3dExport

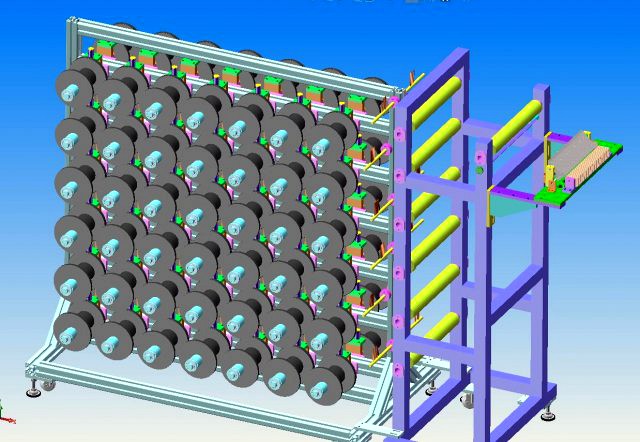

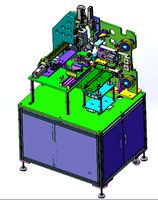

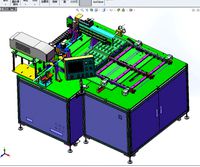

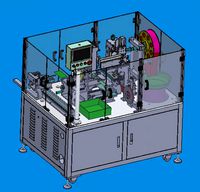

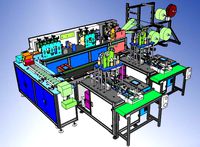

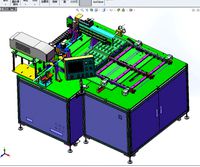

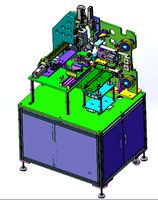

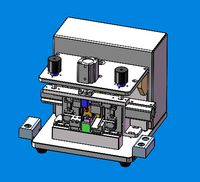

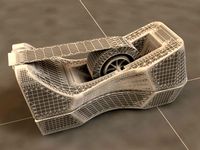

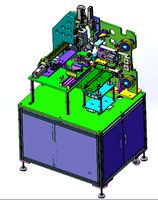

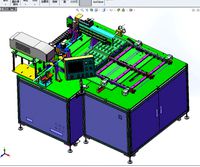

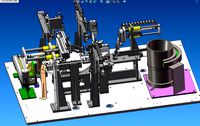

wire and wire copper axis fpc adhesive tape laser cutting peeling cutting machine - final assembly

by 3dExport

Last crawled date: 1 year, 10 months ago

this equipment is suitable for: industrial wire, fpc, ffx flexible cable, 0.3-1 mm wire diameter, various products adhesive laser cutting, etc. the equipment is mainly a copper wire cutting and processing equipment: the full set of drawings after decompression has more than 300 mb, the switchboard has more than 900 parts, the equipment is mainly used for copper wire fpc flexible cable cutting and gluing, the main highlights of the equipment are wire feeding frame part, there is also a complex gluing structure, this feeding frame can be on dozens of coils of wire at a time, the main functions of the equipment are: 1 2. wire ultrasonic cleaning, 3. wire body adhesive tape mechanism, 4. soft wire laser cutting and peeling, 5. wire cutting, 6. soft wire automatic receiving manipulator, 7. automatic feeding tray, circulating conveyor belt, equipment bus for integrated automatic operation, manual auxiliary loading and unloading, loading frame structure, the loading frame can be used for various sizes of drum incoming wire and copper wire fpc soft wire, loading and unloading operation to make it simple, we just need to put the wire into the rotating shaft of the feeding frame. the copper wire in the material frame is cleaned by ultrasonic after finishing the structure through the roller and wire harness. the cleaned wires enter the gluing machine. the incoming materials of the wire body can arrange up to more than 30 wires. the number of wires can be selected and arranged automatically, and the size of the gluing tape can also be selected. when the wires enter the gluing station, they can be cleaned by ultrasonic the glue pulling mechanism pulls out the adhesive tape and cuts it off, and then pastes it on the wire. the upper and lower sides stick it together to tie the wire together. the glue pulling structure of the cell is a stepping motor, and the moving structure is complex. the switchboard is composed of two servo motors, a stepping motor and more than ten cylinders. this is a complicated glue sticking mechanism. the sticking head and suction label are of vacuum adsorption type, and the position of glue sticking is stable the length can be adjusted according to the requirements, the adjustable range is relatively large, and the wire feeding structure is also cleverly designed. the gluing position of the wire arrangement is segmented, but the laser cutting at the back end of the gluing is also carried out. after the laser cutting, the wire body is cut by the cutting machine, and the cutting length is manually set. after the cutting, the picking manipulator grabs the wire directly into the receiving box, and the receiving box is recycled the conveyor belt is driven by six small motors, which are two one-stage conveyor belts, two two two-stage conveyor belts and two jacking transfer machines respectively. the conveyor belt is divided into one in and one out. the feeding conveyor is on the left side, and the discharging conveyor belt is on the right side. the vehicles in the left feeding conveyor belt are in the state of products. when the products are used up, the jacking transfer conveyor will transfer the empty ones with a disk or plastic plate, the lifting scale is loaded into the empty conveyor belt on the right side, and then the empty material plate is recycled. the motor power of this conveyor belt is relatively small, and the conveying products are relatively light, so the circular belt design is adopted, which is very convenient in the installation and debugging, and the circular belt is relatively wear-resistant, and it is also very convenient to replace, because the action in the equipment is more complex there are also many structures. most of the structures can be seen from the pictures. if you need and are interested, you can download and learn the drawings. it's very good to draw lessons from the contents of the drawings. after downloading, you can analyze and study in detail, and you can certainly learn a lot. i won't introduce other details here. the above is the whole structure and working principle of this equipment.

Similar models

cg_trader

$29

Automatic wire sticking laser cutting and receiving line

...f things, i won’t give more detailed introduction here, the above is the whole structure and working principle of this equipment.

3d_export

$20

power cord adhesive tape machine

...of the upper and lower glue feeding mechanism is similar to that of the labeling machine. the cutting precision...

3d_export

$20

wire laser cutting peeling cutting machine ffc cutting machine

...and receiving machine, with the structure of this drawing, you don't need to draw by yourself, welcome to collect, thank you.

3d_export

$15

automobile wiring harness clamp packaging

...anism, etc. it is very complete, and the equipment has been made and shipped! completely original! welcome to download reference!

grabcad

free

Mini conveyor belt Nema 17

...elt with tensioner incorporated in the frame that houses the motor.

tslot 30x30 profile as a reference structure.

tape width 2cm.

cg_trader

$9

Motor conveying device

...two devices through a synchronous belt.it is representative of similar kinds of pore products. if you like,you can paypal...

cg_trader

$18

Large belt conveyor

...eel compaction roller motor industrial machine manufacture convey translate equipment production industrial machine conveyor belt

thingiverse

free

Conveyor Belt Design For BO Motor by salmanansari

...r bo motor by salmanansari

thingiverse

simple conveyor belt driven by bo motor design also include bracket for 5mm laser and ldr

3d_export

$50

one drag two automatic mask production linemask machine

...automatic paper receiving, welding, cutting, transferring conveyor belt, ear belt welding, automatic blanking conveyor belt, etc.

cg_trader

$300

Pcb board loading package stacking conveyor line

...rated equipment line for packing and stacking, which can be used in the packaging industry, electronic industry and food industry

Fpc

3d_export

$10

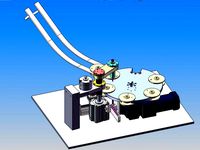

Battery Fpc Instrument

...battery fpc instrument

3dexport

fpc battery instrument musical

3d_ocean

$30

Tree poplar

...leves fpc=1,72gb, main branches fpc= 179 mb, midle branch fpc = 0,99gb,...

3d_export

$20

wire laser cutting peeling cutting machine ffc cutting machine

...the equipment is suitable for cutting and peeling products: fpc coaxial line, ffc wire, laser cutting and peeling of...

3d_export

$20

power cord adhesive tape machine

...adhesive tape machine<br>this equipment is suitable for industrial wire, fpc flat wire, 0.3-0.8mm wire diameter, all kinds of household...

3dfindit

free

FPC

...fpc

3dfind.it

catalog: a&t

thingiverse

free

Camera FPC Cable Clip

...ds flat cables up to 25mm wide.

it only spans 2/3 of the profile.

i use it to guide the pi-cam cable on the bottom of the printer

thingiverse

free

FFC FPC 26 pin Connector Replacement for keyboard notebook by alien_2005

... fpc 26 pin connector replacement for keyboard notebook by alien_2005

thingiverse

repair from keyboard notebook

noizze abs 0.2mm

thingiverse

free

ImmersionRC Ghost Atto antenna holder for FPC Cycle Glide by TheFlyingEagle

...onrc ghost atto antenna holder for tinytrainer

i made a small adjustment to fit it on my fpv cycle glide with 6mm wide standoffs.

thingiverse

free

Prusa i3 MK3 Lack Enclosure V2 Corner Front with FPC and USB Port by CraignRush

...the front left door to feed the usb - cable of the einsy board to the octopi and a flatband cable to a pi cam inside the housing.

Peeling

3d_ocean

$19

Peeled banana

...ng fbx food fruit mental ray obj peel peeled photorealistic scanned vray

scanned 3d model of peeled banana on white square plate.

3d_export

$5

peeled banana - cartoon banana peel

...peeled banana - cartoon banana peel

3dexport

texture size:256px number of texture:1

turbosquid

$10

A banana peel

...yalty free 3d model a banana peel for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1663699)

3d_export

free

peels stadium

...dium with a roof shaped like onion peels and supported by high tensile titanium cables mounted on 3 curved horizontal steel bars.

turbosquid

$20

Banana Peel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Peel Knife

...odel peel knife for download as 3ds, obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1461343)

turbosquid

$3

Banana peel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

wire breaking and peeling machine

...wire breaking and peeling machine

3dexport

wire breaking and peeling machine

design_connected

$13

Peel Fruit Bowl with Pears

...peel fruit bowl with pears

designconnected

peel fruit bowl with pears computer generated 3d model.

digiprops

$15

Old wall with peeling paint

...old wall with peeling paint

digiprops

old stucco wall with two screened windows and patches of peeling paint.

Copper

3d_export

free

Copper Golem

...copper golem

3dexport

the minecraft copper golem

3ddd

$1

COPPER FAUCET

...copper faucet

3ddd

смеситель

a copper faucet made for a client

3d_export

$5

copper

...copper

3dexport

a robot made of gold material

3d_ocean

$5

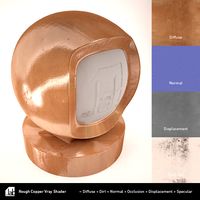

Rough Copper

...ng fixture elements et cetera. this is a v-ray shader intended for use in 3ds max, although the texture maps provided can be u...

design_connected

$16

Copper Bowls

...copper bowls

designconnected

smallaccents copper bowls computer generated 3d model.

design_connected

free

Copper Lights

...copper lights

designconnected

free 3d model of copper lights by vij5 designed by derksen, david.

3ddd

$1

Moscow copper mug

...moscow copper mug

3ddd

copper , mug

3d model of moscow copper mug

3d_export

$5

copper set

...copper set

3dexport

copper kitchen accessories platform: 3dsmax + obj version: 3dsmax2018 unit: centimeters

design_connected

$13

Copper Blow

...copper blow

designconnected

tom dixon copper blow computer generated 3d model. designed by dixon, tom.

3d_export

$5

copper bar

...

the copper bar. this model is ideal for any project. it is perfect for cinematic scenes, as well as ideal for any game project.

Adhesive

turbosquid

$1

Adhesive tape

...quid

royalty free 3d model adhesive tape for download as obj on turbosquid: 3d models for games, architecture, videos. (1352737)

3d_export

$5

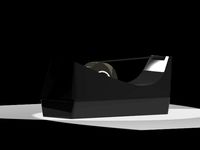

adhesive tape carrier

...adhesive tape carrier

3dexport

adhesive tape carrier

turbosquid

$18

adhesive tape

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

NORDSK STYLISH ADHESIVE TAPE DISPENSER IGES

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$20

power cord adhesive tape machine

...anipulator: 0.005 mm, repeated positioning accuracy of manipulator: ≤ ± 0.01 mm, and material change mode: manual material change

3d_export

$1000

bead triangle adhesive laminating machine

...m onto the steel ring (3) the outlet of the rubber conveying device is connected with the inlet of the winding laminating device.

3d_export

$16

Two White Round Stickers - smooth and bended adhesive labels

...rt editable mesh object to editable poly and load *stickers_uvw.uvw* in unwrap uvw modifier; -studio environment is not included;

3d_export

$20

Black Stickers set - 8 adhesive sticky labels

...bject to editable poly and load<br>*stickers_uvw.uvw* in unwrap uvw modifier;<br>-studio environment is not included;

3d_export

$20

White Stickers set - 8 adhesive sticky labels

...bject to editable poly and load<br>*stickers_uvw.uvw* in unwrap uvw modifier;<br>-studio environment is not included;

3d_export

$20

8 Stickers set - silver adhesive sticky labels

...bject to editable poly and load<br>*stickers_uvw.uvw* in unwrap uvw modifier;<br>-studio environment is not included;

Tape

3d_ocean

$5

Scotch Tape

...scotch tape

3docean

desk holder scotch tape sticky tape tape roll tesa work

scotch tape and a tape holder

3ddd

$1

Cassette Tape

...cassette tape

3ddd

кассета

cassette tape model of tdk

3ddd

$1

Paulangelo / Tape

...paulangelo / tape

3ddd

paulangelo , угловой

диван tape от paulangelo, home collection.

3d_ocean

$25

Tape recorder

...ic old realistic recording recordplayer reel tape retro senheiser speak stereo stylish tape turntable vintage voice

tape recorder

3d_export

$10

measuring tape

...ng tape

3dexport

measuring tape 3dmodel includes all materials , texture and lighting ,3dmax , 3ds , obj , dw. rendererd by vray

3d_export

$5

adhesive tape carrier

...adhesive tape carrier

3dexport

adhesive tape carrier

turbosquid

$15

Tape Measure

...uid

royalty free 3d model tape measure for download as blend on turbosquid: 3d models for games, architecture, videos. (1700720)

turbosquid

$5

Tape measures

...quid

royalty free 3d model tape measures for download as max on turbosquid: 3d models for games, architecture, videos. (1319446)

turbosquid

$3

Pvc taping

...bosquid

royalty free 3d model pvc taping for download as max on turbosquid: 3d models for games, architecture, videos. (1161550)

turbosquid

$1

Adhesive tape

...quid

royalty free 3d model adhesive tape for download as obj on turbosquid: 3d models for games, architecture, videos. (1352737)

Laser

3d_export

$5

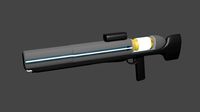

laser

...laser

3dexport

a 3d laser

3d_export

free

cnc 3dp laser nozzle for 2w laser opt lasers

...logy that gave birth to cutting and engraving laser heads this laser nozzle was designed for, read the article in the link below:

3d_export

free

cnc laser mount opt lasers

...eive the engraving and cutting laser heads this cnc machine laser mount was designed for, read the article on the following page:

turbosquid

$20

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Laser

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

laser sword

...laser sword

3dexport

it is a blue laser sword with a metal frame

3d_ocean

$19

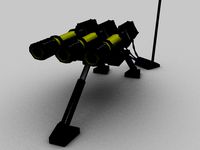

Laser Turret

...be used in any sf type of game, especially in tower defense games. - laser turret: 3025 polygons - props: 270 polygons - textu...

3d_export

free

workbee cnc laser mount for opt lasers

...the specifications of engraving and cutting laser heads this mount was designed for, please take a look at the following website:

3d_export

free

shapeoko cnc laser mount for opt lasers

...ind out the opportunities that adding a cutting and engraving laser head to your cnc can bring, take a look at the website below:

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award

Wire

design_connected

$11

Wired

...wired

designconnected

wired computer generated 3d model.

design_connected

$11

Wires

...wires

designconnected

wires computer generated 3d model.

design_connected

$11

Wire

...wire

designconnected

ronda design wire computer generated 3d model. designed by roccadadria, luca.

3d_export

$5

wire

...wire

3dexport

wire 180x180 cm arhive rar 3dmax2019. obj. fbx. mat corona

turbosquid

$2

HDMI wire

... 3d model hdmi wire for download as wire, wire, fbx, and wire on turbosquid: 3d models for games, architecture, videos. (1644937)

turbosquid

free

wires

...bosquid

free 3d model wires for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1214233)

3ddd

$1

Wire chair

...wire chair

3ddd

wire chair

turbosquid

$10

wires

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Wire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

wire stripper

...wire stripper

3dexport

wire stripper 5 in 1

Final

3ddd

$1

Ardecora-Finale

...ardecora-finale

3ddd

ardecora

ткань итальянского производителя ardecora, артикул finale. в архиве 7 цветов. ткань портьерная.

turbosquid

$3

Wheel Final

...osquid

royalty free 3d model wheel final for download as fbx on turbosquid: 3d models for games, architecture, videos. (1364402)

turbosquid

free

Final Sword

...osquid

royalty free 3d model final sword for download as max on turbosquid: 3d models for games, architecture, videos. (1428573)

turbosquid

$16

Yeti final

...lty free 3d model yeti final for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1374065)

turbosquid

$180

moto final

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$80

final cowboy.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$36

Final UZI

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Gumout Final

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

money finals

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

guitar final

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Cutting

design_connected

$11

e15 Cut Cutting Boards

...e15 cut cutting boards

designconnected

e15 cut cutting boards computer generated 3d model.

design_connected

$16

Cut

...cut

designconnected

lapalma cut computer generated 3d model. designed by rota, francesco.

3d_export

$5

cutting machine

...cutting machine

3dexport

crop cutting machine

3d_export

$5

cutting board

...cutting board

3dexport

12 models for cutting boards

3d_export

$20

wire laser cutting peeling cutting machine ffc cutting machine

...and receiving machine, with the structure of this drawing, you don't need to draw by yourself, welcome to collect, thank you.

3ddd

$1

Lapalma CUT

... cut

фабрика: lapalma

коллекция: cut

размер:↑ 74 cm, ↔ 55 см.

описание: стул, ткань, кожа, дерево.

сайт: www.lapalma.it

3ddd

$1

стул lapalma cut

...стул lapalma cut

3ddd

lapalma , cut

стул lapalma cut

3ddd

$1

Lapalma CUT

...

коллекция: cut

размер:↑ 74 cm, ↔ 55 см.

описание: стул, порошковое покрытие, черный, белый, ткань, пластик.

сайт: www.lapalma.it

design_connected

$16

Hi Cut

...hi cut

designconnected

kartell hi cut computer generated 3d model. designed by starck, philippe.

3ddd

$1

Vorwerk Cut

...vorwerk cut

3ddd

ковер

vorwerk cut

прямоугольный:

размеры : 2400mm x 3200mm

круглый:

размеры : 2400mm

Assembly

3d_export

$7

Electronic product assembly machine assembly machine

...electronic product assembly machine assembly machine

3dexport

electronic product assembly machine assembly machine

3d_export

$15

generator assembly line

...ced and assembled in the form of module block. it is a demonstration project of generator assembly. welcome to download and learn

3d_export

$10

elevator traction machine assembly line motor assembly process

... traction machine assembly line motor assembly process

3dexport

elevator traction machine assembly line (motor assembly process)

3d_export

$16

pin assembly machine

...pin assembly machine

3dexport

pin assembly machine

3d_export

$7

tower-crane-assembly

...tower-crane-assembly

3dexport

tower-crane-assembly

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658296)

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658293)

turbosquid

$100

Engine Assembly

...id

royalty free 3d model engine assembly for download as stl on turbosquid: 3d models for games, architecture, videos. (1658291)

turbosquid

$75

Platform Assembly

...royalty free 3d model platform assembly for download as blend on turbosquid: 3d models for games, architecture, videos. (1472939)

turbosquid

$15

generator assembly

...y free 3d model generator assembly for download as and sldas on turbosquid: 3d models for games, architecture, videos. (1469469)

Machine

archibase_planet

free

Machine

...machine

archibase planet

sewing-machine sewing machine equipment

singer machine- 3d model for interior 3d visualization.

archibase_planet

free

Machine

...hine

archibase planet

percolator equipment coffee-machine

machine n230708 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Machine

...chibase planet

percolator coffee-machine kitchen equipment

coffee machine - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Slot machine

...ase planet

slot machine slot-machine playing machine

slot machine n260311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$7

Machine

...ne

turbosquid

royalty free 3d model machine for download as on turbosquid: 3d models for games, architecture, videos. (1391792)

3d_ocean

$10

War machine

...war machine

3docean

camuflage machine robot war war machine

war machine created in 3dmax 2009 15.497-poly count

turbosquid

$7

machine

...turbosquid

royalty free 3d model machine for download as obj on turbosquid: 3d models for games, architecture, videos. (1452674)

3d_ocean

$12

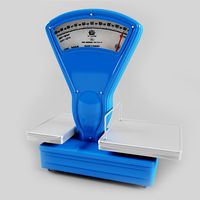

Weighing-machine

...weighing-machine

3docean

market shop weighing-machine

3d model weighing-machine

archibase_planet

free

Sewing machine

...ine

archibase planet

sewing machine sewing-machine

sewing machine n080311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Coffee machine

...se planet

coffee machine percolator coffee-machine

coffee machine n010715 - 3d model (*.gsm+*.3ds) for interior 3d visualization.