Thingiverse

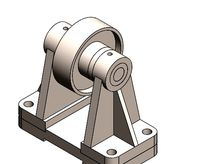

Yarn/Wool Winder All printed power tool driven by DAC3D7

by Thingiverse

Last crawled date: 3 years, 3 months ago

Yarn/Wool Winder - 3D Printed - Power Tool Driven

This design only uses printed parts, no additional screws or bearings are required. To do this I have used large printed screws and threads. The all printed Yarn Winder runs surprisingly well and I have seen no wear at all after the equivalent of 50 skeins of wool.

The yarn winder is all printed, clamps to a desk or counter and is powered by a cordless Drill/Driver using a 9/16 inch or 14 mm socket.

Demos and assembly video on Youtube.https://youtu.be/086WCk0imxk

Parts and printing suggestions (See diagram)

I used PLA for all parts and increased the wall thickness from 1.2 mm to 3.6 mm to get the strength I needed.

Main Body - Wall thickness 3.6 mm. Support everywhere. 3 times the normal thickness to add strength for the G Clamp and screw thread. I used 20% infill everywhere but you can go higher.

Gear 1 - Standard wall thickness 1.2 mm

Gear 2 - Standard wall thickness 1.2 mm

Center Gear - Wall thickness 3.6 mm. Supports - touching build plate

Large Gear - Standard wall thickness 1.2 mm - no supports

Large Gear Screw - Wall thickness 3.6 mm. Supports - touching build plate

G-Clamp Screw - Wall thickness 3.6 mm. Supports - none

Center gear Tool - Standard wall thickness 1.2 mm no supports

I have provided the AMF/STL files in the position I printed the parts.

Optional

Gear 2 Lid. Standard wall thickness 1.2 mm No supports

Counter Weights

Yarn Guide/Tension - Wall thickness 3.6 mm. Support everywhere. 3 times the normal thickness to add strength for the G Clamp and screw thread. I used 20% infill everywhere but you can go higher. The Yarn Guide/Tension uses the same G-Clamp screw as the Winder.

Assembly instructions in the attached document

This design only uses printed parts, no additional screws or bearings are required. To do this I have used large printed screws and threads. The all printed Yarn Winder runs surprisingly well and I have seen no wear at all after the equivalent of 50 skeins of wool.

The yarn winder is all printed, clamps to a desk or counter and is powered by a cordless Drill/Driver using a 9/16 inch or 14 mm socket.

Demos and assembly video on Youtube.https://youtu.be/086WCk0imxk

Parts and printing suggestions (See diagram)

I used PLA for all parts and increased the wall thickness from 1.2 mm to 3.6 mm to get the strength I needed.

Main Body - Wall thickness 3.6 mm. Support everywhere. 3 times the normal thickness to add strength for the G Clamp and screw thread. I used 20% infill everywhere but you can go higher.

Gear 1 - Standard wall thickness 1.2 mm

Gear 2 - Standard wall thickness 1.2 mm

Center Gear - Wall thickness 3.6 mm. Supports - touching build plate

Large Gear - Standard wall thickness 1.2 mm - no supports

Large Gear Screw - Wall thickness 3.6 mm. Supports - touching build plate

G-Clamp Screw - Wall thickness 3.6 mm. Supports - none

Center gear Tool - Standard wall thickness 1.2 mm no supports

I have provided the AMF/STL files in the position I printed the parts.

Optional

Gear 2 Lid. Standard wall thickness 1.2 mm No supports

Counter Weights

Yarn Guide/Tension - Wall thickness 3.6 mm. Support everywhere. 3 times the normal thickness to add strength for the G Clamp and screw thread. I used 20% infill everywhere but you can go higher. The Yarn Guide/Tension uses the same G-Clamp screw as the Winder.

Assembly instructions in the attached document

Similar models

thingiverse

free

Wool Winder

...o planning to improve the attachment method for the gears. once i've got all this sorted, i'll move on to the yarn swift.

thingiverse

free

Wool Winder Cone and Sleeve by yasmin_k

...; those cones are very difficult to acquire here.

i am very new to this 3d printing and designing process, so please be gentle :)

thingiverse

free

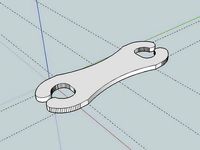

Optimized G-clamp by FransJ

... you print it standing with supports.

looking for a job in the am industry, please contact me on contact@fransjohansson.se

enjoy!

thingiverse

free

Hollow cone for standard electric yarn winder by kerri9494

...up arm of a standard electric yarn winder like this one http://www.amazon.com/simplicity-boye-electric-yarn-winder/dp/b002vrf7hq.

thingiverse

free

Wool / Yarn Winder support by mbafford

...had the excellent idea of just using a spring to push the arm out so it stays locked. but that person must not have a 3d printer.

thingiverse

free

Indicator light housing Neon LED for panel mount by seba1337

...with setting: 2 mm thickness wall, which causes to have no infill, just walls.

height resolution was 0.12 mm using 0.4 mm nozzle.

thingiverse

free

Aquarium water change hose holder clamp by Egghebrecht

...and click on the pads and it's ready for use

design compatible with the longer screw and smaller pad from the original design

thingiverse

free

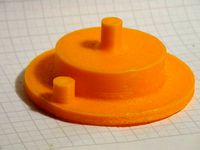

MBI Large spool winder tool for powerdrill by hjorthmobile

...er drill adaptor. i used liquid abs/acetone to cast the exact match for the bit. printed in orange abs on the 5th gen replicator.

thingiverse

free

Yarn Winder (gear driven) by Seminex222

...t

yarnguide:

i tapped a m4 thread into it and bent a small keychain-ring to make the guide

if something is unclear - improvise :d

thingiverse

free

Cone for Yarn Winder, small skeins

...in https://www.thingiverse.com/thing:1963818

i printed 6 prototypes, refining and correcting the design to get what you see here.

Yarn

turbosquid

$2

Yarn Bowl

...urbosquid

royalty free 3d model yarn bowl for download as ma on turbosquid: 3d models for games, architecture, videos. (1505055)

turbosquid

$7

Y for Yarn

...d

royalty free 3d model y for yarn model for download as max on turbosquid: 3d models for games, architecture, videos. (1699732)

turbosquid

$2

Knitting Needles Plus Yarn

...y free 3d model knitting needles plus yarn for download as ma on turbosquid: 3d models for games, architecture, videos. (1505048)

turbosquid

$49

yarn wire mouse toy

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$8

ball of yarn

...;- normal<br>- roughness<br>2048x2048 png texture<br>320 poly<br>162 vert<br>in subdivision level 0

3ddd

free

SPOTLIGHT SILVER

...set design. a feat of craftsmanship, the darker wool yarn gradually fade into the pale silk centre, creating a...

3d_export

$10

Drum Sticks 3D Model

...mallet drum stick sticks beater instrument tool bass pair yarn kit wrapped musical music acoustic drumset drummer snare gong...

3d_export

$10

Drum Mallet 3D Model

...mallet drum stick sticks beater instrument tool bass pair yarn kit wrapped musical music acoustic sound drumset drummer snare...

3d_export

$15

Spinning Wheel 3D Model

...spinning wheel 3d model 3dexport spinning wheel thread yarn fibres spindle machine ancient vintage historic hand wooden wood...

3d_ocean

$5

Tangle of thread

...red ropemaking sewing spokes synthetic tangle textiles thread weaving yarn tangle of thread project features: the scene consists of...

Winder

turbosquid

$10

window strap winder (external)

...del window strap winder (external) for download as ma and fbx on turbosquid: 3d models for games, architecture, videos. (1281687)

3d_export

$14

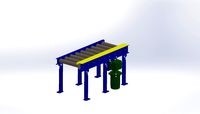

winder textile special equipment

...s a role of "bridge" connecting the preceding and the following, so it plays an important role in the field of textile.

3d_export

$30

gold pocket watch

...(parented to watch)<br>hour hand (parented to watch)<br>lid (parented to watch)<br>winder (parented to watch)<br>pocketwatch - 2k -<br>diffuse<br>roughness<br>normal - (opengl unity...

3d_export

$30

helmets hats pack lowpoly

...newsboy cap sun cap war guard helmet winter cap winder fold cap<br>fbx-embed texture fbx<br>mb(maya binary)<br>obj<br>blender file only exports without...

3d_export

$32

speed reducer gear box worm helical wpx

...common household uses are washing machines, food blenders and window-winder. reduction drives are also used to decrease the rotational...

thingiverse

free

Side Winder by airdronez

...side winder by airdronez

thingiverse

side winder

thingiverse

free

Earphone winder by wangdong

...earphone winder by wangdong

thingiverse

a simple but useful earphone winder.

thingiverse

free

Earphone Winder by wangdong

...earphone winder by wangdong

thingiverse

a simple but useful earphone winder.

thingiverse

free

Spool Winder by Verohomie

...spool winder by verohomie

thingiverse

spool winder for a cordless drill

thingiverse

free

Cable Winder by kazsoft

...cable winder by kazsoft

thingiverse

just a simple cable winder.

Wool

3d_ocean

$3

Wool texture

...wool texture

3docean

seamless wool texture

3d_ocean

$3

Naturally wool texture

...naturally wool texture

3docean

carpet fabric seamless textilem naturally wool

seamles texture of wool.

3d_ocean

$3

Gray wool texture

...gray wool texture

3docean

carpet chair clothes fabric furniture sofa wool

seamles texture of wool

turbosquid

$19

Wool Sofa

...rbosquid

royalty free 3d model wool sofa for download as max on turbosquid: 3d models for games, architecture, videos. (1158509)

turbosquid

$5

Wool Snowman

... 3d model wool snowman for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1264202)

design_connected

$16

Studded Wool Curtain

...studded wool curtain

designconnected

studded wool curtain computer generated 3d model.

3d_ocean

$4

Blue seamless wool

...blue seamless wool

3docean

blue seamless wool texture. diffuse and bump are included.

3d_ocean

$3

Wool seamless texture

...wool seamless texture

3docean

great seamless texture of white wool. resolution: 3000×3000px

design_connected

$16

Geo Wool Kilim

...geo wool kilim

designconnected

west elm geo wool kilim computer generated 3d model.

design_connected

$16

Asymetric Wool Rug

...asymetric wool rug

designconnected

west elm asymetric wool rug computer generated 3d model.

Driven

turbosquid

$50

CHAIN DRIVEN CONVEYOR

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

driven shaft of the lump crusher

...driven shaft of the lump crusher

3dexport

3d_export

$27

n95 full servo driven mask printer

...n95 full servo driven mask printer

3dexport

n95 full servo driven mask printer

turbosquid

$16

(Project) Food packing helper machine with holding clamp and press table driven by an actuator

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$47

the fifth generation of one driven two new mask machine

...ing, lamination, pressing, ear band tapping, ultrasonic, etc. the structure of the model is detailed, including model parameters.

3d_export

$15

industrial belt-driven air cooler

...leaning up necessary, just drop your models into the scene and start rendering/texturing. no special plugin needed to open scene.

3d_export

free

golf cart

...golf cart 3dexport golf cart for golfers to be driven in...

3d_export

$10

design and assembly of pulley

...pulley 3d model which is used for drive and driven ...

archive3d

free

Windmill 3D Model

...windmill 3d model archive3d wind turbine wind-driven powerplant wind-electric set windmill n181208 - 3d model (*.gsm+*.3ds)...

3d_export

$30

Compressed Air Engine 3D Model

...motor flywheel shaft camshaft piston valve block engineering compressed-air driven compressed air engine 3d model zenmunster 92451...

Power

turbosquid

$100

power

...ower

turbosquid

royalty free 3d model power for download as on turbosquid: 3d models for games, architecture, videos. (1421990)

3d_export

$5

Power

...power

3dexport

3d_export

$5

power outlets

...power outlets

3dexport

power outlets

3ddd

$1

lion power

...lion power

3ddd

лев , статуя

lion power gold sculpture

3ddd

$1

Sea Power

...

компас , море , часы

часы с компасом sea power

3ddd

free

Meridiani / Power

...power

3ddd

meridiani , круглый

стол power производитель meridiani, диаметр 120,высота 67

3d_export

$5

Power Surge

...power surge

3dexport

the power surge is a all mesh carnival ride to lower in game part count and lag

turbosquid

$8

Airport Ground Power Unit (AXA Power )

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

Power Houser

...rbosquid

royalty free 3d model power houser for download as on turbosquid: 3d models for games, architecture, videos. (1333800)

3d_export

$5

power outlet

...power outlet

3dexport

power outlet<br>format file maya 2018, 3d max 2017, obj, fbx

Tool

turbosquid

$21

Tool box with tools

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archibase_planet

free

Tools

...tools

archibase planet

tools instruments implements

tools n070114 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

3d_ocean

$12

Tools

...tools

3docean

hammer metal old screw tools wrench

maya

turbosquid

$6

Tool Cart / Tool Box

...

royalty free 3d model tool cart / tool box for download as on turbosquid: 3d models for games, architecture, videos. (1241859)

3d_ocean

$15

crimp tool

... tool copper cutter crimp crimp tool electrical electrical tools press tools pressing tool tools wire cutter

created in maya 2013

3d_ocean

$5

Tools

...tools

3docean

3d models paint tools work

3d,models,works,paint,art,create,working,

3d_export

free

tools

...tools

3dexport

coldsteel

turbosquid

$15

Tools

...turbosquid

royalty free 3d model tools for download as blend on turbosquid: 3d models for games, architecture, videos. (1331352)

3ddd

$1

bar tool

...bar tool

3ddd

барный

bar tool

turbosquid

$35

tools

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

All

turbosquid

$20

all

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

all

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$29

All-Two

...all-two

designconnected

bonaldo all-two computer generated 3d model. designed by bicego, sergio.

design_connected

$29

All-One

...all-one

designconnected

bonaldo all-one computer generated 3d model. designed by bicego, sergio.

design_connected

$16

Holly All

...holly all

designconnected

serralunga holly all computer generated 3d model. designed by starck, philippe.

3d_export

$15

all terrain

...all terrain

3dexport

turbosquid

$29

Holly All

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Fireplace (All)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Printed

design_connected

$27

...print

designconnected

moroso print computer generated 3d model. designed by wanders, marcel.

3ddd

free

Eichholtz Prints

...- eichholtz print central station i

13 - eichholtz print central station ii

14 - eichholtz print marisa

15 - eichholtz print tish

3ddd

$1

Eichholtz Prints

...print abstract - set of 2

10 - eichholtz print orange abstract

11 - eichholtz print buddha right

12 - eichholtz print buddha left

turbosquid

$1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Eichholtz Prints

...of 4

2 - print dunbar 2 set of 4

3 - print guadeloupe 1 set of 4

4 - print guadeloupe 2 set of 4

5 - print giles

6 - print trett

3ddd

$1

Eichholtz Prints

...nt tutti frutti

3 - eichholtz prints watson - set of 2

4 - eichholtz prints antique nautilus - set of 2

5 - eichholtz print tiara

3d_export

$5

Monster for printing

...monster for printing

3dexport

monster 3d model printing

3ddd

free

printed rug

...printed rug

3ddd

ковер

very creative printed rug

3ddd

free

Eichholtz Prints

...иал: бумага

габариты (вхш): 72 x 62 см

описание: print sweetmeat - постер в деревянной раме.

3 - prints varsity set of 2

арти

3ddd

free

Art Print Posters

...art print posters

3ddd

прованс

art print posters by patrician prints