Thingiverse

Z18 levelling jig by luben111

by Thingiverse

Last crawled date: 3 years ago

Hello,

Few weeks ago I purchased Z18 in excellent condition for a good price (bargain) but in the same moment I joined the club of the dissapointed Z18 users. I have to agree - the printer mechanic is great - linear rails, isolated heat chamber, everything to the highest standards. But when you see the print results, you start to reconcider your purchase. The most obvious things which are concerning the quality are :

You can't print without rafts, Z18 is much slower compared to Replicator 2 but when you add the rafts + heating the chamber the print time doubles and tripples compared to my older and reliable Replicator 2. If you try to print without rafts - the filament doesn't stick to the plate and you finish with mess

Layers are shifted - I'm talking about small shifts 0.1..0.2mm in any direction. My guess is that this is caused by two reasons

a/ Z18 uses CoreXY configuration and the belt is probably 3m long

b/ the idler pulleys are smooth (no teeth) despite that the belt teeth are facing the pulley. Like result the teeth are pushing the idler pulley smooth surface and can introuce small legth variations of the belt tension

As an owner of Z18 the worst I found is the Smart Extruder - this is probably the worst combination of well made hardware with bad concept in the same time. Z18 Smart Extruder (also 5th gen printers) uses the nozzle to measure the surface level. Nozzle is not fixed to the body but uses spring and sophisticated mechanic to move up a little bit up and by using magnet and Hall sensor to detect the moment when nozzle touches the surface. You can imagine how small drop of filament on top of the nozzle will shift the levelling, Hall sensor is not that precise and nozzle can't return always to the same place .

The non perfect surface detection of Smart extruder affect the levelling of the build plate - what I found is that the build plate will have at least +/- 0.3..0.7mm difference between different points. This explains why MakerBot recommends for Z18 and 5th gen printers to always use rafts. I my not against using rafts in some cases, but there is something wrong if you can never print without rafts. And the solution to avoid rafts in Z18 includes two things:

B) Platform levelling should be done by using dial indicator attached on Smart Extruder place (instead of using the Smart extruder).

A) Use Z offset in the Z18 settings. Personally I use the Desktop software instead of Print because Desktop slicer is much better and Desktop brings access to some advanced settings. I found that whatever I did, the nozzle is about 0.5mm higher than it should be and only by using the Z offset I was able to bring the nozzle back to the right height.

After using A and B, now I'm able to print on Z18 mainly without rafts, I use rafts only for large objects where maximising the adhesion to the build plate is highly desirable.

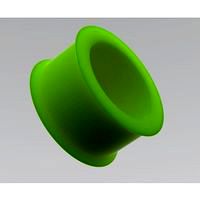

About the Z18 levelling jig - it uses D10x8 magnets to attach to the Smart Extruder place, magnet holes have draft angle which allows the magnets to stay in place once inserted. Ensure the polarity of the magnets is correct when inserting them into the holes. I copied the Smart extruder design from another place and I found that positioning holes are not 100% precise - be aware that the jig will require little filing and tweaking before it fits in place.

The dial indicator holder STL and SLDPRT files are attached to the project.

Few weeks ago I purchased Z18 in excellent condition for a good price (bargain) but in the same moment I joined the club of the dissapointed Z18 users. I have to agree - the printer mechanic is great - linear rails, isolated heat chamber, everything to the highest standards. But when you see the print results, you start to reconcider your purchase. The most obvious things which are concerning the quality are :

You can't print without rafts, Z18 is much slower compared to Replicator 2 but when you add the rafts + heating the chamber the print time doubles and tripples compared to my older and reliable Replicator 2. If you try to print without rafts - the filament doesn't stick to the plate and you finish with mess

Layers are shifted - I'm talking about small shifts 0.1..0.2mm in any direction. My guess is that this is caused by two reasons

a/ Z18 uses CoreXY configuration and the belt is probably 3m long

b/ the idler pulleys are smooth (no teeth) despite that the belt teeth are facing the pulley. Like result the teeth are pushing the idler pulley smooth surface and can introuce small legth variations of the belt tension

As an owner of Z18 the worst I found is the Smart Extruder - this is probably the worst combination of well made hardware with bad concept in the same time. Z18 Smart Extruder (also 5th gen printers) uses the nozzle to measure the surface level. Nozzle is not fixed to the body but uses spring and sophisticated mechanic to move up a little bit up and by using magnet and Hall sensor to detect the moment when nozzle touches the surface. You can imagine how small drop of filament on top of the nozzle will shift the levelling, Hall sensor is not that precise and nozzle can't return always to the same place .

The non perfect surface detection of Smart extruder affect the levelling of the build plate - what I found is that the build plate will have at least +/- 0.3..0.7mm difference between different points. This explains why MakerBot recommends for Z18 and 5th gen printers to always use rafts. I my not against using rafts in some cases, but there is something wrong if you can never print without rafts. And the solution to avoid rafts in Z18 includes two things:

B) Platform levelling should be done by using dial indicator attached on Smart Extruder place (instead of using the Smart extruder).

A) Use Z offset in the Z18 settings. Personally I use the Desktop software instead of Print because Desktop slicer is much better and Desktop brings access to some advanced settings. I found that whatever I did, the nozzle is about 0.5mm higher than it should be and only by using the Z offset I was able to bring the nozzle back to the right height.

After using A and B, now I'm able to print on Z18 mainly without rafts, I use rafts only for large objects where maximising the adhesion to the build plate is highly desirable.

About the Z18 levelling jig - it uses D10x8 magnets to attach to the Smart Extruder place, magnet holes have draft angle which allows the magnets to stay in place once inserted. Ensure the polarity of the magnets is correct when inserting them into the holes. I copied the Smart extruder design from another place and I found that positioning holes are not 100% precise - be aware that the jig will require little filing and tweaking before it fits in place.

The dial indicator holder STL and SLDPRT files are attached to the project.

Similar models

thingiverse

free

UP BOX Extruder Mounting Plate - Magnet Removal by ATPerformance

...atsink.

you can now slide the extruder off and on by pulling it forward, no need to un-bolt.

i hope this is helpful for someone.

cults

free

belt idler pulley

...lley with teeths, it is possible to look at it here. that there was couple.

https://cults3d.com/en/3d-model/tool/idler_pulley_2gt

thingiverse

free

X Tensioner and Pully for 2GT toothed idler pulley, 6mm belt, 4mm bore by jnsanders1983

...ion. so i redrew the brace and puller in inventor. i lengthen the brace and redimensioned the puller to fit the new idler pulley.

thingiverse

free

Timer pulley by Zaggo

...r belt doesn't get enough grip on its teeth at .5mm printing.

the gcode file contains the object, processed for .5mm nozzles!

thingiverse

free

V-Slot NEMA 17 offset mounting plate by dmatsumoto

...empty space inside of the extrusion.

once this prints out, i'll start making a revised idler pulley mounting plate as well.

thingiverse

free

Prism Z belt springy idler by DeuxVis

...de effect bonuses are : better belt path with more teeth engaged on the driving and driven pulleys, easy belt tension adjustment.

thingiverse

free

608ZZ Idler Pulley for 10mm GT2 Belt by Skyline89

...y for 10mm gt2 belt by skyline89

thingiverse

idler pulley for 10mm gt2 belt using 8x22x7mm 608zz bearings

print with 100% infill

thingiverse

free

Tevo Little Monster - Upgraded Idler Pulley by Redemptioner

...e amount of pressure on the main idler pulley preventing it being warped over when you add the correct belt tension (around 30kg)

thingiverse

free

AM8 Belted extruder (geared) by ajna8093

...o the stepper motor into the loop and once the motor is mounted it should take any slack left in the belt.

enjoy!

modify!

share!

thingiverse

free

Redesigned extruder idler by zapprae

... the right shape. either way, the idler springs will never pop out again!

i made the design using autocad 2000 (dwg. file format)

Luben111

thingiverse

free

ER20 Collet holder by luben111

...t holder - place 9 er20 collets with labels

put your er20 collets into nice and slim holder - easy access and requires less space

thingiverse

free

Air valve by luben111

...ep model of the engine.

a short video showing how the engine works is on the following link:https://youtu.be/09nnfs2ehyo

thanks.

thingiverse

free

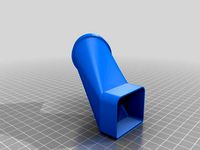

CNC Sieg KX1 vacuum suction by luben111

...ing detail and sucks all the particles created from the milling process. use m3 screw to tide the suction collet on spindle base.

thingiverse

free

Sieg KX1 vacuum suction by luben111

...le detail exceeds the makerbot replicator 2 3d printing area so it was split into two details.

solidworks files also included.

thingiverse

free

Small XY servo movement by luben111

...erppezxvq-a

converting the rotation angle of the servos into cartesian coordinate system requires some trigonometry calculations.

thingiverse

free

Kleenex 6340 adapter for Cien HandWash by luben111

...16150/

the adapter was printed and tested into real kimberly-clark hand wash unit and works flawlessly (0.2 mm layers, 20% fill).

thingiverse

free

Touch probe by luben111

...rinting the components (0.1mm layers 50%) and assembling the unit the sensitivity is excellent.

more text will be added soon.....

thingiverse

free

Oscilloscope probe holder by luben111

...the first design which is not perfect for 3d printing, i'll post soon another version which is more friendly for 3d printing.

thingiverse

free

Test jig (clamp) by luben111

.../www.youtube.com/watch?v=cmesfn8o52q

attached is the complete design in solidworks 2016 (zip file) and the iges for the assembly.

thingiverse

free

Fast fixture by luben111

...e fixture.

unfortunately the working prototype was lost long time ago but the design remains and i'm pleased to share it now.

Z18

thingiverse

free

XY Z18 3 Layers by Toolpath_Team

...xy z18 3 layers by toolpath_team

thingiverse

adhesion test for the z18

thingiverse

free

External spool holder for Z18 by robwand

... the 'backer plate' and 'holder arm', and is designed to use 10-32 csk screws thru the vent slots in the z18 lid.

thingiverse

free

Buildplate Retainer Z18 by PaulVl

...ement for z18, standard retainer does not fully lock the buildplate which degenerates print quality.

designed by remko schiphorst

thingiverse

free

Filament spool holder Z18 by activa1969

...8 by activa1969

thingiverse

remake for z18 of universal stand-alone filament spool holderhttp://www.thingiverse.com/thing:508896

thingiverse

free

Tilted Cone for Z18 by Toolpath_Team

...tilted cone for z18 by toolpath_team

thingiverse

adhesion test

thingiverse

free

Empire State Building z18 Style by MacInspires

...empire state building z18 style by macinspires

thingiverse

love nyc. just got a z18. so....

thingiverse

free

Z18 Maker Better by PXD

...rse.com/groups/z18-make-better"

2015-1-21:

upload the "fans holder" version 2, which add one protection cover.

thingiverse

free

Dustfilter MakerBot Smart Extruder + Z18 by 3D-EDU

...makerbot smart extruder + z18 by 3d-edu

thingiverse

this is a dustfilter for the makerbot smartextruder+ for the replicator z18.

thingiverse

free

Filament stand(Laser Cutted) for Makerbot Z18 by David_Key

...filament stand(laser cutted) for makerbot z18 by david_key

thingiverse

filament stand for makerbot z18 (filament slip - solved)

thingiverse

free

Z18 Dalek, 400mm high by RevK

...caled and positioned to fit on a z18. prints with no supports. weapons snap in. estimated print time at standard res is 98 hours!

Jig

turbosquid

$25

jig-saw_mid_SM

...uid

royalty free 3d model jig-saw_mid_sm for download as obj on turbosquid: 3d models for games, architecture, videos. (1244761)

turbosquid

$20

jig-saw_low

...osquid

royalty free 3d model jig-saw_low for download as obj on turbosquid: 3d models for games, architecture, videos. (1244760)

turbosquid

$10

jig-saw_hi

...bosquid

royalty free 3d model jig-saw_hi for download as obj on turbosquid: 3d models for games, architecture, videos. (1244757)

turbosquid

$7

Jig Armchair

...squid

royalty free 3d model jig armchair for download as max on turbosquid: 3d models for games, architecture, videos. (1648936)

turbosquid

$5

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Head

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Jig Tail

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Levelling

design_connected

$11

Levels

...levels

designconnected

one nordic levels computer generated 3d model. designed by form us with love.

design_connected

$7

Level

...level

designconnected

zanotta level shelves and storage computer generated 3d model. designed by arik levy.

turbosquid

$29

level

...ty free 3d model level for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1272856)

turbosquid

$1

level

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Mario level

...mario level

3dexport

mario level low quality for fun videos

3ddd

$1

LEVELS OF DISCOVERY

...етская мебель "levels of discovery". rab10003 princess mini rocker

кресло-качалка (мини) "принцесса навсегда"

3d_export

$19

level design

...level design

3dexport

you can use this design (level design) in your own game.

turbosquid

$60

Desert level

...squid

royalty free 3d model desert level for download as fbx on turbosquid: 3d models for games, architecture, videos. (1208131)

turbosquid

$15

Transit Level

...quid

royalty free 3d model transit level for download as max on turbosquid: 3d models for games, architecture, videos. (1158112)

turbosquid

$14

Districts Level

...id

royalty free 3d model districts level for download as max on turbosquid: 3d models for games, architecture, videos. (1408410)