Thingiverse

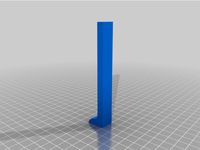

Z axis level indicator gauge (Dual Z axis stepper alignmen / synchronization check) by krahut

by Thingiverse

Last crawled date: 3 years, 4 months ago

This is an indicator tool for checking the synchronization of the two Z stepper motors at any time, even during printing. Thus, it can also be detected if one of the stepper motors has missed any steps or the steps sizes (layer height) are uneven. After homing, it shows the accuracy of alignment and if necessary the correct position of both motors easily adjustable again.

For printers with single motor Z system, this indicator also can be useful because it indicates the real level on Z axis compared to the shown value on the printer display.

If the scales and the rings are correctly mounted, the resolution of height indicator is 0.02mm (or with good eyes and estimating about 0.01mm). With this resolution, one can verify whether the printer is able or not the fine height positioning evenly on both sides over the full range of Z.

This indicator is designed for printers where one turn of Z stepper motor (lead screw) lifts the head by 8mm. This is a common 3D printer hardware setup many printers use it.

The ring inner diameter is 19mm, fits the most popular aluminum couplers. However, this size of the couplers is not critical so they are manufactured with a fairly large tolerance. Use the scaler tool in your slicer accordingly to get the proper indicator ring.

Why do we need it?

The dual-motor Z system easily loses its alignment to each other when the printer is off or the electronic disables the stepper motors (goes to idle). Any touching of the printer for example replacing filament, cleaning, etc may lead to skewing of the X-gantry in the XZ plane.

If this misalignment is not noticed, the extruder may rise at an angle stressing the printer mechanism or causes uneven layer heights, weak layer adhesion and spotty surfaced print (nozzle is not perpendicular to the bed). Skewed / tilted X-gantry is more sensitive to bent Z lead screws, causing periodic jamming during lifting the printer head what leads to inaccuracy of the fine positioning. It may even be stuck somewhere at any height. Skewed system also leads to faulty bed leveling.

Some videos for better understanding:https://youtu.be/8k2pWQ4To8shttps://youtu.be/dBP7pHOG7X0

For printers with single motor Z system, this indicator also can be useful because it indicates the real level on Z axis compared to the shown value on the printer display.

If the scales and the rings are correctly mounted, the resolution of height indicator is 0.02mm (or with good eyes and estimating about 0.01mm). With this resolution, one can verify whether the printer is able or not the fine height positioning evenly on both sides over the full range of Z.

This indicator is designed for printers where one turn of Z stepper motor (lead screw) lifts the head by 8mm. This is a common 3D printer hardware setup many printers use it.

The ring inner diameter is 19mm, fits the most popular aluminum couplers. However, this size of the couplers is not critical so they are manufactured with a fairly large tolerance. Use the scaler tool in your slicer accordingly to get the proper indicator ring.

Why do we need it?

The dual-motor Z system easily loses its alignment to each other when the printer is off or the electronic disables the stepper motors (goes to idle). Any touching of the printer for example replacing filament, cleaning, etc may lead to skewing of the X-gantry in the XZ plane.

If this misalignment is not noticed, the extruder may rise at an angle stressing the printer mechanism or causes uneven layer heights, weak layer adhesion and spotty surfaced print (nozzle is not perpendicular to the bed). Skewed / tilted X-gantry is more sensitive to bent Z lead screws, causing periodic jamming during lifting the printer head what leads to inaccuracy of the fine positioning. It may even be stuck somewhere at any height. Skewed system also leads to faulty bed leveling.

Some videos for better understanding:https://youtu.be/8k2pWQ4To8shttps://youtu.be/dBP7pHOG7X0

Similar models

thingiverse

free

Anet A6 Z Axis Synchronizer by prr8814

...s well as not restricting the z height of the printer as built.

https://www.youtube.com/watch?v=dw1pjbg8ybk&feature=youtu.be

thingiverse

free

X Gantry / Z Alignment by 3DPrintInGreece

... hand onto the tools. rotate the leadscrews to settle them and re-tighten the grub screws. raise the gantry and remove the tools.

grabcad

free

NEMA 17 Coupler

...which has a 5mm shaft. i modeled this off the coupler on my creality3d cr10s updated 3d printer with the dual z axis lead screws.

thingiverse

free

Prusa i3 Z-axis Coupler by rj_168

...od and stepper motor

5mm to 5mm coupler

3mm bolts used

try not to over tighten or it may split

has worked very well on my printer

thingiverse

free

CR-10 / 10s Dual Z-Axis Belt Synchronizer by frans84

...ight, to avoid given stress on both z axis rod

credit

the knob is designed by @skartz.https://www.thingiverse.com/thing:2562946

thingiverse

free

Z axis wobbling Terminator for TEVO Tornado, CR-10, Anet... by anunez

...anet... by anunez thingiverse tevo tornado, cr-10 and others similar printers come with a spring stepper coupler and no...

thingiverse

free

Z Axis Calibration tool by dusty256

...otor housing . print out two and you can place them on the z axis stepper motor housing to adjust the gantry to the same height .

thingiverse

free

CR-10 Gantry Levelling Blocks by CreateCafe3D

...on the blocks. then use the control box to move the z axis up, which will engage the steppers and keep it in the proper position!

thingiverse

free

Z axis leadscrew stepper rotation position indicator by OndrejP_SK

...e device attaches to the coupler and i can quickly check if the leadscrews are in the same starting position after homing z axis.

3dwarehouse

free

3D Printer Detailed Design

...gn

3dwarehouse

a design for a 3d printer. uses belt-and-pinion for x and y axes, dual lead screws and stepper motors for z axis.

Krahut

thingiverse

free

Ball (bead) chain gears by krahut

...ballchain.com/chain-sizes/

click like if you find a good one or write a comment if you feel there would be something to change...

thingiverse

free

Self winding pendulum clock (climbing weight for weight driven clocks) by krahut

...ls to protect the switch against the inductive voltage spikes. component added to the bom list. see photo about the installation.

Synchronization

turbosquid

$29

Gatsby Chandelier by Synchronicity

...chandelier by synchronicity for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1299138)

turbosquid

$60

The synchronous belt sander

...elt sander for download as 3ds, max, ige, obj, fbx, and sldas on turbosquid: 3d models for games, architecture, videos. (1424296)

3d_export

$5

Synchronization Symbol

...max 2015,blender,cinema4d obj fbx stl warning:dont forget to active turbosmooth after final modeling. enjoy 3d modeling good luck

3d_export

$60

the synchronous belt sander

...r the purchase.<br>designed with solidworks 2017, render with photoview 360<br>**************************************

3d_export

$14

turnover hydraulic mold base

...alistic, the innovation is the synchronous mechanism, there is a certain reference learning value, welcome to download and learn!

3d_export

$50

SDRAM 3D Model

...ccess memory dimm computer electronic double data rate dual in-line module laptop desktop

sdram 3d model plutonius 21264 3dexport

3d_export

$9

large lifting mechanism

...any questions also you can email to me. designed with solidworks 2017, render with keyshot **************************************

3d_export

free

profile gantry shifting mechanism

...any questions also you can email to me. designed with solidworks 2017, render with keyshot **************************************

cg_studio

$45

Wiper with transmission and drive unit3d model

...c4d .lwo .obj - wiper with transmission and drive unit 3d model, royalty free license available, instant download after purchase.

3d_export

$17

Automatic unloading mobile welding machine

...he solder joints are firm, and there are no burn marks. the welding speed is fast, and the operation is simple and easy to learn.

Gauge

3d_ocean

$10

Gauges

...rim to them. each gauge has an xpresso tag to give them an automatic animation without the need for keyframing and can be chan...

3d_export

$5

pressure gauge

...pressure gauge

3dexport

pressure gauge

3d_export

$5

gauge protector

...gauge protector

3dexport

gauge protector

3d_export

$5

Gauge 3D Model

...gauge 3d model

3dexport

gauge pressure gas air liquid

gauge 3d model fau 71180 3dexport

3d_export

$5

protected pressure gauge

...protected pressure gauge

3dexport

protected pressure gauge

3d_export

$5

hard gauge protector

...hard gauge protector

3dexport

hard gauge protector

turbosquid

$29

Screw Gauge

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$29

Marking Gauge

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Blade Gauge

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

12 Gauge 3D Model

...12 gauge 3d model

3dexport

shotgun shell gauge 12

12 gauge 3d model pirog 54511 3dexport

Indicator

3ddd

$1

Indice Sofa

...indice sofa

3ddd

indice sofa , roche bobois

indice sofa roche bobois

archive3d

free

Indicator 3D Model

...sor indicator pointer

indicator n130508 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$26

Km indicator

...squid

royalty free 3d model km indicator for download as max on turbosquid: 3d models for games, architecture, videos. (1153786)

turbosquid

free

Road Indicator

...d

royalty free 3d model road indicator for download as blend on turbosquid: 3d models for games, architecture, videos. (1299938)

turbosquid

$30

Dial Indicator

...ree 3d model dial indicator for download as 3ds, max, and obj on turbosquid: 3d models for games, architecture, videos. (1302779)

3d_export

$7

dial indicator

...r is any of various instruments used to accurately measure small distances and angles, and amplify them to make them more obvious

turbosquid

$3

Power Indicator

...ree 3d model power indicator for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1143828)

turbosquid

$50

Digital Indicator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

altitude indicator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Dial Indicator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Stepper

turbosquid

$85

Stepper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$22

Mini Stepper

...gymnastic indoor legs machine mini silver sport stepper trainer workout

3d model of silver and black mini stepper with a counter.

turbosquid

$3

stepper deluxe

...osquid

royalty free 3d model stepper deluxe for download as on turbosquid: 3d models for games, architecture, videos. (1284335)

turbosquid

$49

Stepper Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Fitness Stepper

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

stepper motor driver

...stepper motor driver for download as , fbx, dae, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1688860)

turbosquid

$1

Stepper motor driver

... model stepper motor driver for download as obj, stl, and ige on turbosquid: 3d models for games, architecture, videos. (1577811)

3d_export

$5

Stepper motor Nema17 17HS4401

...stepper motor nema17 17hs4401

3dexport

turbosquid

$1

Nema 17 Stepper motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Nema 17 Stepper Motor 59Nm

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Dual

turbosquid

free

Dual Pistols

...ls

turbosquid

free 3d model dual pistols for download as fbx on turbosquid: 3d models for games, architecture, videos. (1320360)

turbosquid

$2

Dual Axe

...urbosquid

royalty free 3d model dual axe for download as fbx on turbosquid: 3d models for games, architecture, videos. (1332372)

turbosquid

$10

Dual Lesaths

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

плитка Dual Bianco (Испания)

...й плитки venis dual (испания). технические качества: устойчивость к стирания, отличная геометрия, отсутствие проблем при укладке.

turbosquid

$35

Dual Mesh Fonts

...ree 3d model dual mesh fonts for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1352989)

turbosquid

$29

Dual Flask with Bungs

...del dual flask with bungs for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1210512)

turbosquid

$19

Dual Socket Plug

...3d model dual socket plug for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1303912)

turbosquid

$13

Dual Adjustable Pulley

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Amoi N809 Dual

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Dual Turret Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)

Level

design_connected

$11

Levels

...levels

designconnected

one nordic levels computer generated 3d model. designed by form us with love.

design_connected

$7

Level

...level

designconnected

zanotta level shelves and storage computer generated 3d model. designed by arik levy.

turbosquid

$29

level

...ty free 3d model level for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1272856)

turbosquid

$1

level

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Mario level

...mario level

3dexport

mario level low quality for fun videos

3ddd

$1

LEVELS OF DISCOVERY

...етская мебель "levels of discovery". rab10003 princess mini rocker

кресло-качалка (мини) "принцесса навсегда"

3d_export

$19

level design

...level design

3dexport

you can use this design (level design) in your own game.

turbosquid

$60

Desert level

...squid

royalty free 3d model desert level for download as fbx on turbosquid: 3d models for games, architecture, videos. (1208131)

turbosquid

$15

Transit Level

...quid

royalty free 3d model transit level for download as max on turbosquid: 3d models for games, architecture, videos. (1158112)

turbosquid

$14

Districts Level

...id

royalty free 3d model districts level for download as max on turbosquid: 3d models for games, architecture, videos. (1408410)

Check

design_connected

$18

Cross Check

...cross check

designconnected

knoll cross check computer generated 3d model. designed by gehry, frank.

turbosquid

$39

Check in Desk

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Check Valve

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

check valve

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Coloro Check Room

...coloro check room

3ddd

check board design at , 3ds max + vray

3ddd

$1

Spor check shoes

...s , sporcheck

simple spor check shoes using unwarp uvw for texturing .. hope you like it

turbosquid

$59

Woman in checked shirt

...alty free 3d model woman in checked shirt for download as obj on turbosquid: 3d models for games, architecture, videos. (1507064)

turbosquid

$50

check valve parametric

...alty free 3d model check valve parametric for download as rfa on turbosquid: 3d models for games, architecture, videos. (1522639)

turbosquid

$65

check in counter

...ree 3d model check_in_counter for download as ma, ma, and fbx on turbosquid: 3d models for games, architecture, videos. (1519701)

archive3d

free

Check-point 3D Model

...d

check-point

check point - kpp n200208 - 3d model (*.gsm+*.3ds) for interior 3d visualization.