Thingiverse

Yellowjacket Quad by makermand

by Thingiverse

Last crawled date: 4 years, 8 months ago

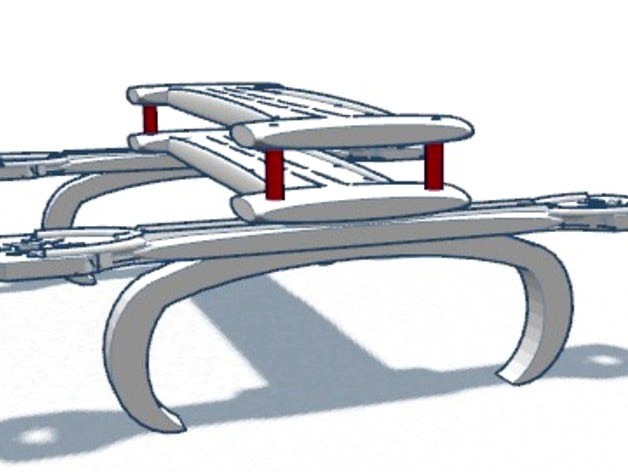

A racing quad design. Inspired by so many different 250 class racers.

Its modular and you can actually mount it together in different ways. For example, with the arms mid-deck (as shown) it has a nice COB for racing and sufficient room for the battery underbelly and camera mid deck.

You could mount the arms topdeck and hang a small gimble underneath. the props would be well clear and having the arms top deck would mean you could use larger props than the standard 5 inchers.

Printing in ABS

the decks and arms are done 0.4mm nozzle with 0.32mm layer height and 3 perimeters with 50% infill. Skids don't need to be as tough so 25% infill should be good. I actually want the skid to be a weak point so that in the event of a crash they go first. You will note that 4 long m3 bolts hold the majority of the structure together and subsequently the impact forces will be imparted on the skids.

Get some standoffs and m3 bolts, long ones like 35mm for the main assembly, some short 10mm ones for top deck. I fly it with sunnysky 2204 2300kv's on 3s with afro esc's

Feel free to mod the parts to fit your favourite components !!

Additional notes:

When I was making the first versions of this quad I was actually running into some interesting structural issues. For example, the first versions of the decks where simply solid flat extrusions of a 2d drawing. I was simply making lineare infill at 0degrees to the y axis and you can imagine what happened, they would twist over the length!! Also, when getting some loading they would vibrate like hell. So I went back to basics and created a shape based on 3d shapes, I also changed my infill pattern to +45 and -45 degrees to the Y axis to imitate the effect of biaxial glass in composites. Addidionally I added the long loops down the middle. By making sure I slice with 3 perimiters I ensure a nice strong truss system. With the arms I ran in to the same issues but they were more difficult to deal with because the size of the object limits the type of tricks you can do, in addition to which i wished to make the arms longer than I had them originally so I could fit the deck lower and not whack props into the standoffs. I also went to 3 perimeters and I added some 3d structure to the shape to add some truss and I also increased the infill density, my latest arms are 55% infill, lineare but at +45/-45 to print axis (depending on your bed size you may need to print them across so do the math to ensure your infill pattern is correct). I fly them now with sunnysky 2300kvs and HQ 5045 on 3s and it works nicely but I can imagine if you go 4s it may be dodgy so I am working on a solution. One of which may be to make a longitudinal groove where you can glue in a carbon flatrod but we'll see how it goes. If you guys tinker up a solution please share!

{feb 15} edit: I am back to 5030 props for power consumption reasons

Its modular and you can actually mount it together in different ways. For example, with the arms mid-deck (as shown) it has a nice COB for racing and sufficient room for the battery underbelly and camera mid deck.

You could mount the arms topdeck and hang a small gimble underneath. the props would be well clear and having the arms top deck would mean you could use larger props than the standard 5 inchers.

Printing in ABS

the decks and arms are done 0.4mm nozzle with 0.32mm layer height and 3 perimeters with 50% infill. Skids don't need to be as tough so 25% infill should be good. I actually want the skid to be a weak point so that in the event of a crash they go first. You will note that 4 long m3 bolts hold the majority of the structure together and subsequently the impact forces will be imparted on the skids.

Get some standoffs and m3 bolts, long ones like 35mm for the main assembly, some short 10mm ones for top deck. I fly it with sunnysky 2204 2300kv's on 3s with afro esc's

Feel free to mod the parts to fit your favourite components !!

Additional notes:

When I was making the first versions of this quad I was actually running into some interesting structural issues. For example, the first versions of the decks where simply solid flat extrusions of a 2d drawing. I was simply making lineare infill at 0degrees to the y axis and you can imagine what happened, they would twist over the length!! Also, when getting some loading they would vibrate like hell. So I went back to basics and created a shape based on 3d shapes, I also changed my infill pattern to +45 and -45 degrees to the Y axis to imitate the effect of biaxial glass in composites. Addidionally I added the long loops down the middle. By making sure I slice with 3 perimiters I ensure a nice strong truss system. With the arms I ran in to the same issues but they were more difficult to deal with because the size of the object limits the type of tricks you can do, in addition to which i wished to make the arms longer than I had them originally so I could fit the deck lower and not whack props into the standoffs. I also went to 3 perimeters and I added some 3d structure to the shape to add some truss and I also increased the infill density, my latest arms are 55% infill, lineare but at +45/-45 to print axis (depending on your bed size you may need to print them across so do the math to ensure your infill pattern is correct). I fly them now with sunnysky 2300kvs and HQ 5045 on 3s and it works nicely but I can imagine if you go 4s it may be dodgy so I am working on a solution. One of which may be to make a longitudinal groove where you can glue in a carbon flatrod but we'll see how it goes. If you guys tinker up a solution please share!

{feb 15} edit: I am back to 5030 props for power consumption reasons