Thingiverse

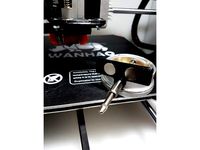

X-axis Tensioner for Wanhao Di3 by printingotb

by Thingiverse

Last crawled date: 3 years, 1 month ago

What

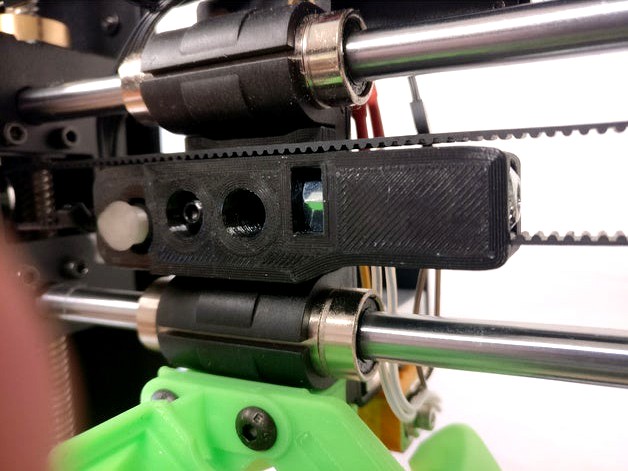

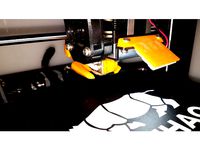

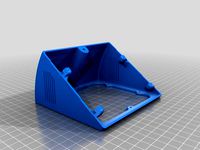

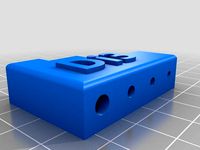

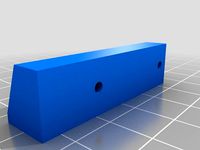

This is my X axis tensioner. There are many like it, but this one is mine.

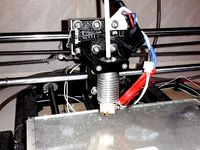

Consideration is taken to allow space for the extruder motor cable if you want to rotate the motor (to move the cable from the top of the motor to the back).

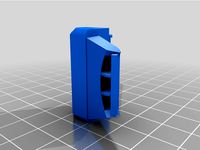

The grip holding the belt is visible through a slot in the front, allowing you to see how much you can tighten the screw before it bottoms out.

Why

For easy adjustment of the X belt tension. I use a guitar-tuning app to tune the tension of my belts to 100Hz. Please note that I do not know what the perfect tension is or how accurate the app is. This is what I feel is at the upper end of the right amount of tension. Tightening too much can rip the belt or skew the printer..

Move the carriage to one side and pluck the lower belt with the phone mic close to the belt.

Hardware needed

1 M4x20mm (re-use one of the stock screws)

1 M4x10mm (can be left out)

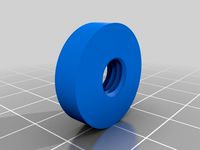

1 M6 nut

1 M6x30mm or x35mm screw with cylindrical or round head with max Ø10mm.

Print recommendations

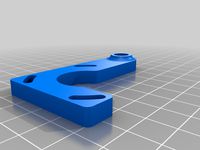

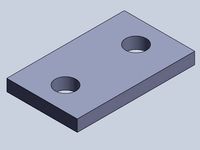

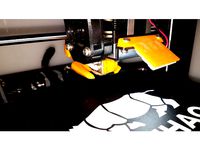

Print everything without supports, in the direction they appear.

Print the body at 0.16mm layer height, 15% infill.

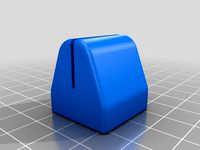

Print the grip at 0,12mm layer height.

If you are only printing at PLA temps, you can use PLA for this. PETG or ABS is recommended for anything hotter. But make sure you can print them with good layer adhesion.

Preferably print the Lock and Grip in a different colour.

Installation

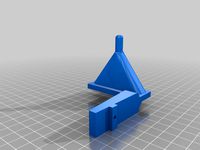

See pictures

Remove the screws holding the belt and the springy thing on the belt.

Remove the zip-ties on the right side of the belt but leave the outer one on the left side (seen from the back of the printer).

Re-use one of the M4x20 screws to mount the XTensionerBody. Optionally add M4x10 screw in the second hole. Make sure the body is parallel to the belt to prevent the belt from rubbing.

Insert the XTensionerLock in the slot and give the belt a pull.

Cut the other end of the belt just long enough for the XTensionerGrip to enter the body with the belt and a few extra millimetres.

If you haven't already, you can work through some more of the extruder motor cable through the cable-chain and run it between the lower rod and the XTensionerBody. Gives ome extra room when printing at the upper Z limit.

This is my X axis tensioner. There are many like it, but this one is mine.

Consideration is taken to allow space for the extruder motor cable if you want to rotate the motor (to move the cable from the top of the motor to the back).

The grip holding the belt is visible through a slot in the front, allowing you to see how much you can tighten the screw before it bottoms out.

Why

For easy adjustment of the X belt tension. I use a guitar-tuning app to tune the tension of my belts to 100Hz. Please note that I do not know what the perfect tension is or how accurate the app is. This is what I feel is at the upper end of the right amount of tension. Tightening too much can rip the belt or skew the printer..

Move the carriage to one side and pluck the lower belt with the phone mic close to the belt.

Hardware needed

1 M4x20mm (re-use one of the stock screws)

1 M4x10mm (can be left out)

1 M6 nut

1 M6x30mm or x35mm screw with cylindrical or round head with max Ø10mm.

Print recommendations

Print everything without supports, in the direction they appear.

Print the body at 0.16mm layer height, 15% infill.

Print the grip at 0,12mm layer height.

If you are only printing at PLA temps, you can use PLA for this. PETG or ABS is recommended for anything hotter. But make sure you can print them with good layer adhesion.

Preferably print the Lock and Grip in a different colour.

Installation

See pictures

Remove the screws holding the belt and the springy thing on the belt.

Remove the zip-ties on the right side of the belt but leave the outer one on the left side (seen from the back of the printer).

Re-use one of the M4x20 screws to mount the XTensionerBody. Optionally add M4x10 screw in the second hole. Make sure the body is parallel to the belt to prevent the belt from rubbing.

Insert the XTensionerLock in the slot and give the belt a pull.

Cut the other end of the belt just long enough for the XTensionerGrip to enter the body with the belt and a few extra millimetres.

If you haven't already, you can work through some more of the extruder motor cable through the cable-chain and run it between the lower rod and the XTensionerBody. Gives ome extra room when printing at the upper Z limit.

Similar models

thingiverse

free

Pivot Lever Belt Tensioner by selmo

...ably better than pla as the flexibility will help it grip the belt better.

requires only one screw, one nut, and one cable tie.

thingiverse

free

HTC Vive Tracker Dock with Side-Tightening Wheel by matzman666

...zations, and one that can be mounted on a picatinny rail.

four m3x6 screws required for connecting lower and upper body together.

thingiverse

free

Z-axis sync belt-tensioner

...its not tight enough you could mount a second one on the other side. you can tighten the belt when you rotate the belt tensioner.

thingiverse

free

X-Axis GT2 Belt Tensioner by porksusanjoe

... two tops required. support with #10 machine screws on top and standard machine screws through one or both sides to tension belt.

thingiverse

free

Tensioner Knob by Thirkell

... have hex head screws, and tighten all the way to the end.

version 1 can be found here: http://www.thingiverse.com/thing:561529

thingiverse

free

Hictop Prusa I3 Y-Axis Belt Tensioner by Fr8Dog

...belt. that got old very quickly. i saw another similar tensioner, thing # 807702, and i adapted the general...

thingiverse

free

CR-10 X AXIS BELT TENSIONER by camaroboy383

...and above if left on... this isn't an issue if your printing models smaller than that... you decide..

hope this can be useful

thingiverse

free

6mm Belt Tensioners for Monoprice Select Mini 3D Printer by USWaterRockets

...ach printer would not be an issue, but since i only tested this on my printer, feedback on any tolerance issues would be welcome.

thingiverse

free

Robo 3D Y Axis Cable Tensioner by Fichthorn

...ine broke from over tightening the tension screw. print solid fill in pla. may have to sand sides a little, it's a tight fit.

thingiverse

free

Y-Axis Belt Clamp for ANET A6 or A8 by kkrebs76

... the right side of the assembly drawing and image views is the stepper motor side. note the cura image for printing orientation.

Printingotb

thingiverse

free

DecapiCat by printingotb

...support under the tongue and the lowest part of he head.

attached my support settings but they are by no means the best settings.

thingiverse

free

Hinges by printingotb

...tertight and suitable for 3d-printing.

i have printed these in every material i have tried. pla, abs, petg, nylon all work well.

thingiverse

free

Robo Rally Twitch upgrade by printingotb

...ree supports + a modelled custom break away support under the middle.

a total 1.5 workdays to design, print and paint.

100% happy

thingiverse

free

Curve Overhang test *halved* by printingotb

...all lines works better than more but only if you allow the bottom skin on top of the walls, see picture from cura (yellow areas).

thingiverse

free

Anycubic kossel L+ Corner Supports and Bed holder by printingotb

...ee pictures for instructions.

the top corners can be used everywhere if you only want the corner supports and not the bed holder.

thingiverse

free

Z-Brace 0.5 by printingotb

...ble "helper" to get the holes right as well as easy to follow instructions.

https://www.youtube.com/watch?v=aglek3ychea

thingiverse

free

Spool core with sides for Eco refill by printingotb

...es.

cut-out for layer seam on inner diameter.

lots of holes for attaching the filament end

designated place for material sticker.

thingiverse

free

Stepper Smoother Box by printingotb

...ave one:https://www.thingiverse.com/thing:1997411

performance

see second picture, the issue was mild on my printer to begin with.

thingiverse

free

Simple topmounted spoolholder for enclosure by printingotb

...ss.

oh, and no need to mount it so close to the edge of your enclosure, i had a leaning ceiling just above my printer before :-p

thingiverse

free

CR10 2.3kg Spool Holder for controlbox by printingotb

...realized that there is not enough space for them lol.

feel free to remix this in any way you want :)

https://youtu.be/sw5s5zl6jey

Di3

thingiverse

free

Wanhao Di3 v2 Light / Wanhao Di3 v2 Beleuchtung by JMDesigns

...wanhao di3 v2 light / wanhao di3 v2 beleuchtung by jmdesigns

thingiverse

wanhao di3 v2 light / wanhao di3 v2 beleuchtung

thingiverse

free

Wanhao Di3 MagFix System by JMDesigns

...wanhao di3 magfix system by jmdesigns

thingiverse

wanhao di3 magfix system

thingiverse

free

Wanhao Di3 Silicone Softgrip by JMDesigns

...wanhao di3 silicone softgrip by jmdesigns

thingiverse

wanhao di3 silicone softgrip

thingiverse

free

Di3 rotary dial by 3Dplanner

...hingiverse

original model of jo3ri http://www.thingiverse.com/thing:33286 , adjusted for the di3.

layer 0.2

shell 2

fill 50%

pla

thingiverse

free

Di3 LCD Angler ( With Air Vents ) by diamonddrake

...3 lcd angler ( with air vents ) by diamonddrake

thingiverse

this is a remix of rtideas di3 lcd angler, i simply added air vents.

thingiverse

free

Di3 Hex Wrench Holder by BliNDF123

...de a hex wrench holder for the ones that come with the di3, stuck it to the side frame of my printer with some double sided tape.

thingiverse

free

E3D v6 mount for Wanhao Di3 by slimc

...w design http://www.thingiverse.com/thing:1657971

set of components that allow the e3d v6 hotend to be mounted on the wanhao di3.

thingiverse

free

Wanhao Di3 V2.1 Knob Grip by Hyperlinks

...

thingiverse

this is a remix for the di3 v2.1. it did not fit properly on my printer (too tall), so i scaled it down minus 7 mm.

thingiverse

free

Wanhao Di3+ filament cleaner by Alpin3D

...wanhao di3+ filament cleaner by alpin3d

thingiverse

v1.1

filament cleaner / sponge

v1.2

better filament control

thingiverse

free

Di3 Nozzle LED Mount by sprfly

...e cooler. uses a 3 led section of self adhesive strip leds. i tapped into the always on hotend fan to provide the 12v to my leds.

Wanhao

thingiverse

free

Wanhao Logo Plate / Wanhao Logo Schild by JMDesigns

...wanhao logo plate / wanhao logo schild by jmdesigns

thingiverse

wanhao logo plate / wanhao logo schild

thingiverse

free

Wanhao logo by nebtio

...wanhao logo by nebtio

thingiverse

wanhao logo

thingiverse

free

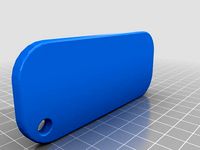

Wanhao keychain by Rein3003

...wanhao keychain by rein3003

thingiverse

a keychain with the logo of wanhao

thingiverse

free

Wanhao Di3 v2 Light / Wanhao Di3 v2 Beleuchtung by JMDesigns

...wanhao di3 v2 light / wanhao di3 v2 beleuchtung by jmdesigns

thingiverse

wanhao di3 v2 light / wanhao di3 v2 beleuchtung

thingiverse

free

TUSH For Wanhao by wtmi1992

...tush for wanhao by wtmi1992

thingiverse

the ultimate spool holder, modified for the top of the wanhao control box. fits snug.

thingiverse

free

fanduct wanhao d12 by theopoilmek

...fanduct wanhao d12 by theopoilmek

thingiverse

fanduct pour wanhao d12

thingiverse

free

Wanhao i3 Marlin by johan21

...wanhao i3 marlin by johan21

thingiverse

marlin for wanhao i3 rampsboard 1.4.

thingiverse

free

Wanhao Duplicator i3 by imagineering4

...wanhao duplicator i3 by imagineering4

thingiverse

these are the stl files for the improvements to the wanhao duplicator i3, v2

thingiverse

free

Wanhao D6 filament guard

...wanhao d6 filament guard

thingiverse

this is a filament guard for wanhao d6 machine to avoid the filament unrolling

thingiverse

free

Wanhao Duplicator i3 Model by Hilde3D

...wanhao duplicator i3 model by hilde3d

thingiverse

wanhao duplicator i3 model

Tensioner

3d_export

$5

adjustable tension lock

...adjustable tension lock

3dexport

adjustable tension lock

turbosquid

$5

tension ring

...oyalty free 3d model tension ring for download as fbx and stl on turbosquid: 3d models for games, architecture, videos. (1553452)

turbosquid

$3

Tension Chair

...free 3d model tension chair for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1251503)

3d_export

$5

transformador de tension

...transformador de tension

3dexport

transformador de tension entrada 460vac salida 220vac marca audax

turbosquid

$20

Motorbike Chain Tensioner

...y free 3d model motorbike chain tensioner for download as stl on turbosquid: 3d models for games, architecture, videos. (1428322)

turbosquid

$25

TENSION-WOOD-CHAIR

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

tension-bentwood-chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Tension engagement ring

...n engagement ring for download as obj, fbx, 3dm, dwg, and stl on turbosquid: 3d models for games, architecture, videos. (1491631)

3d_export

$10

Ruby Tension set Ring 3D Model

...ruby tension set ring 3d model

3dexport

tension set ruby ring in 18k

ruby tension set ring 3d model rehansheikh 25254 3dexport

turbosquid

$20

Superficial Tension Exp. Image.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award