extractor 200m Fan by jtranfpv

...

print 2 top-bottom plates

print 2 side plates

print 1 front plates

print 1 back plates

assembly required by fitting in the slots

thingiverse

free

wall connector for fume extractor by Juonio

...wall connector for fume extractor by juonio

thingiverse

wall connector for fume extractor 69729

thingiverse

free

Corner & USB cover for maty-taneczne.pl dancepads

...inters with 0.4mm nozzle:

layer 0.24

fill 50%

no support

petg, abs, asa, nylon

after printing get rid of designed support.

voila!

thingiverse

free

Mini bathroom sink by Mewalela

...ave a glue to connect bathroom sink to a bathroom cabinet.

those are links for miniature toilet and miniature shower i also made.

thingiverse

free

Corner bat excluder flange for 2" ABS pipe by bluecoast

...nge id 60.5mm.

you can modify the id to match whatever pipe you have.

i'll add some photos once i have it made and intalled.

Mrh85

thingiverse

free

Adapter-Mask-Aqua-Speed_2hepa_filters by mrh85

...adapter-mask-aqua-speed_2hepa_filters by mrh85

thingiverse

rft

thingiverse

free

Wtyczka-Zenska-Aqua-Speed_2wejscia by mrh85

...enska-aqua-speed_2wejscia by mrh85

thingiverse

aqua speed drift to filter adapter for 2 hepa filters.

draft version. not tested!

thingiverse

free

Icosahedron with ball inside by mrh85

...rtrax z-suite

have fun!

if you would like to have it printed please visit:https://www.3dhubs.com/pozna%c5%84/hubs/carrot-projects

thingiverse

free

Snowflake mold for cakes by mrh85

...

enjoy!

want to to have it printed and support me ?

please visit my hub: https://www.3dhubs.com/pozna%c5%84/hubs/carrot-projects/

Zortrax

thingiverse

free

Zortrax M200

...zortrax m200

thingiverse

pipe holder for zortrax m200 and m300

thingiverse

free

Zortrax button by SaintBrieucFactory

...zortrax button by saintbrieucfactory

thingiverse

zortrax button

thingiverse

free

Zortrax M200 Clip

...zortrax m200 clip

thingiverse

zortrax m200 clip

thingiverse

free

porte-clef ZORTRAX by steftroisd

...porte-clef zortrax by steftroisd

thingiverse

porte-clef zortrax

thingiverse

free

Zortrax door-knob by snakehessman

...zortrax door-knob by snakehessman

thingiverse

zortrax door-knob

thingiverse

free

Zortrax Tool Holder by Terranova

...zortrax tool holder by terranova

thingiverse

this is a holder for the tools of the zortrax m200.

have fun!

thingiverse

free

Hinge for Zortrax M200 by snakehessman

...hinge for zortrax m200 by snakehessman

thingiverse

hinge for zortrax m200 with laser-cut doors!

thingiverse

free

Zortrax M300 Hinge by honeybeeprints

...acement hinge for the zortrax m300 printer.

at the time of creation, zortrax does not sell replacement hinges for their printers.

thingiverse

free

filament holder for zortrax by albo86

...filament holder for zortrax by albo86

thingiverse

a simple filament holder for zortrax spool

--working in progress--

thingiverse

free

Zortrax Carabiner with separator by palawanisland

...ortrax carabiner with separator by palawanisland

thingiverse

zortrax carabiner with separator, so that key wont fall out easily.

Fumes

thingiverse

free

Soldering Fume Extractor by VenomPrinter

...extractor by venomprinter thingiverse diy fume extractor for soldering fumes or any kind of...

thingiverse

free

Fume extractor by radioslicer

...fume extractor by radioslicer

thingiverse

https://github.com/ikatkov/fume-extractor/

thingiverse

free

Fume Scrubber by unitconversion

...simple fume scrubber to help get rid of abs fumes it's intended to go inside of a heated build...

thingiverse

free

Fume Extractor by Arkadi

...fume extractor by arkadi

thingiverse

fume extractor designed for 70 mm fan and 1watt leds.

thingiverse

free

i3_top by fuming

...i3_top by fuming

thingiverse

i3 top frame

thingiverse

free

Fume Extractor DIY by mwieland

...fume extractor diy by mwieland

thingiverse

diy fume extractor.

project page: https://www.tsb.space/bl0g/diy-fume-extractor/

thingiverse

free

Solder Soldier, Fume extractor

...soldier, fume extractor thingiverse this is a simple soldering fumes ...

thingiverse

free

cool fume extractor by eric20136065

...cool fume extractor by eric20136065

thingiverse

this is a cool looking fume extractor

thingiverse

free

fume extractor by noah_makes_things

...y noah_makes_things

thingiverse

a 3d printed fume extractor made for a youtube video

https://www.youtube.com/watch?v=ful6yhimnxu

thingiverse

free

Solder Fume extractor by Apache64

...

thingiverse

solder fume extractor that can be moved more easily, focused more easily, and allow localised fume to be extracted.

Extraction

thingiverse

free

Extraction V1.0

...extraction v1.0

thingiverse

test, first try to upload.

thingiverse

free

defy extracter by hvr250

...defy extracter by hvr250

thingiverse

thingiverse

free

Extraction hood by mikie10

...s design is made for someone that needs a bigger extraction hood for his grinding machine to grind skates at the ice hockey club.

thingiverse

free

protector for extraction plate by bertrand_maubert

...r extraction plate by bertrand_maubert

thingiverse

a device to prevent contamination of plates used during rna / dna extraction.

thingiverse

free

Baking extract caddy by billiamthesecond

...baking extract caddy by billiamthesecond

thingiverse

a 2 x 3 caddy for 1 fl oz mccormick baking extract.

thingiverse

free

Bates Grain Mold Extraction Frame

...bates grain mold extraction frame

thingiverse

this is the 3d file to the mold extraction frame.

thingiverse

free

Slit extract by kaka_things

...slit extract by kaka_things

thingiverse

you can change and print for your need.~~~

just enjoy~~~

thingiverse

free

Smoke Extraction for Prusa I3 and Zimpure by The_Gorille

... the_gorille

thingiverse

smoke extraction pipe for prusa i3 (compatible zimpure extraction station) to screw on the fan radiator

thingiverse

free

(6040 CNC) 1.5kw Spindle extraction by Niklas_Voigt

...(6040 cnc) 1.5kw spindle extraction by niklas_voigt

thingiverse

extraction for 6040 cnc

thingiverse

free

100mm 4" dust extraction connector

...100mm 4" dust extraction connector

thingiverse

100mm/4" face connector for either dust or fume extraction.