Thingiverse

Velux Hook – Sloping Roof Window Handle by Zed42

by Thingiverse

Last crawled date: 2 years, 11 months ago

A robust “hook” handle to manage opening and closing of (Velux) sloping roof windows.

The hook is designed to fit an extension (telescopic, paint) pole (originally intended for paint roller) – both with and without the original soft plastic tip and also a round aluminum rod with 15 mm outer diameter.

The hook was designed with intention to absorb rather extensive forces (just in case the window does not move that freely) and is intended for handling opening/closing of the window only. I don’t have any auxiliary accessories like inner shades etc. hence these are ignored for the time being.

Model A – fits extension pole with the original soft plastic tip on. I.e. the pole goes without any modification except drill through the soft plastic tip in two spots to hold the handle in place. In fact another drill & screw tightening might be needed to keep the plastic tip in place since it is originally only glued atop of the pole however downward forces when opening the window may soon wear the glue out.

The extension pole itself is sold in hobby market(s) – German-headquartered Hornbach in my case – and the original soft plastic tip measures are: bottom diameter = 30 mm, top diameter = 23 mm, length = 120 mm.

Model A is round and appears rather bulky given the size of the soft plastic tip it’s got to swallow.

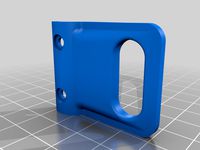

Model B – just like Model A also Model B fits an extension rod however this time without the original soft plastic tip, i.e. expects evenly round profile of 21 mm in diameter.

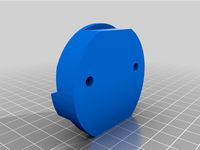

Model C – is designed to sit atop of 15 mm aluminum round rod. Since the rod is expected to be hollow a bottom Cap is provided alongside of this version.

Printing and usage: the hook handles look better when printed standing - however layers in that case have to resist the strongest forces as they are perpendicular to the direction of pull / push force. So I prefer to print them lying horizontally on printer bed.

I myself was printing in 0.3 mm resolution with 9 outline/perimeter shells with 60% infill. The positive effect of several outline/perimeter shells is in particular noticeable with Model C – which is the only model designed as squared on the outside so it prints well in horizontal position. Since this model is rather subtle (compared to A & B) the square outside shape looks & prints well lying on printer build platform. Outline/perimeter shells run alongside of entire shape uninterrupted thus giving good resistance to push/pull force of the print.

The rounded shapes of Model A and B need outer supports (definitely model A as it is also conic) when printing horizontally. When printing inside with supports (recommendable since the inner shape is round also for Model C) I manually removed a row of supports every 10 – 20 mm. In that way I could easily push them in to disengage before pulling them out and the support gaps were easily bridged. Only inside supports needed in case of model C.

The hook is designed to fit an extension (telescopic, paint) pole (originally intended for paint roller) – both with and without the original soft plastic tip and also a round aluminum rod with 15 mm outer diameter.

The hook was designed with intention to absorb rather extensive forces (just in case the window does not move that freely) and is intended for handling opening/closing of the window only. I don’t have any auxiliary accessories like inner shades etc. hence these are ignored for the time being.

Model A – fits extension pole with the original soft plastic tip on. I.e. the pole goes without any modification except drill through the soft plastic tip in two spots to hold the handle in place. In fact another drill & screw tightening might be needed to keep the plastic tip in place since it is originally only glued atop of the pole however downward forces when opening the window may soon wear the glue out.

The extension pole itself is sold in hobby market(s) – German-headquartered Hornbach in my case – and the original soft plastic tip measures are: bottom diameter = 30 mm, top diameter = 23 mm, length = 120 mm.

Model A is round and appears rather bulky given the size of the soft plastic tip it’s got to swallow.

Model B – just like Model A also Model B fits an extension rod however this time without the original soft plastic tip, i.e. expects evenly round profile of 21 mm in diameter.

Model C – is designed to sit atop of 15 mm aluminum round rod. Since the rod is expected to be hollow a bottom Cap is provided alongside of this version.

Printing and usage: the hook handles look better when printed standing - however layers in that case have to resist the strongest forces as they are perpendicular to the direction of pull / push force. So I prefer to print them lying horizontally on printer bed.

I myself was printing in 0.3 mm resolution with 9 outline/perimeter shells with 60% infill. The positive effect of several outline/perimeter shells is in particular noticeable with Model C – which is the only model designed as squared on the outside so it prints well in horizontal position. Since this model is rather subtle (compared to A & B) the square outside shape looks & prints well lying on printer build platform. Outline/perimeter shells run alongside of entire shape uninterrupted thus giving good resistance to push/pull force of the print.

The rounded shapes of Model A and B need outer supports (definitely model A as it is also conic) when printing horizontally. When printing inside with supports (recommendable since the inner shape is round also for Model C) I manually removed a row of supports every 10 – 20 mm. In that way I could easily push them in to disengage before pulling them out and the support gaps were easily bridged. Only inside supports needed in case of model C.

Similar models

thingiverse

free

Velux Hook – Sloping Roof Window Handle by Zed42

...in to disengage before pulling them out and the support gaps were easily bridged. only inside supports needed in case of model c.

thingiverse

free

Velux hook roof window rooflight reinforced by matter13

...t reinforced by matter13

thingiverse

reinforced the window hook to make it stronger and easier to print flat with fewer supports

thingiverse

free

Velux hook by nyx_4

...he adaptator you can use a 20mm or 18mm. thanks to the 3 screw systeme you can surely use a smaller handle and tighten a bit more

thingiverse

free

Shader hook for VELUX skylight windows by Hejzenberg

...ook for velux skylight windows by hejzenberg

thingiverse

replacement window shader hook for velux or any other skylight windows.

thingiverse

free

Hook Velux Roof Windows, by franic

...hook velux roof windows, by franic

thingiverse

hook for the opening and closing bar of a velux brand roof window.

thingiverse

free

Fishing rod replacement tip by paulschonfeld

...erse

this print will replace the tip of a broken fishing rod. the existing stl will fit around a rod that is 2.9 mm in diameter.

thingiverse

free

Tent-Pole Coat Hook by gjodink

...tent-pole coat hook by gjodink

thingiverse

tent-pole coat hook, 23 mm pole diameter

thingiverse

free

Tea Towel Kitchen Multi-hook (20mm) by Mickice

...meter round handles

10~mm big gap

2~mm small gap

pro-tip: ensure you have a good first layer to prevent sharp edges / scratching.

thingiverse

free

Window Stop for velux handle by andyinfrance

...window stop for velux handle by andyinfrance

thingiverse

locks the velux window partly open to let air in.

thingiverse

free

Ergonomic Velux hook by Backmann

...ound.

now it is possible to print this amazing tool on a small printer like the mini fabrikator with a print bed of only 80x80mm.

Zed42

thingiverse

free

Cable Port in 60mm Desk Grommet by Zed42

... a long one with several options hence giving more freedom e.g. for shorter cables while maintaining the same overall rod length.

thingiverse

free

Velux Hook – Sloping Roof Window Handle by Zed42

...in to disengage before pulling them out and the support gaps were easily bridged. only inside supports needed in case of model c.

Velux

3ddd

$1

Мансардное окно Velux

...ардное окно velux

3ddd

окно , velux

мансардное окно velux, может открываться, 1600 polys

thingiverse

free

Velux

...velux

thingiverse

velux sparepart

3d_sky

free

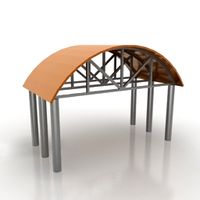

Mansard Windows Velux

...mansard windows velux

3dsky

mansard windows velux, can be opened, 1600 polys

thingiverse

free

Velux Dachfenster Jalousie by GHennrich

...velux dachfenster jalousie by ghennrich

thingiverse

velux dachfenster jalousie

thingiverse

free

Holder for VELUX remote by thingfisch

...holder for velux remote by thingfisch

thingiverse

holder for velux remote

thingiverse

free

Velux VK Verschluss by kadrim

...velux vk verschluss by kadrim

thingiverse

replacement part for velux vk windows

thingiverse

free

Velux Window-Holder by Spider69

...velux window-holder by spider69

thingiverse

velux roof window holder, mounted on the sidewall.

thingiverse

free

Old Velux Strike / Recepteur de serrure pour ancien Velux by richard_8442

... window.

juste une copie des anciennes gâches / receveur de serrure velux. elle a été copié à partir d'un velux ghl4 de 1985.

thingiverse

free

Crochet Velux by yo_yo

...50% infill for robustness

crochet pour fenêtre de toit velux.

imprimé avec des parois de 3mm et 50% infill pour plus de solidité.

thingiverse

free

Velux Part by lordpositron

...sitron

thingiverse

this 3d model can replace ves/v21 velux part.

i printed this with a creality ender 3 pro and a pla filament.

Sloping

design_connected

$11

Slope

...slope

designconnected

miniforms slope computer generated 3d model. designed by skrivo.

3ddd

$1

Pendant lamp SLOPE

...pendant lamp slope

3ddd

slope

pendant lamp slope

3ddd

$1

Italux slope md9193

...italux slope md9193

3ddd

italux

italux slope md9193

turbosquid

$15

slope stone

...osquid

royalty free 3d model slope stone for download as stl on turbosquid: 3d models for games, architecture, videos. (1666168)

3d_export

$9

cameron slope

...cameron slope

3dexport

turbosquid

$12

Sloping armchair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

free

Slope Lamp by Skrivo Design

... miniforms , skrivo design

потолочные подвесные светильники "slope"

3d_export

$30

slope chair west elm

...slope chair west elm

3dexport

slope chair west elm max fbx obj

turbosquid

$20

House 2x2 slope

...lty free 3d model house 2x2 slope for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1278517)

3d_export

$5

snow slope lowpoly

...snow slope lowpoly

3dexport

Hook

turbosquid

$11

Hooked hooks

... 3d model hooked hooks for download as max, obj, fbx, and stl on turbosquid: 3d models for games, architecture, videos. (1629361)

archibase_planet

free

Hook

...hook

archibase planet

coatrack hook peg

hook - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Hook

...hook

archibase planet

coatrack stand hook

hook - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Hook

...hook

archibase planet

coatrack hook peg

hook - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Hook

...hook

archibase planet

hook bathroom ware

hook - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$14

Hook

...ok

turbosquid

royalty free 3d model hook for download as c4d on turbosquid: 3d models for games, architecture, videos. (1436676)

3d_export

$10

butcher hooks

...butcher hooks

3dexport

butcher hooks

3d_export

$5

nut hook

...nut hook

3dexport

nut hook

3d_export

$5

rope hook

...rope hook

3dexport

rope hook

3d_export

$5

j hook

...j hook

3dexport

j hook

Roof

3ddd

$1

Roof

...roof

3ddd

kare , roof

kare кресло roof.

archibase_planet

free

Roof

...roof

archibase planet

roof iron roof

fence roof - 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Roof

...roof

archibase planet

roof iron roof

fence roof-3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Roof

...roof

archibase planet

roof iron roof

fence roof-5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Roof

...roof

archibase planet

roof iron roof

fence roof-6 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Roof

...roof

archibase planet

roof iron roof

fence roof-1- 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

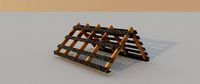

free

roof

...roof

3dexport

roof construct

archibase_planet

free

Roof

...roof

archibase planet

roof skylight

fence roof-7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Roof

...roof

archibase planet

roof skylight

fence roof-8 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Roof

...roof

archibase planet

roof house-top

roof n070211 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

Handle

archibase_planet

free

Handle

...handle

archibase planet

handle furniture handle

handle 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Handle

...handle

archibase planet

handle furniture handle

handle 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Handle

...handle

archibase planet

handle furniture handle

handle 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Handle

...handle

archibase planet

handle furniture handle

handle 6 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Handle

...handle

archibase planet

handle furniture handle

handle 4 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Handle

...handle

archibase planet

handle furniture handle

handle 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Handle

...handle

archibase planet

handle furniture handle knob

handle 2 n140814 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Handle

...handle

archibase planet

handle door knob door-handle

handle n110413 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Handle

...handle

archibase planet

door-handle handle door-knob

handle n070209 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Handle

...handle

archibase planet

door-handle handle door-knob

handle n270309 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Window

3d_ocean

$3

Window

...window

3docean

window

a lowpoly window .

3d_ocean

$2

Window

...window

3docean

window

a lowpoly window.

3d_ocean

$2

Window

...window

3docean

window

a lowpoly window.

3d_ocean

$2

Window

...window

3docean

window

a lowpoly window .

3d_ocean

$5

Window

...window

3docean

window

a high quality window.

3d_ocean

$4

Window

...window

3docean

window

a high quality window.

3d_ocean

$4

Window

...window

3docean

window

a high quality window.

3d_ocean

$4

Window

...window

3docean

window

a high quality window.

3d_ocean

$3

Window

...window

3docean

window

a high quality window.

3d_ocean

$3

Window

...window

3docean

window

a high quality window .