Thingiverse

Two Trees Sapphire Plus Volcano (from Dragon) Direct Drive Orbiter tweaks by SimonSolar2C

by Thingiverse

Last crawled date: 3 years, 3 months ago

Many thanks to the originator(s) of this Oribiter Volcano design, with integrated cable tensioners.

I had a few issues fitting it, so Im sharing the adjustments I made.

You will need to source the original parts from sources listed:https://www.thingiverse.com/thing:4223085 ( ref to marvelous Orbiter Extruder design (138grams including motor!)

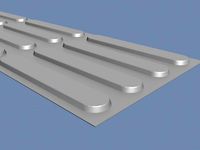

Tensioner - the gates belts that came with my Plus were cutoff too short by the factory for the tensioner, so I modified the dimensions so they would reach. The they pulled out of the non-adjuster side so I ended up putting those back in to the edge of the mount with small cable ties. Adjuster side working well.

OP had the BLT set so low that it hits the Z screws. I didn't want to loose Z height by the method many use of spacing the z motors down. With careful measurement the BLT can sit higher up and just have enough reach to get below the nozzle height when deployed. Advantage is that the BLT needle is somewhat protected by the fan ducts.

Offsets: #define NOZZLE_TO_PROBE_OFFSET { -26, 20, -3.45 }

Fan ducts - I started off moving these up, similarly to clear the Z screws, but then ended up using 5015 fans, so I changed those also to fit without hitting the Z screws - you will need to use a silicon cover on your Volcano hotend for reliable operation close to the heat bed.

Spacer under Orbiter - fits to avoid extruder hitting frame

Cable tidy - the one by OP hits the frame at maximum Y, so adjusted this so cables sit to one side.

The entry to the volcano sits slightly below the rail enough that there is no way to have a direct line from the extruder, so I made a little guide for to put some PTFE tubing down - 33.9mm of tube from memory.

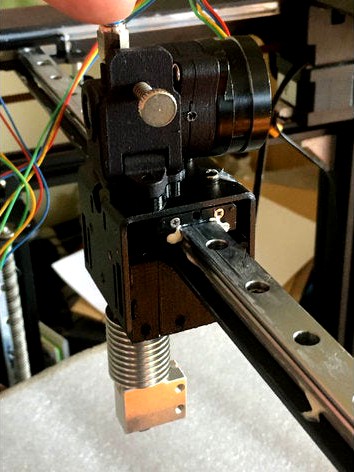

Rather than try to explain how it comes together from various mashup of parts, I hope my photos will demonstrate. I've included one photo shows where you drill holes in the top of the gantry mount - I put threads inserts in there, others have cut threads into the metal. Please don't do this over your printer. There are also two holes needed in the front-I mislabelled these on the uploaded photo!!!

Don't forget to put the nuts into the tensioner blocks before assembling the whole thing into the gantry.

Metal fragments will wreak your machine!

Its a big change putting in 9 more wires (5xBLT, 4xExtruder) - You'll want to have appropriate tools and parts, screws, etc.etc.

I used screws with flat heads when mounting the fans - you'll see they are sitting at a weird angle. You'll need 2 tapered head screws about 15mm long. Or just superglue some plastic to hold the fan base apart.

-Two test dogs sitting together - you can see the improvement after I calibrated Linear Advance (left )

Videos showing building mess, speed and quality resultshttps://youtu.be/0B6mjV7Pxbwhttps://youtu.be/e1uwbyc3Xnghttps://youtu.be/B3CFxNQh1Tc

I had a few issues fitting it, so Im sharing the adjustments I made.

You will need to source the original parts from sources listed:https://www.thingiverse.com/thing:4223085 ( ref to marvelous Orbiter Extruder design (138grams including motor!)

Tensioner - the gates belts that came with my Plus were cutoff too short by the factory for the tensioner, so I modified the dimensions so they would reach. The they pulled out of the non-adjuster side so I ended up putting those back in to the edge of the mount with small cable ties. Adjuster side working well.

OP had the BLT set so low that it hits the Z screws. I didn't want to loose Z height by the method many use of spacing the z motors down. With careful measurement the BLT can sit higher up and just have enough reach to get below the nozzle height when deployed. Advantage is that the BLT needle is somewhat protected by the fan ducts.

Offsets: #define NOZZLE_TO_PROBE_OFFSET { -26, 20, -3.45 }

Fan ducts - I started off moving these up, similarly to clear the Z screws, but then ended up using 5015 fans, so I changed those also to fit without hitting the Z screws - you will need to use a silicon cover on your Volcano hotend for reliable operation close to the heat bed.

Spacer under Orbiter - fits to avoid extruder hitting frame

Cable tidy - the one by OP hits the frame at maximum Y, so adjusted this so cables sit to one side.

The entry to the volcano sits slightly below the rail enough that there is no way to have a direct line from the extruder, so I made a little guide for to put some PTFE tubing down - 33.9mm of tube from memory.

Rather than try to explain how it comes together from various mashup of parts, I hope my photos will demonstrate. I've included one photo shows where you drill holes in the top of the gantry mount - I put threads inserts in there, others have cut threads into the metal. Please don't do this over your printer. There are also two holes needed in the front-I mislabelled these on the uploaded photo!!!

Don't forget to put the nuts into the tensioner blocks before assembling the whole thing into the gantry.

Metal fragments will wreak your machine!

Its a big change putting in 9 more wires (5xBLT, 4xExtruder) - You'll want to have appropriate tools and parts, screws, etc.etc.

I used screws with flat heads when mounting the fans - you'll see they are sitting at a weird angle. You'll need 2 tapered head screws about 15mm long. Or just superglue some plastic to hold the fan base apart.

-Two test dogs sitting together - you can see the improvement after I calibrated Linear Advance (left )

Videos showing building mess, speed and quality resultshttps://youtu.be/0B6mjV7Pxbwhttps://youtu.be/e1uwbyc3Xnghttps://youtu.be/B3CFxNQh1Tc

Similar models

thingiverse

free

Makertech Axis 3D printer Z gantry guides by Nitrowing

...s up than the knobs that were included.

mine are attached so that the adjustment screws are away from the gantry for easy access.

thingiverse

free

Removable Extruder Fan Holder A8 with Z probe by Aeolian

...wo 50mm screws to put the mount in place

add the z-probe

simply slide the fan in!

feel free for comments and photo if you make it

thingiverse

free

Titan Aero + Volcano / Standart Extruder + BLTouch sturdy mount by AndroVet

...hout blt), for standart or volcano extruder.

https://youtu.be/479kqtiaplqhttps://youtu.be/edyhblqchzkhttps://youtu.be/odbsxfsm1ru

thingiverse

free

Adimlab Gantry BL Touch Mount by ypatel9

...n.

for your firmware after:

nozzle_to_probe_offset { 14,25, -4.9 } //volcano offset for z, change to 0 for v6 and adjust after.

thingiverse

free

Improved Extruder Arm with adjustable tension by darren_bergen

...adjustment screw.

extruder_arm_b_180: original extruder arm top plate but rotated by 180 degrees for proper printing orientation.

thingiverse

free

Tronxy X5S v2 extruder tension adjuster by jpnurro

...nal screw with this one allows you to adjust the optimal extruder tension with the 4mm screw (there are the ready made threads)..

thingiverse

free

Orbiter 1.5 direct-drive extruder mount for Prusa Mini by paenian

...p as needed.

m900 k0.03 ; set the linear advance for the orbiter

i made a video of the install here: https://youtu.be/f6vlfakn_5i

thingiverse

free

Sapphire Pro Plus Orbiter mount with cable management by nlucc

...s

print with support touching the build plate

use 4 top layers

infill 50-100%

you can print it in pla but i recommend petg or abs

thingiverse

free

Ender 3 Gantry Cables Clip For Z Motor by zuberio

...

simple remix that uses less plastic. you'll also need two m3x8 screws to attach this clip to the free holes on the z-motor.

thingiverse

free

Anet A3 Centered Blower Fan Mount with Cable Holder

...ake sure it's not taking too much stress.

i use 2 m3 10mm screw from the z stepper. to put cable holder on the blower mount.

Simonsolar2C

thingiverse

free

Nozzle for KathmanduPump2IntexColeman by SimonSolar2C

...onsolar2c

thingiverse

my pump was missing the nozzle to pump up my airbed and boat (coleman & intex) so here is the nozzle.

thingiverse

free

Cookie Cutter - 4K by SimonSolar2C

...cookie cutter - 4k by simonsolar2c

thingiverse

i wanted more resolution (detail) in my cutter so increased image size for inputs

thingiverse

free

Coathanger Clamp by SimonSolar2C

...r.

see pictures

note this is not designed for strength, its more like a locator, so please uses metal washers to spread the load.

thingiverse

free

ThiEYE T5e USB Cover by SimonSolar2C

...hipping.

update - i added version that includes microphone plug. it does not sit flush with the side of the camera edge, by 0.5mm

thingiverse

free

Battery Holder by enif-txoof-webmongersimonsolar2c by SimonSolar2C

...the txoof script which caused a hole underneath.

putting it here so i can make battery holder with his improvement to the markers

thingiverse

free

C965 Mount Extender by SimonSolar2C

... non symmetrical part - testing now

update v5 - okay it broke with my dogs paws on it, so this version is stronger where it broke

thingiverse

free

Modular Rocket Section Joiner by SimonSolar2C

...t same dimensions as original so it should work nicely under same print settings

original: https://www.thingiverse.com/thing:8754

thingiverse

free

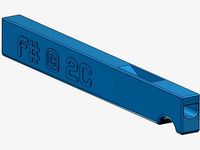

Micro Whistle in F#(4) by SimonSolar2C

...m working on.

update

i removed the hole that made it a necklace because it was causing weakness in the essential windpipe section

thingiverse

free

Titan Aero Layer Fan Shroud_BiggerBehind by SimonSolar2C

...he orientation i had it in, and the thickness of the e3d sock, then wrapped in kapton tape.

i also slightly enlarged the airflow.

thingiverse

free

Tevo BW Cable Clamp by SimonSolar2C

... i have another whole different clamp in mind.

it is laid out in the direction needed to provide the strength needed to the clamp

Volcano

3d_export

$10

volcano

...volcano

3dexport

erupting volcano for 3d printing

3d_export

$5

volcano

...volcano

3dexport

an erupting volcano with lava flows

design_connected

$11

Volcano

...volcano

designconnected

chista volcano computer generated 3d model.

3d_export

free

volcano

...volcano

3dexport

a volcano surrounded by stones<br>perfect for simple, unre demanding games

3d_export

$10

temple in volcano

...temple in volcano

3dexport

temple in volcano for 3d printing

turbosquid

$8

Volcano

... free 3d model volcano for download as fbx, stl, obj, and dae on turbosquid: 3d models for games, architecture, videos. (1664127)

turbosquid

$40

volcano

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Volcano

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Volcano

...e 3d model volcano for download as ma, max, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1567779)

turbosquid

free

volcano

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Orbiter

3ddd

free

Orbit

...ь - orbit 6225

габарит - 1450*400*310

сайт производитель -http://www.garsnas.se/en-gb/products/screens-lamps/orbit-6225

design_connected

$16

Orbital

...orbital

designconnected

modus furniture orbital lounge chairs computer generated 3d model. designed by christophe pillet.

3d_ocean

$5

Benzene Orbitals

...l arrangement. orbitals represent electronic cloud around atoms involved in benzene particle. red-green lobes of p-orbitals cr...

3ddd

$1

Dedon / Orbit

...dedon / orbit

3ddd

dedon

dedon / orbit

3ddd

$1

orbit lamps

...t lamps

3ddd

orbit

new modern orbit lamp.

it is a ceiling lamp, every element is parent father - child, and dummy. easy control.

3ddd

free

Dedon / Orbit

...d

dedon , германия , круглая

dedon orbit daybed

3ddd

$1

Люстра ORBITAL SP10

...люстра orbital sp10

3ddd

orbital

люстра orbital sp10

3ddd

$1

Foscarini Orbital

...foscarini orbital

3ddd

foscarini , orbital

дизайнер ferruccio laviani, 1992 г.

3ddd

$1

Dandelion Orbit Chandelier

...dandelion orbit chandelier

3ddd

dandelion , orbit

dandelion orbit chandelier

3ddd

$1

Orbit Chandelier

...orbit chandelier

3ddd

orbit

manufacturer:

townsend design, usa

www.townsenddesign.net

designer:

patrick townsend

Tweaks

3d_export

$5

camera

...era

3dexport

the camera is done completely, but the textures need to be tweaked a little (because, i did everything in a hurry).

3d_export

$5

modern house

...modern house

3dexport

a great model for someone who would edit this model both inside and a little more tweaking on the outside

3d_ocean

$19

MaxMounts

...ds max, in a single click. several tweak-able parameters have been provided to get an infinite variety. the script also has an...

3d_ocean

$16

Mermaid

...olygons. made entirely in 3ds max 2015. it’s completely editable which means you can tweak whatever you need – if needed. not ...

3d_export

$45

Cyborg Head Bust V1

...ade with blender 2.9 render cycles and workbench, with some tweak and edit, its 3d print ready files ready: .blend .fbx .obj .stl

3d_ocean

$9

dragon (devil) character

...dragon devil character design. base model, with some minor tweaks you’ve got yourself a tiny little fellah. files included;...

3d_ocean

$15

Generic Laptop

...to a software, might need some texture linkings, and tweaks ...

3d_ocean

$9

ACOG Scope

...ll uv’s *parenting configured for easy movement/tweaking (moving the base will move everything) not included: normal/specular ...

3ddd

$1

Finn Juhl Poet Sofa

...e and hit render, nothing to cleanup, and dont need to tweak any material. texures are tilable. obj included for other platforms.

3d_ocean

$8

alien cartoon character

...from here with this alien. with a couple of tweaks here and there you’ve got your own alien! files...

Sapphire

turbosquid

$30

Sapphire

...alty free 3d model sapphire for download as obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1304434)

turbosquid

$9

Sapphire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

free

sapphire pro

...sapphire pro

3dexport

sapphire pro 3d printer head mask

turbosquid

$35

Sapphire ring

...quid

royalty free 3d model sapphire ring for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1320838)

turbosquid

$22

Ring with sapphires

...royalty free 3d model ring with sapphires for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1375607)

turbosquid

$20

sapphire ring

...quid

royalty free 3d model sapphire ring for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1306560)

turbosquid

$3

Zora Sapphire

... free 3d model zora sapphire for download as ma, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1613795)

turbosquid

$50

sapphire ring

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Sapphire Lode

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Sapphire Gem

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Dragon

3d_export

$15

dragon

...dragon

3dexport

dragon

3d_export

$15

dragon

...dragon

3dexport

dragon

3d_export

$5

dragon

...dragon

3dexport

dragon figurine

3d_export

$6

dragon

...dragon

3dexport

cool dragon for decoration

3d_export

$20

dragon

...dragon

3dexport

glass dragon made in blender.

3d_export

$8

dragon

...dragon

3dexport

3d model of the dragon (sculpting)

3d_export

$5

dragon

...dragon

3dexport

dragon 3d model printing

3d_export

$5

dragon

...dragon

3dexport

black dragon with model+render

archibase_planet

free

Dragon

...dragon

archibase planet

toy dragon

dragon n170508 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Dragon

...dragon

archibase planet

sculpture dragon statue

dragon 1- 3d model (*.3ds) for interior 3d visualization.

Direct

design_connected

free

Compas Direction

...compas direction

designconnected

free 3d model of compas direction by vitra designed by prouvé, jean.

design_connected

$18

Direction Pivotant

...direction pivotant

designconnected

vitra direction pivotant computer generated 3d model. designed by prouvé, jean.

turbosquid

$6

not direct the front

...oyalty free 3d model not direct the front for download as max on turbosquid: 3d models for games, architecture, videos. (1213034)

turbosquid

$10

Rails Direct

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Picto toilet directions

...lude 3d files next to rhino6: x3dv, step, igus, obj and stl. double-sided, flipping changes the gender directions to the toilets.

3ddd

$1

fauteuli direction

...d

chair , vitra , fauteuli

fauteuli vitra chair

design_connected

$18

Fauteuil Direction, 1951

...fauteuil direction, 1951

designconnected

vitra fauteuil direction, 1951 computer generated 3d model. designed by prouvé, jean.

3d_export

$5

Directional tactile 3D Model

...tactile 3d model

3dexport

directional tactile braille tile flooring interior

directional tactile 3d model renob000 71068 3dexport

turbosquid

$26

Radio direction finder A

...ty free 3d model radio direction finder a for download as fbx on turbosquid: 3d models for games, architecture, videos. (1212490)

turbosquid

$7

Wooden direction signage

...ty free 3d model wooden direction signage for download as max on turbosquid: 3d models for games, architecture, videos. (1453747)

Plus

turbosquid

$2

plus-plus puzzle and lego

...d model plus-plus puzzle and lego for download as stl and obj on turbosquid: 3d models for games, architecture, videos. (1662633)

3ddd

$1

Стенка Plus

...стенка plus

3ddd

plus , модная мебель

фабрика "модная мебель", модель plus

3ddd

$1

Спальня METIS plus

... hulsta , metis , спальня

спальня metis plus

design_connected

$11

be plus B+

...be plus b+

designconnected

blå station be plus b+ chairs computer generated 3d model. designed by börge lindau.

design_connected

$11

Bank Plus

...bank plus

designconnected

röthlisberger kollektion bank plus coffee tables computer generated 3d model. designed by atelier oi.

3ddd

$1

elos Plus

... candela

elos plus — мультифункциональный аппарат для проведения лазерного и ipl лечений

3ddd

$1

Calligaris Even Plus

...calligaris even plus

3ddd

calligaris

calligaris_chair_even plus

design_connected

$29

Basket Plus

...nconnected

photo-realistic 3d models of the basket plus bed from bonaldo for 3d architectural and interior design presentations.

3ddd

free

Artpole Faktum Plus

... артполе , панель

artpole faktum plus

размеры:

высота 625мм

ширина 800мм

глубина 17мм

3ddd

$1

Мария / Jazz Plus

...мария / jazz plus

3ddd

мария

кухня фабрики мария модель__jazz plus

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)

Trees

3d_ocean

$9

tree

...tree

3docean

textured tree

textured tree

3d_ocean

$9

tree

...tree

3docean

textured tree

textured tree made with cinema4d

3d_ocean

$9

tree

...tree

3docean

cinema4d textured tree

textured tree made with cinema4d

3d_export

$10

tree

...tree

3dexport

this is a tree.

3d_export

$7

Tree

...tree

3dexport

tree

3d_export

$5

tree

...tree

3dexport

tree

3d_export

$5

Tree

...tree

3dexport

tree

3d_export

$5

Tree

...tree

3dexport

tree

3d_export

$5

Tree

...tree

3dexport

tree

3d_export

free

tree

...tree

3dexport

tree.

Two

turbosquid

$4

Two Axes Two States

...free 3d model two axes two states for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1468396)

3d_export

$5

s of two one and two

...blender file. one burner cooker: vertices: 16,221 faces: 14,780 triangle: 31,490 two burner stove: vertices: 25,200 faces: 23,625

turbosquid

$20

two

...osquid

royalty free 3d model two for download as 3ds and stl on turbosquid: 3d models for games, architecture, videos. (1435051)

3ddd

$1

avec two

...avec two

3ddd

jmm , avec two

jmm avec two

3ddd

$1

cea two

... вентилятор , потолочный

cea two

все размеры

vray+corona

3d_export

$5

Two speaker

...two speaker

3dexport

this is a 3d model of two speakers from sven

3d_export

free

Two wall

...two wall

3dexport

two wall<br>.blend

design_connected

$29

All-Two

...all-two

designconnected

bonaldo all-two computer generated 3d model. designed by bicego, sergio.

design_connected

$9

Two Timer

...two timer

designconnected

established & sons two timer computer generated 3d model. designed by industrial facility.

turbosquid

$21

DAVENTRY Two Over Two Chest of Drawers

... chest of drawers for download as max, max, max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1684477)