Thingiverse

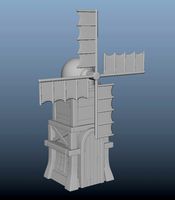

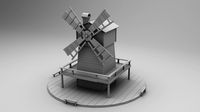

Vertical Windmill Mk2 by miiiike

by Thingiverse

Last crawled date: 2 years, 12 months ago

Here's my 'Mk2' Vertical Axis Wind Turbine (VAWT). I've always liked the lines of these, but they really caught my attention a few weeks ago when I realised that I couldn't explain how they work.

I'm now a lot less confused about how a wing works (really good explanation here if you're interested: http://www.av8n.com/how/htm/airfoils.html), and I've learnt a few new tricks with the printer.

This is my second version and it can generate a much bigger turbine regardless of the printer that's used; it's a lot more efficient with filament too.

At the moment I don't have this driving anything, but the plan is to attach a small water pump (printed of course) to lift water into a gravity feed system.

update: I've added a couple of different blades sizes to suit different build volumes. If you're after something different, have a play with the SCAD file or if that's not your thing, let me know and I can generate some.

update 2: Well it's been up for a while now and I've got a better idea of how it behaves in different winds. It takes a fair bit to get it going and unless it's really blowing it doesn't spin too fast. I think the idea of driving something with it was probably a bit hopeful, but as a sculpture, I still quite like it. The next version will probably have a few more blades and a bigger diameter. All this takes is a few different settings int he scad file, but I haven't gotten around to it yet.

Changes from Mk1

You can find a copy of my first go here http://www.thingiverse.com/thing:940911.

The blade profile has changed to a NACA0024 which is apparently better suited to a VAWT than my 'that looks about right' effort;

The blades are hollow now. This reduces filament use (obviously) and reduces the weight in the blade which in turn reduces the 'centrifugal' force. This is a big deal as the core of the blade adds very little to its strength, but does increase the force acting on it. The other nice thing about this is that there were lots of tiny delaminations along the tail in the Mk1 which are gone now.

The blade is now made up of 'n' sections (3 in this print) which slot together. By splitting it up like this, the blade can really be as long as you like regardless of build area.

The first version used pins to align the two halves (didn't work all that well). This version prints a socket on one side of the join that slots into the hollow section of the other piece.

The blade is now connected to the central shaft via 'n' struts (again, 3 in this case). One of the big problems with the first one was that the joint (weakest point) was in the middle of the blade where the force is greatest and each half was supported from it's end. This arrangement should be much stronger.

By getting rid of the base, the diameter of the windmill can be as long the struts are. Between this and the segmented blades, you can probably make quite a big version if you're keen.

Ideas for Mk3

A transverse web across the widest part of the blade; this will improve the strength without adding much weight.

Apparently a 'solidity' ratio of 88% (i.e. 88% of the space is taken up by blade) is the optimum for a VAWT. This would mean blade about double the size of this one.

I've got an idea for how to make the struts printable with a very strong connection to the blade.

https://youtu.be/jbJLZhv7Xt8

I'm now a lot less confused about how a wing works (really good explanation here if you're interested: http://www.av8n.com/how/htm/airfoils.html), and I've learnt a few new tricks with the printer.

This is my second version and it can generate a much bigger turbine regardless of the printer that's used; it's a lot more efficient with filament too.

At the moment I don't have this driving anything, but the plan is to attach a small water pump (printed of course) to lift water into a gravity feed system.

update: I've added a couple of different blades sizes to suit different build volumes. If you're after something different, have a play with the SCAD file or if that's not your thing, let me know and I can generate some.

update 2: Well it's been up for a while now and I've got a better idea of how it behaves in different winds. It takes a fair bit to get it going and unless it's really blowing it doesn't spin too fast. I think the idea of driving something with it was probably a bit hopeful, but as a sculpture, I still quite like it. The next version will probably have a few more blades and a bigger diameter. All this takes is a few different settings int he scad file, but I haven't gotten around to it yet.

Changes from Mk1

You can find a copy of my first go here http://www.thingiverse.com/thing:940911.

The blade profile has changed to a NACA0024 which is apparently better suited to a VAWT than my 'that looks about right' effort;

The blades are hollow now. This reduces filament use (obviously) and reduces the weight in the blade which in turn reduces the 'centrifugal' force. This is a big deal as the core of the blade adds very little to its strength, but does increase the force acting on it. The other nice thing about this is that there were lots of tiny delaminations along the tail in the Mk1 which are gone now.

The blade is now made up of 'n' sections (3 in this print) which slot together. By splitting it up like this, the blade can really be as long as you like regardless of build area.

The first version used pins to align the two halves (didn't work all that well). This version prints a socket on one side of the join that slots into the hollow section of the other piece.

The blade is now connected to the central shaft via 'n' struts (again, 3 in this case). One of the big problems with the first one was that the joint (weakest point) was in the middle of the blade where the force is greatest and each half was supported from it's end. This arrangement should be much stronger.

By getting rid of the base, the diameter of the windmill can be as long the struts are. Between this and the segmented blades, you can probably make quite a big version if you're keen.

Ideas for Mk3

A transverse web across the widest part of the blade; this will improve the strength without adding much weight.

Apparently a 'solidity' ratio of 88% (i.e. 88% of the space is taken up by blade) is the optimum for a VAWT. This would mean blade about double the size of this one.

I've got an idea for how to make the struts printable with a very strong connection to the blade.

https://youtu.be/jbJLZhv7Xt8

Similar models

grabcad

free

Fanless barebone idea (abandoned)

...;m not really happy about the final looking, and i don't have any ideas about how to improve it

you can modify it as you want

cg_trader

free

Fanless barebone idea abandoned

...have any ideas about how to improve it

you can modify it as you want fanless barebone idea abandoned concept electronics computer

grabcad

free

Thunder Hammer

...r hammer really.

skull is this http://grabcad.com/library/skull-1

because i really have no idea how i's go about making that.

thingiverse

free

Vertical Windmill by miiiike

...ink about what i can get it to do.

i really wish there was a bit of wind at the moment; i'd quite like to see if it spins.

3dwarehouse

free

Nando - Bookcase/Reading Throne #1

...or a while, but i'm tossing around ideas. if you download it, i'd appreciate feedback/ideas on how to better the concept!

thingiverse

free

Queen Demon by mcallaghan95

...y push my printer's capabilities. i hope you enjoy it.

update: i've now uploaded a hi-res version and one with support.

thingiverse

free

rattle by Rensoes

...#39;t make much sound. if you want it to make sound it should probably be made out of metal. but i stil really like how it looks.

thingiverse

free

Replicator Print Cooling, Ludicrous Version by garyacrowellsr

...so some deranged individual might want to try something similar ...

cg_trader

$2

Fire-Spitting mechanical Scythe

...ned some ideas i need to polish for next projects. i've also tried to do some fire simulations with different configurations.

3dwarehouse

free

Space ship WIP

...interior. p.s. you won't be seeing my logo from now on, i can't use it. x( ###i canz now! read the first part!### #rogue1

Miiiike

thingiverse

free

Bird Feeder by miiiike

...bird feeder by miiiike

thingiverse

just a simple egg shaped bird feeder.

thingiverse

free

Archery Arm Guard by miiiike

...archery arm guard by miiiike

thingiverse

simple archery arm guard

thingiverse

free

Bike Stand End Cap by miiiike

...bike stand end cap by miiiike

thingiverse

small cap to go on the end of a bike stand.

thingiverse

free

Magnet Grabber by miiiike

... use a couple of these myself.

the *.scad file is pretty easy to modify to suit the dimensions of whatever magnet you've got.

thingiverse

free

Twisty Pencil Cup / Vase by miiiike

...fy to make all sorts of shapes.

i've make a couple of pencil cups, but i think i might have a crack at a decent sized vase.

thingiverse

free

Egg Slicer by miiiike

...h was a bit tricky, so the stl i've uploaded has slightly larger wire-holes and the slots in the base are a little wider too.

thingiverse

free

Pool Step Vacuum Head by miiiike

...pool vacuum.

you can modify the diameter of the tapered end in the.scad file to fit whatever size vacuum hose you're using.

thingiverse

free

Twisty Vase by miiiike

...ith the script, but it wouldn't show up for simple objects and at 9+ hours to render, trial and error is pretty slow going...

thingiverse

free

Flying Fox Handle by miiiike

...more strength.

if anyone has a go at printing this, please be careful; i really have no idea what sort of weight it can handle.

thingiverse

free

Wind Indicator by miiiike

...is on an angle if you don't do this!).

the nose should be printed with 100% infill and the tail with 5 - 15% infill.

enjoy :)

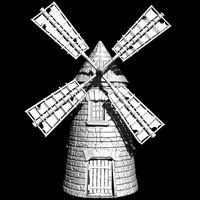

Windmill

3d_export

$20

windmill

...windmill

3dexport

windmill

3d_export

$9

windmill

...windmill

3dexport

windmill.

3d_export

$5

Windmill

...windmill

3dexport

windmill

turbosquid

$60

Windmill

...urbosquid

royalty free 3d model windmill for download as max on turbosquid: 3d models for games, architecture, videos. (1396123)

turbosquid

$30

Windmill

...bosquid

royalty free 3d model windmill for download as blend on turbosquid: 3d models for games, architecture, videos. (1698533)

turbosquid

$10

windmill

...turbosquid

royalty free 3d model windmill for download as ma on turbosquid: 3d models for games, architecture, videos. (1434195)

turbosquid

$4

windmill

...urbosquid

royalty free 3d model windmill for download as fbx on turbosquid: 3d models for games, architecture, videos. (1485882)

3d_ocean

$9

Windmill

... number of polygons – 1794 • number of vertices – 1833 • separate meshes for blades, tower, motor area etc. • size approx. 260ft.

turbosquid

$19

Windmill

...ty free 3d model windmill for download as , fbx, stl, and obj on turbosquid: 3d models for games, architecture, videos. (1692264)

turbosquid

$10

Windmill

...alty free 3d model windmill for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1226691)

Mk2

turbosquid

$4

Mk2

...

royalty free 3d model mk2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1305687)

turbosquid

$9

Mk2 Grenade

...osquid

royalty free 3d model mk2 grenade for download as fbx on turbosquid: 3d models for games, architecture, videos. (1175401)

turbosquid

$4

Mk2 Grenade

...quid

royalty free 3d model mk2 grenade for download as blend on turbosquid: 3d models for games, architecture, videos. (1228888)

turbosquid

$2

GRENADE MK2

...osquid

royalty free 3d model grenade mk2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1202615)

turbosquid

$2

Grenade Mk2

...osquid

royalty free 3d model grenade mk2 for download as max on turbosquid: 3d models for games, architecture, videos. (1658201)

turbosquid

$2

mk2 Grenade

...osquid

royalty free 3d model mk2 grenade for download as fbx on turbosquid: 3d models for games, architecture, videos. (1329079)

turbosquid

$75

Lanchester Mk2

...alty free 3d model lanchester mk2 for download as 3ds and max on turbosquid: 3d models for games, architecture, videos. (1497085)

turbosquid

$10

Grenade MK2

...royalty free 3d model grenade mk2 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1146970)

turbosquid

$10

MK2 helmet

...

royalty free 3d model mk2 helmet for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1371428)

turbosquid

free

MK2 Grenade

...

free 3d model mk2 grenade for download as png, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1225336)

Vertical

3ddd

$1

Vertical curtain

...vertical curtain

3ddd

роллеты

vertical curtain

modern curtain

design_connected

$11

Mr.Tubes Vertical

...mr.tubes vertical

designconnected

tonone mr.tubes vertical computer generated 3d model.

3ddd

free

Vertical gardening

... фитомодуль , фитостена

vertical gardening

2000x1000x165

vizpark

$5

Einstein Vertical

...tical is a set of 3d brick textures for modern buildings, including mulit-textures and 4k tileable textures with material layers.

turbosquid

$5

brazier vertical

... free 3d model brazier vertical for download as sldas and ige on turbosquid: 3d models for games, architecture, videos. (1647570)

turbosquid

$18

Vertical blinds

...ee 3d model vertical blinds for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1604868)

3d_export

$40

vertical stirling engine

...vertical stirling engine

3dexport

vertical stirling engine

turbosquid

$6

vertical fence

...d model vertical fence for download as c4d, 3ds, dxf, and obj on turbosquid: 3d models for games, architecture, videos. (1571631)

turbosquid

$50

Vertical Garden

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

vertical flag

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.