Thingiverse

USB Powered Printer Lighting for Lulzbot Mini (or others) Using Eveready LED Flashlight by hemocyanin

by Thingiverse

Last crawled date: 3 years ago

I have many Eveready 6v flashlights because the price of a battery/flashlight combo ($4.97), is only 29 cents more than the cost of a battery alone ($4.68) at my local Home Depot (FN1). It's really hard to force myself to not buy the combo even though I've got these things coming out my ears by now and I almost always break down and just buy the combo. I've finally found a use for some of my dead flashlights: cheap lighting for my printer!

Basically, for 29 cents I get some LEDs and resistors soldered to a board already drilled with mounting holes, a button, and an unbreakable beer mug (not really of course, I doubt the plastic is food grade). The only other non-printed part needed is one of the many now useless mini-USB cords I have sitting in a box because nothing uses those anymore.

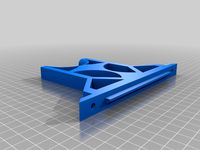

I've uploaded the files in STL and FreeCAD native file format. If you don't have a printer like mine, but do have a stack of these flashlights, I've also included just the button mount for the Eveready button which you can attach to something made for your printer. When printed sideways with the supports in place, the button fits in nice and snug because of the fine bits of support material left over -- you could get away with using no glue to hold it in place. If printed on its back, no support is needed, but you'll probably need glue or epoxy.

My example is printed in natural ABS on a Lulzbot Mini, Cura basic settings, normal (med) quality.

--- assembly instructions (FN2) ---

Removing the LED board: the first thing to do is grab the large conductive ring at the base of the flashilight head, cut through the plastic supports and attachment bits, and break that off. The board isn't screwed down -- instead little melted plastic posts hold it in place. A few snips will allow you to wiggle it free. You'll see where positive and negative get attached -- take a mental note and clip off the positive wire (negative is just a contact spring).

Removing the button: the button is held in place by friction, not a nut. First, remove the rubber weather boot by pulling it off (again, not screwed down). Then, using a flathead screwdriver or something similar, from the inside of the flahslight body pry the switch body down through the hole. It kind of helps to pry along the vertical walls too. You can also try pounding it down through the hole from outside the flashlight body. If you try to use pliers to pull on the switch body from the inside, it will probably split in half, the spring will go sprong and dissapear from the face of the earth, and you won't have a button. Just keep prying with the screwdriver or bash it through. This will take a bit of force, but it'll squeeze out eventually.

Sacrificing mini-USB cord: snip off the useless end, strip outer insulation. Almost certainly, pos and neg will correspond to red and black wires. You can always plug it in and test to be certain. Snip back the data wires, shielding, and anything else (different levels is nice to make shorting almost impossible), leaving just the positive and negative wires. Strip those a little -- red should be pretty short and black fairly long (red will go to one pole of the switch, black to the LED board.

Final Assembly: Break off the four tabs in the button box of the printed part, then feed the USB wire through a hole in the button box of the printed part from outside to inside. Solder the red wire to one pole of the button, then solder another length of wire to the other pole of the button. If the USB cord is loose in its hole, you can add some tape to wedge it in there and it wouldn't hurt to tape over the poles of the switch to prevent anything accidentally running down the USB data lines. Feed the loose positive and negative lines out through another hole, and then slide the button into place. Now you can solder the positive and negative leads to the LED board: red to the positive terminal of the LED board, and black to the negative (big circular pad in the center). The board can then be mounted to the printed bracket with a small screw (FN3).

--- Footnotes ---

FN1: Flashlight/battery combo -- Just the battery. Ridiculous 29 cent difference in price.

FN2: this is for the older 3 LED version. New versions of this flashlight in the store have a single LED. I'm sure it isn't rocket science to get that one out either, but I'm going to wait till the batteries die in my newer flashlights before breaking them down.

FN3: I bought a 1000 of these screws and they're very useful: http://www.amazon.com/gp/product/B00GMQDSRI (I'm not trying to flog this product or push the particular seller -- it just took me forever to find some reasonably priced tiny screws and I spent a lot of money on things that turned out to not be what I wanted, so I thought the link might be useful). If you have different size screws, you can always drill the hole out to make use of whatever you have on hand.

Basically, for 29 cents I get some LEDs and resistors soldered to a board already drilled with mounting holes, a button, and an unbreakable beer mug (not really of course, I doubt the plastic is food grade). The only other non-printed part needed is one of the many now useless mini-USB cords I have sitting in a box because nothing uses those anymore.

I've uploaded the files in STL and FreeCAD native file format. If you don't have a printer like mine, but do have a stack of these flashlights, I've also included just the button mount for the Eveready button which you can attach to something made for your printer. When printed sideways with the supports in place, the button fits in nice and snug because of the fine bits of support material left over -- you could get away with using no glue to hold it in place. If printed on its back, no support is needed, but you'll probably need glue or epoxy.

My example is printed in natural ABS on a Lulzbot Mini, Cura basic settings, normal (med) quality.

--- assembly instructions (FN2) ---

Removing the LED board: the first thing to do is grab the large conductive ring at the base of the flashilight head, cut through the plastic supports and attachment bits, and break that off. The board isn't screwed down -- instead little melted plastic posts hold it in place. A few snips will allow you to wiggle it free. You'll see where positive and negative get attached -- take a mental note and clip off the positive wire (negative is just a contact spring).

Removing the button: the button is held in place by friction, not a nut. First, remove the rubber weather boot by pulling it off (again, not screwed down). Then, using a flathead screwdriver or something similar, from the inside of the flahslight body pry the switch body down through the hole. It kind of helps to pry along the vertical walls too. You can also try pounding it down through the hole from outside the flashlight body. If you try to use pliers to pull on the switch body from the inside, it will probably split in half, the spring will go sprong and dissapear from the face of the earth, and you won't have a button. Just keep prying with the screwdriver or bash it through. This will take a bit of force, but it'll squeeze out eventually.

Sacrificing mini-USB cord: snip off the useless end, strip outer insulation. Almost certainly, pos and neg will correspond to red and black wires. You can always plug it in and test to be certain. Snip back the data wires, shielding, and anything else (different levels is nice to make shorting almost impossible), leaving just the positive and negative wires. Strip those a little -- red should be pretty short and black fairly long (red will go to one pole of the switch, black to the LED board.

Final Assembly: Break off the four tabs in the button box of the printed part, then feed the USB wire through a hole in the button box of the printed part from outside to inside. Solder the red wire to one pole of the button, then solder another length of wire to the other pole of the button. If the USB cord is loose in its hole, you can add some tape to wedge it in there and it wouldn't hurt to tape over the poles of the switch to prevent anything accidentally running down the USB data lines. Feed the loose positive and negative lines out through another hole, and then slide the button into place. Now you can solder the positive and negative leads to the LED board: red to the positive terminal of the LED board, and black to the negative (big circular pad in the center). The board can then be mounted to the printed bracket with a small screw (FN3).

--- Footnotes ---

FN1: Flashlight/battery combo -- Just the battery. Ridiculous 29 cent difference in price.

FN2: this is for the older 3 LED version. New versions of this flashlight in the store have a single LED. I'm sure it isn't rocket science to get that one out either, but I'm going to wait till the batteries die in my newer flashlights before breaking them down.

FN3: I bought a 1000 of these screws and they're very useful: http://www.amazon.com/gp/product/B00GMQDSRI (I'm not trying to flog this product or push the particular seller -- it just took me forever to find some reasonably priced tiny screws and I spent a lot of money on things that turned out to not be what I wanted, so I thought the link might be useful). If you have different size screws, you can always drill the hole out to make use of whatever you have on hand.

Similar models

thingiverse

free

Mini flashlight by VyacheslavSS

...de of the led is bent over the positive side of the battery and is clamped by the cover. fixation with m3 or self-tapping screws.

thingiverse

free

18650 holder 1S / 2S

...make sure they are correctly oriented. 1s instructions follow similar steps as described in the2s construction, however: solder two...

thingiverse

free

Flashlight by Goldeagle_54321

...rts i had.

!!!

instead of the bredboard wires i used to connect the lipo you can just solder the cutoffs from the leds to a wire.

thingiverse

free

12v 23A Battery Holder by FwA

...ing setup you need. i used jst connectors for mine.

i also added a small hole in the bottom to assist with removal of the battery

thingiverse

free

Mother's Day Sculpture Light Up Base by PagliaIndustries

...hould be able to power the 5v led with a male to male usb cable or from usb to a battery pack.

update (05/10/21):

fixed a typo.

thingiverse

free

Amoeba LED Lamp-V1 by ChrisTheViolaNerd

...ints, and negative battery terminal will be wired to the (com) switch point. no wires will be connected to the (nc) switch point.

thingiverse

free

Retrofalg GPI Case - LiPo battery adapter (no mod version)

...protect your solders from short circuits (see pictures)

it was designed for type-c usb 5 v 1a 18650 tp4056 printed circuit board.

thingiverse

free

Portable Ambient Light LED Powerbank by vmi

...te controller 5v

single 18650 diy powerbank

18650 li-ion battery

22mm switch

wire

soldering iron

glue

heat shrink tube

multimeter

thingiverse

free

Ryobi 18V dual QC3.0 USB Charger by rwagz

...upports inside.

you need full supports on the "base" to support the battery snap clips.

no support needed on the insert

cults

free

Amoeba LED Lamp-V1

...nts, and negative battery terminal will be wired to the (com) switch point. no wires will be connected to the (nc) switch point.

Eveready

turbosquid

$30

batteries Eveready AA - AAA - C

... free 3d model battrey for download as 3ds, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1464645)

3d_export

$30

C Battery 3D Model

...battery amp resistance current electricity cell duracell energizer rayovac eveready alkaline power energy c battery 3d model plutonius 22376...

3d_export

$30

AA Battery 3D Model

...battery amp resistance current electricity cell duracell energizer rayovac eveready alkaline power energy aa battery 3d model plutonius 22355...

3d_export

$30

9V Battery 3D Model

...battery amp resistance current electricity cell duracell energizer rayovac eveready alkaline power energy 9v battery 3d model plutonius 22289...

3d_export

$5

Simple Lamp 3D Model

...xenon solar waterproof best buy small brightest rechargable dorcy eveready battery free ablaze cheap crank bulb powerful kit uk...

thingiverse

free

7 x CR2032 to NEDA 215 / Eveready 412 adapter by S0N1C

...to neda 215 / eveready 412 adapter, used in old electronics. 3mm desoldering braid as contacts.

turn to the side before printing!

thingiverse

free

Eveready Model 2602 LED Upgrade by Delphius

...o project page for a complete parts list.

more details here: https://hackaday.io/project/12183-1925-eveready-model-2602-upgrade

thingiverse

free

Eveready 417 to Exell504 15Volt batarry converter for Simpson 260 series 5 by erniepike

...

i made the dimensions slightly smaller than the 417 standard so i could remove it and replace it w/o removing the circuit board.

thingiverse

free

Wheelbarrow Headlight Using Eveready 6V Flashlight Guts by hemocyanin

...sions where the post and the housing are separate pieces which can be epoxied together later -- these will save support material.

thingiverse

free

Threaded Ring for Eveready 6v Flashlight Guts by hemocyanin

...e files to make using it in your own project, or modifying it, easier.

dimensions: inside: 42.75mm radius; outside: 49mm radius

Hemocyanin

turbosquid

$49

Hemocyanin

...

royalty free 3d model hemocyanin for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1238350)

turbosquid

$16

Hemocyanin

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$49

Hemocyanin Structure

...free 3d model hemocyanin structure for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1238351)

turbosquid

$16

Hemocyanin(1)

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

thingiverse

free

Hole Test 6mm and 3mm Diameters by hemocyanin

...the 3d equivalent of hello world, but if you want to see how freecad works at the most basic level, it might be worth looking at.

thingiverse

free

Mallet, Weighted Head by hemocyanin

...handle up a tiny bit to correct that. you'll also probably want to flip the heads over so the wide end is on the buildplate.

thingiverse

free

SSD Adapter for Lenovo TS130 Series by hemocyanin

... the holes don't match up to your specific ssd, i have included the freecad source to make modification of the design easier.

thingiverse

free

Shoe for Hakko FX888D Iron Stand by hemocyanin

...ll enough in that.

i've included the freecad source file to make modifications easier if you want to customize or improve it.

thingiverse

free

Handle for thread making taps by hemocyanin

... i figure the extra holes are there to be used when i eventually strip a screw hole.

made with freecad -- source file included.

thingiverse

free

Screw Mount Cable Clamps by hemocyanin

...ke them stronger, but these are good enough for my purposes so i'm quitting here.

edit: fixed a small error in 10mm files.

Lulzbot

thingiverse

free

LulzBot Rocktomek by LulzBot

...lulzbot rocktomek by lulzbot

thingiverse

https://download.lulzbot.com/3d_models/rocktomek/

thingiverse

free

THE Lulzbot spool holder

...the lulzbot spool holder

thingiverse

stl and ipt topmount spool holder for lulzbot

thingiverse

free

Lulzbot logo by Halg199703

...lulzbot logo by halg199703

thingiverse

this is the lulzbot logo. i also have a file for dual extruder.

thingiverse

free

LulzBot Bio printer Model

...lulzbot bio printer model

thingiverse

this is a model of the lulzbot bioprinter

thingiverse

free

Lulzbot Taz Enclosure by MrMcGuire

...lulzbot taz enclosure by mrmcguire

thingiverse

parts for an enclosure for lulzbot taz

thingiverse

free

Lulzbot Spool Holder by MAKE

...lulzbot spool holder by make

thingiverse

a spool holder for your lulzbot.

thingiverse

free

Lulzbot mini spool holder by chewie80524

...lulzbot mini spool holder by chewie80524

thingiverse

this part holds the spool on a lulzbot mini. this design came from lulzbot.

thingiverse

free

Lulzbot Claystruder by 102drewt

...r for the lulzbot taz 4. every thing is snap together, and it only requires a threaded rod, a nut to fit it, and a stepper motor.

thingiverse

free

Lulzbot Mini Enclosure brackets by chewie80524

...lulzbot mini enclosure brackets by chewie80524

thingiverse

lulzbot taz/mini enclosure brackets.

thingiverse

free

Lulzbot mini toolbox by nicsna

...t mini using cura scale down to 0.97.

hope you like it and make sure to leave some feedback or suggestions for my next design. :)

Flashlight

3d_export

$5

Flashlight

...flashlight

3dexport

flashlight

3d_ocean

$6

Flashlight

...flashlight

3docean

beam flashlight light

hello! is pleased to present you my new project-flashlight

3d_export

free

Flashlight

...flashlight

3dexport

the most common portable flashlight.

3d_export

$10

flashlight

...flashlight

3dexport

3d model of a flashlight for horror video games or other

3d_export

$15

flashlight

...flashlight

3dexport

low poly model - flashlight, modeling in blender, texturing in substance painter

turbosquid

$2

Flashlight

...squid

royalty free 3d model flashlight for download as blend on turbosquid: 3d models for games, architecture, videos. (1686591)

turbosquid

$1

Flashlight

...squid

royalty free 3d model flashlight for download as blend on turbosquid: 3d models for games, architecture, videos. (1434506)

turbosquid

$10

Flashlights

...ree 3d model flashlights for download as fbx and unitypackage on turbosquid: 3d models for games, architecture, videos. (1286431)

turbosquid

$5

flashlight

...yalty free 3d model flashlight for download as , fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1657266)

turbosquid

free

Flashlight

...

royalty free 3d model flashlight for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1272424)

Usb

3d_ocean

$3

USB Thumbdrive

...usb thumbdrive

3docean

thumbdrive usb usb drive usb stick

this is a swivel type usb thumb drive.

3d_ocean

$5

Usb Stick

...usb stick

3docean

flash stick usb usb memory usb stick

usb stick created using 3ds max 2015 and rendered on mental ray.

3ddd

$1

USB cable

... кабель , провод

высокополигональные модели кабелей usb.

3d_ocean

$5

USB Stick

...usb stick

3docean

32gb computer memory plug plugin protection usb usb stick

an usb stick with built-in plug protection

3d_ocean

$6

USB Stick

...tick

3docean

32 gb flash ram gigabyte memory metal nand plug ram stick usb usb 3 usb stick

usb stick with texture and normal map.

turbosquid

$5

USBS

...bs

turbosquid

royalty free 3d model usbs for download as max on turbosquid: 3d models for games, architecture, videos. (1466594)

3d_export

$5

usb flash

...usb flash

3dexport

usb flash

3d_export

free

usb flash

...usb flash

3dexport

usb flash

3d_export

free

usb flash

...usb flash

3dexport

usb flash driver

3ddd

$1

usb

...usb

3ddd

флешка

флешка

Mini

turbosquid

$10

Mini Mini Luceplan

...

royalty free 3d model mini mini luceplan for download as max on turbosquid: 3d models for games, architecture, videos. (1227359)

3d_ocean

$39

Mini Cooper

...mini cooper

3docean

cabrioler cooper mini

mini cooper cabrioler

3d_export

$30

Mini lathe

...mini lathe

3dexport

mini lathe

3d_export

$5

mini mouse

...mini mouse

3dexport

mini mouse

3d_export

$5

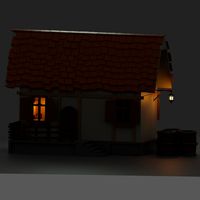

mini house

...mini house

3dexport

mini house

3d_export

free

Mini Mecha

...mini mecha

3dexport

concept of mini mecha

3d_ocean

$20

Mini Gun

...mini gun

3docean

gatling gun gun machine gun mini gun weapon

model of a mini gatling gun.

3ddd

free

Herve mini

... кофейный , herve

http://www.mobiliavenanti.it/ru/products/hervè-mini

3d_export

$5

mini wall

...mini wall

3dexport

mini wall for living room

3d_export

$5

mini bank

...mini bank

3dexport

mini bank 3d model

Led

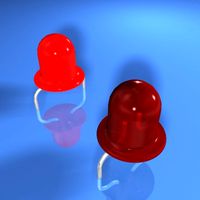

3d_export

$5

led

...led

3dexport

the led is cut with all the parts.

3ddd

$1

Monacor / PARL56DMX / LED-320RGBW / LED-345RGBW / LED-300RGB

... прожектор

http://www.monacor.dk/

parl56dmx

led-320rgbw

led-345rgbw

led-300rgb

turbosquid

$10

LED

...led

turbosquid

free 3d model led for download as blend on turbosquid: 3d models for games, architecture, videos. (1691856)

3d_export

$5

led lamp

...led lamp

3dexport

led lamp, brightness animation

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

современный торшер

3ddd

free

leds-c4

...leds-c4

3ddd

leds-c4

настольный лампа

turbosquid

$19

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$12

Led

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

LED

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Powered

turbosquid

$100

power

...ower

turbosquid

royalty free 3d model power for download as on turbosquid: 3d models for games, architecture, videos. (1421990)

3d_export

$5

Power

...power

3dexport

3d_export

$5

power outlets

...power outlets

3dexport

power outlets

3ddd

$1

lion power

...lion power

3ddd

лев , статуя

lion power gold sculpture

3ddd

$1

Sea Power

...

компас , море , часы

часы с компасом sea power

3ddd

free

Meridiani / Power

...power

3ddd

meridiani , круглый

стол power производитель meridiani, диаметр 120,высота 67

3d_export

$5

Power Surge

...power surge

3dexport

the power surge is a all mesh carnival ride to lower in game part count and lag

turbosquid

$8

Airport Ground Power Unit (AXA Power )

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$50

Power Houser

...rbosquid

royalty free 3d model power houser for download as on turbosquid: 3d models for games, architecture, videos. (1333800)

3d_export

$5

power outlet

...power outlet

3dexport

power outlet<br>format file maya 2018, 3d max 2017, obj, fbx

Printer

archibase_planet

free

Printer

...inter

archibase planet

printer laser printer pc equipment

printer n120614 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Printer

...rchibase planet

laser printer office equipment computer equipment

printer - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$100

Printer

...er

turbosquid

royalty free 3d model printer for download as on turbosquid: 3d models for games, architecture, videos. (1487819)

turbosquid

$3

Printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1670230)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595546)

turbosquid

$1

printer

...turbosquid

royalty free 3d model printer for download as max on turbosquid: 3d models for games, architecture, videos. (1595105)

turbosquid

$10

Printer

...id

royalty free 3d model printer for download as max and 3dm on turbosquid: 3d models for games, architecture, videos. (1607146)

turbosquid

$7

Printer

...royalty free 3d model printer for download as ma, ma, and obj on turbosquid: 3d models for games, architecture, videos. (1644580)

turbosquid

$30

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

Printer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Lighting

archibase_planet

free

Light

...light archibase planet lamp lighting light light - s2 - 3d model for interior...

archibase_planet

free

Light

...light archibase planet light luminaire lighting light l0465 - 3d model (*.gsm+*.3ds) for interior 3d...

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light archibase planet luster lighting solution light - s - 3d model for interior...

archibase_planet

free

Light

...light archibase planet luster lamp lighting light 1 - 3d model for interior 3d...

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light archibase planet lighting luminaire candlelight light l0463 - 3d model (*.gsm+*.3ds) for...

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...

Others

design_connected

$16

ST12 Other

...signconnected

photo-realistic 3d models of the st12 other stool from e15 for 3d architectural and interior design presentations.

turbosquid

$26

Oar and Other

...quid

royalty free 3d model oar and other for download as fbx on turbosquid: 3d models for games, architecture, videos. (1473409)

turbosquid

$5

chair with other

...id

royalty free 3d model chair with other for download as ma on turbosquid: 3d models for games, architecture, videos. (1171468)

3ddd

$1

parfume and other

...parfume and other

3ddd

тумбочка

create by sametyuzer

turbosquid

$79

The Others Collection

...others collection for download as 3ds, max, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1480228)

turbosquid

$25

Other Man

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$15

other car.max

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Other Mothers Hand

... 3d model other mothers hand for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1663825)

turbosquid

$8

other sport wheel

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

pool and other elements

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Using

3ddd

$1

US flag

...us flag

3ddd

флаг

us flag

3d_export

free

Among us

...among us

3dexport

among us red

3d_export

free

Among Us

...among us

3dexport

this 3d-model of a character from the game "among us". it can be used as a toy or decoration.

3d_export

$6

among us

...among us

3dexport

doll from among us in red

3d_export

$5

amoung us

...amoung us

3dexport

amoung us character. was created by cinema 4d 19

3d_export

$5

Humvee us

...humvee us

3dexport

humvee us 3d model good quality for animation

3d_export

$15

among us

...among us

3dexport

turbosmooth modifier can be used to increase mesh resolution if necessary

3d_export

$25

mailbox us

...mailbox us

3dexport

low poly model mailbox us. modeling in the blender, texturing in substance painter

design_connected

$13

Use Me

...use me

designconnected

sitland use me computer generated 3d model. designed by paolo scagnellato.

3d_export

$5

Among Us

...rt

the among us model comes in a variety of colors that can be customized by anyone, and even works with little in the animation