3dExport

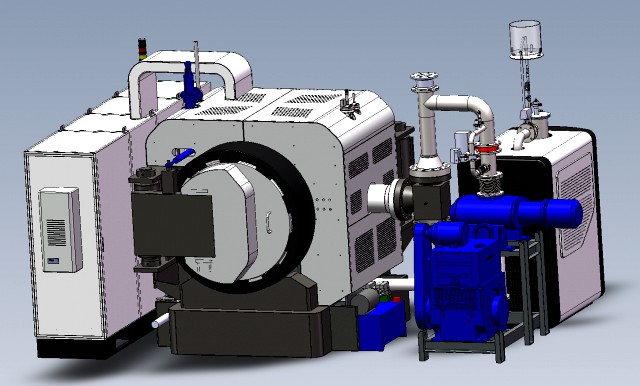

vacuum sintering furnace

by 3dExport

Last crawled date: 1 year, 10 months ago

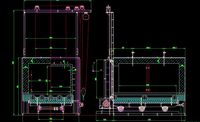

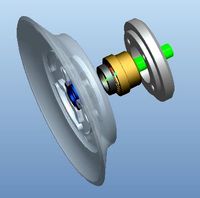

i also have cad production drawings, please search and download, welcome to download!

operation instruction of vacuum bidirectional pressure sintering furnace

pressurized operation

check whether the valves of the cooling water system are in the open state, whether the vacuum valves are closed, whether the 4 ා valves are in the vacuum position → turn on the cooling water pump to make the cooling water work → turn on the cabinet power, put the 4 ා valve at the venting position, so that the air can enter the vacuum furnace → open the furnace door to install the sample → pre press the sample by manual pressure regulation after that, the sample is automatically pressurized. after the automatic pressurization is completed, the 4 ා valve is placed in the vacuum position, and then the furnace door is closed for the next step.

matters needing attention:

firstly, the sample is pre pressed by hand. when the pressure is manually applied, the oil pressure cannot be opened too much at one time. after preloading, turn the manual oil pressure adjustment button to the minimum, set the oil pressure switch to automatic, and then pressurize the sample automatically. during automatic pressurization, slow pressurization is adopted (adjust the pressure control display to increase slowly at the speed of 0.1mpa. after each increase of 0.1mpa, the number on the equal displacement display will be increased by 0.1mpa. it is forbidden to adjust the pressure value to the pressure value required by the experiment at one time).

vacuum operation

start the power supply of the mechanical pump → after the mechanical pump runs smoothly, slowly open the 1 ᦇ valve to vacuum the furnace body → after about 10 minutes, open the 2 ᦇ valve, vacuum the diffusion pump → after the vacuum reaches 250 pa, start the roots pump → after the vacuum reaches 15 pa, turn on the power supply of the diffusion pump, preheat the diffusion pump → after about 45 minutes, open the 3 ᦇ valve, close the 1 ᦇ valve to pump high vacuum to the furnace body.

heating operation

when the vacuum degree reaches 6 × 10-2pa, the heating power can be turned on, and the temperature can be raised according to the heating program set by the process or manually adjusting the heating speed.

after the temperature rises to the required temperature of the pressing sintering process, the holding pressure and holding time are set according to the process.

argon or nitrogen can be used to keep sintering in atmosphere

when inflating, the 3 ᦇ valve must be closed first, and then the 4 ා valve should be placed in the atmosphere position.

f5 mode is used in the flowing atmosphere experiment, which is set as st2 > st3. when making the flowing atmosphere, first vacuum the furnace body, tighten the four bolts on the furnace door, and then ventilate. it is best to operate according to the following process: vacuumizing → ventilating → vacuuming → ventilating, and starting heating. do not use vacuum system in the process of circulation atmosphere.

matters needing attention:

it is forbidden to cut off water and power during heating.

discharge operation

at the end of the process: turn off the heating power and diffusion pump power supply → turn off the power supply of the hydraulic pump → close the 3 ᦇ valve and roots pump → keep the cooling water pump and mechanical pump working continuously → wait for the furnace temperature ≤ 60 ℃ and the surface temperature of the diffusion pump ≤ 30 ℃, then turn off the mechanical pump and cooling water pump, and open the 4 ᦇ valve for venting, when the furnace temperature is close to room temperature, open the furnace door to discharge, and the process cycle ends.

matters needing attention

to relieve the pressure, first set the set value on the pressure gauge to zero, and then turn the air pressure knob to manual position. finally, the ram is lifted and lowered.

when switching from high temperature to low temperature, first set the button under the heating switch to low temperature to let the program finish, and then switch back to automatic.

after the experiment

after discharging, close the furnace door, open the mechanical pump and vacuum the furnace body → when the vacuum reaches about 20pa, turn off the mechanical pump → turn off all the power supply on the cabinet → turn off the cooling water pump → cut off all power supply on the equipment.

matters needing attention

during the whole experiment, it is strictly forbidden to cut off water, power and unattended state. after the experiment, all the data on the control instruments are set to zero, and the heating gear switch is set to the automatic position. turn off all power to the device. close the doors and windows, turn off the lights and fans, etc. close the windows and lock the door of the laboratory.

operation instruction of vacuum bidirectional pressure sintering furnace

pressurized operation

check whether the valves of the cooling water system are in the open state, whether the vacuum valves are closed, whether the 4 ා valves are in the vacuum position → turn on the cooling water pump to make the cooling water work → turn on the cabinet power, put the 4 ා valve at the venting position, so that the air can enter the vacuum furnace → open the furnace door to install the sample → pre press the sample by manual pressure regulation after that, the sample is automatically pressurized. after the automatic pressurization is completed, the 4 ා valve is placed in the vacuum position, and then the furnace door is closed for the next step.

matters needing attention:

firstly, the sample is pre pressed by hand. when the pressure is manually applied, the oil pressure cannot be opened too much at one time. after preloading, turn the manual oil pressure adjustment button to the minimum, set the oil pressure switch to automatic, and then pressurize the sample automatically. during automatic pressurization, slow pressurization is adopted (adjust the pressure control display to increase slowly at the speed of 0.1mpa. after each increase of 0.1mpa, the number on the equal displacement display will be increased by 0.1mpa. it is forbidden to adjust the pressure value to the pressure value required by the experiment at one time).

vacuum operation

start the power supply of the mechanical pump → after the mechanical pump runs smoothly, slowly open the 1 ᦇ valve to vacuum the furnace body → after about 10 minutes, open the 2 ᦇ valve, vacuum the diffusion pump → after the vacuum reaches 250 pa, start the roots pump → after the vacuum reaches 15 pa, turn on the power supply of the diffusion pump, preheat the diffusion pump → after about 45 minutes, open the 3 ᦇ valve, close the 1 ᦇ valve to pump high vacuum to the furnace body.

heating operation

when the vacuum degree reaches 6 × 10-2pa, the heating power can be turned on, and the temperature can be raised according to the heating program set by the process or manually adjusting the heating speed.

after the temperature rises to the required temperature of the pressing sintering process, the holding pressure and holding time are set according to the process.

argon or nitrogen can be used to keep sintering in atmosphere

when inflating, the 3 ᦇ valve must be closed first, and then the 4 ා valve should be placed in the atmosphere position.

f5 mode is used in the flowing atmosphere experiment, which is set as st2 > st3. when making the flowing atmosphere, first vacuum the furnace body, tighten the four bolts on the furnace door, and then ventilate. it is best to operate according to the following process: vacuumizing → ventilating → vacuuming → ventilating, and starting heating. do not use vacuum system in the process of circulation atmosphere.

matters needing attention:

it is forbidden to cut off water and power during heating.

discharge operation

at the end of the process: turn off the heating power and diffusion pump power supply → turn off the power supply of the hydraulic pump → close the 3 ᦇ valve and roots pump → keep the cooling water pump and mechanical pump working continuously → wait for the furnace temperature ≤ 60 ℃ and the surface temperature of the diffusion pump ≤ 30 ℃, then turn off the mechanical pump and cooling water pump, and open the 4 ᦇ valve for venting, when the furnace temperature is close to room temperature, open the furnace door to discharge, and the process cycle ends.

matters needing attention

to relieve the pressure, first set the set value on the pressure gauge to zero, and then turn the air pressure knob to manual position. finally, the ram is lifted and lowered.

when switching from high temperature to low temperature, first set the button under the heating switch to low temperature to let the program finish, and then switch back to automatic.

after the experiment

after discharging, close the furnace door, open the mechanical pump and vacuum the furnace body → when the vacuum reaches about 20pa, turn off the mechanical pump → turn off all the power supply on the cabinet → turn off the cooling water pump → cut off all power supply on the equipment.

matters needing attention

during the whole experiment, it is strictly forbidden to cut off water, power and unattended state. after the experiment, all the data on the control instruments are set to zero, and the heating gear switch is set to the automatic position. turn off all power to the device. close the doors and windows, turn off the lights and fans, etc. close the windows and lock the door of the laboratory.

Similar models

3d_export

$2000

pressure sintering furnace for cemented carbide

... protective atmosphere. it is designed for the industrial production of cemented carbide, dysprosium metal and ceramic materials.

grabcad

free

Water Control Valve. su kontrol valfi.

...at a preset value. a pressure sustaining valve is similar to a pressure reducing valve but governs the pressure...

3d_export

$400

horizontal vacuum drying furnace cemented carbide equipment

...ess completion, and the operation process, parameters and process progress status information are displayed on the control panel.

3d_export

$49

drawing of 3x2x15m full fiber trolley resistance furnace

...plosive gas and corrosive gas seriously damaging metal and insulation around the equipment. there is no vibration and turbulence.

grabcad

free

Pressure water booster

... respectively. it stops the pump when senses the lack of water flow, preventing it from any damaging dry operation.

grabcad

free

valve

...afety valves, and vacuum pressure safety valves.

safety valves were first used on steam boilers during the industrial revolution

grabcad

free

Safety valve

...defined in any norm, particularly in the hot cip / cold water scenario, but some manufacturers have developed sizing simulations.

grabcad

free

SPRING LOADED SAFETY VALVE

...afety valves, and vacuum pressure safety valves.

safety valves were first used on steam boilers during the industrial revolution

grabcad

free

Exit AirLock

...m, you can see the vacuum valves on upper side, and after a secon group of valves equalise the pressur with the outside pressur.

grabcad

free

Butterfly Valve

...sts, quick operation and availability in very large sizes. these valves can be operated by handles, gears or automatic actuators.

Sintering

3d_export

$2000

pressure sintering furnace for cemented carbide

... protective atmosphere. it is designed for the industrial production of cemented carbide, dysprosium metal and ceramic materials.

3d_export

$13

stribog nose aseutra silencer

...quality on hp jet fusion 3d or selective laser sintering ...

3d_export

$21

stock adapter grand power stribog

...quality on hp jet fusion 3d or selective laser sintering ...

thingiverse

free

Mount for Sinter Bearings 8x10x10 by dvoelkel

...or sinter bearings 8x10x10 by dvoelkel

thingiverse

i did a remix of that to carry my sinter bearings.

thanks for the original :)

thingiverse

free

Selective Laser Sintering: Alpha 1 by peter_

...is a follow up to the selective laser sintering powder test rig that i recently posted ( http://www.thingiverse.com/thing:3389 ).

thingiverse

free

Bronze sintered bushing adapter for LM8UU replacement by misan

... all. if you want to replace your lm8uu for bronze sintered bushings, this part may help, provided you bushings are similar size.

thingiverse

free

Open Source Laser sintering 3D printer by lukask

...you-sls-the-first-desktop-open-source-lasersinter/x/10003734

check out the video at:https://www.youtube.com/watch?v=txitbq2ykp8

thingiverse

free

Selective Laser Sintering: Powder test rig by peter_

...purposes -- i've been actively developing a more capable system, which was largely based on lessons learned from this one. :)

thingiverse

free

Sintered Bronze Bushing Holder by AlucardWulf

...r. the bores are the same as for a sc8uu as last time.

as always if there are any questions feel free to ask in german or english

Furnace

3d_export

$18

blacksmith-furnace-furnace

...blacksmith-furnace-furnace

3dexport

blacksmith-furnace-furnace<br>3ds max 2015

3d_export

$5

furnace

...furnace

3dexport

this is old furnace

archibase_planet

free

Furnace

...furnace

archibase planet

stove oven furnace

furnace - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Furnace

...furnace

archibase planet

furnace forge kiln

furnace n081010 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Furnace

...furnace

archibase planet

oven furnace fireside

furnace n190210 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$12

Bagua Copper Furnace alchemy furnace three-legged furnace tripod

...hemy furnace three-legged furnace tripod for download as max on turbosquid: 3d models for games, architecture, videos. (1630879)

3ddd

$1

TA Furnace

...ta furnace

3ddd

classic ta furnace model

turbosquid

$2

Furnace

... free 3d model furnace for download as png, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1471641)

turbosquid

$19

furnace

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

Furnace

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Vacuum

archibase_planet

free

Vacuum cleaner

...cuum cleaner vacuum hoover exhauster

vacuum cleaner stefano galli n250213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$12

vacuum cleaner

...vacuum cleaner

3dexport

vacuum cleaner fo houses

3ddd

$1

Vacuum Cleaner

...vacuum cleaner

3ddd

пылесос

vacuum cleaner + obj + textures

3d_export

$170

VACUUM BOWL

...vacuum bowl

3dexport

3d_export

$5

Bracket vacuum 3D Model

...bracket vacuum 3d model

3dexport

vacuum

bracket vacuum 3d model bkl1989 63086 3dexport

3d_export

$50

Vacuum Cleaner 3D Model

...vacuum cleaner 3d model

3dexport

vacuum cleaner

vacuum cleaner 3d model kaxa3d 12593 3dexport

3d_export

$5

vacuum cleaner

...vacuum cleaner

3dexport

diameter 32 mm

archive3d

free

Vacuum cleaner 3D Model

...er

vacuum cleaner stefano galli n250213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$69

vacuum furnaces

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$59

Vacuum Italian

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.