Thingiverse

Z SYNC - TRONXY X5SA by VisiTor

by Thingiverse

Last crawled date: 2 years, 11 months ago

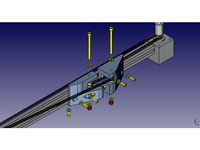

Z - Sync for TRONXY X5SA 300 (adaptable to 400 and 500 and probably X5S)

I'm still testing!!!

Items you need to mod your TRONXY X5SA (330 x 330 mm bed):

1 x 2020 - 470 mm max length**. Around 469/468 mm will do fine. Measure the distance between both Z Nemas before ordering/cutting the 2020

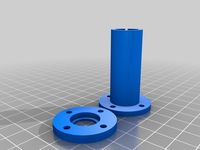

2 x pulleys 2GT / 6mm.

I'm actually using these 20 teeth on my NEMAs (see picture):https://www.aliexpress.com/item/32914938878.html

... they work well so far, but after some height adjustments my feeling about the locking screws is some sort of :((

These pulleys use 3 mm locking screws: either you 'kill' the screws or most likely your allen key dies after the first tightening ...

1 x pulley 2GT / 6 mm – 20T, no teeth / 5 mm bore

1 x pulley 2GT / 6 mm – 20T, with teeth / 5 mm bore

1 x 2GT / 6 mm belt *** – 1220 mm closed loop belt

Screws, nuts and washers:

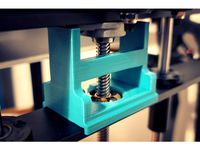

2 x M5 - 60 mm screws (I recommend half thread, so there’s less clearance when mounting the 20T pulleys) + 8 x washers + 2 x M5 locking nuts ==> for block 1 & 2

1 x M5 - 50 mm screws + 2 x M5 nuts + 2 washers ==> for the extension tensioner

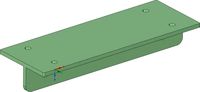

6 x wood screws around 20 mm long ==> for top & bottom plates

8 x M4 - 8 mm screws + 8 x washers (max 9 mm external diam.) + 8 x T-nuts 4 mm diam ==> to fasten bottoms & blocks to the 2020 profile

4 x M3 – 50 or 60 mm screws + 4 x M3 locking nuts + 4 washers

2 x Nema 17 mount plates (aluminium 82 mm long with central holes) + 4 x M4 - 6 mm screws + 4 x T-nuts 4 mm diam

For X5SA-400 and X5SA-500 (X5SA-600 ????)

** Longer 2020 profile needed

*** Larger closed loop belt needed. Probably something between 1400 and 1600 mm. Be adviced that I'm guessing, so test with a 2GT belt, cord or whatever you have at hand before ordering the closed loop belt.

NOTE: take care, not to overtightening, when tensioning, even with a 2020 profile acting as a stiffening antitorsion bar.

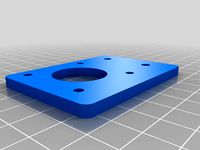

PRINTING:

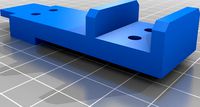

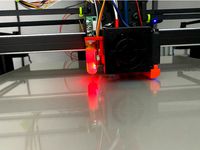

I printed ABS with 100% infill.

Scaled up the STLs to 100,7% before generating gcodes.

To glue ABS use acetone. Use a mask to avoid inhaling fumes.

If you go for less infill, think about the tension acting on the pulley shafts and make sure to print at least 4 walls.

After printing, rework the holes carefully. Use 4 and 5 mm drills. Always drill very slowly, especially if you printed PLA.

Here's a 7 sec sample https://www.youtube.com/watch?v=rxuj-Y_QQK8

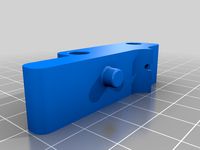

If you managed to read all this and at this point you think 6 prints means too much printing time, then you should think about the "mono-blocks" layout. It's only two pieces, but you will have to remove the supporting structures, and sand the pulley bed, so the pulleys spin easily.

TRONXY X5SA

Z Axis Synchronizer

Z Synchronizer

Z Syncro

Z Sync

I'm still testing!!!

Items you need to mod your TRONXY X5SA (330 x 330 mm bed):

1 x 2020 - 470 mm max length**. Around 469/468 mm will do fine. Measure the distance between both Z Nemas before ordering/cutting the 2020

2 x pulleys 2GT / 6mm.

I'm actually using these 20 teeth on my NEMAs (see picture):https://www.aliexpress.com/item/32914938878.html

... they work well so far, but after some height adjustments my feeling about the locking screws is some sort of :((

These pulleys use 3 mm locking screws: either you 'kill' the screws or most likely your allen key dies after the first tightening ...

1 x pulley 2GT / 6 mm – 20T, no teeth / 5 mm bore

1 x pulley 2GT / 6 mm – 20T, with teeth / 5 mm bore

1 x 2GT / 6 mm belt *** – 1220 mm closed loop belt

Screws, nuts and washers:

2 x M5 - 60 mm screws (I recommend half thread, so there’s less clearance when mounting the 20T pulleys) + 8 x washers + 2 x M5 locking nuts ==> for block 1 & 2

1 x M5 - 50 mm screws + 2 x M5 nuts + 2 washers ==> for the extension tensioner

6 x wood screws around 20 mm long ==> for top & bottom plates

8 x M4 - 8 mm screws + 8 x washers (max 9 mm external diam.) + 8 x T-nuts 4 mm diam ==> to fasten bottoms & blocks to the 2020 profile

4 x M3 – 50 or 60 mm screws + 4 x M3 locking nuts + 4 washers

2 x Nema 17 mount plates (aluminium 82 mm long with central holes) + 4 x M4 - 6 mm screws + 4 x T-nuts 4 mm diam

For X5SA-400 and X5SA-500 (X5SA-600 ????)

** Longer 2020 profile needed

*** Larger closed loop belt needed. Probably something between 1400 and 1600 mm. Be adviced that I'm guessing, so test with a 2GT belt, cord or whatever you have at hand before ordering the closed loop belt.

NOTE: take care, not to overtightening, when tensioning, even with a 2020 profile acting as a stiffening antitorsion bar.

PRINTING:

I printed ABS with 100% infill.

Scaled up the STLs to 100,7% before generating gcodes.

To glue ABS use acetone. Use a mask to avoid inhaling fumes.

If you go for less infill, think about the tension acting on the pulley shafts and make sure to print at least 4 walls.

After printing, rework the holes carefully. Use 4 and 5 mm drills. Always drill very slowly, especially if you printed PLA.

Here's a 7 sec sample https://www.youtube.com/watch?v=rxuj-Y_QQK8

If you managed to read all this and at this point you think 6 prints means too much printing time, then you should think about the "mono-blocks" layout. It's only two pieces, but you will have to remove the supporting structures, and sand the pulley bed, so the pulleys spin easily.

TRONXY X5SA

Z Axis Synchronizer

Z Synchronizer

Z Syncro

Z Sync

Similar models

thingiverse

free

TRONXY X5S - Z motor sync by WT1704

...e platform on the stepper and 3 * m5 screws and nuts for the pulley

1 * m3 screw and nut to hold the tension stick with the block

thingiverse

free

Belt tensioner axis Y Prusa i3 by 3DWnico

...self-locking nut m5

4 m4 nuts

2 m4 screws

belt tensioner designed for prusa i3 hictop but extensible for all prusa i3 versions.

grabcad

free

Pulley GT2 - 20T B5

... 2 m4x4 grub screws.

created by dzino

gt2 - 20t napínacia ozubená kladka s ložiskom pre ozubené remene 2gt - 6mm. pre 5mm osku.

thingiverse

free

belt tensioner by derJoe

...ensioner by derjoe

thingiverse

belt tensioner for t6 belts

constructed for my tronxy x5sa

you need spring and pulley to assambly

thingiverse

free

x-BeltTensioner-20 Pulley

...a x-belt tensioner for the stock 20t pulley.

you have to stop the print at 7,20 mm and put the square nut in place.

fits perfect.

thingiverse

free

Geeetech i3 Upper support with X- and Z- Tierod and Bearings by Diplomator

...z-sync

2beerings 608zz

belt gt2 670mm

2 gt2 pulleys 8mm

z-sync tensioner

2 screws m5x20

1screw m5 x 25 and m5 nut

1 gt pulley 5mm

thingiverse

free

Tronxy X5SA Z Synchronization with Belt Tensioner by Toto-42

...ound in the videos section below or in this youtube playlist. all show an auto-bed-levelling tour with obviosly some z movements.

thingiverse

free

Tronxy X5SA Belt Tensioner Y & X Axis by n02m4n

...tronxy x5sa belt tensioner y & x axis by n02m4n

thingiverse

a belt tensioner y & x axis for my tronxy x5sa.

thingiverse

free

Z SYNC - TRONXY X5SA - TWO BLOCKS by VisiTor

...ed the 6 wood screws to fix the top & bottom plates.

enjoy!

o.

tronxy x5sa

z axis synchronizer

z synchronizer

z syncro

z sync

thingiverse

free

Ender 3 v2 belt tensioners by tom_sim

...nder 3 v2 belt tensioners by tom_sim

thingiverse

your will need, pulley bore 5 mm, belt 6 mm, with teeth. m5 bolt 25 mm. m5 nut.

X5Sa

thingiverse

free

Chain riser X5SA by xanatorium

...chain riser x5sa by xanatorium

thingiverse

chain risers for x5sa

thingiverse

free

Tronxy X5S X5SA Organizer

...tronxy x5s x5sa organizer

thingiverse

organizer for tronxy x5s; x5sa

thingiverse

free

Tronxy X5SA Z-Blocker by n02m4n

...tronxy x5sa z-blocker by n02m4n

thingiverse

a z-blocker for my x5sa.

thingiverse

free

Tronxy X5SA Fan Duct by Noobik4ever

...tronxy x5sa fan duct by noobik4ever

thingiverse

fun duct for tronxy x5sa

thingiverse

free

Tronxy X5S, X5SA linear rail

...tronxy x5s, x5sa linear rail

thingiverse

linear rail tronxy x5sa

thingiverse

free

Tronxy X5SA Filament holder Screw

...tronxy x5sa filament holder screw

thingiverse

better holder for tronxy x5sa filament as screw

thingiverse

free

TronXY X5SA PRO BLTouch Mount

...tronxy x5sa pro bltouch mount

thingiverse

a simple bltouch mount for the tronxy x5sa pro.

thingiverse

free

Tronxy X5SA Extruder TPU Upgrade

...tronxy x5sa extruder tpu upgrade

thingiverse

redesigned anycubic kossel extruder tpu upgrade for tronxy x5sa

thingiverse

free

X5SA Tronxy Towline by Daelin89

... towline by daelin89

thingiverse

broke the towline on my tronxy x5sa-400. so i remade it in fusion 360. have yet to test print

thingiverse

free

Tronxy X5SA Display Offset by Darkwulf3D

...tronxy x5sa display offset by darkwulf3d

thingiverse

tronxy x5sa pro display offset for the large table adjustment wheels

Sync

3ddd

$1

Fagerhult Sync

...fagerhult sync

3ddd

fagerhult

fagerhult sync светильник встроенный

turbosquid

$10

G-Sync

...oyalty free 3d model g-sync for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1508352)

3ddd

$1

Sms Sync By 50 Headphones

...ync by 50 headphones

3ddd

sms sync by 50 headphones , наушники

sms sync by 50 headphones

3ddd

$1

USB micro Charge Sync Kit

...usb micro charge sync kit

3ddd

коробка , зарядное устройство

usb micro charge sync kit

turbosquid

$15

Wheel Baccarat - Sync rims and tire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

Wheel Baccarat Sync rims and tyre 3D Model

...rformance disk brake caliper brembo yokohama baccarat sync

wheel baccarat sync rims and tyre 3d model 3dlogicline 54611 3dexport

turbosquid

$45

E3D - GoPro Omni Sync Rig 360 Camera Spherical

...nc rig 360 camera spherical for download as max, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1158772)

turbosquid

$25

USB, Keyboard, Pen Drive, Mouse, PC, Toshiba Laptop, Apple 24" LED, Samsung Sync Master215TW Monitor

..." led, samsung sync master215tw monitor for download as on turbosquid: 3d models for games, architecture, videos. (1694575)

3ddd

free

Монитор Samsung 22'

...монитор samsung 22' 3ddd монитор , samsung монитор samsung sync master p2250...

3d_export

$22

Clapperboard 3D Model

...clapperboard 3d model 3dexport clapper clapboard slate board sync time sticks marker ciak film movie cinema clapperboard 3d...

Visitor

3ddd

$1

The Visitor

... the visitor. в материалах используется бесплатный плагин bercon maps. в fbx формат экспортировалась только сетка без turbosmooth

design_connected

$16

Tempo Visitor

...tempo visitor

designconnected

sitia tempo visitor computer generated 3d model. designed by battocchio, pergentino.

3d_export

$10

kiosk visitor

...kiosk visitor

3dexport

this is the kiosk with visitor management. it has id card reader, camera and alcohol sterilizer.

3ddd

$1

Стул Visitor

...стул visitor

3ddd

visitor

высота (см): 72,5

высота седалища (см): 44,5

ширина (см): 59

глубина (см): 53

turbosquid

$20

Visitor Chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Visitor Chair

...l visitor chair for download as 3ds, max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1375131)

turbosquid

$7

Visitor chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Visitor chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$6

Sofa for visitors

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

Visitor Chair 3D Model

...odel

3dexport

visitor chair white chair conference metting office cafe furniture

visitor chair 3d model grayback23 50803 3dexport

Tronxy

thingiverse

free

LMF8LUU for tronxy x5s

...lmf8luu for tronxy x5s

thingiverse

lmf8luu for tronxy x5s

thingiverse

free

TRONXY XY2PRO by MaiMaiFACTORY

...tronxy xy2pro by maimaifactory

thingiverse

tronxy xy2-pro

sadebox

thingiverse

free

Power_supply_cover for TRONXY by Karollo

...power_supply_cover for tronxy by karollo

thingiverse

power supply cover for tronxy.

thingiverse

free

Tronxy support by d3m1sf

...tronxy support by d3m1sf

thingiverse

soporte para impresora tronxy x3.

thingiverse

free

Tronxy 13mm wrench

...tronxy 13mm wrench

thingiverse

13mm wrench for hotend fitting on tronxy x1...

thingiverse

free

Tronxy x5s by alex190074

...tronxy x5s by alex190074

thingiverse

tronxy x5s cart x fully adjustable only !!

thingiverse

free

Tronxy Logo

...tronxy logo

thingiverse

made this logo

thingiverse

free

Patas TronXY X3 - Vitofeli - TronXY Legs by Todopic

...todopic

thingiverse

patas separadoras para la tronxy x3, permite colocar la caja de control debajo y aprovechas mejor el espacio

thingiverse

free

TRONXY X5S EXTRUDER by ADAM98

...tronxy x5s extruder by adam98

thingiverse

tronxy x5s extruder

thingiverse

free

Belt tensioner Tronxy by jpalianak

...belt tensioner tronxy by jpalianak

thingiverse

belt tensioner tronxy

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)