Thingiverse

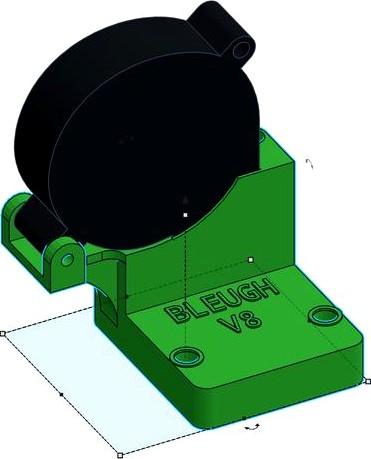

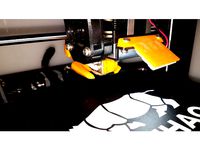

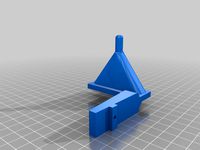

Wanhao Duplicator 9 D9 Top Fan Blower upgrade - V12 by Bleugh

by Thingiverse

Last crawled date: 3 years, 1 month ago

Small Edit...

Seems that most D9's are using only 3 screws to hold the upper fan in place.

I've left 4 holes in the model though as it looks better!

My blower's been working fantastically for a few months now, and it's only my 'trial' PLA print!

There's a few files in here, Just print the one with the highest number! V12 as of typing this.

V12 should help fix some issues seen with holes offset slightly on the extruder

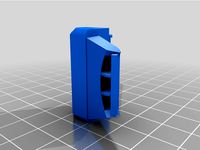

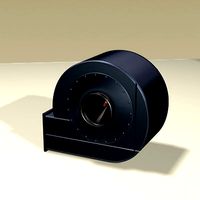

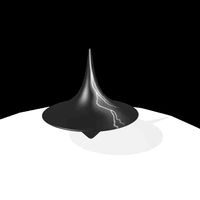

This replaces the top fan in the wanhao duplicator 9. The top fan is the heat break fan and doesn't seem quite strong enough for those 30+ hour prints...By replacing the existing fan with this blower, it should keep things cooler and prevent heat creep.

Uses standard cheapy 5015 radial fans / blowers like the one shown in the image

You need

3 x M3 x 12 Allen Key Bolts / screws (Re-use the original ones!)

1 x M3 x 25 Allen Key Bolt / Screw (to lock the blower in place)

I've made this so that you can re-use the 4 existing allen key screws.

Those are 4 x M3 x 12 - the front two are a snug fit - the holes are 5.5mm diameter. the rear two, taller holes, i've made the holes 6mm diameter, on my printer, it's snug, a little force is needed, but they'll go alright....if you really don't want to use force, just drill them a little, not all the way through to about 8mm from the bottom.

(see REV 4 pictures)

My printer has a 15.5 to 16.5mm clearance (yes, it's slightly 'diagonal!) behind the stepper motor to the X carriage so this print at 15mm thickness on the back part should jam in nicely.

if yours doesn't fit, you should be able to loosen the upwards facing screws holding the two large red parts of the extruder together, jam this in, then tighten them back

Happy to discuss any commercial use of the device

Thanks tohttps://www.thingiverse.com/thing:1576438

for the model of the blower that really helped to get the first run of this design right....

Things remaining

Investigate airflow optimisation

Revision History -

Rev 4 - Original Upload - Functional,works well but flimsy

Rev 6 - Uploaded - Improved supports for fan screw holder, Costmetic changes

Rev 7 - More minor changes, Vertical 'slot' moved forwards slightly to help alignment. - Screw holes for Fan mount changed to M3 x 25

Filled in area on the right hollowed out to assist with bed adhesion - the print seems to lift a little in the front right corner

Fan screw support bracket thickened to enable easier printing and better functionality

STL generally tidied up and aligned to give a perfect finish

Rev 8 - Tiny tweaks to cosmetics only.

Rev 9 - Adjustment to rear 'wall' so it's tapered to assist airflow

Rev 10 - Adjustments made to allow for Wanhao manufacturing variations.

Adjustment to screw holes and locations - I've made them bigger (from 6mm to 7.5mm) to give much more allowance for manufacturing variations from wanhao.

I've also reduced the length of the blower from front to back by 1mm to make fitting easier

Rev 11 - Cosmetic changes, alignment adjustments of the holes and increase of screw holes to 4mm to allow 1mm 'free play' for an M3

Slimmed down the walls by around 1/2mm on the rear, front and right hand side to make fitment easier

Rev12 - Fattened up the internal parts, especially at the tall back side as the walls were a bit thin when printed, should be at least two widths thick now!

Seems that most D9's are using only 3 screws to hold the upper fan in place.

I've left 4 holes in the model though as it looks better!

My blower's been working fantastically for a few months now, and it's only my 'trial' PLA print!

There's a few files in here, Just print the one with the highest number! V12 as of typing this.

V12 should help fix some issues seen with holes offset slightly on the extruder

This replaces the top fan in the wanhao duplicator 9. The top fan is the heat break fan and doesn't seem quite strong enough for those 30+ hour prints...By replacing the existing fan with this blower, it should keep things cooler and prevent heat creep.

Uses standard cheapy 5015 radial fans / blowers like the one shown in the image

You need

3 x M3 x 12 Allen Key Bolts / screws (Re-use the original ones!)

1 x M3 x 25 Allen Key Bolt / Screw (to lock the blower in place)

I've made this so that you can re-use the 4 existing allen key screws.

Those are 4 x M3 x 12 - the front two are a snug fit - the holes are 5.5mm diameter. the rear two, taller holes, i've made the holes 6mm diameter, on my printer, it's snug, a little force is needed, but they'll go alright....if you really don't want to use force, just drill them a little, not all the way through to about 8mm from the bottom.

(see REV 4 pictures)

My printer has a 15.5 to 16.5mm clearance (yes, it's slightly 'diagonal!) behind the stepper motor to the X carriage so this print at 15mm thickness on the back part should jam in nicely.

if yours doesn't fit, you should be able to loosen the upwards facing screws holding the two large red parts of the extruder together, jam this in, then tighten them back

Happy to discuss any commercial use of the device

Thanks tohttps://www.thingiverse.com/thing:1576438

for the model of the blower that really helped to get the first run of this design right....

Things remaining

Investigate airflow optimisation

Revision History -

Rev 4 - Original Upload - Functional,works well but flimsy

Rev 6 - Uploaded - Improved supports for fan screw holder, Costmetic changes

Rev 7 - More minor changes, Vertical 'slot' moved forwards slightly to help alignment. - Screw holes for Fan mount changed to M3 x 25

Filled in area on the right hollowed out to assist with bed adhesion - the print seems to lift a little in the front right corner

Fan screw support bracket thickened to enable easier printing and better functionality

STL generally tidied up and aligned to give a perfect finish

Rev 8 - Tiny tweaks to cosmetics only.

Rev 9 - Adjustment to rear 'wall' so it's tapered to assist airflow

Rev 10 - Adjustments made to allow for Wanhao manufacturing variations.

Adjustment to screw holes and locations - I've made them bigger (from 6mm to 7.5mm) to give much more allowance for manufacturing variations from wanhao.

I've also reduced the length of the blower from front to back by 1mm to make fitting easier

Rev 11 - Cosmetic changes, alignment adjustments of the holes and increase of screw holes to 4mm to allow 1mm 'free play' for an M3

Slimmed down the walls by around 1/2mm on the rear, front and right hand side to make fitment easier

Rev12 - Fattened up the internal parts, especially at the tall back side as the walls were a bit thin when printed, should be at least two widths thick now!

Similar models

thingiverse

free

50x15 blower duct for Wanhao Duplicator 6 / Monoprice Ultimate by claancy

...r fan wire on the rear of the duct

blower attaches to duct with 2, 18mm long m4 machine screws threaded directly into the plastic

thingiverse

free

Wanhao Duplicator 6 blower shroud by gimp

...ight. no loss of any movement area. no drop in extruder temp after initial turn on. designed to press fit into blower fan nozzle.

thingiverse

free

Wanhao I3 Rear Mount for Original Fan Housing by cgsnz

...s were empty on my printer, check that yours are also empty before printing.

printed mine at .2mm layer thickness and 25% infill.

thingiverse

free

WANHAO DUPLICATOR D9 x axis tensioner by bubu1882

...thingiverse

wanhao duplicator d9 x axis tensioner

you need to add 50 mm m3 size screws to strengthen the part between the layers

thingiverse

free

40mm fan to 5015 Blower adapter by CaptainQuint

...l the hotend to much. adjust fan speed if you notice temperatures unstable.

fasteners used:

1 - m3 x 25mm

1 - m3 nut

4 - m3 x 5mm

thingiverse

free

Cooling Fan Duct for E3D Cyclops by Filip_F

...ink with m3 12mm allen bolts. fan mounts with m2 12mm screws cutting into the abs. let me finally print a good marvin key chain

thingiverse

free

K40 Laser Air Assist for 5015 blower by jannis

...

changed laser head screw hole to be only 3mm and work directy with an m3 screw

added 5mm space between head mount and blower fan

thingiverse

free

QUIET 40mm Axial Fan adapter - instead of 5015 Blower Fan by Lee1502

...d have normally used to install the 5015 blower fan. you'll use these to secure this adapter using its diagonal screw holes.

thingiverse

free

E3D v6 Mount for DreamMaker OverLord by AFIF

..., and not the e3d upgrade parts from dreammaker. the heater block from dreammaker seems a bit larger, so your mileage may vary :)

thingiverse

free

Ultimaker Bed mount adapter 4-point to 3-point leveling by Musti

...th this modification simply first level the print bed on the back side where there is a single screw, then adjust the front ones.

Bleugh

thingiverse

free

Lego Sorting Sieves for large format printers - 290mm by Bleugh

...enscad, python and solidpython as per the instructions,

edited the generate file to make these larger sieves for larger printers!

thingiverse

free

Heroquest Secret Door Tile by Bleugh

...order heroquest secret door tile

https://www.tinkercad.com/things/coqbuoo3wiz

has the mashup if you want to tinker a bit yoruself

thingiverse

free

Remix of Wanhao Duplicator D9 X Axis Upgraded Brackets - Left by Bleugh

...ngiverse

i changed the bracket slightly as the original interfered with the mounting of a mgn12h bracket for the z axis on my d9

thingiverse

free

Wanhao Bed mount camera - Rugged version by Bleugh

.../ nuts will do the job

there are 3 arms, only need to print two, either a 4mm wide end, or a 3mm depending on your camera housing

thingiverse

free

Anycubic Photon Mono - 90 Degree Bed resin drainer by Bleugh

... resin will have dripped off, and your item will be ready to clean.

less resin to clean means your ipa lasts a little longer also

thingiverse

free

Wanhao Duplicator D9 Reworked Cooling Fan - Added Slot for upper cooling....(Uses Stock Port & 5015 Fan!)) by Bleugh

...the top heatsink fan. this should make the thermal barrier in the hotend more effective for longer prints and help reduce jamming

thingiverse

free

Anycubic Photon Mono - 30 and 60 Degree bed drainer by Bleugh

...eded, just print with the text side up!

edit -https://www.thingiverse.com/thing:4817204

see that link for a new 90 degree drainer

thingiverse

free

Wanhao Duplicator 9 D9 Carriage and print head by Bleugh

...069

and, here's the tinkercad link

https://www.tinkercad.com/things/fhyg5rufzqi-wanhao-duplicator-9-d9-extruder-carriage-mk10

thingiverse

free

Wanhao Duplicator 9 D9 Raspberry Pi Camera Bed Mount by Bleugh

... other has a 3mm width on one side as most camera mounts on thingverse seem to be 3mm...

message me if you want a different width

thingiverse

free

Upgrade - X rail linear Wanhao D9 V2 by Nikos33

...nikos33 thingiverse inspired by the cart support created by bleugh this modification makes it possible to stiffen the original...

D9

3d_export

$12

industrial desk lamp d9

... real object. 3. lights and cameras are included in the scenes renders using vray * renders are made in 3ds max 2018 using vray 5

3ddd

free

Ceramica Bardelli (Fornasettiana)

...плитки: bianco extra, l.111, c&c; a1, c&c; a9, c&c; d9 c&c; d3, nero...

thingiverse

free

splitter d9 by jkiki

...splitter d9 by jkiki

thingiverse

thingiverse

free

D9 Hotend Blower by RidHS

...d9 hotend blower by ridhs

thingiverse

modified d9 hotend blower to provide more direct nozzle cooling

thingiverse

free

D9 Dozer with Bar Armor by ThudOne

...d9 dozer with bar armor by thudone

thingiverse

d9 dozer with bar armor ho scale.

israeli and us army version.

thingiverse

free

Wanhao D9 Cable relief for MK10 by OZ9HMN

...wanhao d9 cable relief for mk10 by oz9hmn

thingiverse

wanhao d9 cable relief for mk10

thingiverse

free

Rocket model. Engine D6 or D9. by qlrs

...rocket model. engine d6 or d9. by qlrs

thingiverse

rocket model. engine d6 or d9.

thingiverse

free

RS232 / SUB-D9 box by vidiq

...as to create a female-to-female crossing adapter for fluke-45. the design is tuned for my printer with 0.4 nozzle and 0.2 height.

thingiverse

free

WANHAO DUPLICATOR D9 300 Bed Levelling knob by bubu1882

...wanhao duplicator d9 300 bed levelling knob by bubu1882

thingiverse

wanhao duplicator d9 300 bed levelling knob

thingiverse

free

WANHAO DUPLICATOR D9 400 Bed Levelling knob by bubu1882

...wanhao duplicator d9 400 bed levelling knob by bubu1882

thingiverse

wanhao duplicator d9 400 bed levelling knob

V12

turbosquid

$100

V12 Hypercar

...squid

royalty free 3d model v12 hypercar for download as skp on turbosquid: 3d models for games, architecture, videos. (1482605)

turbosquid

$30

Sword V12

...rbosquid

royalty free 3d model sword v12 for download as c4d on turbosquid: 3d models for games, architecture, videos. (1374966)

turbosquid

$100

V12 Engine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$90

V12 Engine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

V12 Engine

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$12

v12 engine assembly

...v12 engine assembly

3dexport

it is a full v12 engine working assembly. all the parts included in the have been given.

3d_export

free

Aston Martin V12 Vantage

...aston martin v12 vantage

3dexport

aston martin v12 vantage

3d_export

free

1999 CAR V12 LMR

...1999 car v12 lmr

3dexport

1999 car v12 lmr

3d_export

free

Audi Q7 V12 TDI

...audi q7 v12 tdi

3dexport

2009 audi q7 v12 tdi

3d_export

$9

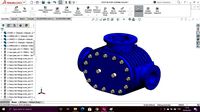

V12 Engine

...v12 engine

3dexport

this 3d model is design in solidworks. render in keyshot.

Wanhao

thingiverse

free

Wanhao Logo Plate / Wanhao Logo Schild by JMDesigns

...wanhao logo plate / wanhao logo schild by jmdesigns

thingiverse

wanhao logo plate / wanhao logo schild

thingiverse

free

Wanhao logo by nebtio

...wanhao logo by nebtio

thingiverse

wanhao logo

thingiverse

free

Wanhao keychain by Rein3003

...wanhao keychain by rein3003

thingiverse

a keychain with the logo of wanhao

thingiverse

free

Wanhao Di3 v2 Light / Wanhao Di3 v2 Beleuchtung by JMDesigns

...wanhao di3 v2 light / wanhao di3 v2 beleuchtung by jmdesigns

thingiverse

wanhao di3 v2 light / wanhao di3 v2 beleuchtung

thingiverse

free

TUSH For Wanhao by wtmi1992

...tush for wanhao by wtmi1992

thingiverse

the ultimate spool holder, modified for the top of the wanhao control box. fits snug.

thingiverse

free

fanduct wanhao d12 by theopoilmek

...fanduct wanhao d12 by theopoilmek

thingiverse

fanduct pour wanhao d12

thingiverse

free

Wanhao i3 Marlin by johan21

...wanhao i3 marlin by johan21

thingiverse

marlin for wanhao i3 rampsboard 1.4.

thingiverse

free

Wanhao Duplicator i3 by imagineering4

...wanhao duplicator i3 by imagineering4

thingiverse

these are the stl files for the improvements to the wanhao duplicator i3, v2

thingiverse

free

Wanhao D6 filament guard

...wanhao d6 filament guard

thingiverse

this is a filament guard for wanhao d6 machine to avoid the filament unrolling

thingiverse

free

Wanhao Duplicator i3 Model by Hilde3D

...wanhao duplicator i3 model by hilde3d

thingiverse

wanhao duplicator i3 model

Duplicator

turbosquid

$10

duplicate

...

turbosquid

royalty free 3d model duplicate for download as on turbosquid: 3d models for games, architecture, videos. (1566034)

turbosquid

$20

Wonderful duplicate kids room

...ul duplicate kids room for download as skp, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1609462)

archive3d

free

Copier 3D Model

...hine duplicating machine

copier n160808 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$30

connect four set

...ate objects that can be disassembled. includes one red and one black checker which can be duplicated to the standard 42 checkers.

3ddd

$1

Черепица

...del

- put it in your scene and duplicate

- level of detail can be edited

- open with 3ds max 2010-2013 or import in your program.

3d_export

$27

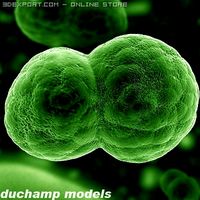

Dividing Cell / Ovule 3D Model

...al microbe blob ovum fiction science ovule duplication divide dividing

dividing cell / ovule 3d model duchampmodels 9691 3dexport

3d_ocean

$16

Folding Chair

...tubing. designed to be good low poly at a distance and mesh smooth pretty well and light weight for duplicating a lot. package...

3d_export

$8

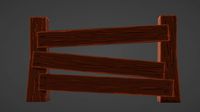

wooden fence

... one post separate so the fence can be duplicated and extended. created in blender 3.0 file format fbx with texture painted maps.

3d_export

$8

wooden fence

... one post separate so the fence can be duplicated and extended. created in blender 3.0 file format fbx with texture painted maps.

3d_ocean

$2

DNA Strands Of 5 Types

... strands that can be multiplied and can be made long chains by duplicating them and can be easily applied materials and textures.

Blower

3d_export

$5

ball blower

...ball blower

3dexport

ball blower

3d_export

$10

engine blower assambly

...engine blower assambly

3dexport

engine blower assambly

3d_export

$5

air pipe blower

...air pipe blower

3dexport

air pipe blower

3d_export

$5

air hand blower

...air hand blower

3dexport

air hand blower

3d_export

$5

Blower Boom 3D Model

...blower boom 3d model

3dexport

boom blower

blower boom 3d model bkl1989 63079 3dexport

turbosquid

$44

blower-dxf

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Old Blower

...l old blower for download as ma, max, gltf, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1638848)

3d_export

$7

zy series centrifugal blower

...zy series centrifugal blower

3dexport

zy series centrifugal blower

3d_export

$5

root blower compressor

...oot blower compressor

3dexport

you will get both .stl and .sldprt format of root blower compressor from here at very cheap rate.

turbosquid

$5

V8 engine with blower

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Upgrade

turbosquid

$15

Upgraded Glock

...e 3d model upgraded glock for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1185950)

3ddd

$1

Calligaris / UPGRADE

...calligaris / upgrade

3ddd

calligaris

c материалом

3d_export

free

cz upgrade

...cz upgrade

3dexport

https://www.buymeacoffee.com/mestrezen3d https://linktr.ee/mestrezen3

turbosquid

$80

Custer Tank upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Domestos 1 upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Upgraded tea cup

...upgraded tea cup

3dexport

a cup with an unusual design and a unique shape for a more enjoyable tea experience

3d_export

$8

dixy outlander classic style upgraded poplar wood lounge chair

...utlander classic style upgraded poplar wood lounge chair

3dexport

dixy outlander classic style upgraded poplar wood lounge chair

turbosquid

free

AK-12 + Upgrades low-poly 3D model

...ow-poly 3d model for download as fbx, blend, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1501145)

evermotion

$700

Upgrade from V-ray 1.5 to 3.5 for 3ds max

...here is no need to purchase a new dongle - your current dongles will be reprogrammed to carry v-ray 3. evermotion 3d models shop.

evermotion

$300

Upgrade from V-Ray 2.0 to V-ray 3.5 for 3ds Max

... interface (gui) for editing settings on one machine and one render node for rendering on one machine. evermotion 3d models shop.

9

3ddd

$1

9

...9

3ddd

консоль

9

turbosquid

$40

Apple iPhone 9 & 9+

...del apple iphone 9 & 9+ for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1284550)

turbosquid

$12

Calligraphic Digit 9 Number 9

...hic digit 9 number 9 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389349)

3ddd

$1

PLANTS 9

...plants 9

3ddd

папоротник , кашпо

plant 9.. hope u all like it

design_connected

$11

194 9

...194 9

designconnected

194 9 computer generated 3d model. designed by lissoni, piero.

design_connected

free

Tangram 9

...tangram 9

designconnected

free 3d model of tangram 9 by lago designed by lago, daniele.

design_connected

$11

Domino 9

...domino 9

designconnected

zanotta domino 9 computer generated 3d model. designed by progetti, emaf.

design_connected

$20

Docks 9

...docks 9

designconnected

gandia blasco docks 9 computer generated 3d model. designed by romero vallejo.

3d_export

$80

mq-9

...mq-9

3dexport

3d_export

$6

washbasin-9

...washbasin-9

3dexport

Fan

3d_export

$5

fan

...fan

3dexport

fan 3d model, table fan, fan, electric fan, ventilator

archibase_planet

free

Fan

...fan

archibase planet

fan large fan

fan out n260707 - 3d model for interior 3d visualization.

archibase_planet

free

Fan

...fan

archibase planet

fan ceiling fan ventilator

fan stealth n300615 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$15

fan

...fan

3dexport

is an ancient fan

3ddd

$1

Fan-C-Fan by marco gallegos

...n-c-fan by marco gallegos

3ddd

вентилятор , marco gallegos

fan-c-fan by marco gallegos

3d_export

$10

fan

...fan

3dexport

a detailed fan designed for home or space blowing is now available for only 19.99!

turbosquid

$1

Fan

...fan

turbosquid

free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1427865)

turbosquid

$14

Fan

...fan

turbosquid

royalty free 3d model fan for download as on turbosquid: 3d models for games, architecture, videos. (1415642)

3ddd

$1

Светильник Fan

...светильник fan

3ddd

fan , italamp

светильник fan, производитель italamp

turbosquid

$25

Fan

...fan

turbosquid

royalty free 3d model fan for download as c4d on turbosquid: 3d models for games, architecture, videos. (1483246)

Top

archibase_planet

free

Top

...top

archibase planet

top

top - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

free

Range Top V36C top

...range top v36c top

3ddd

гриль

проф. гриль range top v36c top

archibase_planet

free

Top

...top

archibase planet

dresser kitchen furniture

top - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Top

...top

archibase planet

bracket bar furniture

bar top - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$5

Top

...lty free 3d model top for download as ma, max, blend, and obj on turbosquid: 3d models for games, architecture, videos. (1579951)

turbosquid

$39

Top

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Top

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

top knifle

...top knifle

3dexport

top knifle

design_connected

$11

Drop Top

...drop top

designconnected

plumen drop top computer generated 3d model.

3d_export

$245

top of the material

...top of the material

3dexport

top of the material,commercial ceiling ceiling material, metal material