Thingiverse

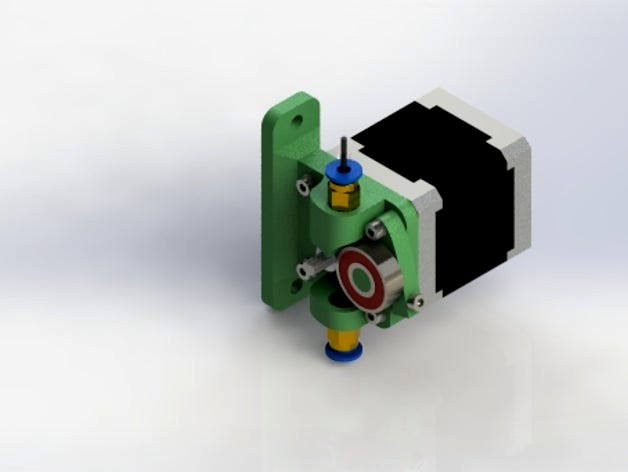

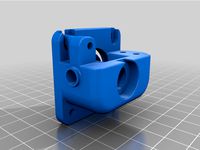

V/T-slot bowden extruder by austingeorge

by Thingiverse

Last crawled date: 3 years ago

This extruder was designed by myself specifically for my C-Bot clone build.

It uses some commonly available components, and tools that i happened to have lying around.

I've managed to get 8mm3/S volumetric extrusion through my e3Dv6 hotend with this extruder; so it is capable of some grunt

The extruder is intended to be mounted directly to T-Slot or V-slot 20mm extrusion with 2x M5 bolts and washers. I've put a recommended size for the M5 bolt in the required list, incase you are mounting this to aluminium extrusion like i have.

The extruder at the moment, only fits 1.75mm filament. I don't currently intend to expand this to any other sizes.

I recommend not to use filament with a bad diameter tolerance. I typically use good quality filament with stated +-0.03mm tolerance and haven't had a jam or slip.

There is no need for a print or suspension mechanism for the idler arm in this design. The springiness is exerted on the idler arm itself. Another good reason to print in PETG or similar strong filament.

Parts

Required:

5x M3x16mm bolts (preferentially hex head)

5x M3 washers

1x M3 brass heat-set insert

2x M5x12mm or M5x10mm bolts and washers (M5x10mm might be a bit short) (to attach mount to extrusion)

1x skateboard bearing (608 - no flange!)

1x MK8 9mm external diameter, 7mm drive diameter gear

1x NEMA17 motor with rotor length of minimum

1x BPT bowden connector (drill out the hex hole to >=4mm if you would like the bowden tube to extend up to the drive gear - This isn't essential though)

Optional:

1x BPT bowden connector for reel-side bowden tube if you're intending to print air-sensitive filaments

Assembly tools:

Soldering iron with temp control

M3 bolt fastening tool (allen key, screwdriver)

9mm spanner or adjustable wrench

Print settings:

I printed at 0.3mm layer height in PETG. I have not tried this design in PLA, or ABS.

Care should be taken pirnting and using this in PLA as it's possible that PLA is too brittle and weak. I have no experience of ABS strength, so can't comment.

Instructions:

Print all 3 parts. ensuring that relevant supports are included wherever required.

Remove supports

Clean up any bolt holes, and bowden connector holes

Test fit the three parts together with bolts. The idler arm should swing on the top left M3 bolt and the extrusion mount should slot nicely into the motor mount and allow the two M3 bolt holes to be fitted to hold them together.

(optional) Drill out bowden tube hole in outlet of extruder. Minimum 4mm drill bit

Carefully, thread the bowden connectors onto the outlet (and inlet if required, using optional bowden connector) motor mount plate. Make sure they thread in straight. They do correct thmselves slightly as they thread in, but be weary that threads are hard to remove once created.

Test fit one of the M3 bolts through the idler arm to the motor mount plate. The hole in the motor mount plate can be threaded with a tap instead of a heat set insert, but i can't imagine it'll hold very well under tension.

Using your soldering iron set to [hotend extrusion temp - 30degC], push the heat-set insert into the hole in the motor mount plate.

Check the heat set insert is lined up with the idler arm bolt by repeating step.608

Push the idler bearing onto the bearing arm

Attach the motor to the back-side of the motor mount.

Mate the extrusion mount and motor mount and bolt together using the motor as the fastening nut. The bolt holes are snug. This is intentional, just keep threading the bolts in

Bolt the final lower right bolt of the motor mount to the motor.

Thread in some filament, insert bowden tube, attach to your printer, and tension the idler arm to suit.

It uses some commonly available components, and tools that i happened to have lying around.

I've managed to get 8mm3/S volumetric extrusion through my e3Dv6 hotend with this extruder; so it is capable of some grunt

The extruder is intended to be mounted directly to T-Slot or V-slot 20mm extrusion with 2x M5 bolts and washers. I've put a recommended size for the M5 bolt in the required list, incase you are mounting this to aluminium extrusion like i have.

The extruder at the moment, only fits 1.75mm filament. I don't currently intend to expand this to any other sizes.

I recommend not to use filament with a bad diameter tolerance. I typically use good quality filament with stated +-0.03mm tolerance and haven't had a jam or slip.

There is no need for a print or suspension mechanism for the idler arm in this design. The springiness is exerted on the idler arm itself. Another good reason to print in PETG or similar strong filament.

Parts

Required:

5x M3x16mm bolts (preferentially hex head)

5x M3 washers

1x M3 brass heat-set insert

2x M5x12mm or M5x10mm bolts and washers (M5x10mm might be a bit short) (to attach mount to extrusion)

1x skateboard bearing (608 - no flange!)

1x MK8 9mm external diameter, 7mm drive diameter gear

1x NEMA17 motor with rotor length of minimum

1x BPT bowden connector (drill out the hex hole to >=4mm if you would like the bowden tube to extend up to the drive gear - This isn't essential though)

Optional:

1x BPT bowden connector for reel-side bowden tube if you're intending to print air-sensitive filaments

Assembly tools:

Soldering iron with temp control

M3 bolt fastening tool (allen key, screwdriver)

9mm spanner or adjustable wrench

Print settings:

I printed at 0.3mm layer height in PETG. I have not tried this design in PLA, or ABS.

Care should be taken pirnting and using this in PLA as it's possible that PLA is too brittle and weak. I have no experience of ABS strength, so can't comment.

Instructions:

Print all 3 parts. ensuring that relevant supports are included wherever required.

Remove supports

Clean up any bolt holes, and bowden connector holes

Test fit the three parts together with bolts. The idler arm should swing on the top left M3 bolt and the extrusion mount should slot nicely into the motor mount and allow the two M3 bolt holes to be fitted to hold them together.

(optional) Drill out bowden tube hole in outlet of extruder. Minimum 4mm drill bit

Carefully, thread the bowden connectors onto the outlet (and inlet if required, using optional bowden connector) motor mount plate. Make sure they thread in straight. They do correct thmselves slightly as they thread in, but be weary that threads are hard to remove once created.

Test fit one of the M3 bolts through the idler arm to the motor mount plate. The hole in the motor mount plate can be threaded with a tap instead of a heat set insert, but i can't imagine it'll hold very well under tension.

Using your soldering iron set to [hotend extrusion temp - 30degC], push the heat-set insert into the hole in the motor mount plate.

Check the heat set insert is lined up with the idler arm bolt by repeating step.608

Push the idler bearing onto the bearing arm

Attach the motor to the back-side of the motor mount.

Mate the extrusion mount and motor mount and bolt together using the motor as the fastening nut. The bolt holes are snug. This is intentional, just keep threading the bolts in

Bolt the final lower right bolt of the motor mount to the motor.

Thread in some filament, insert bowden tube, attach to your printer, and tension the idler arm to suit.

Similar models

thingiverse

free

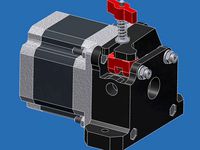

Bowden Extruder with captured connector by bradjshannon

...nt path removed for now. not needed except for flexible filaments, anyways

public fusion 360 project link: http://a360.co/2devcfk

thingiverse

free

Bowden Extruder for 2020 Profile - 1.75 MK7 608zz by Enrike_X5

...around 15mm lenth)

1x nema17 stepper

1x ptfe tube

you may need a tap kit (m5 and m8) to correct the threads, and a 2mm drill bit.

thingiverse

free

Alpha Direct Drive Extruder by engineglue

...upply list; this is a minimal design. you can use m4 bolts and nuts to mount it. it mounts to a standard aluminum mounting plate.

thingiverse

free

Printrbot 1401 - Bowden Conversion Extruder Motor to Bowden connector by astemoi

...otor to bowden connector by astemoi

thingiverse

attach to the aluminium extuder motor mount to and thread bowden tube connector.

thingiverse

free

Compact bowden extruder mount plate by BubaLettow

...

thingiverse

here is a mount to stiffen the bowden extruder for a through hole mounting scenario. set up for a m3 bolts and nuts

thingiverse

free

Bowden Mount for Greg's Wade's Extruder by Tearabite

...nd just trap a couple of nuts threaded onto the bowden tube in between the mount and the extruder itself. it works fantastically.

thingiverse

free

Ball Joint Filament Guide for 2040 Extrusion by Slava_Z

... m5x10mm, m5x10mm or m5x6mm bolt, and 4mm wide ptfe tube.

use 4mm drill bit if ptfe tube doesn't wand to go through the hole.

thingiverse

free

Yet Bondtech Bowden Extruder - Geared with Belt

... be printed in the orientation they are in when loading the files.

designed to be printed with 0.2mm layer or a division here of.

thingiverse

free

Openbuilds v-slot X axis for Lulzbot TAZ 6 printers by piercet

...head m5 bolts and nuts 30mm (standard bolts will not fit, need the flat ones. ). longer if you plan to add the cable chain pieces

thingiverse

free

Nema23 Bowden Extruder Cold End (1.75mm) by 4ndreas

...rod.

for the motor mount i used din 933 hex screws, the head fits in the extruder mount and can attracted from the motor side.

Austingeorge

thingiverse

free

M5 20x20 extrusion cable tie mount by austingeorge

... m5 nut.

two cable tie mount points are on either side of the mount, assuming wires would run perpendicular to cable tie opening.

thingiverse

free

Wanhao duplicator i3 extruder assembly reference by austingeorge

....

please point out any changes i can make.

and feel free to improve upon these models by adding further detailing where required.

thingiverse

free

Wanhao i3 Z endstop - No extra bolts needed by austingeorge

...o.

don't throw away the two bolts that originally mounted the switch as they're used to mount the bracket to the frame.

thingiverse

free

Wanhao Di3 30mm to 40mm fan adapter by austingeorge

...#39;s not neccessary

pictures show how to use the nuts and tapped threads.

let me know if there's any improvements i can make

thingiverse

free

Gear generator for Solidworks (Straight / Helix / Herringbone) by austingeorge

...ting of gears

added gear profile for gear ratio mate

adjusted how the herringbone is generated as it broke on some configurations

thingiverse

free

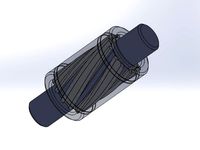

4mm PTFE LM8UU replacement by austingeorge

...y less than ideal bridging on the inside of the bearing casing

slide onto an 8mm linear rod and run up and down to check movement

thingiverse

free

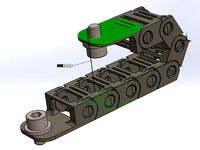

20mm Extrusion cable chain - Small bend radius - Minimal twist by austingeorge

...m internal face

internal cavity measures 12mm width, 7mm height.

end connectors fit bolts commonly used with 20x20 extrusion (m5)

thingiverse

free

Wanhao duplicator i3 <=V1 - Glass bed XY corner clamp by austingeorge

...d over time.

i also recommend you print this in abs, due to thermal properties and to avoid warping when your bed gets to temp.

thingiverse

free

Duplicator i3 Adjustable Z Endstop - no extra hardware by biohazrd

...hardware by biohazrd thingiverse this is a remix of austingeorge#39;s adjustable endstop. the original puts the endstop too high...

Bowden

turbosquid

$199

Vintage Ben Bowden Spacelander bike

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Manooi Artica

...and pendants in various sizes and forms. suspension: galvanized bowden - dia. 1,5 mm. bulb: max 60 w -...

thingiverse

free

Remix Compact Bowden extruder - m6 bowden couplers and bowden tube pass-through

...ouplers and bowden tube pass-through

thingiverse

remix compact bowden extruder - m6 bowden couplers and bowden tube pass-through

thingiverse

free

Bowden Extruder

...bowden extruder

thingiverse

i have created bowden extruder for flsun delta 3d printer.

thingiverse

free

bowden 3mm by spee_D

...bowden 3mm by spee_d

thingiverse

for bowden 3mm

thingiverse

free

Bowden Tube Cutter

...bowden tube cutter

thingiverse

bowden tube cutter

thingiverse

free

Customizable Bowden Clip

...customizable bowden clip

thingiverse

customizable bowden clip

thingiverse

free

Bowden Oiler by fcheshire

...bowden oiler by fcheshire

thingiverse

inline bowden oiler

thingiverse

free

Bowden adapter by helkaroui

...bowden adapter by helkaroui

thingiverse

this is a fixed bowden adapter

thingiverse

free

Adventure3 Bowden Clip

...adventure3 bowden clip

thingiverse

adventure3 bowden clip

Extruder

3ddd

$1

Extruded Chair

...extruded chair

3ddd

extruded , tom dixon

inspired by tom dixon extruded chair

turbosquid

$15

Extruded Table

... extruded table for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1634137)

turbosquid

$2

3D Printer Extruder

...d

royalty free 3d model 3d printer extruder for download as on turbosquid: 3d models for games, architecture, videos. (1537359)

turbosquid

$1

Zombie extruded text

...oyalty free 3d model zombie extruded text for download as obj on turbosquid: 3d models for games, architecture, videos. (1322198)

turbosquid

$4

Extruder conical screw

...el extruder conical screw for download as sldpr, ige, and stl on turbosquid: 3d models for games, architecture, videos. (1524433)

turbosquid

$50

3d PRINTER - Extruder

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Extruded Table 2

...xtruded table 2 for download as blend, dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1621846)

turbosquid

$10

Maya Extrude Tool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

world earth extrude map

...world earth extrude map

3dexport

3ddd

$1

Simply Elegant Extruded Tree Coffee Table Design

...ble by link studios. the silhouette of a tree is visible at one angle, extruded from the surface to create the support structure.

Slot

3d_export

$5

slot handle

...slot handle

3dexport

slot handle

archibase_planet

free

Slot machine

...ase planet

slot machine slot-machine playing machine

slot machine n260311 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Slot machine

... machine slot-machine one-armed bandit

slot machine novomatic gaminator n240911 - 3d model (*.3ds) for interior 3d visualization.

3d_export

$5

narrow slot handle

...narrow slot handle

3dexport

narrow slot handle

turbosquid

$15

Slot Machine

...oyalty free 3d model slot machine for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1710861)

turbosquid

$25

Slot Machine

... free 3d model slot machine for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1649555)

turbosquid

$25

Coin Slots

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$11

Slotted spoon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Slot Sofa

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

slotted spoon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

V

design_connected

$16

V Chair

...v chair

designconnected

v chair computer generated 3d model.

design_connected

$11

V Hanglamp

...v hanglamp

designconnected

arturo alvarez v hanglamp computer generated 3d model. designed by alvarez, arturo .

turbosquid

$25

Borbet V

...v

turbosquid

royalty free 3d model borbet v for download as on turbosquid: 3d models for games, architecture, videos. (1381618)

turbosquid

free

Saturn V

...rn v

turbosquid

free 3d model saturn v for download as blend on turbosquid: 3d models for games, architecture, videos. (1651098)

turbosquid

$40

V motor

...turbosquid

royalty free 3d model v motor for download as max on turbosquid: 3d models for games, architecture, videos. (1379483)

turbosquid

$7

V for Van

...rbosquid

royalty free 3d model v for van for download as max on turbosquid: 3d models for games, architecture, videos. (1695889)

turbosquid

$5

Letter v

...urbosquid

royalty free 3d model letter v for download as max on turbosquid: 3d models for games, architecture, videos. (1408535)

turbosquid

$5

Letter v

...urbosquid

royalty free 3d model letter v for download as max on turbosquid: 3d models for games, architecture, videos. (1408534)

turbosquid

$15

BonePile V

...oyalty free 3d model bonepile v for download as blend and obj on turbosquid: 3d models for games, architecture, videos. (1546310)

turbosquid

$2

FONT V

...quid

royalty free 3d model font v for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1549450)

T

design_connected

$11

T & T

...t & t

designconnected

dark t & t computer generated 3d model. designed by de ryck, christophe.

3d_export

$5

t-800

...t-800

3dexport

t-800

3ddd

$1

Table T

...table t

3ddd

журнальный

table t

3ddd

free

T-Rex

...t-rex

3ddd

t-rex

rrrrrr

3d_export

$5

t-virus

...t-virus

3dexport

it's t-virus

3d_export

$5

T-26T

...t-26t

3dexport

artillery tractor on the t-26 chassis ussr

3ddd

$1

T 45

...t 45

3ddd

t-45

кабинет руководителя t 45

12 предметов

подробнее:http://www.prezident-mebel.ru/index.php?productid=1541

3ddd

free

SAFE T

...safe t

3ddd

огнетушитель

креативные огнетушители от компании safe t

3d_export

free

t-rex

...t-rex

3dexport

t-rex have normal map and base color textures

3d_export

$75

T-55

...nally, but these improvements made the tank more efficient and lethal. the t-55 was officially adopted by the soviet army in 1958