Thingiverse

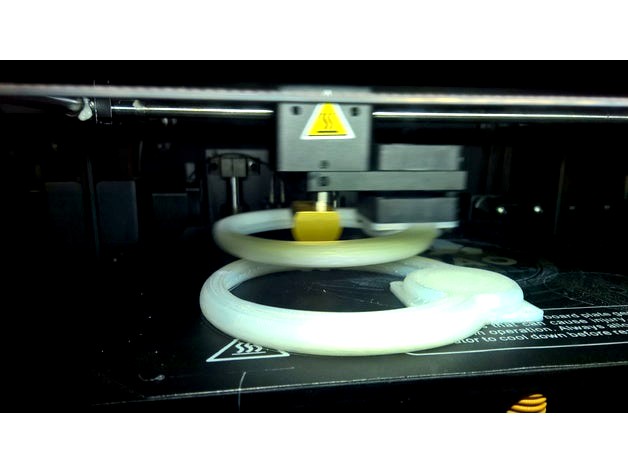

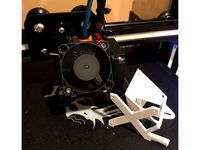

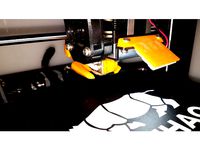

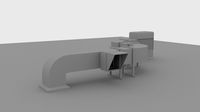

Wanhao Duplicator 6 Air Inducement Duct by Reflector

by Thingiverse

Last crawled date: 3 years ago

Edit: Offset fan version for anyone interestedhttps://www.thingiverse.com/thing:2448580

I tried printing an air inducement shroud for the Duplicator 6 but it was:

Far, far too thin all over

Square in the channel profile (How is this good for airflow?)

Relatively fragile during removal

Slic3r hated it (It also hates what I made so this is OK)

Something about printing another one of them and then trying to remove it from the bed unsuccessfully, again.

With that, I wanted to see if it actually worked. I'm still unsure if it does because I should probably use the latest version of Cura and see if it'll do that thing where it freaks out, makes walls too thin and whatnot.

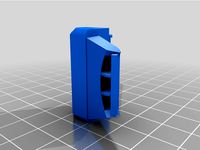

So you get to have my DFAM optimized version of the Son of Air Inducement Duct, with:

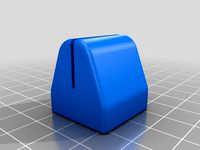

Thick overengineered skookum as frig walls so it doesn't disintegrate when you whip out your woodworking chisel and start slamming it down to try to separate it from the bed. No seriously just try bending the thing if you print it out. Alternatively attempting to crush the profile of the airflow channel with a finger and thumb works as a way to determine grip strength and optionally personal insecurity.

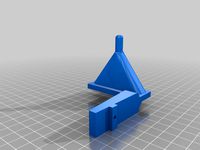

A tiny little divot that connects the gap at the opposing end so the thing isn't SO FRAGILE as to fall apart after you lift it off the bed.

Nice, round fillets everywhere so your machine won't have to slam on the emergency brakes and make a maximum instanteous acceleration in another direction, making it vibrate and generally slow the print down constantly. Why this is known in the machinist world and not in the 3D printing world is beyond me.

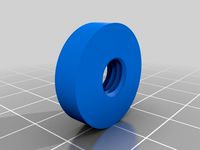

A "stop drooping when I try to bridge a tiny little gap" feature in the middle of the area where the fan is supposed to mount*. I doubt it messes with airflow too much given it sits right below the motor hub and airflow goes to the two tubes anyway.

Even more fillets everywhere because stress points and relative notchiness is NFG in plastics.

Extra thickened structure, because that tiny square profile cannot be the answer to airflow. Instead you get a nice tubular channel that resembles a P in profile for the downward channel component. Who knew that level of recursion could occur. Oh wait printing 3D printer parts with a 3D printer and all.

Have I mentioned the whole rounded, filleted all over thing that seems to help with printing it as well as the round cross section for airflow?

*And with any luck, you will probably see a new version of this design (eventually™**) that actually OFFSETS the fan so its not trying to suck air from an area that has a plate and cavitate like a drowning adult that's never been in a body of hopefully fresh water but has inexplicably become irrationally thirsty and proceeds to do a drowning kind of an interpretive dance in a body of water.. That could mean that puny little stock fan might become suddenly useful. Wishful thinking and all.

**https://www.thingiverse.com/thing:2445979

A full disclosure: I don't claim to know anything about thermoprinterfluidnomics. I just had some real personal issues on a miserably humid and hot day in trying to get a better fan shroud that doesn't require me to find and buy a new fan then print a new shroud so I put my energy into making a clean room "derivative" that solves my personal issues. I still think I am expressing those personal issues as I upload this but go ahead and watch this if you want to eventually see an improved version or have extraordinarily high amounts of overwhelming positivity, hopefulness and excessively high amounts of sloth.

A warning: You will lose a little bit of print area in the left corner (Perspective: You facing the printer) if you use these ducts, they will bump the motor. They effectively take about 1 inch/2-3cm, as in the legs of a triangle more or less. Obviously you have more to lose if you stick anything like a heatsink onto your steppers.

I tried printing an air inducement shroud for the Duplicator 6 but it was:

Far, far too thin all over

Square in the channel profile (How is this good for airflow?)

Relatively fragile during removal

Slic3r hated it (It also hates what I made so this is OK)

Something about printing another one of them and then trying to remove it from the bed unsuccessfully, again.

With that, I wanted to see if it actually worked. I'm still unsure if it does because I should probably use the latest version of Cura and see if it'll do that thing where it freaks out, makes walls too thin and whatnot.

So you get to have my DFAM optimized version of the Son of Air Inducement Duct, with:

Thick overengineered skookum as frig walls so it doesn't disintegrate when you whip out your woodworking chisel and start slamming it down to try to separate it from the bed. No seriously just try bending the thing if you print it out. Alternatively attempting to crush the profile of the airflow channel with a finger and thumb works as a way to determine grip strength and optionally personal insecurity.

A tiny little divot that connects the gap at the opposing end so the thing isn't SO FRAGILE as to fall apart after you lift it off the bed.

Nice, round fillets everywhere so your machine won't have to slam on the emergency brakes and make a maximum instanteous acceleration in another direction, making it vibrate and generally slow the print down constantly. Why this is known in the machinist world and not in the 3D printing world is beyond me.

A "stop drooping when I try to bridge a tiny little gap" feature in the middle of the area where the fan is supposed to mount*. I doubt it messes with airflow too much given it sits right below the motor hub and airflow goes to the two tubes anyway.

Even more fillets everywhere because stress points and relative notchiness is NFG in plastics.

Extra thickened structure, because that tiny square profile cannot be the answer to airflow. Instead you get a nice tubular channel that resembles a P in profile for the downward channel component. Who knew that level of recursion could occur. Oh wait printing 3D printer parts with a 3D printer and all.

Have I mentioned the whole rounded, filleted all over thing that seems to help with printing it as well as the round cross section for airflow?

*And with any luck, you will probably see a new version of this design (eventually™**) that actually OFFSETS the fan so its not trying to suck air from an area that has a plate and cavitate like a drowning adult that's never been in a body of hopefully fresh water but has inexplicably become irrationally thirsty and proceeds to do a drowning kind of an interpretive dance in a body of water.. That could mean that puny little stock fan might become suddenly useful. Wishful thinking and all.

**https://www.thingiverse.com/thing:2445979

A full disclosure: I don't claim to know anything about thermoprinterfluidnomics. I just had some real personal issues on a miserably humid and hot day in trying to get a better fan shroud that doesn't require me to find and buy a new fan then print a new shroud so I put my energy into making a clean room "derivative" that solves my personal issues. I still think I am expressing those personal issues as I upload this but go ahead and watch this if you want to eventually see an improved version or have extraordinarily high amounts of overwhelming positivity, hopefulness and excessively high amounts of sloth.

A warning: You will lose a little bit of print area in the left corner (Perspective: You facing the printer) if you use these ducts, they will bump the motor. They effectively take about 1 inch/2-3cm, as in the legs of a triangle more or less. Obviously you have more to lose if you stick anything like a heatsink onto your steppers.

Similar models

thingiverse

free

Prusa i3 MK2 Modified Extruder Housing and Fan Shroud by IsmaelPR1

...e fan housing as seen in the photo.

this mod is only for the people that don't have an issue with drilling two tiny holes ;-)

thingiverse

free

FanDuct_2in1_40mm_E3Dv6 by MoayadH

... the results are amazing. my printing quality improved significantly, i tried it on regular apa, carbon fiber pla, and ninjaflex.

thingiverse

free

Satsana Ender 3 Fan Duct remix with 12mm sensor mount by Mark456

...h 12mm sensor mounting hole. i added some fillets inside and outside on the air chamber so it doesn't block the airflow much.

thingiverse

free

Ducted 60 mm fan for Mendel90 by richgain

...here was not enough space to fit this so i have released an updated low-profile version at http://www.thingiverse.com/thing:91931

thingiverse

free

E3D Aero High Flow Fan Shroud by NoahSkrzypczak

...slicer does not build support material inside the shroud. they are easy to remove once the print is complete). i hope this helps.

thingiverse

free

40mm Print Fan Shroud (Short version) by bionik

... also a bit thicker, now 1.2mm.

make sure to print this so that the fan hole is facing the hotbed. (rotate 160 degrees on x-axis)

thingiverse

free

Hot end cooling shroud

...del this myself, i used the other person's thing as a direct guide in blender. so props to that person! you know who you are!

thingiverse

free

Monoprice MP Select Mini 40mm Fan Duct Shroud Improved by A_Makers_Life

...duct so i designed this duct to be functionally similar to the stock unit while fitting a 40mm fan....

thingiverse

free

Cooling Duct that works! by doctek

...s to use a centrifugal fan. the duct i'm posting uses one, and believe me, it provides plenty of cooling air for your prints.

thingiverse

free

Micro Swiss Fan Shroud Creality by Fordari

...ok no further, this shroud works mounts with the existing hardware and is easily removed in the same fashion as the stock shroud.

Inducement

3d_ocean

$1

Business Card Stack

... psd realistic reflection render

a 3d business card model. files induced: • a c4d r14 file • an .obj file for other program user.

3d_ocean

$5

Planet Boreas

...g powerful electromagnetic storms. with temperatures a cool -446°c, nothing on here survives.. or does there seem to be life i...

3d_export

$5

tracked tank chassis model

...nd there are induced teeth in the middle to regulate the track and prevent the track from falling off when the tank turns or roll

3d_export

$20

sifi corridor 8j

...nd glow textures can not be transferred in obj format reassignment instructions induced. 2.8 or higher works perfectly. enjoy ;d

3d_export

$7

fire fighting gate valve

... are available in many options, including various sizes, materials, temperature and pressure ratings, and gate and bonnet designs

3d_export

$5

The moon sofa modern sofa post-modern sofa

...imilar to the traditional french causeuse of the petit salon, it is designed for an intimate hangout or a laid-back conversation.

3d_export

$26

cooling tower

...ers.<br>model with full detail in real size. all nodes and bolted connections are built. it was designed for nuclear power.

3d_export

$10

arclinea principia

...a dinner table, perfect for socialising, with edges in shaped solid wood.<br>https://www.arclinea.com/eng/products/principi

thingiverse

free

halfling hotpot - blood bowl inducement

...halfling hotpot - blood bowl inducement

thingiverse

smells good

thingiverse

free

Snappy Dresser by cerberus333

...snappy dresser by cerberus333

thingiverse

the result of a flu induced fever

modeled in sculptris

Reflector

3d_export

$5

reflector

...reflector

3dexport

reflector doble

3ddd

$1

REFLECTOR INDUSTRIAL

...reflector industrial

3ddd

reflector industrial

3ddd

$1

Reflector - SR15

... колонки

открытая акустическая система латвийской компании "reflector", модель - sr15

archive3d

free

Reflector 3D Model

...lector led light lamp spot n220915 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

turbosquid

$99

Reflector Telescope

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Collapsible Reflector

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

floor lamp reflector brass

...floor lamp reflector brass

3dexport

floor lamp reflector brass

3d_export

$40

Collapsible reflector 3D Model

...hoto photography set studio fashion bulb fluorescent lightstand adapter holder

collapsible reflector 3d model braz 23253 3dexport

turbosquid

$2

Reflector Low poly

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$99

Reflector Telescope 3D Model

...highpoly rigged

reflector telescope 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl blendingbastian 111208 3dexport

Wanhao

thingiverse

free

Wanhao Logo Plate / Wanhao Logo Schild by JMDesigns

...wanhao logo plate / wanhao logo schild by jmdesigns

thingiverse

wanhao logo plate / wanhao logo schild

thingiverse

free

Wanhao logo by nebtio

...wanhao logo by nebtio

thingiverse

wanhao logo

thingiverse

free

Wanhao keychain by Rein3003

...wanhao keychain by rein3003

thingiverse

a keychain with the logo of wanhao

thingiverse

free

Wanhao Di3 v2 Light / Wanhao Di3 v2 Beleuchtung by JMDesigns

...wanhao di3 v2 light / wanhao di3 v2 beleuchtung by jmdesigns

thingiverse

wanhao di3 v2 light / wanhao di3 v2 beleuchtung

thingiverse

free

TUSH For Wanhao by wtmi1992

...tush for wanhao by wtmi1992

thingiverse

the ultimate spool holder, modified for the top of the wanhao control box. fits snug.

thingiverse

free

fanduct wanhao d12 by theopoilmek

...fanduct wanhao d12 by theopoilmek

thingiverse

fanduct pour wanhao d12

thingiverse

free

Wanhao i3 Marlin by johan21

...wanhao i3 marlin by johan21

thingiverse

marlin for wanhao i3 rampsboard 1.4.

thingiverse

free

Wanhao Duplicator i3 by imagineering4

...wanhao duplicator i3 by imagineering4

thingiverse

these are the stl files for the improvements to the wanhao duplicator i3, v2

thingiverse

free

Wanhao D6 filament guard

...wanhao d6 filament guard

thingiverse

this is a filament guard for wanhao d6 machine to avoid the filament unrolling

thingiverse

free

Wanhao Duplicator i3 Model by Hilde3D

...wanhao duplicator i3 model by hilde3d

thingiverse

wanhao duplicator i3 model

Duplicator

turbosquid

$10

duplicate

...

turbosquid

royalty free 3d model duplicate for download as on turbosquid: 3d models for games, architecture, videos. (1566034)

turbosquid

$20

Wonderful duplicate kids room

...ul duplicate kids room for download as skp, 3ds, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1609462)

archive3d

free

Copier 3D Model

...hine duplicating machine

copier n160808 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$30

connect four set

...ate objects that can be disassembled. includes one red and one black checker which can be duplicated to the standard 42 checkers.

3ddd

$1

Черепица

...del

- put it in your scene and duplicate

- level of detail can be edited

- open with 3ds max 2010-2013 or import in your program.

3d_export

$27

Dividing Cell / Ovule 3D Model

...al microbe blob ovum fiction science ovule duplication divide dividing

dividing cell / ovule 3d model duchampmodels 9691 3dexport

3d_ocean

$16

Folding Chair

...tubing. designed to be good low poly at a distance and mesh smooth pretty well and light weight for duplicating a lot. package...

3d_export

$8

wooden fence

... one post separate so the fence can be duplicated and extended. created in blender 3.0 file format fbx with texture painted maps.

3d_export

$8

wooden fence

... one post separate so the fence can be duplicated and extended. created in blender 3.0 file format fbx with texture painted maps.

3d_ocean

$2

DNA Strands Of 5 Types

... strands that can be multiplied and can be made long chains by duplicating them and can be easily applied materials and textures.

Duct

turbosquid

$19

Duct Set

...d

royalty free 3d model duct set for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1145038)

turbosquid

$10

Duct Tape

...id

royalty free 3d model duct tape for download as ma and ma on turbosquid: 3d models for games, architecture, videos. (1580351)

turbosquid

free

Duct Tape

...

free 3d model duct tape for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1486518)

3d_ocean

$7

Air-duct

... ventilation

high quality industrial air duct ventilation model. created in cinema 4d but comes in various other formats as well.

turbosquid

$20

Air ducts

...lty free 3d model air ducts for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1262476)

3d_export

$10

Supply air duct

...supply air duct

3dexport

supply air duct with two axial fans and hangers

turbosquid

$2

Duct Tape

...e 3d model duct tape for download as obj, fbx, blend, and dae on turbosquid: 3d models for games, architecture, videos. (1473972)

turbosquid

free

Duct Tape

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Duct tape

...polys. includes: cinema 4d project. model in 3 formats (obj, fbx, 3ds). 6 .tga texture maps (albedo, ambient occlusion, diffus...

turbosquid

$40

Ventilation Duct PACK

...tion duct pack for download as ma, obj, fbx, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1287068)

Air

3ddd

$1

Calligaris air

...calligaris air

3ddd

air , calligaris

cтул calligaris air

3ddd

$1

Air freshener

...air freshener

3ddd

air freshener , освежитель

air freshener

design_connected

$16

Air

...air

designconnected

flexform air lounge chairs computer generated 3d model. designed by antonio citterio.

turbosquid

$250

Heat pump air air

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

air

...air

3dexport

3ddd

$1

Кухня AIR

...кухня air

3ddd

air , мария

кухня air фабрики "мария"

3ddd

$1

Лампа AIR

...лампа air

3ddd

boconcept , air

настольная лампа air, boconcept. в50½xø32см

3d_export

$40

air deflector

...air deflector

3dexport

air deflector

3d_export

$15

air purifier

...air purifier

3dexport

air purifier

3d_export

$5

macbook air

...macbook air

3dexport

macbook air

6

3d_export

$18

tulip 6

...tulip 6

3dexport

tulip 6

3d_export

$5

hinge 6

...hinge 6

3dexport

hinge 6

3ddd

$1

MASIERO / FLASHWOOD STL 6 + 6

...6

3ddd

masiero

торшер flashwood stl 6 + 6 фабрики masiero

http://www.masierogroup.com/c87_697/it/flashwood%20stl%206%20+%206.ashx

turbosquid

$110

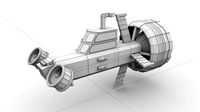

Atmos Cannon 2000 6*6

...yalty free 3d model atmos cannon 2000 6*6 for download as skp on turbosquid: 3d models for games, architecture, videos. (1528591)

turbosquid

$1

ae 6 6 electric locomotive

... free 3d model ae 6 6 electric locomotive for download as obj on turbosquid: 3d models for games, architecture, videos. (1707537)

turbosquid

$39

A-6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

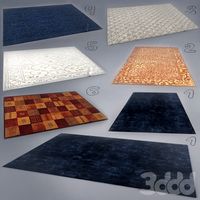

6 ковров

...6 ковров

3ddd

ковры , ковер

6 ковров

turbosquid

$12

Calligraphic Digit 6 Number 6

...hic digit 6 number 6 for download as max, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1389336)

turbosquid

$19

Case For Phone 6 Girl 6

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$35

Iphone 6 & 6 Plus All

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.