Thingiverse

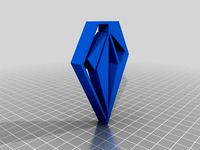

Volcom Snowboard Stomp Pad by 0161design

by Thingiverse

Last crawled date: 3 years, 1 month ago

Quick copy of the Volcom Stone Snowboard Stomp Pad set, lost one of my originals.

(Top Centre in photo is Volcom origional)

This was a Polycarbonate Test (Hobby-king black PC)

Enclosed Stock CR-10 (with some mods In marlin flashed to allow High Temps and Mesh levelling)

Nozzle 0.4

Extrusion Multiplier 1.0

Retract distance 5mm

Retract speed 30mm/s

Bed temp 100

Hot-end 280 first layer, 275 for rest of build

Top and bottom 4 layers

Outer shells 5

First Layer 91 %

Cooling 0

Layer Hight 0.2

Infill 30% Fast Honeycomb

Print Speed 40 mm/s

Supports 0

Simplify 3D

Using Stock CR-10 Hot-end with Capricorn Bowden tube.(Best upgrade you can buy)

Tuned Stock Power Supply to 13 Volts ( see youtube for this stock mod it will allow your

heat-bed to heat quickly and achieve 100* Plus)

I Don't see any reason Why PLA or ABS would work for this. It would be defiantly easier

than printing Polycarbonate. Its a short build so bump up your infill.

Because it was pollycarbonate I had slight curling on the narrow end which I had to sand out, precision is not necessary on a stomp pad.

Notes on Polycarbonate :

Very hard to stop shrinkage

Defiantly need a heated chamber (mine is not hot enough yet)

Tough as F&*K so get it right the first time because sanding theses little Doodads flat was

hard work on a belt sander. Really this stuff is Super Strong !!!

High Glass Transition Temp

Amazing material if you Dial it in !

Shred !

(Top Centre in photo is Volcom origional)

This was a Polycarbonate Test (Hobby-king black PC)

Enclosed Stock CR-10 (with some mods In marlin flashed to allow High Temps and Mesh levelling)

Nozzle 0.4

Extrusion Multiplier 1.0

Retract distance 5mm

Retract speed 30mm/s

Bed temp 100

Hot-end 280 first layer, 275 for rest of build

Top and bottom 4 layers

Outer shells 5

First Layer 91 %

Cooling 0

Layer Hight 0.2

Infill 30% Fast Honeycomb

Print Speed 40 mm/s

Supports 0

Simplify 3D

Using Stock CR-10 Hot-end with Capricorn Bowden tube.(Best upgrade you can buy)

Tuned Stock Power Supply to 13 Volts ( see youtube for this stock mod it will allow your

heat-bed to heat quickly and achieve 100* Plus)

I Don't see any reason Why PLA or ABS would work for this. It would be defiantly easier

than printing Polycarbonate. Its a short build so bump up your infill.

Because it was pollycarbonate I had slight curling on the narrow end which I had to sand out, precision is not necessary on a stomp pad.

Notes on Polycarbonate :

Very hard to stop shrinkage

Defiantly need a heated chamber (mine is not hot enough yet)

Tough as F&*K so get it right the first time because sanding theses little Doodads flat was

hard work on a belt sander. Really this stuff is Super Strong !!!

High Glass Transition Temp

Amazing material if you Dial it in !

Shred !

Similar models

thingiverse

free

Snowboard Stomp Pad Anti Slide

...snowboard stomp pad anti slide

thingiverse

stomp pad/ grip mat for snowboards

thingiverse

free

Kleiderstange by Daraff

...es

no

complete individual objects

no

enable ooze prevention

no

keep fan on

no

retract on layer change

no

wipe while retracting

no

thingiverse

free

Snowboard Stomp Pads Customizable (Nitro, Burton, Quiksilver, Anon, Vans, Volcom, ..) by Tomblarom

...n't wait for it! :)

to fix it on the board i used 3m double-sided tape, but i don't know if it resists cold temperatures.

thingiverse

free

JUMANJI DRAGONFLY by LocoBeeFPV

...d, 4mm/s initial layer jerk, 6mm/s regular layer jerk, 300mm/s accelerations, 1.5mm retraction distance, 35mm/s retraction speed.

thingiverse

free

MIATA RADIO BEZEL ANGLED GAUGES by Natech603

...layer

polycarbonate abs 290 first layer 285 every other later

use brim

adhesive used was gluestick..... alot of it

thingiverse

free

Hot end CR-10

...hot end cr-10

thingiverse

3d model heat sink and heat break of cr-10 hot end.

thingiverse

free

RaceWhoop by Freezillion

...ything''

retraction 8,5 and retraction speed 30

gcodes tested on ender 3/5 and crealety cr10

print in taulman pctpe nylon

thingiverse

free

SkULL Stomp Pad by roadhog

...a stomp pad for my snowboard.

this is what i came up with so far not sure if it would work or what to print it in ?

have fun.

thingiverse

free

Slipper Clutch Friction Pad for 1/10 Traxxas Vehicles

...use the clutch does get very hot.

i used a vice to put these onto the clutch where the stock pads go on, it will take some force.

thingiverse

free

Fishman Stomp Pad by T311

...t311

thingiverse

snowboarding stomp pad inspired by the jon fishman moo moo.

set the gear shift to the high gear of your soul.

Volcom

thingiverse

free

volcom by Ema3006

...volcom by ema3006

thingiverse

the volcom logo

thingiverse

free

VOLCOM LOGO by jaimecastegym18

...volcom logo by jaimecastegym18

thingiverse

volcom logo

thingiverse

free

volcom necklace by print3dXYZ

...volcom necklace by print3dxyz

thingiverse

volcom logo

thingiverse

free

Volcom Keychain by Marios1983

...volcom keychain by marios1983

thingiverse

volcom ... keys ... chains ...

thingiverse

free

Volcom Star by Marios1983

...volcom star by marios1983

thingiverse

volcom star logo ...

thingiverse

free

Volcom and Burton Keyring by Ema3006

...volcom and burton keyring by ema3006

thingiverse

volcom logo keyring and burton keyring

thingiverse

free

Volcom keychain by facucor

...volcom keychain by facucor

thingiverse

enjoy it!

thingiverse

free

Volcom Logo by sp4nky

... with sw, have fun with it.

there's a version with bridges between some parts so that nothing can fall off after printing :p

thingiverse

free

Volcom logo by facucor

...volcom logo by facucor

thingiverse

hope to be useful!

please share alike!

thingiverse

free

Volcom Stone by curly_J_productions

...volcom stone by curly_j_productions

thingiverse

let me know any possible improvements

Stomp

3d_export

$5

Forest package 3D Model

...forest package 3d model 3dexport forest tree stomp fire pit night camp forest package 3d model shadowlight123...

3d_ocean

$15

Low poly plants pack

...game grass low poly mobile mushroom nature plants reeds stomp stylized low poly plants and assets, great for mobile...

3d_export

$40

Worker Robot

...animation files for character studio biped. idle, walk, run, stomp and carry.<br>|formats|<br>three *.max files for the 3 render engines....

3d_export

$150

animated shantungosaurus dinosaur

...optimized identically for game engine compatibility.<br>||specs||<br>polys 12196 verts 6276<br>animations:<br>1. idle<br>2.walk<br>3.run<br>4.stomplt;br>5.roar<br>6.call<br>7.drink<br>8.sniff<br>format ...

thingiverse

free

Stomp Rocket by adamthole

... compatible with stomp rocket launchers. for more information see this page:

http://www.adamthole.com/3d-printable-stomp-rocket/

thingiverse

free

HX Stomp Stand by PhillBagnall

...hx stomp stand by phillbagnall

thingiverse

stand for the line 6 hx stomp effects pedal.

thingiverse

free

Snowboard Stomp Pad Anti Slide

...snowboard stomp pad anti slide

thingiverse

stomp pad/ grip mat for snowboards

thingiverse

free

Snowboarding Stomps by MakerBot

...e ski lift? brush that snow off your boot and show off your 3d printing skills at the same time with this snowboarding stomp pad.

thingiverse

free

Fishman Stomp Pad by T311

...t311

thingiverse

snowboarding stomp pad inspired by the jon fishman moo moo.

set the gear shift to the high gear of your soul.

thingiverse

free

Stomp Rocket - Replacement Rocket. by phoughton

...thingiverse

these hollow cylinders are replacement rockets for a child's stomp ocket.

fits a launch tube of 8.75mm (± 0.2mm)

Snowboard

turbosquid

$22

Snowboarder with Snowboard

... snowboarder with snowboard for download as 3ds, obj, and c4d on turbosquid: 3d models for games, architecture, videos. (1235992)

turbosquid

$1

Snowboard

...rbosquid

royalty free 3d model snowboard for download as fbx on turbosquid: 3d models for games, architecture, videos. (1352634)

turbosquid

$9

snowboard

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Snowboard

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$5

Snowboard

...ygonal model, easy to animate. - poly count: 700 - formats: max /obj /fbx/3ds/dxf - high detail was preserved with 2048...

3d_ocean

$20

Snowboarder

...details and personal features designing. the model of such quality perfectly suits for using in games or cg movies. the face w...

3d_export

$5

Snowboard 3D Model

...nowboard snowboarding board desk bindings 3dmax gamedev 3d winter snow sport

snowboard 3d model sniperbdc199787497 93534 3dexport

archive3d

free

Snowboard 3D Model

...ve3d

snowboard

snowboard burton vapor n080211 - 3d model (*.3ds) for interior 3d visualization.

turbosquid

$12

Snowboards 03

...free 3d model snowboards 03 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1489977)

3d_ocean

$6

Snowboard & Bindings

...er then this model is perfect to showcase your designs on. the model can also be dragged straight in to ibooks author for an i...

Pad

turbosquid

$15

Note Pad Writing Pad

...oyalty free 3d model note pad writing pad for download as max on turbosquid: 3d models for games, architecture, videos. (1309269)

3ddd

$1

Bed Padded

...bed padded

3ddd

padded bed , pixellin

padded bed , pixellin , bed 3d model

3d_export

$5

Padded stool

...padded stool

3dexport

padded stool

3d_export

free

Padded stool

...padded stool

3dexport

padded stool

3d_export

$5

pads

...pads

3dexport

3d_ocean

$2

mouse pad

...mouse pad

3docean

3d models computer electronics mouse

mouse pad 3d models. it’s mouse pad.

3d_export

$5

Padded stool

...padded stool

3dexport

leather padded stool on a metal base

3d_export

$5

Padded stool

...padded stool

3dexport

leather padded stool on a metal base.

3d_export

$8

Padded chair

...padded chair

3dexport

padded chair, black spout and light blue leatherette.

3d_export

$7

Padded Stool

...padded stool

3dexport

padded stool, black spout and light blue leatherette.