Thingiverse

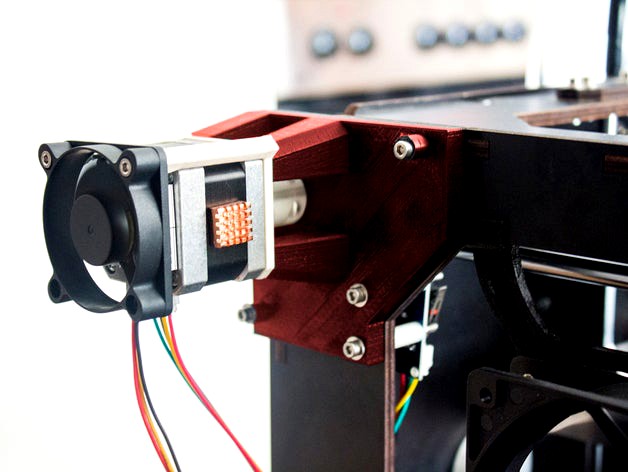

Y-Axis Direct Drive for CTC Replicator Flashforge by 3DWorkhorse

by Thingiverse

Last crawled date: 3 years ago

Recommended for heated build chambers! (to protect stepper from the heat)

Hi folks!

Another upgrade item for your replicator-like 3D printer. It is a mount to drive the y-axis' rod directly without another belt, so there is no additional force on the y-rod (no bending, easier to rotate) and no backlash due to a "loose" belt.

I found that my prints are a bit more precise since the upgrade. Especially the ringing effect (wave pattern after sharp corners) was reduced on the y-axis.

Why it's mounted on the left side of the printer?

The original mounting point and the new one allow the same direction of rotation for the stepper. It can be mounted on the right side too, but then you have to invert the y-axis in the firmware config, which i didn't want to do.

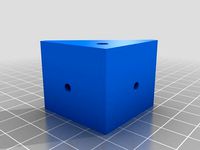

Why there are 3 versions of the base? What is the difference?

All 3 version have different positions for the upper hole of the y-endstop sensor. I found that my CTC printer isn't laser-cutted as precisely as expected. One hole for the sensor (the upper one) is 2mm off! So i printed the 2mm offset version for myself and added 2 additional version with 1mm offset and 0mm offset. Just in case your printer case is more precise. ;)

Let me know if your holes are off too. When it will not align with your holes tell me and I will upload another version.

Do I need a fan for the stepper?

No, but it's recommended to install a fan to cool down the stepper, because it can become quite hot during long print jobs. And hot steppers can loose steps or can be damaged.

How much space i got between the fan and the stepper for additional heatsinks?

7mm max

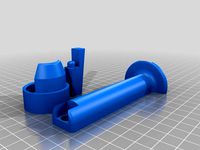

Is there a reason the coupler has a non-round hole at the bottom?

Of course ;) The side with the flat-sided hole is for the nema17 stepper's flattened rod to translate as much torgue from the stepper to the y-rod as possible.

Hi folks!

Another upgrade item for your replicator-like 3D printer. It is a mount to drive the y-axis' rod directly without another belt, so there is no additional force on the y-rod (no bending, easier to rotate) and no backlash due to a "loose" belt.

I found that my prints are a bit more precise since the upgrade. Especially the ringing effect (wave pattern after sharp corners) was reduced on the y-axis.

Why it's mounted on the left side of the printer?

The original mounting point and the new one allow the same direction of rotation for the stepper. It can be mounted on the right side too, but then you have to invert the y-axis in the firmware config, which i didn't want to do.

Why there are 3 versions of the base? What is the difference?

All 3 version have different positions for the upper hole of the y-endstop sensor. I found that my CTC printer isn't laser-cutted as precisely as expected. One hole for the sensor (the upper one) is 2mm off! So i printed the 2mm offset version for myself and added 2 additional version with 1mm offset and 0mm offset. Just in case your printer case is more precise. ;)

Let me know if your holes are off too. When it will not align with your holes tell me and I will upload another version.

Do I need a fan for the stepper?

No, but it's recommended to install a fan to cool down the stepper, because it can become quite hot during long print jobs. And hot steppers can loose steps or can be damaged.

How much space i got between the fan and the stepper for additional heatsinks?

7mm max

Is there a reason the coupler has a non-round hole at the bottom?

Of course ;) The side with the flat-sided hole is for the nema17 stepper's flattened rod to translate as much torgue from the stepper to the y-rod as possible.

Similar models

thingiverse

free

Z-Axis Offset / Endstop 5mm for CTC Bizer / Flashforge Creator / Replicator Dual

...rge creator or replicator dual.

this offset is needed if a thicker aluminum plate or glass surface is mounted on your 3d-printer.

thingiverse

free

Makerbot CTC PRINTER Y-AXIS END STOP OFFSET by Snave3D

... this is usefull if you need to attach an active cooler with back mounted fans, or anything that changes the distance of the bed.

thingiverse

free

Replicator Y Axis Rod pillow block mount by bluemax9

...illow block, that i made for my ctc replicator. here is the link to the original bracket: http://www.thingiverse.com/thing:112128

thingiverse

free

CTC Y Axis Stepper Motor Mount with belt tensioner V2 (And all Replicator clones) by Facocero

...thingiverse

this useful motor mount with adjustable belt tension, is compatible with all printers clone of makerbot replicator.

thingiverse

free

Active Cooling Fan Duct - Additional mounting

...ts, using existing holes in the extruder fan housings. it's fitting the ctc bizer, but can be adapted to other printers, too.

thingiverse

free

Z Axis Tom Mount by nikolastsr

...ess nut in the upper part of the x-axis mounts.

this also improves the prints.the further away from the stepper motor the better.

thingiverse

free

CTC Y Axis Stepper Motor Mount with adjustable belt tensioner V2.0 (And all Replicator clones) by Facocero

... definitive fixing

necessary materials:

1 wing-head thumb screws m3x6

1 wing screws m4.0x20

1 nut m4

1 washer m4

printing in abs!

thingiverse

free

CTC i3 Y stepper motor holder / plate by deserr

...the y stepper motor of the ctc i3 pro b printer. i've created the model with the measurement of an original replacement part.

thingiverse

free

Y-Axis Endstop Mount Front Side for CTC, Flashforge and similar by zumili

...d on the front side for the y-axis.

you need 2 m3 30mm screws and 2 m3 nuts. and you have to drill 2 holes inside the left plate.

thingiverse

free

Prusa i3 Z axis upper mounts with 5mm threaded rod top bush hole by wayne69x

...hese z axis upper mounts to allow me to fir a bush on the m5 threaded rod and stop the wobble/squeak. the additional hole is 10mm

3Dworkhorse

thingiverse

free

Am4 Ryzen Shell And Lapping Helper by 3DWorkhorse

...1% steps. usually it's a loose fit, there is 0.2mm space on both sides.

feel free to share!

no commercial use allowed.

cheers

thingiverse

free

Geeetech i3 x - Z Axis Top Plate with integrated bearing mount by 3DWorkhorse

...the geeetech i3 x, not b, just for the x!

additional hardware you need:

8mm bearing with 22mm outer diameter (for example: 608zz)

thingiverse

free

High Feets for CTC Replicator Flashforge by 3DWorkhorse

...% or 98%. do not rescale the z-axis (height)!

the screwable feet is a tight fit with ~0.3mm space between outer and inner thread.

thingiverse

free

Y Axis Bearing 11mm x 5mm M4 for CTC Replicator Flashforge by 3DWorkhorse

...t i was nearly that stupid.

the bearings improved the stiffness of the y-axis a lot. much less wobbling on fast prints.

have fun!

thingiverse

free

Filament guide for MK8 spring loaded aluminium arms for CTC Replicator Flashforge Dual (update: for flex) by 3DWorkhorse

...39;s all. work's nice and flawless for me. filament can be pushed directly by hand into the hotend with tiny force.

have fun!

thingiverse

free

Universal Projector Legs by ftwelve

...of the projector. this work is a remix of 3dworkhorse work, which is a remix of daviepadilla work. why...

Ctc

turbosquid

$4

CTC Railroad Telephone

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Onibus Ciferal Padron Briza Volvo B58e CTC Azul

...briza volvo b58e ctc azul for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1692482)

3dfindit

free

CTC

...ctc

3dfind.it

catalog: rcm

thingiverse

free

CTC by apone4

...ctc by apone4

thingiverse

modifica per ctc montaggio e3d

thingiverse

free

Filiamenthalter CTC by e2mars

...filiamenthalter ctc by e2mars

thingiverse

filiamenthalter ctc makebot

thingiverse

free

CTC's Feet by zion_taron

...ctc's feet by zion_taron

thingiverse

feet to ctc printers

thingiverse

free

CTC Abdeckung by Einstein77

...ctc abdeckung by einstein77

thingiverse

abdeckung für die hinteren bohrungen im gehäuse des ctc

thingiverse

free

CTC Corner caps by KyoFR

...ctc corner caps by kyofr

thingiverse

corner caps ctc

thingiverse

free

FILAMENT GUIDE CTC by HugoNogier

...filament guide ctc by hugonogier

thingiverse

filament guide ctc

thingiverse

free

CTC Bizer Fusshalter by FPV57

...ctc bizer fusshalter by fpv57

thingiverse

haltewinkel für gummifüsse ctc

Flashforge

thingiverse

free

Flashforge Logo

...flashforge logo

thingiverse

flashforge logo

thingiverse

free

flashforge logo by morive3d

...flashforge logo by morive3d

thingiverse

this is a flashforge stamphttps://www.youtube.com/channel/ucu6ge9qrju9cpgg6wrlxkqw

thingiverse

free

Flashforge Glass Bed by olo2000pm

...flashforge glass bed by olo2000pm

thingiverse

flashforge glass bed

thingiverse

free

Toolbox for FlashForge Finder by Gringo1970

...toolbox for flashforge finder by gringo1970

thingiverse

smal toolbox for flashforge finder

thingiverse

free

Flashforge / Dremel lid by Disco_Rob

...flashforge / dremel lid by disco_rob

thingiverse

lid extension for the flashforge dreamer

thingiverse

free

Flashforge Dreamer Filamentguide by PeterS1

...de for flashforge dreamer / dremel idea. you need also flashforge dreamer lid spacer (http://www.thingiverse.com/thing:1219953)

thingiverse

free

Flashforge creator legs by cybadigitals

...flashforge creator legs by cybadigitals

thingiverse

these legs gives a clearance of 25mm for flashforge creator series

thingiverse

free

Flashforge Inventor/Dreamer by Iprintr7

...orge inventor/dreamer by iprintr7

thingiverse

this is my first thingiverse project and is a model of the flashforge 3d printer

thingiverse

free

Flashforge Filiment Guide by russellscanlan

...flashforge filiment guide by russellscanlan

thingiverse

my design to feed filament through the door on a flashforge adventure 3

thingiverse

free

Flashforge Winder Adapter by newky2k

...winder adapter by newky2k

thingiverse

adapters for the flashforge 0.5 kg spools to the for the filament spool winder by ssinnott

Replicator

turbosquid

$5

Bucati USB Stick "replic"

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$75

3D Scania S730 8x4 Recovery SWS Edition

... of work with custom made parts to replicate the real truck unit<br>textures included<br>format available : obj files

3ddd

$1

Restoration Hardware - 1950s Dutch Shipyard Triple Shelving

...right to access the lofty upper shelves. crafted from solid walnut and iron, its antiqued finish replicates an aged, worn patina.

3d_export

$50

3D Scania Vabis 110 Model

...s 110 truck<br>very detailed and accurate replicated model<br>textures included<br>format available : obj files

3d_export

$11

Batman

...eled to replicate the original lego model to meet the highest quality , each part are arranged in hierarchy and parented objects.

3d_export

$85

3D Scania S730T Omars Recovery Truck Model

...ded<br>format available: obj file<br>on request,after purchase,i can offer other file formats the customer is in need

3d_ocean

$10

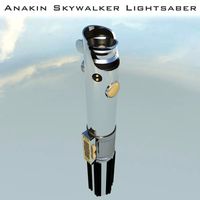

Star Wars: Anakin Skywalker Lightsaber

...tsaber of anakin skywalker. it contains a fairly high amount of polygons, suitable for semi-close up renders. main focus is it...

3d_ocean

$30

Ashley Jaidyn Poster Bedroom Set

...esser, mirror, chest. all models are made in compliance with the proportions and sizes of real furniture. with the replicated ...

3d_ocean

$10

Ashley Stages Chest

...w x 16”d x 49”h. material: wood products and other. color: replicated pine grain. this model is made in accordance with the pr...

3d_ocean

$6

Ashley Stages Table Lamp

...other. color: replicated pine grain. this model is made in accordance with the proportions and sizes of real furniture. the di...

Direct

design_connected

free

Compas Direction

...compas direction

designconnected

free 3d model of compas direction by vitra designed by prouvé, jean.

design_connected

$18

Direction Pivotant

...direction pivotant

designconnected

vitra direction pivotant computer generated 3d model. designed by prouvé, jean.

turbosquid

$6

not direct the front

...oyalty free 3d model not direct the front for download as max on turbosquid: 3d models for games, architecture, videos. (1213034)

turbosquid

$10

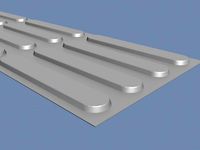

Rails Direct

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Picto toilet directions

...lude 3d files next to rhino6: x3dv, step, igus, obj and stl. double-sided, flipping changes the gender directions to the toilets.

3ddd

$1

fauteuli direction

...d

chair , vitra , fauteuli

fauteuli vitra chair

design_connected

$18

Fauteuil Direction, 1951

...fauteuil direction, 1951

designconnected

vitra fauteuil direction, 1951 computer generated 3d model. designed by prouvé, jean.

3d_export

$5

Directional tactile 3D Model

...tactile 3d model

3dexport

directional tactile braille tile flooring interior

directional tactile 3d model renob000 71068 3dexport

turbosquid

$26

Radio direction finder A

...ty free 3d model radio direction finder a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1212490)

turbosquid

$7

Wooden direction signage

...ty free 3d model wooden direction signage for download as max on turbosquid: 3d models for games, architecture, videos. (1453747)

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award

Y

turbosquid

$1

Tetera y Galletas y Caf

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Смеситель Y-CON

...смеситель y-con

3ddd

смеситель , y-con

смеситель y-con

3ddd

$1

Y-Chair

...y-chair

3ddd

tom dixon

y-chair designed by tom dixon,

3ds max + obj, corona

3ddd

$1

Y Chair compilation

....net/products/us/y-chair-sled-base

y chair swivel basehttp://www.tomdixon.net/products/us/y-chair-swivel-base

turbosquid

$190

Y-8

...y-8

turbosquid

royalty free 3d model y-8 for download as max on turbosquid: 3d models for games, architecture, videos. (1658891)

turbosquid

$7

Bench Y

...turbosquid

royalty free 3d model bench y for download as obj on turbosquid: 3d models for games, architecture, videos. (1488746)

turbosquid

$15

bonePile Y

...oyalty free 3d model bonepile y for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1546374)

turbosquid

$7

Y for Yarn

...d

royalty free 3d model y for yarn model for download as max on turbosquid: 3d models for games, architecture, videos. (1699732)

turbosquid

$2

FONT Y

...quid

royalty free 3d model font y for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1549457)

3ddd

$1

WOOD-y

...wood-y

3ddd

wooden guy