Thingiverse

YALFE V2 - YET ANOTHER LYMAN'S FILAMENT EXTRUDER V2 by Cos

by Thingiverse

Last crawled date: 3 years ago

PLEASE CHECK YALFE 3!http://www.thingiverse.com/thing:951240

YES, V2 IS HERE!

Of course, it follows Lyman's ideas on spooling, but with some new ideas on cooling and spooling the filament.

This work is now working correctly (as of 30/3/2014)

Subsystems:

Extruder.

-It is the original YALFE but with the new voltage regulator.

-i also pulled 12v to supply the other sub systems.

Cooling.

-i used air flow from a big fan. Fan dimensions will follow

Pulling.

-I substituted the rollers with a simple foam wrap. i warped them around a 8mmthreaded rod. it works well but cannot stand hot filament. Silicone rollers work awsome, if you can find 35mm diam of silicone rod. Just drill a hole 7,5 mm and screw the 8mm thread.

Now i am using Polyurethane rollers from 35mm dia polyurethane rod. Same principle with silicone rollers. It pulls great!

-I used simple voltage regulators to regulate motor rpm, my idea seems to work fine. i just need to make it cooperate with extruder's speed.

-The motor regulator i fount, is like this.. http://www.ebay.com/itm/CCM6N-Dc-Motor-Speed-Regulator-6v-12v-24v-200w-Reversing-switch-/161001883584?pt=LH_DefaultDomain_0&hash=item257c75c7c0

-The motor is the cheapest geared motor at 12v.

Spooling.

I used the thing http://www.thingiverse.com/thing:29526

i modified some parts to make them work with motor.

The spooling motor (12v) is a loot form an old inkjet, also the timing belt.

Both were taken from the x carriage that was driving the printer head.

Fotos show the setup.

More to follow.UPDATE 1/3/2014

I finally got the time to give some thought to the pulling problem and i concluded that it is better to purchase another geared motor with lower rpm. Besides, the one i currently have (12v, 120rmp) was from another, abandoned project.

So while waiting for the correct motor (12v, 10 rmp), i put the final touches on the mini shredder that will make the ''YALFE V2'' a complete recycling system for 3d printers.UPDATE 1/4/2014

Filament extrusion and spooling successful!

i let the machine work for 9 hours (all night) and extruded all the pellets.

However, a minor accident i had at the end of extrusion, let the machine work without pellets for about 2 hours. This made me think of some safety features that i have to apply, in order to let the machine work all night unattended but with safety.

I will explain them at the final version of YALFE, the

MO.RE.SYS 3D (modular recycling system for 3D printers).

The tested plastic was HDPE for water piping (this was the only type of plastic for extrusion that i got for free)

extrusion temp was at 270~295 C.

Tolerances were a bit tricky, i got a fluctuation between 2,6 and 3,0 periodically but not more or less than that. Ovality, on the other hand had the same fluctuation and seemed to counterbalance the tolerance.

i mean that if, for example, i measured 2,6 on one axis, when i rotate the micrometer by 90o at the same spot, the other axis was 3,0 and vice-verse. This means that even with this tolerance play, the mean diameter is stable!

In MORESYS 3D i will explain with every detail on how to tune the pid controller, how to set the machine, how to set the safety equipment for overnight, unattended extrusion etc. Stay tuned!

YES, V2 IS HERE!

Of course, it follows Lyman's ideas on spooling, but with some new ideas on cooling and spooling the filament.

This work is now working correctly (as of 30/3/2014)

Subsystems:

Extruder.

-It is the original YALFE but with the new voltage regulator.

-i also pulled 12v to supply the other sub systems.

Cooling.

-i used air flow from a big fan. Fan dimensions will follow

Pulling.

-I substituted the rollers with a simple foam wrap. i warped them around a 8mmthreaded rod. it works well but cannot stand hot filament. Silicone rollers work awsome, if you can find 35mm diam of silicone rod. Just drill a hole 7,5 mm and screw the 8mm thread.

Now i am using Polyurethane rollers from 35mm dia polyurethane rod. Same principle with silicone rollers. It pulls great!

-I used simple voltage regulators to regulate motor rpm, my idea seems to work fine. i just need to make it cooperate with extruder's speed.

-The motor regulator i fount, is like this.. http://www.ebay.com/itm/CCM6N-Dc-Motor-Speed-Regulator-6v-12v-24v-200w-Reversing-switch-/161001883584?pt=LH_DefaultDomain_0&hash=item257c75c7c0

-The motor is the cheapest geared motor at 12v.

Spooling.

I used the thing http://www.thingiverse.com/thing:29526

i modified some parts to make them work with motor.

The spooling motor (12v) is a loot form an old inkjet, also the timing belt.

Both were taken from the x carriage that was driving the printer head.

Fotos show the setup.

More to follow.UPDATE 1/3/2014

I finally got the time to give some thought to the pulling problem and i concluded that it is better to purchase another geared motor with lower rpm. Besides, the one i currently have (12v, 120rmp) was from another, abandoned project.

So while waiting for the correct motor (12v, 10 rmp), i put the final touches on the mini shredder that will make the ''YALFE V2'' a complete recycling system for 3d printers.UPDATE 1/4/2014

Filament extrusion and spooling successful!

i let the machine work for 9 hours (all night) and extruded all the pellets.

However, a minor accident i had at the end of extrusion, let the machine work without pellets for about 2 hours. This made me think of some safety features that i have to apply, in order to let the machine work all night unattended but with safety.

I will explain them at the final version of YALFE, the

MO.RE.SYS 3D (modular recycling system for 3D printers).

The tested plastic was HDPE for water piping (this was the only type of plastic for extrusion that i got for free)

extrusion temp was at 270~295 C.

Tolerances were a bit tricky, i got a fluctuation between 2,6 and 3,0 periodically but not more or less than that. Ovality, on the other hand had the same fluctuation and seemed to counterbalance the tolerance.

i mean that if, for example, i measured 2,6 on one axis, when i rotate the micrometer by 90o at the same spot, the other axis was 3,0 and vice-verse. This means that even with this tolerance play, the mean diameter is stable!

In MORESYS 3D i will explain with every detail on how to tune the pid controller, how to set the machine, how to set the safety equipment for overnight, unattended extrusion etc. Stay tuned!

Similar models

thingiverse

free

LYMAN FILAMENT SPOOL WINDER by hlyman

...ccessory to the lyman filament extruder, wherein the winder winds onto a spool the filament as it is extruding from the extruder.

thingiverse

free

Lyman Cardboard Filament Spool by hlyman

...ost nothing if on hand scrap material is used, such as cardboard. the designed spool holds 1 kg of filament used in 3d printers.

thingiverse

free

Roller and Filament Guides for Anet A8 Filament Spool Roller System by N6MQD

...he spool.

i also designed the clips to also snap to the rod. the clips prevent the roller bearings from sliding out of position.

thingiverse

free

Filament spool rollers by Deltabay

...o help creality spool roll easier. once i used it the filament stepper motor was quieter. since easier to pull off the filament.

thingiverse

free

Filament Spool Roller by Paxy

...roller decrease resistance of pooling filament and pressure on extruder motor.

radius 50mm.

total length 83mm.

inner radius 15mm.

thingiverse

free

LYMAN FILAMENT EXTRUDER by hlyman

...llets for use in a 3d printer. it can extrude 1.75mm and 3mm filament with easy nozzle exchange. the material cost is about $250.

thingiverse

free

Lyman Filament extruder Gear for Russian VAZ wiper motor by Ieshua

...artible for vaz motor. it have cone mount for better compartible and hex for easy assembling) good work with vaz 2101 wiper motor

thingiverse

free

Filament Spool Roller for 2020 Aluminum Extrusion by Delphius

...m rough at first but are perfectly adequate after you break them in. designed using onshape. fits minimum spool diameter of 43mm.

thingiverse

free

Rostock Max V2 Spool Spin Smoother by Agisis

...holder is square at the top so each time the extruder pulled in filament, the machine would jerk a bit. this solved that problem.

thingiverse

free

Spool Roller for aluminum extrusion 2020 printers by gyronictonic

...+meters

can substitute 608zz flanged bearing with printed 608 idler pulleyshttp://www.thingiverse.com/search?q=608+pulley&sa=

Yalfe

thingiverse

free

YALFE - YET ANOTHER LYMAN'S FILAMENT EXTRUDER by Cos

...used for 3d printing.

in 'instructions' section, i also explain some serious issues i confronted and how i solved them.

thingiverse

free

MO.RE.SYS. 3D (YALFE 3) by Cos

...ere is incomplete.

again a big thanks to hugh lyman for making me believing that i can make a home filament extruder on my own.

Lyman

turbosquid

$25

Lyman Street Sofa

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

sketchfab

$15

Lyman Hyde

...

u.s. navy

date of death

may 23, 1894

age at death

50 - lyman hyde - buy royalty free 3d model by cvm (@capturevisualmarketing)

thingiverse

free

Lyman from Animal Crossing by TroySlatton

...lyman from animal crossing by troyslatton

thingiverse

fanart of lyman from animal crossing

thingiverse

free

LYMAN FILAMENT SPOOL WINDER by hlyman

...ccessory to the lyman filament extruder, wherein the winder winds onto a spool the filament as it is extruding from the extruder.

thingiverse

free

Laser cut spool for lyman v5 by trget

...lyman v5 by trget

thingiverse

this is a laser cut spool for the lyman v5. it should match the dimensions for the lyman v5 spool.

thingiverse

free

Lyman Bunny by tomburtonwood

...lyman bunny by tomburtonwood

thingiverse

scanned with the makerbot digitizer desktop 3d scanner

thingiverse

free

Turret Stand for Lyman T-Mag by euler357

...turret stand for lyman t-mag by euler357

thingiverse

this is a stand to hold the lyman t-mag turrets.

thingiverse

free

LYMAN FILAMENT EXTRUDER by hlyman

...llets for use in a 3d printer. it can extrude 1.75mm and 3mm filament with easy nozzle exchange. the material cost is about $250.

thingiverse

free

Lyman Cardboard Filament Spool by hlyman

...ost nothing if on hand scrap material is used, such as cardboard. the designed spool holds 1 kg of filament used in 3d printers.

thingiverse

free

Lyman T-Mag Turrent Wall Mount by euler357

...lyman t-mag turrent wall mount by euler357

thingiverse

made this to hold lyman t-mag turrets on the wall

Cos

turbosquid

$15

Robot Co

...alty free 3d model robot co for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1351209)

turbosquid

$10

co carton

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Heathfield&Co Verdi

...heathfield&co verdi

3ddd

heathfield&co

лампа настольная heathfield&co; verdi

3ddd

$1

стол Moletta&Co

...стол moletta&co

3ddd

стол moletta&co;

3ddd

$1

Gervasoni Letti&Co

...га , картина , тумбочка

gervasoni letti&co;

3ddd

free

Комод в стиле rocco-co

...occo-co , комод , резьба

комод в стиле rocco-co

turbosquid

$5

Barr-Co Salt

...squid

royalty free 3d model barr-co salt for download as max on turbosquid: 3d models for games, architecture, videos. (1149267)

turbosquid

$2

Co working space

...id

royalty free 3d model co working space for download as ma on turbosquid: 3d models for games, architecture, videos. (1477968)

3ddd

free

heathfield & co lotus gold

...heathfield & co lotus gold

3ddd

heathfield&co

heathfield & co lotus gold - 620h

3ddd

$1

Heathfield & Co Bayern Ivory

... bayern ivory

3ddd

heathfield&co , bayern ivory

heathfield & co bayern ivory

V2

3d_export

free

Lamp v2

...lamp v2

3dexport

lamp v2 with solar panel

3d_export

$5

hammerhead v2

...hammerhead v2

3dexport

razer hammerhead v2 headphones, modeled in cinema 4d, render in corona

3d_export

$5

manometer v2

...manometer v2

3dexport

3d_export

$5

potato v2

...potato v2

3dexport

turbosquid

$52

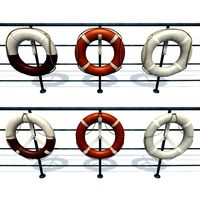

Lifebuoys v2

...squid

royalty free 3d model lifebuoys v2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1560870)

turbosquid

$2

Mask v2

...turbosquid

royalty free 3d model mask v2 for download as stl on turbosquid: 3d models for games, architecture, videos. (1527741)

turbosquid

free

Flashlight V2

...d

free 3d model flashlight v2 for download as , obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1663559)

turbosquid

$29

Thanos v2

...

royalty free 3d model thanos v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1651077)

turbosquid

$29

Titan v2

...d

royalty free 3d model titan v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1540228)

turbosquid

$29

Frieza v2

...

royalty free 3d model frieza v2 for download as ztl and obj on turbosquid: 3d models for games, architecture, videos. (1701238)

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Another

turbosquid

$15

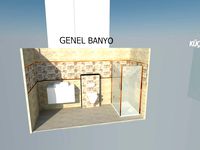

ANOTHER BATHROOM

...quid

royalty free 3d model another bathroom for download as on turbosquid: 3d models for games, architecture, videos. (1171460)

turbosquid

$24

Another World

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Another Red Curb

...ee 3d model another red curb for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1182913)

turbosquid

$9

Another Deberenn Sofa

...model another deberenn sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1497850)

turbosquid

$2

Another picnic table

... model another picnic table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1426381)

turbosquid

$15

door to another world

...oor to another world for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1334842)

3d_export

free

another hacksaw

...another hacksaw

3dexport

. . . 3d model of a hacksaw. 3d model files: - 3ds max 2017 (scanline) - obj (low poly) . . .

turbosquid

$12

Another Country Side Table

... another country side table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1496053)

turbosquid

$29

Furniture - "Another country" modern sofa

...another country" modern sofa for download as obj and c4d on turbosquid: 3d models for games, architecture, videos. (1186189)

3d_ocean

$29

Another Tron Light Cycle with the Rider and Trail

...ther tron light cycle with the rider and the light trail. high quality 3d model,all the materials and lights are included. the...

Filament

3ddd

$1

Filament Cage

...filament cage

3ddd

лофт , filament cage

модель бра, делалась по фото!

turbosquid

$3

FILAMENT COUNTER

...d

royalty free 3d model filament counter for download as stl on turbosquid: 3d models for games, architecture, videos. (1563049)

3d_export

$5

Filament lamp 3D Model

...filament lamp 3d model

3dexport

filament lamp 3d model kevin 54161 3dexport

3d_export

$5

Filament bulb candle 3D Model

...filament bulb candle 3d model

3dexport

filament bulb-candle

filament bulb candle 3d model kevin 54163 3dexport

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3d_export

$5

Filament led light bulb

...filament led light bulb

3dexport

realistic 3d model of filament light bulb with v-ray materials.

3ddd

$1

Factory filament metal shade

...factory filament metal shade

3ddd

restoration hardware

restoration hardware. 20th c. factory filament metal shade.