Thingiverse

Upgrade Prusa i3 (Rework) to MK2 by FDMTech

by Thingiverse

Last crawled date: 3 years ago

I will have some compatible parts lined up here that I have tested or adapted to upgrade the Prusa i3 Rework to Prusa i3 MK2. Feel free to leave a comment if you have any questions or suggestions! Also I would love to see your prints (I made one!)

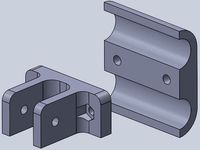

X and Z-axis

x-end-idler_repaired.stl and x-end-motor_repaired.stl

Have both been repaired using NetFabb 2017.1 since there were errors found in their mesh

For these you will need 2pcs of ACME lead screw, size TR8x2 length 300mm. aliexpress ~$4/piece

NEMA17 Couplings 5mm to 8mm aliexpress ~$4/pair

You'll need version POM nuts. Regular brass TR8x2 nuts will not fit these x-ends. aliexpress ~$8/pack of 5 (couldn't buy just 2)

Allows for installing a GT2 Timing Pulley 20T IDLER - 3mm bore, better since these have dual ball bearing and will not pinch the teeth of your belt, less wear. Also looks pro. eBay ~$2.26

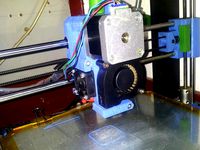

bowden-extruder-body.stl or bowden-extruder-body-m12-p.i.n.d.a..stl

I do not use direct extruder but a bowden setup. Therefore I chopped off the extruder motor section off of the original extruder-body.stl using NetFabb 2017.1.

The original part had some defects that were repaired by NetFabb 2017.1 before making changes.

You can use my x-carriage-chopped-top.stl if you will never go direct drive extruder and you upgraded to the MK2 x-ends. This is necessary for the x-end-stop.

You can use the original MK2 x-carriage, if you upgraded to the MK2 x-ends. This is necessary for the x-end-stop. By using the original MK2 x-carriage you maintain flexibility, if you ever want to go back to direct drive extrusion (original MK2 design).

Original MK2 extruder, cover and carriage in proved zip file.

If anyone is interested I will be working on an affordable M18 P.I.N.D.A. version as well. It has up to double the sensing range of the common affordable M12 size. Which has a sensing range of up to 4mm. While the affordable M8 (MK2) does 2mm. When using BuildTak or Lokbuild the M12's 4mm sensing distance is the minimum requirement, since an aluminium bed is harder to detect.

Y-axis

You have 2 choices. Either print new MK2 y-corners and buy M8 all-thread/threaded rod and a bunch of nuts and washers to go with it. If you are already going to print the parts, use these that work with your current M10 all-thread/threaded rod.

y-belt-guide-10mm-upgrade-rework-to-prusa-mk2.stl

Mounting though hole size was enlarged to 11mm to fit M10 threaded rod, with part shrinkage in mind. Originally 9mm to fit 5/16th or M8mm all-thread / threaded rods.

Allows for installing a GT2 Timing Pulley 20T IDLER - 3mm bore, better since these have dual ball bearing and will not pinch the teeth of your belt, less wear. Also looks pro. eBay ~$2.26

No mesh errors were found.

y-motor-10mm-upgrade-rework-to-prusa-mk2.stl

Mounting though hole size was enlarged to 10.2mm to fit M10 threaded rod, with part shrinkage in mind. Originally 8.2mm to fit 5/16th or M8 all-thread / threaded rods.

Has been repaired using NetFabb 2017.1 since there were errors found in the mesh after redoing the mounting holes of the y-frame using SketchUp Make 2017.

Not mandatory to replace from Rework to MK2 version if you want to keep the Y-end-stop at the current location. Or use the MK2 y-belt-holder.stl so that it can hit the y-end-stop at the MK2 y-motor mount.

Original MK2 y-belt holder in proved zip file.

See picture about endstop situation:

TIPS

ASSEMBLY INSTRUCTIONSOriginal Prusa i3 MK2 kit assembly

ORDERING PARTS

When ordering from Aliexpress or eBay, leave message for the seller to have a better chance of getting better luck with parts you've been waiting for, for weeks. And avoid lengthy disputes.

Dear _insert_seller_name,

please check items for defects before shipping.

please check lead screws for 100% straight.

please check build plate surface is 100% flat.

Maybe even end fancy if you like:

Yours Sincerely,

_insert_your_account_name

Media

ME

Also check out my blog, with helpful content and sidebar links. And subscribe to my YouTube where I add cool video's of the parts I printed and parts I designed myself.

You can watch back printing the Prusa MK2 X-ends stream for example.

PICTURES & ORGINAL STL FILES

Resources originally from www.prusaprinters.org and www.prusa3d.com

X and Z-axis

x-end-idler_repaired.stl and x-end-motor_repaired.stl

Have both been repaired using NetFabb 2017.1 since there were errors found in their mesh

For these you will need 2pcs of ACME lead screw, size TR8x2 length 300mm. aliexpress ~$4/piece

NEMA17 Couplings 5mm to 8mm aliexpress ~$4/pair

You'll need version POM nuts. Regular brass TR8x2 nuts will not fit these x-ends. aliexpress ~$8/pack of 5 (couldn't buy just 2)

Allows for installing a GT2 Timing Pulley 20T IDLER - 3mm bore, better since these have dual ball bearing and will not pinch the teeth of your belt, less wear. Also looks pro. eBay ~$2.26

bowden-extruder-body.stl or bowden-extruder-body-m12-p.i.n.d.a..stl

I do not use direct extruder but a bowden setup. Therefore I chopped off the extruder motor section off of the original extruder-body.stl using NetFabb 2017.1.

The original part had some defects that were repaired by NetFabb 2017.1 before making changes.

You can use my x-carriage-chopped-top.stl if you will never go direct drive extruder and you upgraded to the MK2 x-ends. This is necessary for the x-end-stop.

You can use the original MK2 x-carriage, if you upgraded to the MK2 x-ends. This is necessary for the x-end-stop. By using the original MK2 x-carriage you maintain flexibility, if you ever want to go back to direct drive extrusion (original MK2 design).

Original MK2 extruder, cover and carriage in proved zip file.

If anyone is interested I will be working on an affordable M18 P.I.N.D.A. version as well. It has up to double the sensing range of the common affordable M12 size. Which has a sensing range of up to 4mm. While the affordable M8 (MK2) does 2mm. When using BuildTak or Lokbuild the M12's 4mm sensing distance is the minimum requirement, since an aluminium bed is harder to detect.

Y-axis

You have 2 choices. Either print new MK2 y-corners and buy M8 all-thread/threaded rod and a bunch of nuts and washers to go with it. If you are already going to print the parts, use these that work with your current M10 all-thread/threaded rod.

y-belt-guide-10mm-upgrade-rework-to-prusa-mk2.stl

Mounting though hole size was enlarged to 11mm to fit M10 threaded rod, with part shrinkage in mind. Originally 9mm to fit 5/16th or M8mm all-thread / threaded rods.

Allows for installing a GT2 Timing Pulley 20T IDLER - 3mm bore, better since these have dual ball bearing and will not pinch the teeth of your belt, less wear. Also looks pro. eBay ~$2.26

No mesh errors were found.

y-motor-10mm-upgrade-rework-to-prusa-mk2.stl

Mounting though hole size was enlarged to 10.2mm to fit M10 threaded rod, with part shrinkage in mind. Originally 8.2mm to fit 5/16th or M8 all-thread / threaded rods.

Has been repaired using NetFabb 2017.1 since there were errors found in the mesh after redoing the mounting holes of the y-frame using SketchUp Make 2017.

Not mandatory to replace from Rework to MK2 version if you want to keep the Y-end-stop at the current location. Or use the MK2 y-belt-holder.stl so that it can hit the y-end-stop at the MK2 y-motor mount.

Original MK2 y-belt holder in proved zip file.

See picture about endstop situation:

TIPS

ASSEMBLY INSTRUCTIONSOriginal Prusa i3 MK2 kit assembly

ORDERING PARTS

When ordering from Aliexpress or eBay, leave message for the seller to have a better chance of getting better luck with parts you've been waiting for, for weeks. And avoid lengthy disputes.

Dear _insert_seller_name,

please check items for defects before shipping.

please check lead screws for 100% straight.

please check build plate surface is 100% flat.

Maybe even end fancy if you like:

Yours Sincerely,

_insert_your_account_name

Media

ME

Also check out my blog, with helpful content and sidebar links. And subscribe to my YouTube where I add cool video's of the parts I printed and parts I designed myself.

You can watch back printing the Prusa MK2 X-ends stream for example.

PICTURES & ORGINAL STL FILES

Resources originally from www.prusaprinters.org and www.prusa3d.com

Similar models

thingiverse

free

GTX-Carriage Rework 1.0 by mediaklan

...riage do not make use of the two lme8luu in original geeetech x-carriage, you will need 4 x lme8uu linear bearings with this one.

thingiverse

free

Prusa i3 Rework Y-Belt Tensioner

... tensioner

thingiverse

prusa i3 rework y-belt tensioner with pulley centered between threaded rods.

designed for m3 bolt and nut

thingiverse

free

Prusa i3 x-belt tensionner upgrade by ffleurey

...nut in the middle is the original one from the prusa i3 idler holder. the bolt holding the idler holder in the x end is removed.

thingiverse

free

M5 T-nut for Prusa i3 MK2 by stanoba

...t allows to use m5 threaded rod instead of trapezoidal screw in original prusa i3 mk2 x-end-motor and x-end-idler printed parts.

grabcad

free

Parts for Prusa i3 mk2s

...

parts carefully extracted from stl files from prusa's website.

very accurate.

x-carriage is missing the cable holding part

thingiverse

free

Tevo Tarantula x-z-axis convertion to Original Prusa i3 Mk2 style by PredatorJr

...ula to a mgn12 linear rail instead of a dual steel rod setup.

ps: top left corner bracket is same part as the rework named above.

thingiverse

free

Prusa I3 Rework X Carriage With GT2 Belt Tensioner by b166er

...prusa i3 rework x carriage with gt2 belt tensioner by b166er

thingiverse

prusa i3 rework x carriage with gt2 belt tensioner

thingiverse

free

Prusa i3 mk3s Bear X-Carriage R4 with modified belt holder by TroyJoachim

... by using the affiliate links below

amazon link: 16t pulley

aliexpress: 16t pulley

amazon link: 16t idlers

aliexpress: 16t idlers

thingiverse

free

Prusa I3 10mm rods parts by villamany

... to use 3 o 4 bearings on the x carriage (two different .stl files)

sorry but my prusa i3 was sold and no pictures availables.

thingiverse

free

Prusa MK2 Extruder For BQ Prusa I3 by Tuga_75

...o post x-carriage sorry.

extruder upgrade to use e3d v6 on a bq prusa i3http://manual.prusa3d.com/guide/5.+extruder+assembly/114

Fdmtech

thingiverse

free

"Tube with holes" Vase Organizer by FDMTech

...h

thingiverse

this is my first attempt at freecad, a tube with holes.

i basically follow a youtube tutorial from the start page.

thingiverse

free

Prusa I3 Bed leveling caliper jig 17.3mm by FDMTech

...h

thingiverse

my caliper has a wider leg, so it was easy to adjust for within the source.http://www.thingiverse.com/thing:115671

thingiverse

free

Prusa i3 Improved frame - dual frame connector by FDMTech

...iverse

using aluminium 90º angled profile of 25x25mm.

note: this is stil a wip mounting holes for profile not yet implemented.

thingiverse

free

Fractal Define Nano S - Liquid cooling setup by FDMTech

... the new computer case from fractal suitable for itx systems. capable of containing 2, 2 fan radiators and 1 single fan radiator.

thingiverse

free

Simple kitchen sponge and brush holder by FDMTech

...o that side.

i have include a lefty version as well.

went though model repair service to ensure a mesh correct stl output. :)

thingiverse

free

Parametric proximity sensor mount for i3 Rework E3D Extruder by FDMTech

...11http://www.thingiverse.com/thing:415175 (1.75mm)

the hole for the sensor is 12.2mm, measures 12mm when printed in pla at 195ºc.

thingiverse

free

Tapered thread bowden coupling PC4-M6, PC4-M10 - Repaired by FDMTech

...b and were exported as binary stl's.

reason: there were some mesh issues with the pc4-m6 and pc4-m10 files.

have nice day! :)

thingiverse

free

Christmas tree ornament spinner single / dual color + VIDEO by FDMTech

...ideo showing the printing, short cura 15.04.6 how-to and the fusion 360 design itself:https://www.youtube.com/watch?v=notjef4urgi

thingiverse

free

CNC XT60 Plug Connector Holder / Fixed Mount for RC Model by FDMTech

...to save you all some trouble here are the dimensions:

lxwxh: 24x5x10mm

mount hole spacing: 19mm

screw size: m2.5

have a nice day!

thingiverse

free

Prusa i3 Rework - Y-motor Reverse edition with 608 bearing by FDMTech

...reases y freedom by approx. 44mm.

the y-idler reverse edition adds approx. another 35mm.http://www.thingiverse.com/thing:646518

Rework

3d_export

$25

riva aquarama 1970

...visualization, as well as, if desired, it can be reworkd for 3d printing. in the near future, a model...

3d_export

$8

Mosaic 1 3D Model

...outdoor indoor vector ceramic glass mosaic decorative mosaic manually reworkd into a vector. the image is then modified in...

3d_export

$65

sci-fi scene for rendering restyling - tesla

...colors with the name, metal, light metal, dark metal, reworkd renders for preview and processed in photoshop using a...

3d_export

$22

a filter assembly and inspection line

...laser marking station (op40), one packaging station (op50), one rework and pump water detection station (op60), and two assembly...

3d_export

$19

muuto raw chair

...the muuto raw chair.<br>raw chair is a striking functional reworkng of a recognizable everyday object. a part of the...

3d_export

$12

desert rocks stock in blender

...in obj format (non-textured), together with the textures, for reworkng them in other programs.<br>notes: the scene include 12 simple...

3d_export

$10

arclinea principia

...the essence, with the basic principles of the kitchen, reworkd: new steel technology and natural wood cutting. the extraordinary...

thingiverse

free

Doughnut Rework by Johhnny

...doughnut rework by johhnny

thingiverse

i reworked tzani's mobius doughnut for dual extrusion.

thingiverse

free

Beanie the Transformer rework by Whirl55

...beanie the transformer rework by whirl55

thingiverse

found and reworked head pin

and all files

thingiverse

free

AM10 - am8 rework Y

...am10 - am8 rework y

thingiverse

totaly rework to turn your am8 into an am10 with only 2 pieces

Mk2

turbosquid

$4

Mk2

...

royalty free 3d model mk2 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1305687)

turbosquid

$9

Mk2 Grenade

...osquid

royalty free 3d model mk2 grenade for download as fbx on turbosquid: 3d models for games, architecture, videos. (1175401)

turbosquid

$4

Mk2 Grenade

...quid

royalty free 3d model mk2 grenade for download as blend on turbosquid: 3d models for games, architecture, videos. (1228888)

turbosquid

$2

GRENADE MK2

...osquid

royalty free 3d model grenade mk2 for download as fbx on turbosquid: 3d models for games, architecture, videos. (1202615)

turbosquid

$2

Grenade Mk2

...osquid

royalty free 3d model grenade mk2 for download as max on turbosquid: 3d models for games, architecture, videos. (1658201)

turbosquid

$2

mk2 Grenade

...osquid

royalty free 3d model mk2 grenade for download as fbx on turbosquid: 3d models for games, architecture, videos. (1329079)

turbosquid

$75

Lanchester Mk2

...alty free 3d model lanchester mk2 for download as 3ds and max on turbosquid: 3d models for games, architecture, videos. (1497085)

turbosquid

$10

Grenade MK2

...royalty free 3d model grenade mk2 for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1146970)

turbosquid

$10

MK2 helmet

...

royalty free 3d model mk2 helmet for download as max and obj on turbosquid: 3d models for games, architecture, videos. (1371428)

turbosquid

free

MK2 Grenade

...

free 3d model mk2 grenade for download as png, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1225336)

Upgrade

turbosquid

$15

Upgraded Glock

...e 3d model upgraded glock for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1185950)

3ddd

$1

Calligaris / UPGRADE

...calligaris / upgrade

3ddd

calligaris

c материалом

3d_export

free

cz upgrade

...cz upgrade

3dexport

https://www.buymeacoffee.com/mestrezen3d https://linktr.ee/mestrezen3

turbosquid

$80

Custer Tank upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Domestos 1 upgrade

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$10

Upgraded tea cup

...upgraded tea cup

3dexport

a cup with an unusual design and a unique shape for a more enjoyable tea experience

3d_export

$8

dixy outlander classic style upgraded poplar wood lounge chair

...utlander classic style upgraded poplar wood lounge chair

3dexport

dixy outlander classic style upgraded poplar wood lounge chair

turbosquid

free

AK-12 + Upgrades low-poly 3D model

...ow-poly 3d model for download as fbx, blend, and unitypackage on turbosquid: 3d models for games, architecture, videos. (1501145)

evermotion

$700

Upgrade from V-ray 1.5 to 3.5 for 3ds max

...here is no need to purchase a new dongle - your current dongles will be reprogrammed to carry v-ray 3. evermotion 3d models shop.

evermotion

$300

Upgrade from V-Ray 2.0 to V-ray 3.5 for 3ds Max

... interface (gui) for editing settings on one machine and one render node for rendering on one machine. evermotion 3d models shop.

I3

3d_export

$10

suv i3

...suv i3

3dexport

suv i3 2013 series

3d_ocean

$89

BMW i3 2012

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 20143d model

...

cgstudio

.3ds .c4d .fbx .lwo .max .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20123d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2012 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20143d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

humster3d

$75

3D model of BMW i3 2014

...

buy a detailed 3d model of bmw i3 2014 in various file formats. all our 3d models were created maximally close to the original.

humster3d

$40

3D model of Kitchen Set I3

...uy a detailed 3d model of kitchen set i3 in various file formats. all our 3d models were created maximally close to the original.

3d_ocean

$30

Kitchen set i3

...ensils oven plates shelves sink table ware

kitchen set i3 include 3d models: cooker, oven, sink, cupboards, table, chair, plates.

3d_ocean

$89

BMW i3 2014

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 Concept 20113d model

...i3

.3ds .c4d .fbx .lwo .max .obj - bmw i3 concept 2011 3d model, royalty free license available, instant download after purchase.

Prusa

turbosquid

$2

Frame Filament Guide Clip-On for Prusa Mk3

...rame filament guide clip-on for prusa mk3 for download as stl on turbosquid: 3d models for games, architecture, videos. (1634730)

3d_export

free

prusa i3 mk3s laser mount for opt lasers

...to learn more about the blue laser technology that conceived the cutting and engraving laser heads from opt lasers, please visit:

turbosquid

free

Prusa small printer adapter holder

...er for download as ipt, skp, dwg, dxf, fbx, ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1642936)

3d_export

$30

geisha by jonathan adler

...** i did a 3d printing test in the prusa software, you can find it among the attached images.<br>exchange:<br>.blend...

thingiverse

free

Prusa without Prusa (rc2) by madless

...prusa without prusa (rc2) by madless

thingiverse

just the main part of prusa rc2 faceshield, without writing.

enjoy :)

thingiverse

free

Prusa by acejbc

...prusa by acejbc

thingiverse

prusa knob info

m3 8mm screw

thingiverse

free

Prusa house

...prusa house

thingiverse

how prusa house could look like...

thingiverse

free

Prusa Mk2 "Fake Prusa" LCD cover by anraf1001

...r by anraf1001

thingiverse

version of prusa's lcd cover with "fake prusa" instead of "original prusa"

thingiverse

free

Prusa stabilizator by gutiueugen

...prusa stabilizator by gutiueugen

thingiverse

prusa stabilizator

thingiverse

free

Keychain Prusa by rbarbalho

...keychain prusa by rbarbalho

thingiverse

keychain with text prusa.