Thingiverse

Vise for Hobby Creek Helping Hands by nzeut

by Thingiverse

Last crawled date: 3 years, 1 month ago

OVERVIEW

This was part of a class project. Each student in the class was challenged to design and print a working vise design of your choice (PC board, helping hand, etc). The design required at least two printed parts and use at least one ¼”-20 threaded bolt/rod and nut.

I do a lot of PCB board mods and work for installing electronics into arcade sticks used on video game consoles. I also do similar work for PCB mods that are incorporated into arcade machines. One of my favorite helping hands tools is the Hobby Creek Helping Hands Third Hand Soldering Tool (http://a.co/bVCI6BG). One downside to this helping hands tool is the lack of a centralized vise to use for supporting the boards I work on. I own other helping hands and a PanaVise “Junior”, but I’ve always wanted something that would fit in the center of the Hobby Creek tool.

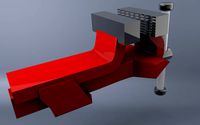

CURRENT VERSION

Pictures included show the current working design. There are four separately printed parts: base, two jaws, and a knob. It is mounted to the helping hands tool via large zip ties. Hardware used:

• 4” long ¼”-20 hex bolt

• 1 ¼” nylon lock nut

• 3 ¼” nuts

• 1 ¼” lock washer

• 2 ¼” flat washers

• Hot glue

The stationary jaw is secured to the base using some hot glue. An attempt was made to allow it to be stationary but floating, but this did not work at all in real use. The moving jaw’s nut was hammered into place using a rubber mallet. The knob was attached by heating the hex head with a hot air gun and pressing it into the knob. The lock nut and a washer are on the outside of the stationary jaw, and a washer, set of nuts and lock nut, are on the inside to keep the bolt from moving side to side.

Opening and closing the jaws is a little counter intuitive, but it functions. Opening is done by turning clockwise. It’s recommended to open the jaws just a little wider than the PCB to be secured, slide the PCB in the stationary jaw, and then secure and align the motion jaw. All four orientations can be tight enough without requiring a lot of pressure.

IMPROVEMENTS TO MAKE

Currently, the vise is usable. Improvements that could be made to the design include:

• Merge stationary jaw with base

• Make jaws capable of having interchangeable heads

• Adjust movement mechanism

• Different channel design for motion of jaws

• Improve mechanical design elements

This was part of a class project. Each student in the class was challenged to design and print a working vise design of your choice (PC board, helping hand, etc). The design required at least two printed parts and use at least one ¼”-20 threaded bolt/rod and nut.

I do a lot of PCB board mods and work for installing electronics into arcade sticks used on video game consoles. I also do similar work for PCB mods that are incorporated into arcade machines. One of my favorite helping hands tools is the Hobby Creek Helping Hands Third Hand Soldering Tool (http://a.co/bVCI6BG). One downside to this helping hands tool is the lack of a centralized vise to use for supporting the boards I work on. I own other helping hands and a PanaVise “Junior”, but I’ve always wanted something that would fit in the center of the Hobby Creek tool.

CURRENT VERSION

Pictures included show the current working design. There are four separately printed parts: base, two jaws, and a knob. It is mounted to the helping hands tool via large zip ties. Hardware used:

• 4” long ¼”-20 hex bolt

• 1 ¼” nylon lock nut

• 3 ¼” nuts

• 1 ¼” lock washer

• 2 ¼” flat washers

• Hot glue

The stationary jaw is secured to the base using some hot glue. An attempt was made to allow it to be stationary but floating, but this did not work at all in real use. The moving jaw’s nut was hammered into place using a rubber mallet. The knob was attached by heating the hex head with a hot air gun and pressing it into the knob. The lock nut and a washer are on the outside of the stationary jaw, and a washer, set of nuts and lock nut, are on the inside to keep the bolt from moving side to side.

Opening and closing the jaws is a little counter intuitive, but it functions. Opening is done by turning clockwise. It’s recommended to open the jaws just a little wider than the PCB to be secured, slide the PCB in the stationary jaw, and then secure and align the motion jaw. All four orientations can be tight enough without requiring a lot of pressure.

IMPROVEMENTS TO MAKE

Currently, the vise is usable. Improvements that could be made to the design include:

• Merge stationary jaw with base

• Make jaws capable of having interchangeable heads

• Adjust movement mechanism

• Different channel design for motion of jaws

• Improve mechanical design elements

Similar models

thingiverse

free

Vise Holder

... the original pcb holder, but it can also be used alone.

you need a m5 x 35mm hex head bolt (or longer) with washer and wing nut.

thingiverse

free

Ender 3 Adjustable Z Endstop Cryo by cryogen

...ing part of the bolt use the lock washed and nut to secure the bolt in the knob.

i use petg for long-term use of the item.

enjoy.

thingiverse

free

Vise Clamp With Detachable Grips by SlimJim24

...e grips into the fixed jaw base and sliding jaw. these grips have dovetail joints and can be redesigned to meet the user’s needs.

thingiverse

free

Versa-Vice by jlh62

...rip round objects either vertically or horizontally. two of the jaws will grip round objects on the inside or outside perimeter.

thingiverse

free

Replacement knob for mailbox by faekie

...ntouched.

use 1 m5 ~45-50mm hex bolt, nylon lock nut and large washer to secure the locking arm to the "knob cylinder".

cg_trader

$6

lock the door | 3D

...rong and it is recommended to use petg filament lock door tool key security door handle hobby diy hobby diy hand tools hand tools

cg_trader

$4

Screw Nut | 3D

... fasten multiple parts together. design nut screw screwnut business round tool together hobby diy hobby diy hand tools hand tools

thingiverse

free

PCB Helping Hands Vise/Clamp

...ing on the position of the magnifying glass, the tool may be top heavy and fall over. this pcb vise design solves these problems.

thingiverse

free

"the Vise" (mini edition) by PRIma

...w includes some support already therefore use

0.2mm layer/nozzle 0.4/shell thickness 0.8

washer/nut/knob printed with 0.1mm layer

thingiverse

free

Vise for Holding a PCB (or other lightweight items) by wisar

...en the jaws is 100mm. there are tabs on the jaws to allow the vise to be secured to a table (a little masking tape also works).

Creek

3d_export

$65

creek

...creek

3dexport

simple rendering of the scene file

3d_export

$65

creek

...creek

3dexport

simple rendering of the scene file

3d_export

$65

creek

...creek

3dexport

simple rendering of the scene file

3d_export

$65

creek

...creek

3dexport

simple rendering of the scene file

3d_export

$65

creek

...creek

3dexport

simple rendering of the scene file

3d_export

$65

creek

...creek

3dexport

simple rendering of the scene file

turbosquid

$40

peppermint creek

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$11

Waterfall Creek Forest model

...waterfall creek forest model

3dexport

waterfall creek forest model

design_connected

$13

Creek Coffee Tables

...creek coffee tables

designconnected

poliform creek coffee tables computer generated 3d model. designed by massaud, jean-marie.

design_connected

$13

Creek Console Tables

...creek console tables

designconnected

poliform creek console tables computer generated 3d model. designed by massaud, jean-marie.

Vise

3d_export

$6

Machine vise

...machine vise

3dexport

machine vise

3d_export

$5

Machine vise

...machine vise

3dexport

machine vise

turbosquid

$2

Vise

...uid

royalty free 3d model vise for download as obj and blend on turbosquid: 3d models for games, architecture, videos. (1445802)

turbosquid

$10

Vise

...

royalty free 3d model vise for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1170628)

turbosquid

$40

Vise

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

Vise

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$19

Vise

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$16

Vise

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

Vise

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

vise

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Hobby

archive3d

free

Hobby 3D Model

...ing-horse hobby-horse

seat baby n070411 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$10

HOBBY ROCKET

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Hobby Knife

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$17

HOBBY PAINT BOTTLE

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Кресло Hello Hobby 3108-01

... hello hobby

классическое кресло из ротанга фабрики hello hobby. арт. 3108-01. габариты 950*890*1030

3ddd

free

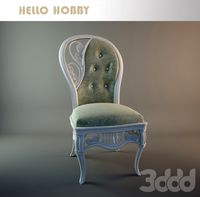

Стул Hello Hobby 3108-09

... hello hobby

классический стул ручной работы из ротанга фабрики hello hobby. арт. 3108-09. габариты 670*580*1030

3d_export

$49

Houston William Hobby Airport 10km

...houston william hobby airport 10km

3dexport

3ddd

$1

Стол Hello Hobby 3014(2)-07

... hello hobby

классический стол ручной работы из ротанга фабрики hello hobby. арт. 3014(2)-07. габариты 900*1600*770.

3ddd

$1

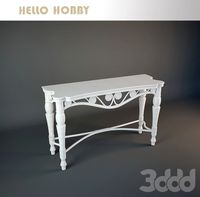

Консоль Hello Hobby 3083-51

... консоль.

консоль в классическом стиле ручной работы из ротанга фабрики hello hobby. арт. 3083-51. габариты 430*1220*760.

turbosquid

$99

Hobby and Decor Set 04 (22 Product)

...d decor set 04 (22 product) for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1262740)

Hands

3d_export

$8

hand

...hand

3dexport

fantasy hand

3d_export

$5

hand

...hand

3dexport

male hand

3d_export

$5

hand

...hand

3dexport

realistic male hand

3d_export

$5

hand

...hand

3dexport

hand with nails and structure

archibase_planet

free

Hand

...hand

archibase planet

hand

hand n190111 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Hand

...hand

3ddd

hand

модель руки будды

3d_export

$5

hand

...hand

3dexport

it is my wrist of hand and this is on 3d sculpt

3d_export

$5

hand

...hand

3dexport

realistic male hand obj file

3d_export

$7

hand-006 rigged hand

...hand-006 rigged hand

3dexport

rigged right hand 3d model additional textures for pbr rendering included

3d_ocean

$6

Hand

...poly rigged texture two this 3d models of the hands made in 3ds max, has textures(.jpg), materials(.mat), rigged, the...

Helping

3d_export

$5

Woman offering help

...woman offering help

3dexport

woman offering help

3ddd

$1

COUPLE STATUE man help

...couple statue man help

3ddd

статуэтка

couple statue man help

turbosquid

free

help wanted biplane banner.blend

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

German soldier ww2 help wounded G5

... 3d model german soldier ww2 help wounded g5 for download as on turbosquid: 3d models for games, architecture, videos. (1687738)

turbosquid

$3

Uttermost Helping Hand Nickel Plated Bookends

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$45

3d Printable May I Help YOu sign STL OBJ 3D Model

...ntable sign may help you mall airport public sidnaique

3d printable may i help you sign stl obj 3d model sidnaique 48477 3dexport

3d_export

free

Diamond Ring

...diamond ring

3dexport

blue diamond ring. who needs help in 3d, please contact, i will be glad to help.

3d_export

$15

police badge photorealistic pbr low-poly

...police badge photorealistic pbr low-poly

3dexport

need help, support, or questions? contact me, i'll be happy to help.

3ddd

$1

Door

...door

3ddd

двери

hope it helps .

3d_export

$15

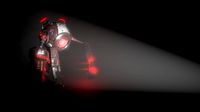

Prototype version of the robot assistant

...a person in a variety of tasks, both in helping in the garden and in armed...